Abstract

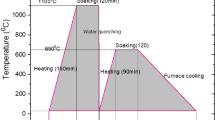

The contributions from the martensitic laths, dislocations, secondary phase particles, and supersaturated solid solutions to the overall strength of the 12%Cr–3%Co–2.5%W creep-resistant steel with low N and high B contents were calculated after various heat treatments consisting of normalizing followed by medium-temperature tempering. An increase in the normalizing temperature from 1050 to 1150 °C led to an increase in the average size of the prior austenitic grains from 44 to 68 μm, but the δ-ferrite fraction did not significantly change. Medium-temperature tempering in the range of 750–800 °C ensured the formation of a tempered martensite lath structure with an average martensitic lath/subgrain size of 0.23–0.34 μm, along with a high dislocation density inside the laths/subgrains, fine secondary phase particles such as M23C6 carbides along the boundaries of the prior austenite grains, packets, blocks, and martensitic laths/subgrains, and (Ta,Nb)X carbonitrides uniformly distributed inside the matrix. After medium-temperature tempering in the range of 750–800 °C, the ferritic matrix was supersaturated with substitutional elements such as Cr, W, Mo, and Cu. An increase in the tempering temperature from 750 to 800 °C led to decreases in the yield strength and ultimate tensile strength by 16.2% and 10.5%, respectively, as well as an increase in the elongation of 43.8%. The main contributions to the overall strengthening of the steel investigated after the different heat treatment regimens produced solid solution strengthening and precipitation hardening, which were independent of the tempering temperature, as well as lath boundary and dislocation strengthening, which was strongly dependent on the tempering temperature. Different approaches for evaluating the strengthening mechanisms and their contributions to the yield strength were applied, and the results are discussed.

Similar content being viewed by others

References

Abe F, Kern T-U, Viswanathan R (2008) Creep-resistant steels. Woodhead Publishing in Materials, Sawston

Kaybyshev R, Skorobogatykh V, Shchenkova I (2010) New martensitic steels for fossil power plant: creep resistance. Phys Met Metall 109:186–200

Kern T-U, Staubli M, Scarlin B (2002) The European efforts in material development for 650 °C USC power plants-COST522. ISIJ Int 42:1515–1519

Kostka A, Tak K-G, Hellmig RJ, Estrin Y, Eggeler G (2007) On the contribution of carbides and micrograin boundaries on the creep strength of tempered martensite ferritic steels. Acta Mater 55:539–550

Abe F (2016) Progress in creep-resistant steels for high efficiency coal-fired power plants. J Press Vessel Technol 138:040804

Eggeler G, Earthman JC, Nilsvang N, Ilshner B (1989) Microstructural study of creep rupture in a 12% chromium ferritic steel. Acta Metall 37:49–60

Szabo PJ (2004) Microstructural development of creep resistant ferritic steel during creep. Mater Sci Eng A 387–389:710–715

Wang Y (2009) Development of new 11%Cr heat resistant ferritic steels with enhanced creep resistance for steam power plants with operating steam temperature up to 650 °C. Mater Sci Eng A 510–511:180–184

Koukal J, Sondel M, Schwarz D, Foldyna V (2011) Development and microstructure of advanced creep resistant ferritic steels. J Microstruct Mater Prop 6:122–131

Panait C, Bendick W, Fuchsmann A, Gourgues-Lorenzon A-F, Besson J (2010) Study of the microstructure of the Grade 91 steel after more than 100 000 h of creep exposure at 600 °C. J Press Vessel Pip 87:326–335

Fedoseeva A, Dudova N, Glatzel U, Kaibyshev R (2016) Effect of W on tempering behaviour of a 3%Co modified P92 steel. J Mater Sci 51:9424–9439. https://doi.org/10.1007/s10853-016-0188-x

Fedoseeva A, Dudova N, Kaibyshev R (2016) Creep strength breakdown and microstructure evolution in a 3%Co modified P92 steel. Mater Sci Eng A 654:1–12

