Abstract

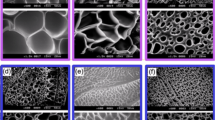

A novel route for obtaining ordered microporous polylactide films has been explored using zinc oxide and a Schiff base. The SEM images reveal that the water vapor condensation near the surface of a polylactide solution containing a synthesized Schiff base and zinc oxide results in well-dispersed water droplets, which upon subsequent evaporation can assist breath figure patterning. The generation of ordered micropores at the film surface is attributed to the interaction between the surface +ve charge of well-dispersed zinc oxide particles and the δ-bearing water droplets from moisture. The potential for biocompatible applications has been revealed for the membranes by the cell viability assay against mice fibroblast (L929) cells and the hemocompatibility assay. The findings suggest an efficient route for the development of porous biodegradable polylactide membranes for various applications, typically for wound dressing.

Similar content being viewed by others

References

Barba F, Callejas P (2006) Calcium phosphate silicate ceramics for heavy metal immobilization and antibacterial activity in waste water. J Mater Sci 41:5227–5230. https://doi.org/10.1007/s10853-006-0440-x

Xu T (2005) Ion exchange membranes: state of their development and perspective. J Membr Sci 263:1–29

Bini TB, Gao S, Wang S, Ramakrishna S (2006) Poly(l-lactide-co-glycolide) biodegradable microfibers and electrospun nanofibers for nerve tissue engineering: an in vitro study. J Mater Sci 41:6453–6459. https://doi.org/10.1007/s10853-006-0714-3

Tran PA, Biswas DP, O’Connor AJ (2014) Simple one-step method to produce titanium dioxide–polycaprolactone composite films with increased hydrophilicity, enhanced cellular interaction and improved degradation for skin tissue engineering. J Mater Sci 49:6373–6382. https://doi.org/10.1007/s10853-014-8364-3

Liu N, Pan J, Miao YE, Liu T, Xu F, Sun H (2014) Electrospinning of poly (ε-caprolactone-co-lactide)/Pluronic blended scaffolds for skin tissue engineering. J Mater Sci 49:7253–7262. https://doi.org/10.1007/s10853-014-8432-8

Hou QP, Grijpma DW, Feijen J (2003) Porous polymeric structures for tissue engineering prepared by a coagulation, compression moulding and salt leaching technique. Biomaterials 24:1937–1947

Harris LD, Kim BS, Mooney DJ (1998) Open pore biodegradable matrices formed with gas foaming. J Biomed Mater Res 42:396–402

Lo H, Ponticiello MS, Leong KW (1995) Fabrication of controlled release biodegradable foams by phase separation. Tissue Eng 1:15–28

Borenstein JT, Terai H, King KR, Weinberg EJ, Kaazempur-Mofrad MR, Vacanti JP (2002) Microfabrication technology for vascularized tissue engineering. Biomed Microdevices 4:167–175

Park JS, Lee SH, Han TH, Kim SO (2007) Hierarchically ordered polymer films by templated organization of aqueous droplets. Adv Funct Mater 17:2315–2320

Wang B, He T, Liu L, Gao C (2005) Poly(ethylene glycol) micro-patterns as environmentally sensitive template for selective or non-selective adsorption. Colloids Surf B 46:169–174

Guessasma S, Oyen M (2016) Virtual design of electrospun-like gelatin scaffolds: the effect of three-dimensional fibre orientation on elasticity behavior. Soft Matter 12:602–613

Guessasma S, Zhang W, Zhu J, Belhabib S, Nouri H (2015) Challenges of additive manufacturing technologies from an optimisation perspective. Int J Simul Multisci Des Optim 6:A9

Mikos AG, Thorsen AJ, Czerwonka LA, Bao Y, Langer R, Winslow DN, Vacanti JP (1994) Preparation and characterization of poly(l-lactic acid) foams. Polymer 35:1068–1077

Mikos AG, Sarakinos G, Leite SM, Vacant JP, Langer R (1993) Laminated three-dimensional biodegradable foams for use in tissue engineering. Biomaterials 14:323–330

Mooney DJ, Baldwin DF, Suh NP, Vacanti JP, Langer R (1996) Novel approach to fabricate porous sponges of poly(d, l-lactic-co-glycolic acid) without the use of organic solvents. Biomaterials 17:1417–1422

Yoon JJ, Park TG (2001) Degradation behaviors of biodegradable macroporous scaffolds prepared by gas foaming of effervescent salts. J Biomed Mater Res 55:401–408

Schugens C, Maquet V, Grandfils C, Jerome R, Teyssie P (1996) Polylactide macroporous biodegradable implants for cell transplantation. II. Preparation of polylactide foams by liquid–liquid phase separation. J Biomed Mater Res 30:449–461

Schugens C, Maquet V, Grandfils C (1996) Biodegradable and macroporous polylactide implants for cell transplantation: 1. Preparation of macroporous polylactide supports by solid–liquid phase separation. Polymer 37:1027–1038

