Abstract

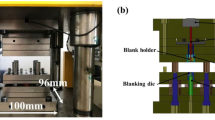

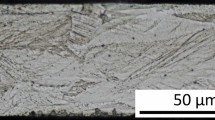

To manufacture micro-drawn cups featuring high CH/CD (cup height/cup diameter ratios) and high quality, a three-stage micro-deep drawing (MDD) system was designed and studied. TA1 pure titanium (Ti) foils with the thickness of 50 μm were annealed at 600–700 °C for 1 h to obtain different grain sizes. Then, the effects of different grain sizes on the deformation behavior of multi-stage MDD and the quality of the formed cups were analyzed. The results show that the as-received pure Ti has a poor formability, suffering a slight fracture problem and significant wrinkling problem of the final drawn cup. At the optimal annealing temperature of 600 °C, the drawn cups show very few wrinkles and a good shape profile. Besides, high CH/CD ratios can be produced for the final drawn cups. Moreover, with the increase in drawing stage, the wrinkling of the cup is significantly reduced due to the "ironing effect" in the multi-stage MDD process. The research can provide a basis for forming high-quality and high CH/CD ratios micro-parts by multi-stage MDD and enrich the knowledge from behavior deformation behavior and product quality assurance.

Graphical abstract

Similar content being viewed by others

References

Tao K, Tang LH, Wu J, Lye SW, Hl C, Miao JM (2018) Investigation of multimodal electret-based mems energy harvester with impact-induced nonlinearity. J Microelectromech S 27(2):276–288. https://doi.org/10.1109/JMEMS.2018.2792686

Persano A, Quaranta F, Taurino A, Siciliano PA, Iannacci J (2020) Thin film encapsulation for RF MEMS in 5G and modern telecommunication systems. Sensors 20(7):2133. https://doi.org/10.3390/s20072133

Mallik S, Chowdhury D, Chttopadhyay M (2019) Development and performance analysis of a low-cost MEMS microphone-based hearing aid with three different audio amplifiers. Innov Syst Softw Eng 15:17–25. https://doi.org/10.1007/s11334-019-00325-7

Xu J, Wang XW, Wang CJ, Yuan L, Chen WJ, Bao JX, Su Q, Xu ZH, Wang CJ, Wang ZL, Shan DB, Guo B (2020) A Review on Micro Nanoforming to Fabricate Metallic Structures. Adv Mater 33(6): 5. doi: https://doi.org/10.1002/adma.202170044.

Jiang ZY, Zhao JW, Xie HB (2017) Microforming technology. Academic Press

Cao J, Brinksmeier E, Fu MW, Gao RX, Liang B, Merklein M, Schmidt M, Yanagimoto J (2019) Manufacturing of advanced smart tooling for metal forming. CIRP Ann - Manuf Techn 68(2): 22. doi: https://doi.org/10.1016/j.cirp.2019.05.001.

Fu MW, Zheng JY, Meng B (2018) A review of progressive and compoundforming of bulk microparts by using sheet metals. Matec Web Conf 190(2):01001. https://doi.org/10.1051/matecconf/201819001001

Fu MW, Wang JL (2021) Size effects in multi-scale materials processing and manufacturing. Int J Mach Tool Manu 167:103755. https://doi.org/10.1016/j.ijmachtools.103755

Fang Z, Jiang ZY, Wang XG, Zhou CL, Wei DB, Liu XH (2015) Grain size effect of thickness/average grain size on mechanical behavior, fracture mechanism and constitutive model for phosphor bronze foil. Int J Adv Manuf Technol 79(9–12):1905–1914. https://doi.org/10.1007/s00170-015-6928-2

Jiang ZY, Zhao JW, Lu HN, Wei DB, Manabe KI, Zhao XM, Zhang XM, Wu D (2017) Influences of temperature and grain size on the material deformability in microforming process. Int J Mater Form 10: 753–764. doi: https://doi.org/10.1007/s12289-016-1317-4

