Abstract

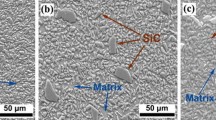

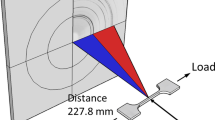

SiC particle reinforced Al matrix composites exhibit high strength, high wear resistance, and excellent high-temperature performance, but can also have low plasticity and fracture toughness, which limits their use in structural applications. This study investigates the plasticity and failure of such a composite on multiple length scales, from strain localization through a complex microstructure to the debonding of individual microparticles from the matrix. Three microscale pillars containing microstructures with different complexities and sizes/volume fraction of SiC particles were used to study the effect of these features on deformation. For the matrix, nanoscale intermetallic precipitates within the Al grains contribute most to the strengthening effect, and the Al grain boundaries are shown to be effective obstacles for preventing strain localization by dominant shear bands and, therefore, catastrophic failure. When shear localization occurs, SiC particles can then debond from the matrix if the shear band and interface are aligned. To investigate whether the interface is a weak point during catastrophic failure, a number of SiC particles were separated from the matrix with direct debonding tests, which yield an interface strength that is much higher than the critical resolved shear stress for a pillar exhibiting both shear localization and interface debonding. Therefore, the matrix–particle interface is ruled out as a possible weak point, and instead, shear localization is identified as the mechanism that can drive subsequent interface debonding.

Graphical abstract

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

Prasad SV, Asthana R (2004) Aluminum metal-matrix composites for automotive applications: tribological considerations. Tribo Lett 17:445–453. https://doi.org/10.1023/B:TRIL.0000044492.91991.f3

Suryanarayanan K, Praveen R, Raghuraman S (2013) Silicon carbide reinforced aluminum metal matrix composites for aerospace applications: a literature review. Int J Innov Res Sci Eng Technol 2(11):6336–6344

Jeong HG, Hiraga K, Mabuchi M, Higashi K (2000) The role of partial melting on superplasticity on Si3N4p/Al-Cu-Mg composite. Scr Mater 42:479–485. https://doi.org/10.1016/S1359-6462(99)00375-9

El-Kady O, Fathy A (2014) Effect of SiC particle size on the physical and mechanical properties of extruded Al matrix nanocomposites. Mater Des 54:348–353. https://doi.org/10.1016/j.matdes.2013.08.049

Papazian JM (1988) Effects of SiC Whiskers and particles on precipitation in aluminum matrix composites. Metall Trans A 19(12):2945–2953

Khadem SA, Nategh S, Yoozbashizadeh H (2011) Structural and morphological evaluation of Al-5 vol.% SiC nanocomposite powder produced by mechanical milling. J Alloys Compd 509:2221–2226. https://doi.org/10.1016/j.jallcom.2010.10.188

Xiong B, Xu Z, Yan Q, Lu B, Cai C (2011) Effects of SiC volume fraction and aluminum particulate size on interfacial reactions in SiC nanoparticulate reinforced aluminum matrix composites. J Alloys Compd 509:1187–1191. https://doi.org/10.1016/j.jallcom.2010.09.171

Canakci A, Fazli A, Temel V (2014) Physical and mechanical properties of stir-casting processed AA2024/B4Cp composites. Sci Eng Compos Mater 21(4):505–515. https://doi.org/10.1515/secm-2013-0118

Park BG, Crosky AG, Hellier AK (2001) Material characterization and mechanical properties of Al2O3-Al metal matrix composites. J Mater Sci 36:2417–2426. https://doi.org/10.1023/A:1017921813503

Ma ZY, Liu J, Yao CK (1991) Fracture mechanism in a SiCw-6061 Al composite. J Mater Sci 26:1971–1976. https://doi.org/10.1007/BF00543631

Chawla N, Habel U, Shen YL, Andres C, Jones JW, Allison JE (2000) The effect of matrix microstructure on the tensile and fatigue behavior of SiC particle-reinforced 2080 Al matrix composites. Metall Trans A 31:531–540. https://doi.org/10.1007/s11661-000-0288-7

Rahimian M, Parvin N, Ehsani N (2011) Investigation of particle size and amount of alumina on microstructure and mechanical properties of Al matrix composite made by powder metallurgy. Mater Sci Eng A 527:1031–1038. https://doi.org/10.1016/j.msea.2009.09.034

Uyyuru RK, Surappa MK, Brusethaug S (2006) Effect of reinforcement volume fraction and size distribution on the tribological behavior of Al-composite/brake pad tribo-couple. Wear 260:1248–1255. https://doi.org/10.1016/j.wear.2005.08.011

