Abstract

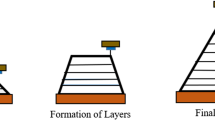

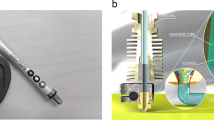

Highly flexible biocompatible materials that are both thermally conductive and electrically insulating are important for implantable and wearable bioelectronics applications. The ability to thermally process these materials into useful structures using additive manufacturing approaches opens up new opportunities for its use in bespoke structures. Here we investigate the three-dimensional (3D) printing of a medical-grade thermoplastic polyurethane (PU) elastomer, which is thermally insulating and enhance its thermal and mechanical properties through the incorporation of boron nitride (BN) as a filler. Via a simple solution compounding approach, a highly flexible and thermally conductive BN nanoparticle/ PU composite has been developed and subsequently processed into simple bio-scaffolds structures via a 3D pneumatic melt extrusion printing process. The addition of up to 20% w/w of BN to the PU significantly enhances the tensile modulus by 659%, from 1.74 to 13.2 MPa, while supporting high mechanical flexibility. The thermal conductivity of 20% w/w BN/PU composite increases by 74% with respect to the unmodified PU. The 3D printed BN/PU composite scaffolds exhibit good biocompatibility and cell attachment enhancement with L929 fibroblast cells.

Graphical abstract

Similar content being viewed by others

References

Moore AL, Shi L (2014) Emerging challenges and materials for thermal management of electronics. Mater Today 17(4):163–174

McGlen RJ, Jachuck R, Lin S (2004) Integrated thermal management techniques for high power electronic devices. Appl Therm Eng 24(8):1143–1156

Cabeza LF (2014) Advances in thermal energy storage systems: methods and applications. Elsevier, USA

Ray TR, Choi J, Bandodkar AJ, Krishnan S, Gutruf P, Tian L, Ghaffari R, Rogers JA (2019) Bio-integrated wearable systems: a comprehensive review. Chem Rev 119(8):5461–5533

Yang Y, Gao W (2019) Wearable and flexible electronics for continuous molecular monitoring. Chem Soc Rev 48(6):1465–1491

Dewhirst MW, Viglianti B, Lora-Michiels M, Hanson M, Hoopes P (2003) Basic principles of thermal dosimetry and thermal thresholds for tissue damage from hyperthermia. Int J Hyperth 19(3):267–294

Ngo TD, Kashani A, Imbalzano G, Nguyen KTQ, Hui D (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos Part B Eng 143:172–196

Valino AD, Dizon JRC, Espera Jr AH, Chen Q, Messman J, Advincula RC (2019) Advances in 3D printing of thermoplastic polymer composites and nanocomposites. Prog Polym Sci 98:101162

Jakus AE, Secor EB, Rutz AL, Jordan SW, Hersam MC, Shah RN (2015) Three-dimensional printing of high-content graphene scaffolds for electronic and biomedical applications. ACS Nano 9(4):4636–4648

Guiney LM, Mansukhani ND, Jakus AE, Wallace SG, Shah RN, Hersam MC (2018) Three-dimensional printing of cytocompatible, thermally conductive hexagonal boron nitride nanocomposites. Nano Lett 18(6):3488–3493

Do AV, Khorsand B, Geary SM, Salem AK (2015) 3D printing of scaffolds for tissue regeneration applications. Adv Healthcare Mater 4(12):1742–1762

Yuk H, Lu B, Zhao X (2019) Hydrogel bioelectronics. Chem Soc Rev 48(6):1642–1667

Kolesky DB, Truby RL, Gladman AS, Busbee TA, Homan KA, Lewis JA (2014) 3D bioprinting of vascularized, heterogeneous cell-laden tissue constructs. Adv Mater 26(19):3124–3130

Liu X, Yuk H, Lin S, Parada GA, Tang TC, Tham E, de la Fuente-Nunez C, Lu TK, Zhao X (2018) 3D printing of living responsive materials and devices. Adv Mater 30(4):1704821

Li H, Tan YJ, Leong KF, Li L (2017) 3D bioprinting of highly thixotropic alginate/methylcellulose hydrogel with strong interface bonding. ACS Appl Mater Interfaces 9(23):20086–20097

Rogers JA, Someya T, Huang Y (2010) Materials and mechanics for stretchable electronics. Science 327(5973):1603–1607

Hong H, Jung YH, Lee JS, Jeong C, Kim JU, Lee S, Ryu H, Kim H, Ma Z, Kim TI (2019) Anisotropic thermal conductive composite by the guided assembly of boron nitride nanosheets for flexible and stretchable electronics. Adv Funct, Mater, p 1902575