Wang CJ, Cheng LD, Liu Y, Zhang H, Wang Y, Shan DB, Guo B (2019) Research on micro-deep drawing process of concial part with ultra-thin copper foil using multi-layered DLC film-coated die. Int J Adv Manuf Technol 100:569–575. https://doi.org/10.1007/s00170-018-2757-4

Çetin ME, Cora ÖN, Sofuoğlu H (2020) Micro deep drawability of the superplasticZn–22Al alloy at a high strain rate and room temperature. J Eng Mater Technol 142(1):011008. https://doi.org/10.1115/1.4044440

Zha CL, Chen W (2019) Theories and experiments on effects of acoustic energy field in micro-square cup drawing. Int J Adv Manuf Technol 104:4791–4802. https://doi.org/10.1007/s00170-019-04338-1

Zhao JW, Wang T, Jia FH, Li Z, Zhou CL, Huang QX, Jiang ZY (2021) Experimental investigation on micro deep drawing of stainless steel foils with different microstructural characteristics. Chin J Mech-En 34(2):1174. https://doi.org/10.1186/s10033-021-00556-5

Shimizu T, Ogawa M, Yang M, Manabe KI (2014) Plastic anisotropy of ultra-thin rolled phosphor bronze foils and its thickness strain evolution in micro-deep drawing. Mat Des 56:604–612. https://doi.org/10.1016/j.matdes.2013.11.048

Gong F, Yang Z, Chen Q, Xie ZW, Yang S (2015) Influences of lubrication conditions and blank holder force on micro deep drawing of C1100 micro conical-cylindrical cup. Precisi Eng 42:224–230. https://doi.org/10.1016/j.precisioneng.2015.05.004

Luo L, Wei DB, Zu GQ, Jiang ZY (2021) Influence of blank holder-die gap on micro-deep drawing of SUS304 cups. Int J Mech Sci 191:106065. https://doi.org/10.1016/j.ijmecsci.2020.106065

Behrens G, Trier FO, Tetzel H, Vollertsen F (2016) Influence of tool geometry variations on the limiting drawing ratio in micro deep drawing. Int J Mater Form 9:253–258. https://doi.org/10.1007/s12289-015-1228-9

Zhang ZC, Chen N, Furushima T, Li B (2018) Deformation behavior of metal foil in micro pneumatic deep drawing process. Proc Manuf 15:1422–1428. https://doi.org/10.1016/j.promfg.2018.07.339

Shimizu T, Murashige Y, Iwaoka S, Yang M, Manabe KI (2013) Scale dependence of adhesion behavior under dry friction in progressive micro-deep drawing. J Solid Mech Mater Eng 7(2):251–263. https://doi.org/10.1299/jmmp.7.251

Zhu CX, Xu J, Yu HP, Shan DB, Guo B (2021) Size effect on the high strain rate micro/meso-tensile behaviors of pure titanium foil. J Mater Res Technol 11:2146–2159. https://doi.org/10.1016/j.jmrt.2021.02.022

Wang S, Niu L, Chen C, Pang Y, Liao B, Zhong ZH, Lu P, Li P, Wu XD, Coenen JW, Cao LF, Wu YC (2018) Size effects on the tensile properties and deformation mechanism of commercial pure titanium foils. Mater Sci Eng A 730:244–261. https://doi.org/10.1016/j.msea.2018.06.009

Tang XF, Peng LF, Shi SQ (2019) Fu MW (2019) Influence of crystal structure on size dependent deformation behavior and strain heterogeneity in micro-scale deformation. Int J Plasticity 118:147–172. https://doi.org/10.1016/j.ijplas.2019.02.004

Jia FH, Zhao JW, Luo L, Xie HB, Jiang ZY (2017) Experimental and numerical study on micro deep drawing with aluminium-copper composite material. Procedia Eng 207:1051–1056. https://doi.org/10.1016/j.proeng.2017.10.1129

