Abstract

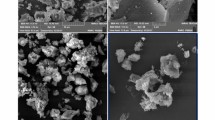

Acicular mullite-reinforced porous self-bonded ceramics were fabricated using mullite powders as principal raw materials, alumina and silicon dioxide powders as starting synthetic source of self-bonded mullite phase, and 2 wt% AlF3·3H2O as an accelerant. The influences of self-bonded mullite weight percent on the phase composition, microstructures, mechanical performance and thermal conductivities of acicular mullite-reinforced porous self-bonded samples were investigated. As self-bonded mullite weight percent varied between 0 and 50 wt%, linear shrinkage, bulk density and thermal conductivities of fired porous self-bonded mullite samples reduced, whereas their porosity increased. Addition of appropriate amounts of self-bonded mullite decreased the mean pore size and window size in porous sample, and enhanced the mechanical strength. When self-bonded mullite weight percent reached 50 wt%, the compressive and flexural strength of acicular mullite-reinforced porous self-bonded ceramics was, respectively, kept as 19.9 MPa and 8.8 MPa, with a porosity of 74.7%, a diminutive mean pore size of 159 μm and a window size of 44 μm. Moreover, the linear shrinkage and thermal conductivity of the materials at 50 °C were only 7.4% and 0.23 W m K−1, respectively.

Similar content being viewed by others

References

Qian HR, Cheng XD, Zhang HP, Zhang RF, Wang YH (2014) Preparation of porous mullite ceramics using fly ash cenosphere as a pore-forming agent by gelcasting process. Int J Appl Ceram Technol 11:858–863

Ma BY, Su C, Ren XM, Gao Z, Qian F, Yang WG, Liu GQ, Li HX, Yu JK, Zhu Q (2019) Preparation and properties of porous mullite ceramics with high-closed porosity and high strength from fly ash via reaction synthesis process. J Alloy Compd 803:981–991

Voigt C, Zienert T, Schubert P, Aneziris CGHJ (2014) Reticulated porous foam ceramics with different surface chemistries. J Am Ceram Soc 97:2046–2053

Liu QZ, Xue T, Yang LN, Hu XX, Du HY (2016) Controllable synthesis of hierarchical porous mullite fiber network for gas filtration. J Eur Ceram Soc 36:1691–1697

Qin ML, Wang XT, Wang ZF, Ma Y, Liu H (2018) Cordierite thermal insulation materials reinforced by aluminosilicate fiber/mullite whiskers hierarchical structure. Int J Appl Ceram Technol 15:1047–1053

Zhu MG, Ji R, Li ZM, Wang H, Liu LL, Zhang ZT (2016) Preparation of glass ceramic foams for thermal insulation applications from coal fly ash and waste glass. Constr Build Mater 112:398–405

Ren JT, Ying W, Zhao J, Xie JJ, Zhou GH, Shi Y, Wang SW (2019) High-strength porous mullite ceramics fabricated from particle-stabilized foams via oppositely charged dispersants and surfactants. Ceram Int 4:6385–6391

Deng XG, Wu YG, Wei TT, Ran SL, Huang L, Zhang HJ, Li FL, Han L, Ge ST, Zhang SW (2018) Preparation of elongated mullite self-reinforced porous ceramics. Ceram Int 44:7500–7508

Zhang JB, Li HQ, Li SP, Hu PP, Wu WF, Wu QS (2018) Mechanism of mechanical– chemical synergistic activation for preparation of mullite ceramics from high- alumina coal fly ash. Ceram Int 44:3884–3892

Han L, Deng XG, Li FL, Huang L, Pei YT, Dong L, Li SS, Jia QL, Zhang HJ, Zhang SW (2018) Preparation of high strength porous mullite ceramics via combined foam-gelcasting and microwave heating. Ceram Int 44:14728–14733. https://doi.org/10.1007/s10853-019-03576-8

Zhang M, Li X, Zhang M, Xiu ZM, Li JG, Li JP, Xie M, Chen JL, Sun XD (2019) High-strength macro-porous alumina ceramics with regularly arranged pores produced by gel-casting and sacrificial template methods. J Mater Sci 54:10119–10129. https://doi.org/10.1007/s10853-019-03576-8

Zhang XY, Huo WL, Lu YJ, Gan K, Yan S, Liu JJ, Yang JL (2019) Porous Si3N4-based ceramics with uniform pore structure originated from single-shell hollow microspheres. J Mater Sci 54:4484–4494. https://doi.org/10.1007/s10853-018-3118-2