Waheed S, Cabot JM, Macdonald NP, Kalsoom U, Farajikhah S, Innis PC, Nesterenko PN, Lewis TW, Breadmore MC, Paull B (2017) Enhanced physicochemical properties of polydimethylsiloxane based microfluidic devices and thin films by incorporating synthetic micro-diamond. Sci Rep 7(1):1–10

Rueda L, d’Arlas BF, Corcuera M, Eceiza A (2014) Biostability of polyurethanes study from the viewpoint of microphase separated structure. Polym Degrad Stab 108:195–200

Cooper SL, Guan J (2016) Advances in polyurethane biomaterials. Woodhead Publishing, New Delhi

Qi H, Boyce M (2005) Stress–strain behavior of thermoplastic polyurethanes. Mech Mater 37(8):817–839

Griffin M, Castro N, Bas O, Saifzadeh S, Butler P, Hutmacher DW (2020) The current versatility of polyurethane 3D-printing for biomedical applications. Tissue Eng Part B 26(3):272–283

Kim NP (2020) 3D-printed conductive carbon-infused thermoplastic polyurethane. Polymers 12(6):1224

Xu C, Miao M, Jiang X, Wang X (2018) Thermal conductive composites reinforced via advanced boron nitride nanomaterials. Compos Commun 10:103–109

Fang H, Bai S-L, Wong CP (2016) “White graphene” – hexagonal boron nitride based polymeric composites and their application in thermal management. Compos Commun 2:19–24

Kim K, Kim M, Kim J (2014) Enhancement of the thermal and mechanical properties of a surface-modified boron nitride–polyurethane composite. Polym Adv Technol 25(8):791–798

Hong H-J, Kwan SM, Lee DS, Kim SM, Kim YH, Lim JS, Hwang JY, Jeong HS (2017) Highly flexible and stretchable thermally conductive composite film by polyurethane supported 3D networks of boron nitride. Compos Sci Technol 152:94–100

Li L, Li LH, Ramakrishnan S, Dai XJ, Nicholas K, Chen Y, Chen Z, Liu X (2012) Controlling wettability of boron nitride nanotube films and improved cell proliferation. J Phys Chem C 116(34):18334–18339

Shtansky DV, Firestein KL, Golberg DV (2018) Fabrication and application of BN nanoparticles, nanosheets and their nanohybrids. Nanoscale 10(37):17477–17493

Lahiri D, Rouzaud F, Richard T, Keshri AK, Bakshi SR, Kos L, Agarwal A (2010) Boron nitride nanotube reinforced polylactide–polycaprolactone copolymer composite: mechanical properties and cytocompatibility with osteoblasts and macrophages in vitro. Acta Biomater 6(9):3524–3533

Wang C, Feng J, Zhou J, Huang X, Wang L, Liu G, Cheng J (2020) Microstructure, mechanical properties and in vitro biocompatibilities of a novel bionic hydroxyapatite bone scaffold prepared by the addition of boron nitride. J Mater Sci 55(29):14501–14515

Çakmakçı E, Koçyiğit Ç, Çakır S, Durmus A, Kahraman MV (2014) Preparation and characterization of thermally conductive thermoplastic polyurethane/h-BN nanocomposites. Polym Compos 35(3):530–538

Zhu Z, Li C, Songfeng E, Xie L, Geng R, Lin C-T, Li L, Yao Y (2019) Enhanced thermal conductivity of polyurethane composites via engineering small/large sizes interconnected boron nitride nanosheets. Compos Sci Technol 170:93–100

Ribeiro H, Trigueiro JPC, Lopes MC, Pedrotti JJ, Woellner CF, Silva WM, Silva GG, Ajayan PM (2018) Enhanced thermal conductivity and mechanical properties of hybrid MoS2/h-BN polyurethane nanocomposites. J Appl Polym Sci 135(30):46560

Wang L, Han D, Luo J, Li T, Lin Z, Yao Y (2018) Highly efficient growth of boron nitride nanotubes and the thermal conductivity of their polymer composites. J Phys Chem C 122(3):1867–1873

Nguyen N, Melamed E, Park JG, Zhang S, Hao A, Liang R (2017) Direct printing of thermal management device using low-cost composite ink. Macromol Mater Eng 302(10):1700135

Farajikhah S (2018) Electroactive fibre sensor systems for fluidics. University of Wollongong, Australia

Yi H-G, Choi Y-J, Kang KS, Hong JM, Pati RG, Park MN, Shim IK, Lee CM, Kim SC, Cho D-W (2016) A 3D-printed local drug delivery patch for pancreatic cancer growth suppression. J Control Release 238:231–241

Guerra V, Wan C, McNally T (2019) Thermal conductivity of 2D nano-structured boron nitride (BN) and its composites with polymers. Prog Mater Sci 100:170–186

Oyane A, Kim HM, Furuya T, Kokubo T, Miyazaki T, Nakamura T (2003) Preparation and assessment of revised simulated body fluids. J. Biomed Mater Res 65(2):188–195