Nam YS, Park TG (1999) Porous biodegradable polymeric scaffolds prepared by thermally induced phase separation. J Biomed Mater Res 47:8–17

Valente TA, Silva DM, Gomes PS, Fernandes MH, Santos JD, Sencadas V (2016) Effect of sterilization methods on electrospun poly(lactic acid) (PLA) fiber alignment for biomedical applications. ACS Appl Mater Interfaces 8:3241–3249

Bognitzki M, Czado W, Frese T, Schaper A, Hellwig M, Steinhart M, Greiner A, Wendorff JH (2001) Nanostructured fibers via electrospinning. Adv Mater 13:70–72

Kim SS, Utsunomiya H, Koski JA, Wu BM, Cima MJ, Sohn J et al (1998) Survival and function of hepatocytes on a novel three-dimensional synthetic biodegradable polymer scaffold with an intrinsic network of channels. Ann Surg 228:8–13

Zeltinger J, Sherwood JK, Graham DA, Mueller R, Griffith LG (2001) Effect of pore size and void fraction on cellular adhesion, proliferation, and matrix deposition. Tissue Eng 7:557–572

Hiroshi S, Ito E, Tanaka M, Yamamoto S, Shimomura M (2006) Effect of honeycomb film on protein adsorption, cell adhesion and proliferation. Colloids Surf A 284–285:548–551

Kurono N, Shimada R, Ishihara T, Shimomura M (2002) Fabrication and optical property of self-organized honeycomb-patterned films. Mol Cryst Liq Cryst 377:285–288

Ghannam L, Garay H, François J, Billon L (2007) New polymeric materials with interferential optical properties. Macromol Chem Phys 208:1469–1479

Li H, Jia Y, Du M, Fei J, Zhao J, Cui Y, Li J (2013) Self-organization of honeycomb-like porous TiO2 films by means of the breath-figure method for surface modification of titanium implants. Chem Eur J 19:5306–5313

Ma Y, Zhou M, Walter S, Liang J, Chen Z, Wu L (2014) Selective adhesion and controlled activity of yeast cells on honeycomb-patterned polymer films via a microemulsion approach. Chem Commun 50:15882–15885

Kulkarni RK, Pani KC, Neuman C, Leonard F (1966) Polylactic acid for surgical implants. Arch Surg 93:839–843

Cipitria A, Skelton A, Dargaville TR, Dalton PD, Hutmacher DW (2011) Design, fabrication and characterization of PCL electrospun scaffolds—a review. J Mater Chem 21:9419–9453

Ellis MJ, Chaudhuri JB (2007) Poly(lactic-co-glycolic acid) hollow fibre membranes for use as a tissue engineering scaffold. Biotechnol Bioeng 96:177–187

Nguyen T, Ghosh C, Hwang S-G, Tran L, Park JS (2013) Characteristics of curcumin-loaded poly (lactic acid) nanofibers for wound healing. J Mater Sci 48:7125–7133. https://doi.org/10.1007/s10853-013-7527-y

Dhar P, Gaur SS, Soundararajan N, Gupta A, Bhasney S, Milli M, Kumar A, Katiyar V (2017) Reactive extrusion of polylactic acid/cellulose nanocrystal films for food packaging applications: influence of filler type on thermomechanical, rheological, and barrier properties. Ind Eng Chem Res 56:4718–4735

Wang G, Wang L, Mark L, Shaayegan V, Wang G, Li H, Zhao G, Park CB (2018) Ultralow-threshold and lightweight biodegradable porous PLA/ MWCNT with segregated conductive networks for high performance thermal insulation and electromagnetic interference shielding applications. ACS Appl Mater Interfaces 10:1195–1203

Dutta K, Deka R, Das DK (2013) A new on-fluorescent probe for manganese (II) ion. J Fluoresc 23:1173–1178

Lo Rea G, Lopresti F, Petrucci G, Scaffaroa R (2015) A facile method to determine pore size distribution in porous scaffold by using image processing. Micron 76:37–45

Lainioti GC, Bounos G, Voyiatzis GA, Kallitsis JK (2016) Enhanced water vapor transmission through porous membranes based on melt blending of polystyrene sulfonate with polyethylene copolymers and their CNT nanocomposites. Polymers 8:190

Pranoto Y, Salokhe V, Rakshit KS (2005) Physical and antibacterial properties of alginate based edible film incorporated with garlic oil. Food Res Int 38:267–272

Li X, Yang Z, Yang K, Zhou Y, Chen X, Zhang Y, Wang F, Liu Y, Ren L (2009) Self-assembled polymeric micellar nanoparticles as nanocarriers for poorly soluble anticancer drug ethaselen. Nanoscale Res Lett 4:1502–1511

