Abstract

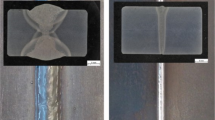

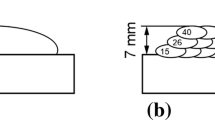

A billet of an AISI 304-type austenitic stainless steel has been built using a wire-feed electron beam additive manufacturing (EBAM) in a layer-by-layer strategy. A microstructure, grain boundary assemble, phase composition and tensile properties of steel billet have been investigated in as-built specimens and after post-built solid-solution treatment. As-built austenitic stainless steel is a highly anisotropic heterophase material with high fraction of interphase boundaries (austenite/ferrite) and intergranular boundaries (austenite/austenite). A macroscopically inhomogeneous (layered) structure with columnar austenitic grain growth has been produced during EBAM processing. The coarse-grained austenitic structure contains δ-ferrite of dendritic morphology in as-built specimens. Ductility and strength properties of the additively manufactured steel show substantial anisotropy, which is strongly correlated with macro- and microstructural peculiarities of the as-built billet. Post-built solid-solution treatment decreases a volume fraction of ferrite in the microstructure, changes the morphology of ferrite phase and, therefore, varies the distribution of interphase boundaries (ferrite/austenite). The effect of post-built solid-solution treatment on tensile properties of the EBAM manufactured steel is discussed taking into account a change in microstructure and phase composition, grain and phase boundary distribution in the specimens.

Similar content being viewed by others

References

Frazier WE (2014) Metal additive manufacturing: a review. J Mater Eng Perform 23:1917–1928

Huang Li N, Zhang S, Qin G et al (2018) Progress in additive manufacturing on new materials. J Mater Sci Technol 35:242–269

Ding D, Pan Z, Cuiuri D et al (2015) Wire-feed additive manufacturing of metal components: technologies, developments and future interests. Int J Adv Manuf Technol 81:465–481

Vayre B, Vignat F, Villeneuve F (2012) Metallic additive manufacturing: state-of-the-art review and prospects. Mech Ind 13:89–96

Utela B, Storti D, Anderson R, Ganter M (2008) A review of process development steps for new material systems in three dimensional printing (3DP). J Manuf Processes 10:96–104

Hu R, Chen X, Yang G, Gong S, Pang S (2018) Metal transfer in wire feeding-based electron beam 3D printing: modes, dynamics, and transition criterion. Int J Heat Mass Transf 126:877–887

Cunningham CR, Flynn JM, Shokrani A, Dhokia V, Newman ST (2018) Invited review article: strategies and processes for high quality wire arc additive manufacturing. Addit Manuf 22:672–686

Lo KH, Shek CH, Lai JKL (2009) Recent developments in stainless steels. Mater Sci Eng R 65:39–104

Suriawanshi J, Prashanth KG, Ramamurty U (2017) Mechanical behavior of selective laser melting 316L stainless steel. Mater Sci Eng A 696:113–121

Casati R, Lemke J, Vedani M (2016) Microstructure and fracture behavior of 316L austenitic stainless steel produced by selective laser melting. J Mater Sci Technol 32:738–744

Yadollahi A, Shamsaei N, Thompson SM, Seely DW (2015) Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel. Mater Sci Eng A 644:171–183

Chen X, Li J, Cheng X, He B, Wang H, Huang Zh (2017) Microstructure and mechanical properties of the austenitic stainless steel 316L fabricated by gas metal arc additive manufacturing. Mater Sci Eng A 703:567–677

Tarasov SYu, Filippov AV, Shamarin NN et al (2019) Microstructural evolution and chemical corrosion of electron beam wire-feed additively manufactured AISI 304 stainless steel. J Alloys Compd 803:364–370

Wang L, Felicelli SD, Coleman J, Johnson R, Taminger KMB, Lett RL (2011) Microstructure and mechanical properties of electron beam deposits of AISI 316L stainless steel. In: Proceedings of the ASME 211 international mechanical engineering congress and exposition. https://doi.org/10.1115/imece2011-62445

Wang Zh, Palmer TA, Beese AM (2016) Effect of processing parameters on microstructure and tensile properties of austenitic stainless steel 304L made by directed energy deposition additive manufacturing. Acta Mater 110:226–235

Skiba T, Baufeld B, van der Bieast O (2009) Microstructure and mechanical properties of stainless steel component manufactured by shaped metal deposition. ISIJ Int 49:1588–1591

Chen X, Li J, Cheng X, Wang H, Huang Zh (2018) Effect of heat treatment on microstructure, mechanical and corrosion properties of austenitic stainless steel 316L using arc additive manufacturing. Mater Sci Eng A 715:307–314

Elmer W, Allen SM, Eagar TW (1989) Microstructural development during solidification of stainless steel alloys. Metall Trans A 20:2117–2131

Inoue H, Koseki T, Ohkita S, Fuji M (2000) Formation mechanism of vermicular and lacy ferrite in austenitic stainless steel weld metals. Sci Technol Weld Join 5:385–396

Brooks JA, Yang NCY, Krafcik JS (2001) Clarification on development of skeletal and lathy ferrite morphologies in stainless steel welds. Sci Technol Weld Join 6:412–414

Suuatala N, Takalo T, Moisio T (1979) Relationship between solidification and microstructure in austenitic and austenitic-ferritic stainless steel welds. Metall Trans A 10:512–514

Saluja R, Moeed KM (2015) Formation, quantification and significance of delta ferrite for 300 series stainless steel weldments. Int J Eng Technol Manage Appl Sci 3:23–36

Suresh G, Nandakumar T, Viswanath A (2018) Effect of low-temperature sensitization on the corrosion behavior of AISI type 304L SS weld metal in simulated groundwater. J Mater Eng Perform 27:2484–2491

Bansod AV, Patil AP, Moon AP, Shukla S (2017) Microstructural and electrochemical evaluation of fusion welded low nickel and 304 ASS at different heat input. J Mater Eng Perform 26:5847–5863

Wang C, Tan X, Liu E, Tor SB (2018) Process parameter optimization and mechanical properties for additively manufactured stainless steel 316L parts by selective electron beam melting. Mater Des 147:157–166

Alvarez-Armas I, Degallaix-Moreuil S (2009) Duplex stainless steels. Wiley, Hoboken

Straumal BB, Kucheev YO, Efron LI et al (2012) Complete and incomplete wetting of ferrite grain boundaries by austenite in the low-alloyed ferritic steel. J Mater Eng Perform 21:667–670

Straumal BB, Dobatkin SV, Rodin AO et al (2011) Structure and properties of nanograined Fe–C alloys after severe plastic deformation. Adv Eng Mater 13:463–469

Acknowledgements

This work was performed within the frame of the Fundamental Research Program of the State Academies of Sciences for 2013--2020, line of research III.23.2.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Astafurova, E.G., Panchenko, M.Y., Moskvina, V.A. et al. Microstructure and grain growth inhomogeneity in austenitic steel produced by wire-feed electron beam melting: the effect of post-building solid-solution treatment. J Mater Sci 55, 9211–9224 (2020). https://doi.org/10.1007/s10853-020-04424-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04424-w