Abstract

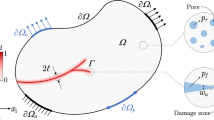

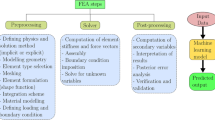

Brittle porous materials are used in many applications, such as molten metal filter, battery, fuel cell, catalyst, membrane, and insulator. The porous structure of these materials causes variations in their fracture strength that is known as the mechanical reliability problem. Despite the importance of brittle porous materials, the origin of the strength variations is still unclear. The current study presents a machine learning approach to characterize the stochastic fracture of porous ceramics and glasses. A combined finite element modeling and fracture mechanics approach was used to generate a unique empirical data set consisting of normalized stress intensity factors (nSIFs, KI/σ∞ = Y\( \sqrt {\pi a} \)) that define fracture strength of brittle systems under uniaxial tensile loading and biaxial tensile loading. These empirical data sets were used to generate prediction functions and validate their accuracy. Monte Carlo simulations with two machine learning algorithms, random forests (RF) and artificial neural networks (ANN), were used to simultaneously determine the optimum percentages for the training and test data set split and the prediction function validation. The constraint was taken to be the mean absolute percentage error (MAPE) during the process. In the implementation step, new porous media with uniformly distributed pores were created and the prediction functions were used to obtain nSIFs and characterize the media. As a novelty of this approach, which ensures the predictive characterization of the generated media, a geometric matching method by means of the Euclidean bipartite matching between the empirical and the generated media was presented and the nSIFs were compared by means of MAPE. As a result of the study, MAPE ranges are 3.4–17.93% (uniaxial load) and 2.83–19.42% (biaxial load) for RF, 3.79–17.43% and 3.39–21.43 for ANN at the validation step; 3.54–18.20% (uniaxial load) and 3.06–21.60% (biaxial load) for RF, 3.57–18.26% and 3.43–21.76% for ANN at the implementation step. The proposed approach can be thus used as a predictive characterization tool, especially for the analysis and Weibull statistics of porous media subjected to brittle failure.

Similar content being viewed by others

References

Roohani-Esfahani SI, Newman P, Zreiqat H (2016) Design and fabrication of 3d printed scaffolds with a mechanical strength comparable to cortical bone to repair large bone defects. Sci Rep. https://doi.org/10.1038/srep19468

Meyers MA, Chen PY (2014) Biological materials science: Biological materials, bioinspired materials, and biomaterials. Cambridge University Press, Cambridge

Ebner M, Chung DW, García RE, Wood V (2014) Tortuosity anisotropy in lithium-ion battery electrodes. Adv Energy Mater. https://doi.org/10.1002/aenm.201301278

Xu H, Chen B, Tan P et al (2018) Modeling of all porous solid oxide fuel cells. Appl Energy. https://doi.org/10.1016/j.apenergy.2018.03.037

Brodnik NR, Faber KT (2019) Out-of-plane mechanical characterization of acicular mullite and aluminum titanate diesel particulate filters. Int J Appl Ceram Technol. https://doi.org/10.1111/ijac.13161

Han L, Li F, Deng X et al (2017) Foam-gelcasting preparation, microstructure and thermal insulation performance of porous diatomite ceramics with hierarchical pore structures. J Eur Ceram Soc. https://doi.org/10.1016/j.jeurceramsoc.2017.02.032

Keleş Ö, Edwin García R, Bowman KJ (2014) Failure variability in porous glasses: stress interactions, crack orientation, and crack size distributions. J Am Ceram Soc. https://doi.org/10.1111/jace.13214

Keleş Ö, García RE, Bowman KJ (2013) Stochastic failure of isotropic, brittle materials with uniform porosity. Acta Mater. https://doi.org/10.1016/j.actamat.2013.01.024

Keleş Ö, García RE, Bowman KJ (2014) Pore-crack orientation effects on fracture behavior of brittle porous materials. Int J Fract. https://doi.org/10.1007/s10704-014-9934-8

Rice RW (2017) Porosity of ceramics. CRC Press, Boca Raton

Omer N, Yosibash Z (2019) Extracting stochastic stress intensity factors using generalized polynomial chaos. Eng Fract Mech. https://doi.org/10.1016/j.engfracmech.2018.12.001

Cui Z, Huang Y, Liu H (2017) Predicting the mechanical properties of brittle porous materials with various porosity and pore sizes. J Mech Behav Biomed Mater. https://doi.org/10.1016/j.jmbbm.2017.02.014

Biswas D (1981) Crack-void interaction in polycrystalline alumina. J Mater Sci 16:2434–2438. https://doi.org/10.1007/BF01113579

Evans A, Biswas D, Fulrath R (1979) Some effects of cavities on the fracture of ceramics: I, cylindrical cavities. J Am Ceram Soc 62:95–100. https://doi.org/10.1111/j.1151-2916.1979.tb18814.x

