Abstract

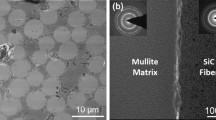

In order to enhance the fracture toughness of mullite, three-dimensional braided carbon fiber reinforced mullite (C/mullite) composites were prepared using the Al2O3-SiO2 sol with a high solid content as raw material. Mullitization behavior of the sol was characterized. Then, the microstructure, mechanical properties and oxidation resistance of C/mullite composites were investigated. It is found that the SiO2-rich mullite with desirable sintering shrinkage can be synthesized at 1 300 °C from the sol with an Al203/SiO2 mass ratio of 1:1. The C/mullite composites with a total porosity of 21.5% were fabricated by repeating 18 cycles of vacuum impregnation-drying-heat treatment, showing a flexural strength of 234.5 MPa and a fracture toughness of 13.1 MPa·m1/2. Since carbon fibers were protected by compact matrix, the C/mullite composites show favorable oxidation resistance during 1 200 °C-1 600 °C even if an open porosity of 10.3% was detected.

Similar content being viewed by others

References

Schneider H, Schreuer J, Hildmann B. Structure and Properties of Mul-lite-A Review [J]. J. Eur. Ceram. Soc, 2008, 28: 329–344

Zhang JH, Wu HD, Zhang SX, et al. Preparation of Mullite Whiskers and Their Enhancement Effect on Ceramic Matrix Composites[J]. J. Wuhan Univ. Technol.-Mater. Sci. Ed., 2013, 28(3): 471–475

Ma QS, Cai LH. Preparation and Anti-oxidation Mechanism of Mul- lite/Yttrium Silicate Coatings on C/SiC Composites[J]. J. Wuhan Univ. Technol.-Mater. Sci. Ed., 2016, 31(6): 1284–1288

Kumar P, Nath M, Ghosh A, et al. Thermo-Mechanical Properties of Mullite-Zirconia Composites Derived from Reaction Sintering of Zircon and Sillimanite Beach Sand: Effect of CaO[J]. Trans. Nonferrous Met. Soc. China, 2016, 26: 2397–2403

Wu J, Jones FR, James PF. Continuous Fibre Reinforced Mullite Matrix Composites by Sol-Gel Processing Part I Fabrication and Micro-structures[J]. J. Mater. Sci., 1997, 32(13): 3361–3368

Wu J, Jones FR, James PF. Continuous Fibre Reinforced Mullite Matrix Composites by Sol-Gel Processing Part II Properties and Fracture Behavior[J]. J. Mater. Sci., 1997, 32(14): 3629–3635

Dong R, Hirata Y, Sueyoshi H, et al. Polymer Impregnation and Py-rolysis (PIP) Method for the Preparation of Laminated Woven Fabric/ Mullite Matrix Composites with Pseudoductility[J]. J. Eur. Ceram. Soc, 2004, 24: 53–64

Wang Y, Liu HT, Cheng HF, et al. Effective Fugitive Carbon Coatings for the Strength Improvement of 3D Nextel 440/Aluminosilicate Composites[J]. Master: Lett., 2014, 126: 236–239

Wang Y, Cheng HF, Wang J. Effects of the Single Layer CVD SiC Interphases on Mechanical Properties of Mullite Fiber-Reinforced Mullite Matrix Composites Fabricated via a Sol-Gel Process[J]. Ceram. Int., 2014, 40(3): 4707–4715

Wang Y, Liu HT, Cheng HF, et al. Effects of Sintering Temperature on Mechanical Properties of 3D Mullite Fiber (ALF FB3) Reinforced Mullite Composites[J]. Ceram. Int., 2013, 39(8): 9229–9235

Xiang Y, Wang Q, Cao F, et al. Sol-Gel Process and High-temperature Property of SiO2/Zr02-SiO2 Composites[J]. Ceram. Int., 2017, 43(1): 854–859

Wang Q, Cao F, Xiang Y, et al. Effects of Zr02 Coating on the Strength Improvement of 2.5D SiCf/SiO2 Composites[J]. Ceram. Int., 2017, 43(1): 884–889

Fan CY, Ma QS, Zeng KH. Thermal Stability and Oxidation Resistance of C/A1203 Composites Fabricated from a Sol with High Solid Content[J]. Ceram. Int., 2017, 43(14): 10983–10990

Beran A, Voll D, Schneider H. Dehydration and Structural Development of Mullite Precursors: an FTIR Spectroscopic Study[J]. J. Eur. Ceram. Soc, 2001, 21: 2479–2485

Cividanes LS, Campos TMB, Rodrigues LA, et al. Review of Mullite Synthesis Routes by Sol-gel Method[J]. J. Sol-Gel Sci. Technol, 2010, 55: 111–125

Author information

Authors and Affiliations

Corresponding authors

Additional information

Funded by the Science Innovation Foundation of Shanghai Academy of Spaceflight Technology (No. SAST2015043), the Open Foundation of Science and Technology on Thermostructural Composite Materials Laboratory(No.614291102010117), and the National Natural Science Foundation of China (No. 11572277)

Rights and permissions

About this article

Cite this article

Zhang, W., Ma, Q., Dai, K. et al. Fabrication and Properties of Three-dimensional Braided Carbon Fiber Reinforced SiOa-rich Mullite Composites. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 34, 798–803 (2019). https://doi.org/10.1007/s11595-019-2120-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-019-2120-0