Abstract

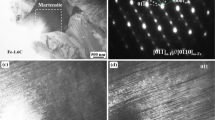

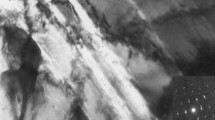

Martensite has a body-centered tetragonal (bct) structure in high carbon steels. However, body-centered cubic (bcc) {112} 〈111〉-type twins instead of bct twins always be observed as the substructure of martensite in high carbon steels. In this paper, martensitic substructure in a quenched high carbon Fe-1.4C (wt%) alloy has been investigated in detail using selected area electron diffraction (SAED) technique in a conventional transmission electron microscopy. The reciprocal lattice of martensite has been built based on the experimental SAED patterns. Two sets of diffraction spots (one face-centered cubic lattice and one hexagonal lattice) in the built reciprocal lattice suggest that two crystalline phases with bcc (or α-Fe) and hexagonal (ω-Fe) structure actually coexist in the twinned martensite. The two-phase diffraction spot patterns from the reciprocal lattice can match perfectly with the experimental results. The fact that the {0001}ω diffraction spot at the 1/3{222}α position and the {0002}ω at 2/3{222}α can support the ω-Fe existence in the twinned martensite.

Similar content being viewed by others

References

Fink WL, Campbell ED (1926) Influence of heat treatment and carbon content on the structure of pure iron–carbon alloys. Trans Am Soc Steel Treat 9:717–751

Kurdjumov G, Kaminsky E (1928) X-ray studies of the structure of quenched carbon steels. Nature 122:476

Honda K, Nishiyama Z (1932) Nature of the tetragonal and cubic martensites. Trans Am Soc Met 20:464–470

Roberts CS (1953) Effect of carbon on the volume fractions and lattice parameters of retained austenite and martensite. Trans AIME 197:203–204

Bain EC, Paxton HW (1966) Alloying elements in steel, 2nd edn. ASM, Metals Park, pp 123–162

Sherby OD, Wadsworth J, Lesuer DR, Syn CK (2007) The c/a ratio in quenched Fe–C and Fe–N steels—a heuristic story. Mater Sci Forum 539–543:215–222

Samuel FH (1987) Further investigations on martensites in Fe-0.5 wt% C and Fe-0.5 wt% C-24 wt% Ni melt spun ribbons. J Mater Sci 22:3883–3892. doi:10.1007/BF01133336

Umenoto M, Yoshitake E, Tamura I (1983) The morphology of martensite in Fe–C, Fe–Ni–C and Fe–Cr–C alloys. J Mater Sci 18:2893–2904. doi:10.1007/BF00700770

Kelly PM (2012) Phase transformations in steels: diffusionless transformations, high strength steels, modelling and advanced analytical techniques. In: Pereloma E, Edmonds D (eds) Crystallography of martensite transformations in steels. Woodhead Publishing, Cambridge, Ch 1, pp 4–23

Kelly PM, Nutting J (1960) The martensite transformation in carbon steels. Proc R Soc A 259:45–58

Crocker AG (1962) Twinned martensite. Acta Metall 10:113–122

Greninger AB (1935) Twinning in alpha iron. Nature 135:916–917

Lee HY et al (2010) Substructures of martensite in Fe–1C–17Cr stainless steel. Scr Mater 62:670–673

Gates JD, Atrens A, Smith IO (1987) Microstructure of as-quenched 3.5 NiCrMoV rotor steel—part II. Double diffraction. Z Werkstofftech 18:179–185

Zhang P, Chen YL, Xiao WL, Ping DH, Zhao XQ (2016) Twin structure of the lath martensite in low carbon steel. Prog Nat Sci Mater Int 26:169–172

Ping DH, Liu TW, Ohnuma M, Ohmura T, Abe T, Onodera H (2017) Microstructural evolution and carbides in quenched ultralow carbon (Fe–C) alloys. ISIJ Int 57:1233–1240

Ping DH, Geng WT (2013) A popular metastable omega phase in body-centered cubic steels. Mater Chem Phys 139:830–835

Liu TW et al (2015) A new nanoscale metastable iron phase in carbon steels. Sci Rep 5(15331):1–12

Ping DH (2015) Understanding solid–solid (fcc → ω + bcc) transition at atomic scale. Acta Metall Sin (Engl Lett) 28:663–670

Ping DH, Singh A, Guo SQ, Ohmura T, Ohnuma M, Abe T, Onodera H (2018) A simple method for observing ω-Fe electron diffraction spots from {112}α-Fe directions of quenched Fe-C twinned martensite. ISIJ Int. doi:10.2355/isijinternational.ISIJINT-2017-270

Ping DH (2014) Review on ω phase in body-centered cubic metals and alloys. Acta Metall Sin (Engl Lett) 27:1–11

Sass SL (1969) The ω phase in a Zr-25 at.% Ti alloy. Acta Metall 17:813–820

Sikka SK, Vohra YK, Chidambaram R (1982) Omega phase in materials. Prog Mater Sci 27:245–310

Borie B, Sass SL, Anderassen A (1973) The short-range structure of Ti and Zr b.c.c. solid solutions containing the ω phase. I. General diffraction theory and development of computational techniques. Acta Cryst A 29:585–594

Togo A, Tanaka I (2013) Evolution of crystal structures in metallic elements. Phys Rev B 87(184104):1–6

Ikeda Y, Tanaka I (2016) ω Structure in steel: a first-principles study. J Alloys Compd 684:624–627

Ping DH, Man TH, Liu TW, Ohmura T, Tomota Y, Ohnuma M (2017) In-Situ heating TEM study on twinned martensite in quenched Fe-1.4C alloys. CAMP-ISIJ-173 30:253

Acknowledgements

This work was supported by JSPS KAKENHI Grant Number JP15H02304.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Liu, T.W., Ping, D.H., Ohmura, T. et al. Electron diffraction analysis of quenched Fe–C martensite. J Mater Sci 53, 2976–2984 (2018). https://doi.org/10.1007/s10853-017-1731-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1731-0