Zhu D, Ren Y, Liao G, Jiang S, Liu F, Guo J, Xu G (2017) Thermal and mechanical properties of polyamide 12/graphene nanoplatelets nanocomposites and parts fabricated by fused deposition modeling. J Appl Polym Sci 134(39):45332

Geisendorfer NR, Shah RN (2019) Effect of polymer binder on the synthesis and properties of 3D-printable particle-based liquid materials and resulting structures. ACS omega 4(7):12088–12097

Ning F, Cong W, Qiu J, Wei J, Wang S (2015) Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos Part B Eng 80:369–378

Chen Q, Mangadlao JD, Wallat J, De Leon A, Pokorski JK, Advincula RC (2017) 3D printing biocompatible polyurethane/poly (lactic acid)/graphene oxide nanocomposites: anisotropic properties. ACS Appl Mater Interfaces 9(4):4015–4023

Xiang D, Zhang X, Han Z, Zhang Z, Zhou Z, Harkin-Jones E, Zhang J, Luo X, Wang P, Zhao C (2020) 3D printed high-performance flexible strain sensors based on carbon nanotube and graphene nanoplatelet filled polymer composites. J Mater Sci 55(33):15769–15786.https://doi.org/10.1007/s10853-020-05137-w

Wu H, Kessler MR (2015) Multifunctional cyanate ester nanocomposites reinforced by hexagonal boron nitride after noncovalent biomimetic functionalization. ACS Appl Mater Interfaces 7(10):5915–5926

Gao T, Yang Z, Chen C, Li Y, Fu K, Dai J, Hitz EM, Xie H, Liu B, Song J (2017) Three-dimensional printed thermal regulation textiles. ACS Nano 11(11):11513–11520

Tan C, Zhu H, Ma T, Guo W, Liu X, Huang X, Zhao H, Long Y-Z, Jiang P, Sun B (2019) A stretchable laminated GNRs/BNNSs nanocomposite with high electrical and thermal conductivity. Nanoscale 11(43):20648–20658

Zhou WY, Qi SH, Zhao HZ, Liu NL (2007) Thermally conductive silicone rubber reinforced with boron nitride particle. Polym Compos 28(1):23–28

Yang X, Guo Y, Luo X, Zheng N, Ma T, Tan J, Li C, Zhang Q, Gu J (2018) Self-healing, recoverable epoxy elastomers and their composites with desirable thermal conductivities by incorporating BN fillers via in-situ polymerization. Compos Sci Technol 164:59–64

Han W, Bai Y, Liu S, Ge C, Wang L, Ma Z, Yang Y, Zhang X (2017) Enhanced thermal conductivity of commercial polystyrene filled with core-shell structured BN@PS. Compos Part A Appl Sci Manuf 102:218–227

Zhang D-L, Zha J-W, Li W-K, Li C-Q, Wang S-J, Wen Y, Dang Z-M (2018) Enhanced thermal conductivity and mechanical property through boron nitride hot string in polyvinylidene fluoride fibers by electrospinning. Compos Sci Technol 156:1–7

Pan C, Kou K, Zhang Y, Li Z, Wu G (2018) Enhanced through-plane thermal conductivity of PTFE composites with hybrid fillers of hexagonal boron nitride platelets and aluminum nitride particles. Compos Part B Eng 153:1–8

Che J, Jing M, Liu D, Wang K, Fu Q (2018) Largely enhanced thermal conductivity of HDPE/boron nitride/carbon nanotubes ternary composites via filler network-network synergy and orientation. Compos Part A Appl Sci Manuf 112:32–39

Chen J, Huang X, Zhu Y, Jiang P (2017) Cellulose nanofiber supported 3D interconnected BN nanosheets for epoxy nanocomposites with ultrahigh thermal management capability. Adv Funct Mater 27(5):1604754

Wang H, Ding D, Liu Q, Chen Y, Zhang Q (2019) Highly anisotropic thermally conductive polyimide composites via the alignment of boron nitride platelets. Compos Part B Eng 158:311–318

Acknowledgements

The authors acknowledge the ARC Center of Excellence for Electromaterials Science (ACES), the Australian National Fabrication Facility (ANFF)—Materials Node, and the facilities of the University of Wollongong Electron Microscopy Center.

Funding

This study was funded by the Australian Research Council Center of Excellence for Materials Science (Grant No CE140100012).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Maude Jimenez.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the supplementary information

Rights and permissions

About this article

Cite this article

Khakbaz, H., Ruberu, K., Kang, L. et al. 3D printing of highly flexible, cytocompatible nanocomposites for thermal management. J Mater Sci 56, 6385–6400 (2021). https://doi.org/10.1007/s10853-020-05661-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05661-9