Fedoseeva A, Dudova N, Kaibyshev R (2016) Creep behavior and microstructure of a 9Cr–3Co–3W martensitic steel. J Mater Sci 52:2974–2988. https://doi.org/10.1007/s10853-016-0595-z

Fedoseeva A, Dudova N, Kaibyshev R (2016) Effect of tungsten on a dispersion of M(C, N) carbonitrides in 9% Cr steels under creep conditions. Trans Indian Inst Met 69:211–215

Hall EO (1951) The deformation and ageing of mild steel: III discussion of results. Proc R Soc 64:747–753

Petch NJ (1953) The cleavage strength of polycrystals. J Iron Steel Inst 174:25–28

Kato M (2014) Hall–Petch relationship and dislocation model for deformation of ultrafine-grained and nanocrystalline metals. Mater Trans 55:19–24

Langford G, Cohen M (1969) Strain hardening of iron by severe plastic deformation. ASM-Trans 62:623–638

Smith DW, Hehemann RF (1971) The influence of structural parameters on the yield strength of tempered martensite and lower bainite. J Iron Steel Inst 209:476–485

Naylor JP (1979) The influence of the lath morphology on the yield stress and transition temperature of martensitic-bainitic steels. Met Trans A 10A:861–873

Daigne J, Guttman M, Naylor JP (1982) The influence of lath boundaries and carbide distribution on yield strength of 0.4% C tempered martensitic steels. Mater Sci Eng 56:1–10

Edmonds DV, Cochrane RC (1990) Structure-property relationships in bainitic steels. Met Trans A 21A:1527–1540

Maropoulos S, Paul JDH, Ridley N (1993) Microstructure-property relationship in tempered low alloy Cr–Mo–3.5Ni–V steel. Mater Sci Technol 9:1014–1019

Young CH, Bhadeshia HKDH (1994) Strength of mixtures of bainite and martensite. Mater Sci Technol 10:209–214

Garcia-Mateo C, Caballero FG, Bhadeshia HKDH (2003) Development of hard bainite. ISIJ Int 43:1238–1243

Li Q (2003) Modeling the microstructure-mechanical property relationship for a 12%Cr–2W–V–Mo–Ni power plant steel. Mater Sci Eng A 361:385–391

Abe F (2008) Precipitate design for creep strengthening of a 9%Cr tempered martensitic steel for ultra-supercritical power plants. Sci Technol Adv Mater 9:013002 (15 pp)

Shang Z, Ding J, Fan C, Song M, Li J, Li Q, Xue S, Hurtwig KT, Zhang X (2019) Tailoring the strength and ductility of T91 steel by partial tempering treatment. Acta Mater 169:209–224

Maruyama K, Sawada K, Koike J (2001) Strengthening mechanisms of creep resistant tempered martensitic steel. ISIJ Int 41:641–653

He SH, He BB, Zhu KY, Huang MX (2017) On the correlation among dislocation density, lath thickness and yield stress of bainite. Acta Mater 135:382–389

Taylor GI (1934) The mechanism of plastic deformation of crystals. Part I.—theoretical. Proc R Soc A 145:362–388

Humphreys FJ, Hatherly M (2004) Recrystallization and related annealing phenomena, 2nd edn. Elsevier, Amsterdam

Lacy CE, Gensamer M (1944) The tensile properties of alloyed ferrites. Trans ASM 9:118–125

Mouawad B, Boulnat X, Fabreque D, Perez M, de Carlan Y (2015) Tailoring the microstructure and the mechanical properties of ultra-fine grained high strength ferritic steels by powder metallurgy. J Nucl Mater 465:54–62

Kocks UF, Argon Ali S, Ashby MF (1975) Thermodynamics and kinetics of slip. Prog Mater Sci 19:156–291

Irvine J, Baker TN (1984) The influence of rolling variables on the strengthening mechanisms operating in niobium steels. Mater Sci Eng 64:123–134

Kassner ME, Miller AK, Sherby OD (1982) The separate roles of subgrains and forest dislocations in the isotropic hardening of type 304 stainless steel. Met Trans A 13A:1977–1986