Akpinar S, Kusoglu IM, Ertugrul O, Onel K (2012) Silicon carbide particle reinforced mullite composite foams. Ceram Int 38:6163–6169

Pugh MD, Drew RAL (2020) Pore structure, porosity and compressive strength of highly porous reaction-bonded silicon nitride ceramics with various grain morphologies. J Mater Sci 55:1–15. https://doi.org/10.1007/s10853-019-04078-3

Fukushima M, Yoshizawa Y (2016) Fabrication and morphology control of highly porous mullite thermal insulators prepared by gelation freezing route. J Eur Ceram Soc 36:2947–2953

Schneider H, Schreuer J, Hildmann B (2008) Structure and properties of mullite-a review. J Eur Ceram Soc 28:329–344

Yuan L, Liu ZL, Hou XH, Liu ZQ, Zhu Q, Ma BY (2019) Fibrous ZrO2-mullite porous ceramics fabricated by a hydratable alumina based aqueous gel-casting process. Ceram Int 45:8824–8831

Ma J, Ye F, Zhang B, Jin YC, Yang CP, Ding JJ (2018) Low-temperature synthesis of highly porous whisker-structured mullite ceramic from kaolin. Ceram Int 44:13320–13327

Zhao F, Ge TZ, Gao JX, Chen LG, Liu XH (2018) Transient liquid phase diffusion process for porous mullite ceramics with excellent mechanical properties. Ceram Int 44:19123–19130

Guo HS, Li WF (2018) Effects of Al2O3 crystal types on morphologies, formation mechanisms of mullite and properties of porous mullite ceramics based on kyanite. J Eur Ceram Soc 38:679–686

Zhou WY, Yan W, Li N, Li YB, Dai YJ, Han BQ (2018) Preparation and characterization of mullite foam ceramics with porous struts from white clay and industrial alumina. Ceram Int 44:22950–22956

Yuan L, Ma BY, Zh QU, Zhang XD, Zhang H, Yu JK (2017) Preparation and properties of mullite-bonded porous fibrous mullite ceramics by an epoxy resin gel-casting process. Ceram Int 43:5478–5483

Deng XG, Wang JK, Zhang HJ, Liu JH, Zhao WG, Huang Z (2016) Effects of firing temperature on the microstructures and properties of porous mullite ceramics prepared by foam-gelcasting. Adv Appl Ceram 115:204–209

Lépinay M, Lee D, Scarazzini R, Michel B, Marc V, Lucile B, Christophe L, Vincent J (2016) Impact of plasma reactive ion etching on low dielectric constant porous organosilicate films’ microstructure and chemical composition. Micropor Mesopor Mat 228:297–304

Deng XG, Ran SL, Han L, Zhang HJ, Ge ST, Zhang SW (2017) Foam-gelcasting preparation of high-strength self-reinforced porous mullite ceramics. J Eur Ceram Soc 37:4059–4066

Guo HS, Ye FB, Li WF, Song XZ, Xie GF (2015) Preparation and characterization of foamed microporous mullite ceramics based on kyanite. Ceram Int 41:14645–14651

Guo HS, Li WF, Ye FB (2016) Preparation of microporous mullite ceramics by foaming for high temperature thermal isolation. Ceram Int 42:17332–17338

Barea R, Osendi MI, Ferreira JMF, Miranzo P (2005) Thermal conductivity of highly porous mullite material. Acta Mater 53:3313–3318

Acknowledgements

This research work in paper was supported by the Natural Science Foundation of Anhui Province (1908085ME117), Natural Science Foundation of Anhui Provincial Education Department (KJ2018A0052), the University Synergy Innovation Program of Anhui Province (GXXT-2019-015), the Opening Project of the Key Laboratory of Metallurgical Emission Reduction and Resources Recycling (JKF 18-04), National Natural Science Foundation of China (51872210, U1860102 and 51972002), and the Open Foundation of the State Key Laboratory of Refractories and Metallurgy (G201801).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Deng, X., Yin, J., Zhang, W. et al. Microstructure and mechanical performance of acicular mullite-reinforced porous self-bonded ceramics. J Mater Sci 55, 9322–9329 (2020). https://doi.org/10.1007/s10853-020-04558-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04558-x