Mandal D, Viswanathan S (2013) Effect of heat treatment on microstructure and interface of SiC particle reinforced 2124 Al matrix composite. Mater Charact 85:73–81. https://doi.org/10.1016/j.matchar.2013.08.014

Uchic MD, Dimiduk DM, Florando JN, Nix WD (2002) Exploring specimen size effects in plastic deformation of Ni3(Al,Ta). Mater Res Soc Symp Proc. https://doi.org/10.1557/PROC-753-BB1.4

Uchic MD, Dimiduk DM, Florando JN, Nix WD (2004) Sample dimensions influence strength and crystal plasticity. Science 305:986–989. https://doi.org/10.1126/science.1098993

Uchic MD, Shade PA, Dimiduk DM (2009) Plasticity of micrometer-scale single crystals in compression. Annu Rev Mater Res 39:361–386. https://doi.org/10.1146/annurev-matsci-082908-145422

Uchic MD, Dimiduk DM, Wheeler R, Shade PA, Fraser HL (2006) Application of micro-sample testing to study fundamental aspects of plastic flow. Scr Mater 54:759–764. https://doi.org/10.1016/j.scriptamat.2005.11.016

Greer JR, Oliver WC, Nix WD (2005) Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater 53:1821–1830. https://doi.org/10.1016/j.actamat.2004.12.031

Hosemann P, Shin C, Kiener D (2015) Small scale mechanical testing of irradiated materials. J Mater Res 30:1–15. https://doi.org/10.1557/jmr.2015.26

Korte-Kerzel S (2017) Microcompression of brittle and anisotropic crystals: recent advances and current challenges in studying plasticity in hard materials. MRS Commun 7:109–120. https://doi.org/10.1557/mrc.2017.15

Khalajhedayati A, Rupert TJ (2014) Emergence of localized plasticity and failure through shear banding during microcompression of a nanocrystalline alloy. Acta Mater 65:326–337. https://doi.org/10.1016/j.actamat.2013.10.074

Khalajhedayati A, Rupert TJ (2015) Disruption of thermally-stable nanoscale grain structures by strain localization. Sci Rep 5:10663. https://doi.org/10.1038/srep10663

Vo HT, Still EK, Lam K, Drnovšek A, Capolungo L, Maloy SA, Chou P, Hosemann P (2021) Experimental methodology and theoretical framework in describing constrained plastic flow of FCC microscale tensile specimens. Mater Sci Eng A 799:140124. https://doi.org/10.1016/j.msea.2020.140124

Zhang H, Schuster BE, Wei Q, Ramesh KT (2006) The design of accurate micro-compression experiments. Scr Mater 54:181–186. https://doi.org/10.1016/j.scriptamat.2005.06.043

Uchic MD, Dimiduk DM (2005) A methodology to investigate size scale effects in crystalline plasticity using uniaxial compression testing. Mater Sci Eng A 400:268–278. https://doi.org/10.1016/j.msea.2005.03.082

Unocic KA, Mills MJ, Daehn GS (2010) Effect of gallium focused ion beam milling on preparation of aluminum thin foils. J Microsc 240(3):227–238. https://doi.org/10.1111/j.1365-2818.2010.03401.x

Xiao Y, Maier-Kiener V, Michler J, Spolenak R, Wheeler JM (2019) Deformation behavior of aluminum pillars produced by Xe and Ga focused ion beams: insights from strain rate jump tests. Mater Des 181:107914. https://doi.org/10.1016/j.matdes.2019.107914

Brandstetter S, Van Swygenhoven H, Van Petegem S, Schmitt B, Maaβ R, Derlet PM (2006) From micro-to macroplasticity. Adv Mater 18:1545–1548. https://doi.org/10.1002/adma.200600397

Thompson DS, Subramanya BS, Levy SA (1971) Quench rate effects in Al-Zr-Mg-Cu alloys. Metall Trans 2(4):1149–1160

Gupta M, Surappa MK (1995) Processing-microstructure-mechanical properties of Al based metal matrix composites synthesized using casting route. Key Eng Mater 104:259–274

Mondal C, Mukhopadhyay AK (2005) On the nature of T(Al2Mg3Zn3) and S(Al2CuMg) phases present in as-cast and annealed 7055 aluminum alloy. Mater Sci Eng A 391:367–376. https://doi.org/10.1016/j.msea.2004.09.013

Ye T, Xu Y, Ren J (2019) Effects of SiC particle size on mechanical properties of SiC particle reinforced aluminum metal matrix composite. Mater Sci Eng A 753:146–155. https://doi.org/10.1016/j.msea.2019.03.037