Fedoseeva A, Tkachev E, Dudko V, Dudova N, Kaibyshev R (2017) Effect of alloying on interfacial energy of precipitation/matrix in high-chromium martensitic steels. J Mater Sci 52:4197–4209. https://doi.org/10.1007/s10853-016-0654-5

Dudko VA, Fedoseeva AE, Belyakov AN, Kaibyshev RO (2015) Influence of the carbon content on the phase composition and mechanical properties of P92-type steel. Phys Met Metall 116:1165–1174

Fedoseeva AE, Kozlov PA, Dudko VA, Skorobogatykh VN, Shchenkova IA, Kaibyshev RO (2015) Microstructural changes in steel 10Kh9V2MFBR during creep for 40000 hours at 600 °C. Phys Met Metall 116:1047–1056

Kipelova AY, Belyakov AN, Skorobogatykh VN, Shchenkova IA, Kaibyshev RO (2010) Tempering-induced structural changes in steel 10Kh9K3V1M1FBR and their effect on the mechanical properties. Met Sci Heat Treat 52(3–4):100–110

Fedorova I, Kostka A, Tkachev E, Belyakov A, Kaibyshev R (2016) Tempering behavior of a low nitrogen boron-added 9%Cr steel. Mater Sci Eng, A 662:443–455

Dudova N, Kaibyshev R (2011) On the precipitation sequence in a 10%cr steel under tempering. ISIJ Int 51:826–831

Nabarro FRN (1947) Dislocations in a simple cubic lattice. Proc Phys Soc 59:256–272

Speich GR, Swann PRJ (1965) Yield strength and transformation substructure of quenched iron–nickel alloys. Iron Steel Inst 203:480–485

Kipelova AY, Belyakov AN, Skorobogatykh VN, Shchenkova IA, Kaibyshev RO (2010) Structural changes in steel 10Kh9K3V1M1FBR due to creep. Met Sci Heat Treat 52(3–4):118–127

Susila P, Sturm D, Heilmaier M, Murty BS, Subramanya Sarma V (2011) Effect of yttria particle size on the microstructure and compression creep properties of nanostructured oxide dispersion strengthened ferritic (Fe–12Cr–2W–0.5Y2O3) alloy. Mat Sci Eng A 528:4579–4584

Wang Ch, Wang M, Shi J, Hui W, Dong H (2008) Effect of microstructural refinement on the toughness of low carbon martensitic steel. Scr Mater 58:492–495

Barrett R, O’Donoghue P, Leen S (2018) A physically-based high temperature yield strength model for 9Cr steels. Mater Sci Eng A 730:410–424

Zhang X, Godfrey A, Huang X, Hansen N, Liu Q (2011) Microstructure and strengthening mechanisms in cold-drawn pearlitic steel wire. Acta Mater 59:3422–3430

Xiao B, Xu L, Tang Z, Zhao L, Jing H, Han Y, Li H (2019) A physical-based yield strength model for the microstructural degradation of G115 steel during long-term creep. Mater Sci Eng A 747:161–176

Mitsuhara M, Yamasaki S, Miake M, Nakashima H, Nishida M, Kusumoto J, Kanaya A (2016) Creep strengthening by lath boundaries in 9Cr ferritic heat-resistant steel. Phil Mag Lett 96:76–83

Kaibyshev R, Mishnev R, Tkachev E, Dudova N (2016) Effect of Ni and Mn on the creep behaviour of 9–10%Cr steels with low N and high B. Trans Indian Inst Met 69:203–210

Acknowledgements

The study was financially supported by Ministry for Scientific Research and Higher Education in Russian Federation, President Grant for PhD—young scientists (Grant No. 075-15-2019-1165). The authors are grateful to the staff of the Joint Research Center, «Technology and Materials» , Belgorod State University, for their assistance with instrumental analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nikitin, I., Fedoseeva, A. & Kaibyshev, R. Strengthening mechanisms of creep-resistant 12%Cr–3%Co steel with low N and high B contents. J Mater Sci 55, 7530–7545 (2020). https://doi.org/10.1007/s10853-020-04508-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04508-7