Evans A, Biswas D, Fulrath R (1979) Some effects of cavities on the fracture of ceramics: II spherical cavities. J Am Ceram Soc 62:101–106. https://doi.org/10.1111/j.1151-2916.1979.tb18815.x

Keleş Ö, Anderson EH, Huynh J et al (2018) Stochastic fracture of additively manufactured porous composites. Sci Rep. https://doi.org/10.1038/s41598-018-33863-4

Xu Y, Cheng L, Zhang L et al (2001) Optimization of sample number for Weibull function of brittle materials strength. Ceram Int. https://doi.org/10.1016/S0272-8842(00)00056-0

Gu GX, Chen CT, Richmond DJ, Buehler MJ (2018) Bioinspired hierarchical composite design using machine learning: simulation, additive manufacturing, and experiment. Mater Horizons. https://doi.org/10.1039/c8mh00653a

Özkan M, Borghei M, Karakoç A et al (2018) Films based on crosslinked TEMPO-oxidized cellulose and predictive analysis via machine learning. Sci Rep. https://doi.org/10.1038/s41598-018-23114-x

Özkan M, Karakoç A, Borghei M et al (2019) Machine Learning assisted design of tailor-made nanocellulose films: a combination of experimental and computational studies. Polym Compos. https://doi.org/10.1002/pc.25262

Swaminathan S, Shah T, Sirkeci-Mergen B, Keles O (2018) Machine learning models for predicting fracture strength of porous ceramics and glasses. In: Proceedings of the 2018 international conference on data science

Ozaki S, Aoki Y, Osada T et al (2018) Finite element analysis of fracture statistics of ceramics: effects of grain size and pore size distributions. J Am Ceram Soc. https://doi.org/10.1111/jace.15468

Zimmermann A, Rödel J (2004) Fracture statistics based on pore/grain-size interaction. J Am Ceram Soc. https://doi.org/10.1111/j.1151-2916.1999.tb02080.x

Moore BA, Rougier E, O’Malley D et al (2018) Predictive modeling of dynamic fracture growth in brittle materials with machine learning. Comput Mater Sci. https://doi.org/10.1016/j.commatsci.2018.01.056

Mangal A, Holm EA (2018) Applied machine learning to predict stress hotspots I: face centered cubic materials. Int J Plast. https://doi.org/10.1016/j.ijplas.2018.07.013

Reid ACE, Langer SA, Lua RC et al (2008) Image-based finite element mesh construction for material microstructures. Comput Mater Sci. https://doi.org/10.1016/j.commatsci.2008.02.016

Evans AG, Langdon TG (1976) Structural ceramics. Prog Mater Sci 21:171–425. https://doi.org/10.1016/0079-6425(76)90006-2

RC shah stress intensity factors for through and part-through cracks originating at fastener holes. ASTM International, West Conshohocken, PA

Breiman L (2001) Random forests. Mach Learn 45:5–32

Matin SS, Farahzadi L, Makaremi S et al (2018) Variable selection and prediction of uniaxial compressive strength and modulus of elasticity by random forest. Appl Soft Comput J. https://doi.org/10.1016/j.asoc.2017.06.030

Wolfram Research Inc (2018) Mathematica

Bose NK, Liang P (1996) Neural network fundamentals with graphs, algorithms, and applications. McGraw-Hill Ser Electr Comput Eng

Tiryaki S, Özşahin Ş, Yildirim I (2014) Comparison of artificial neural network and multiple linear regression models to predict optimum bonding strength of heat treated woods. Int J Adhes Adhes. https://doi.org/10.1016/j.ijadhadh.2014.07.005

Mathworks Classify Patterns with a Shallow Neural Network. https://www.mathworks.com/help/deeplearning/gs/classify-patterns-with-a-neural-network.html. Accessed 23 Sep 2019

Keleş Ö, García RE, Bowman KJ (2013) Deviations from Weibull statistics in brittle porous materials. Acta Mater. https://doi.org/10.1016/j.actamat.2013.08.025

Karakoc A, Taciroglu E (2017) Optimal automated path planning for infinitesimal and real-sized particle assemblies. AIMS Mater Sci. https://doi.org/10.3934/matersci.2017.4.847

Skala J, Kolingerova I, Hyka J (2009) A Monte Carlo solution to the minimal Euclidean matching. In: Handlovicova A, Mikula K, Frolkovic P, Sevcovic D (eds) ALGORITMY. Bratislava, Slovakia

Chao L-Y, Shetty DK (1991) Reliability analysis of structural ceramics subjected to biaxial flexure. J Am Ceram Soc. https://doi.org/10.1111/j.1151-2916.1991.tb06884.x

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Karakoç, A., Keleş, Ö. A predictive failure framework for brittle porous materials via machine learning and geometric matching methods. J Mater Sci 55, 4734–4747 (2020). https://doi.org/10.1007/s10853-019-04339-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04339-1