Gong F, Guo B (2013) Effects of solid lubrication film on SKD11 in micro sheet forming. Surf Coat Technol 232:814–820. https://doi.org/10.1016/j.surfcoat.2013.06.103

Luo L, Jiang Z, Wei D, Manabe KI, Sato H, He XF, Li PF (2015) An experimental and numerical study of micro deep drawing of SUS304 circular cups. Manuf Rev 2:27. https://doi.org/10.1051/mfreview/2015029

Chan WL, Fu MW (2011) Experimental studies and numerical modeling of the specimen and grain size effects on the flow stress of sheet metal in microforming. Mater Sci Eng A 528(25–26):7674–7683. https://doi.org/10.1016/j.msea.2011.06.076

Fang Z, Jiang ZY, Wang XG, Zhou CL, Wei DB, Liu XH (2015) Grain size effect of thickness/average grain size on mechanical behaviour, fracture mechanism and constitutive model for phosphor bronze foil. Int J Adv Manuf Technol 79(9–12):1905–1914. https://doi.org/10.1007/s00170-015-6928-2

Nie DM, Lu Z, Zhang KF (2017) Grain size effect of commercial pure titanium foilson mechanical properties, fracture behaviors and constitutive models. J Mater Eng Perform 26:1283–1292. https://doi.org/10.1007/s11665-017-2559-0

Gau JT, Teegala S, Huang KM, Lin HTJ (2013) Using micro deep drawing with ironing stages to form stainless steel 304 micro cups. J Manuf Process 15:298–305. https://doi.org/10.1016/j.jmapro.2013.01.009

Ma X, Lapovok R, Gu C, Molotnikov A, Estrin Y, Pereloma EV, Davies CHJ, Hodgson PD (2009) Deep drawing behaviour of ultrafine grained copper: modeling and experiment. J Mater Sci 44:3807–3812. https://doi.org/10.1007/s10853-009-3515-7

Fu MW, Yang B, Chan WL (2013) Experimental and simulation studies of micro blanking and deep drawing compound process using copper sheet. J Mater Processing Technol 213(1):101–110. https://doi.org/10.1016/j.jmatprotec.2012.08.007

Wang GF, Li Y, Liu SY, Yang JL, Yang M (2018) Micro deep drawing of T2 copper foil using proportional decreased tools. Int J Adv Manuf Technol 95(1–4):277–285. https://doi.org/10.1007/s00170-017-1111-6

Fu MW, Chan WL (2011) Geometry and grain size effects on the fracture behavior of sheet metal in micro-scale plastic deformation. Mater Design 32(10):4738–4746. https://doi.org/10.1016/j.matdes.2011.06.039

Liu N, Wang Y, He WJ, Chapuis A, Luan BF, Liu Q (2018) Microstructure and textural evolution during cold rolling and annealing of commercially pure titanium sheet. T Nonferr Metal Soc 28(6):1123–1131. https://doi.org/10.1016/S1003-6326(18)64748-X

Zhao JW, Huo MS, Ma XG, Jia FH, Jiang ZY (2019) Study on edge cracking of copper foils in micro rolling. Mater Sci Eng A 747:53–62. https://doi.org/10.1016/j.msea.2019.01.048

Molotnikov A, Lapovok R, Gu CF, Davies CHJ, Estrina Y (2012) Size effects in micro cup drawing. Mater Sci Eng A 550:312–319. https://doi.org/10.1016/j.msea.2012.04.079

Li WT, Fu MW, Wang JL, Meng B (2016) Grain size effect on multi-stage micro deep drawing of micro cup with domed bottom. Int J of Precis Eng and Man 17(6):765–773. https://doi.org/10.1007/s12541-016-0094-9

Acknowledgements

This work was supported by the Shanxi Province Unveils Bidding Project (20201101020).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Han, P., Xing, Y., Yuan, G. et al. Experimental investigation of the multi-stage micro-deep drawing of pure titanium foils with different grain sizes. J Mater Sci 57, 15094–15108 (2022). https://doi.org/10.1007/s10853-022-07556-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07556-3