Thankam FG, Muthu J (2014) Influence of physical and mechanical properties of amphiphilic biosynthetic hydrogels on long-term cell viability. J Mech Behav Biomed Mater 35:111–122

Yousif E, Al-Amiery AA, Kadihum A, Kadhum H, Abu Bakar M (2015) Photostabilizing efficiency of PVC in the presence of Schiff bases as photostabilizers. Molecules 20:19886–19899

Srinivasarao M, Collings D, Philips A, Patel S (2001) Three-dimensionally ordered array of air bubbles in a polymer film. Science 292:79–83

Zhao BH, Zhang J, Wang XD, Li CX (2006) Water-assisted fabrication of honeycomb structure porous film from poly (l-lactide). J Mater Chem 16:509–513

Horino M, Nishizawa M, Kasei M (1999) Dispersion of ultraviolet intercepting moisture-retaining agent and cosmetic article incorporating the dispersion.US patent 5,968,529. Oct. 19, 1999

Watanabe J, Eriguchi T, Ishihara K (2002) Cell adhesion and morphology in porous scaffold based on enantiomeric poly(lactic acid) graft-type phospholipid polymers. Biomacromolecules 3:1375–1383

Kister G, Cassanas G, Vert M (1998) Effects of morphology, conformation and configuration on the IR and Raman spectra of various poly(lactic acid)s. Polymer 39:267–273

Kister G, Cassanas G, Vert M, Pauvert B, Terol A (1995) Vibrational analysis of poly(l-lactic acid). J Raman Spectrosc 26:307–311

Auras R, Harte B, Selke S (2004) An overview of polylactides as packaging materials. Macromol Biosci 4:835–864

Salah M, Azizi S, Boukhachem A, Khaldi C, Amlouk M, Lamloumi J (2017) Structural, morphological, optical and photodetector properties of sprayed Li-doped ZnO thin films. J Mater Sci 52:10439–10454. https://doi.org/10.1007/s10853-017-1218-z

Restrepo I, Benito N, Medinam C, Mangalaraja RV, Flores P, Rodriguez-Llamazares S (2017) Development and characterization of polyvinyl alcohol stabilized polylactic acid/ZnO nanocomposites. Mater Res Express 4:105019

Arfat YA, Benjakul S, Prodpran T, Sumpavapol P, Songtipya P (2014) Properties and antimicrobial activity of fish protein isolate/fish skin gelatin film containing basil leaf essential oil and zinc oxide nanoparticles. Food Hydrocoll 41:265–273

Hockberger PE (2002) A history of ultraviolet photobiology for humans, animals and microorganisms. Photochem Photobiol 76:561–579

Tsuji H (2005) Poly(lactide) stereocomplexes: formation, structure, properties, degradation, and applications. Macromol Biosci 5:569–597

Doumbia AS, Vezin H, Ferreira M, Campagne C, Devaux E (2015) Studies of polylactide/zinc oxide nanocomposites: influence of surface treatment on zinc oxide antibacterial activities in textile nanocomposite. J Appl Polym Sci 132:41776–41785

Murariu M, Doumbia A, Bonnaud L, Dechief AL, Paint Y, Ferreira M, Campagne C, Devaux E, Dubois P (2011) High-performance polylactide/ZnO nanocomposites designed for films and fibers with special end-use properties. Biomacromolecules 12:1762–1771

Xu R, Xia H, He W, Li Z, Zhao J, Liu B, Wang Y, Lei Q, Kong Y, Bai Y, Yao Z, Yan R, Li H, Zhan R, Yang S, Luo G, Wu J (2016) Controlled water vapor transmission rate promotes wound-healing via wound re-epithelialization and contraction enhancement. Sci Rep 6:24596

Paszek E, Czyz J, Woźnicka O, Jakubiak D, Wojnarowicz J, Łojkowski W, Stępień E (2012) Zinc oxide nanoparticles impair the integrity of human umbilical vein endothelial cell monolayer in vitro. J Biomed Nanotechnol 8:957–967

Xu X, Chen D, Yi Z, Jiang M, Wang L, Zhou Z, Fan X, Wang Y, Hui D (2013) Antimicrobial mechanism based on H2O2 generation at oxygen vacancies in ZnO crystals. Langmuir 29:5573–5580

Roy S, Savita K, Kishore N, Thomas KH, Chandan KS (2006) Dermal wound healing is subject to redox control. Mol Ther 13:211–220

Acknowledgements

R.R. acknowledges MHRD, India, for a research fellowship. The authors thankfully acknowledge the help by Dr. A. Sujith and Mr. Manaf O., Materials Research Laboratory, NITC.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Rarima, R., Asaletha, R. & Unnikrishnan, G. Schiff base-assisted surface patterning of polylactide–zinc oxide films: generation, characterization and biocompatibility evaluation. J Mater Sci 53, 9943–9957 (2018). https://doi.org/10.1007/s10853-018-2338-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2338-9