Gnjidić Ž, Božić D, Mitkov M (2001) The influence of SiC particles on the compressive properties of metal matrix composites. Mater Charact 47:129–138. https://doi.org/10.1016/S1044-5803(01)00161-9

Song SG, Shi N, Gray GT, Roberts JA (1996) Reinforcement shape effects on the fracture behavior and ductility of particulate-reinforced 6061-Al matrix composites. Metall Mater Trans A 27(11):3739–3746

Andrews E, Sanders W, Gibson LJ (1999) Compressive and tensile behavior of aluminum foams. Mater Sci Eng A 270:113–124. https://doi.org/10.1016/S0921-5093(99)00170-7

Chawla N, Ganesh VV, Wunsch B (2004) Three-dimensional (3D) microstructure visualization and finite element modeling of the mechanical behavior of SiC particle reinforced aluminum composites. Scr Mater 51:161–165. https://doi.org/10.1016/j.scriptamat.2004.03.043

Hong SI, Gray GT (1994) Dynamic mechanical response of a 1060 Al/Al2O3 composite. J Mater Sci 29:2987–2992. https://doi.org/10.1007/BF01117611

Shen Z, Wagoner RH, Clark WAT (1988) Dislocation and grain boundary interactions in metals. Acta metal 36(12):3231–3242. https://doi.org/10.1016/0001-6160(88)90058-2

Gupta M, Surappa MK, Qin S (1997) Effect of interfacial characteristics on the failure-mechanism mode of a SiC reinforced Al based metal-matrix composite. J Mater Process Technol 67:94–99. https://doi.org/10.1016/S0924-0136(96)02825-7

Ma M, Wang B, Liu H, Yi D, Shen F, Zhai T (2020) Investigation of fatigue crack propagation behavior of 5083 aluminum alloy under various stress ratios: role of grain boundary and Schmid factor. Mater Sci Eng A 773:138871. https://doi.org/10.1016/j.msea.2019.138871

Guo X, Guo Q, Li Z, Fan G, Xiong D, Su Y, Zhang J, Gan CL, Zhang D (2016) Interfacial strength and deformation mechanism of SiC-Al composite micro-pillars. Scripta Mater 114:56–59. https://doi.org/10.1016/j.scriptamat.2015.11.018

Suh YS, Joshi SP, Ramesh KT (2009) An enhanced continuum model for size-dependent strengthening and failure of particle-reinforced composites. Acta Mater 57:5848–5861. https://doi.org/10.1016/j.actamat.2009.08.010

Shao JC, Xiao BL, Wang QZ, Ma ZY, Yang K (2011) An enhanced FEM model for particle size dependent flow strengthening and interface damage in particle reinforced metal matrix composites. Compos Sci Technol 71:39–45. https://doi.org/10.1016/j.compscitech.2010.09.014

Hahnlen R, Dapino MJ (2014) NiTi-Al interface strength in ultrasonic additive manufacturing composites. Compos B Eng 59:101–108. https://doi.org/10.1016/j.compositesb.2013.10.024

Hehr A, Dapino MJ (2015) Interfacial shear strength estimates of NiTi-Al matrix composites fabricated via ultrasonic additive manufacturing. Compos B Eng 77:199–208. https://doi.org/10.1016/j.compositesb.2015.03.005

Ozdemir I, Ahrens S, Mucklich S, Wielage B (2008) Nanocrystalline Al-Al2O3p and SiCp composites produced by high-energy ball milling. J Mater Process Technol 205:111–118. https://doi.org/10.1016/j.jmatprotec.2007.11.085

Prabhu B, Suryanarayana C, An L, Vaidyanathan R (2006) Synthesis and characterization of high volume fraction Al-Al2O3 nanocomposite powders by high-energy milling. Mater Sci Eng A 425:192–200. https://doi.org/10.1016/j.msea.2006.03.066

Amirkhanlou S, Niroumand B (2013) Microstructure and mechanical properties of Al356/SiCp cast composites fabricated by a novel technique. J Mater Eng Perform 22:85–93. https://doi.org/10.1007/s11665-012-0223-2

Acknowledgements

The authors would like to acknowledge financial support from the BIAM-UCI Research Centre for the Fundamental Study of Novel Structural Materials (Research Agreement #210263).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Confilct of interests

The authors declare that they have no competing interests that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lei, T., Wardini, J.L., Donaldson, O.K. et al. In situ mechanical testing of an Al matrix composite to investigate compressive plasticity and failure on multiple length scales. J Mater Sci 56, 8259–8275 (2021). https://doi.org/10.1007/s10853-021-05789-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05789-2