Abstract

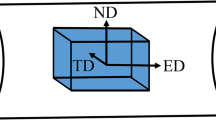

A high-performance extruded Mg96Gd3Zn0.5Ni0.5 alloy containing 14H LPSO phases and two different dynamic recrystallization (DRX) grains was successfully fabricated, which exhibited superior ultimate tensile strength (400 MPa) and outstanding elongation (20%). Meanwhile, the results show that the substitution of 0.5 at.% Zn with Ni element can refine the grain size of as-cast Mg96Gd3Zn1 alloy significantly. While limited 14H LPSO lamellae are formed near the block 14H LPSO phases due to Ni addition during solution treatment, copious 14H LPSO lamellae induced by external force are precipitated in α-Mg matrix after subsequent hot extrusion in the Mg96Gd3Zn0.5Ni0.5 alloy. Furthermore, two different DRX phenomena are successively stimulated with increasing deformation strain. Discontinuous DRX emerges first at the interface of block 14H LPSO phases, and then continuous DRX occurs in the kink bands of 14H LPSO lamellae. The precipitation behaviors of 14H LPSO lamellae and two types of DRX grains contribute to the excellent mechanical properties.

Similar content being viewed by others

References

Lu JW, Yin DD, Ren LB, Quan GF (2016) Tensile and compressive deformation behavior of peak-aged cast Mg–11Y–5Gd–2Zn–0.5Zr (wt%) alloy at elevated temperatures. J Mater Sci 51(23):10464–10477. doi:10.1007/s10853-016-0266-0

Tan XH, Chee WKH, Chan JKW, Kwok RWO, Gupta M (2016) Stretching the engineering strain of high strength LPSO quaternary Mg–Y–Zn–Al alloy via integration of nano-Al2O3. J Mater Sci 51(8):4160–4168. doi:10.1007/s10853-016-9742-9

Rong W, Zhang Y, Wu YJ, Sun M, Chen J, Wang Y, Han JY, Peng LM, Ding HX (2017) Effects of Zr and Mn additions on formation of LPSO structure and dynamic recrystallization behavior of Mg–15Gd–1Zn alloy. J Alloys Compd 692:805–816

Silva CLP, Qliveira AC, Costa CGF, Figueiredo RB, Leite MD, Pereira MM, Lins VFC, Langdon TG (2017) Effect of severe plastic deformation on the biocompatibility and corrosion rate of pure magnesium. J Mater Sci 52(10):5992–6003. doi:10.1007/s10853-017-0835-x

Ali Y, Qiu D, Jiang B, Pan FS, Zhang MX (2015) Current research progress in grain refinement of cast magnesium alloy: a review article. J Alloys Compd 619:639–651

Stjohn DH, Qian M, Easton MA, Cao P, Hildebrand Z (2005) Grain refinement of magnesium alloys. Metall Mater Trans A 36A:1671–1679

Liu H, Xue F, Bai J, Zhou J, Liu XD (2013) Effect of substitution of 1 at.% Ni for Zn on the microstructure and mechanical properties of Mg94Y4Zn2 alloy. Mater Sci Eng A 585:387–395

Yin J, Lu CH, Ma XJ, Dai BY, Chen HL (2016) Investigation of two-phase Mg–Gd–Ni alloys with highly stable long period stacking ordered phases. Intermetallics 68:63–70

Zhu SM, Lapovok R, Nie JF, Estrin Y, Mathaudhu SN (2017) Microstructure and mechanical properties of LPSO phase dominant Mg85.5Y7.1Zn7.1 and Mg85.8Y7.1Ni7.1 alloys. Mater Sci Eng A 692:35–42

Wang DD, Zhang WB, Zong XM, Nie KB, Xu CX, Zhang JS (2014) Abundant long period stacking ordered structure induced by Ni addition into Mg–Gd–Zn alloy. Mater Sci Eng A 618:355–358

Liu W, Zhang JS, Wei LY, Xu CX, Zong XM, Hao JQ (2017) Extensive dynamic recrystallized grains at kink boundary of 14H LPSO phase in extruded Mg92Gd3Zn1Li4 alloy. Mater Sci Eng A 681:97–102

Liu H, Ju J, Yang XW, Yan JL, Song D, Jiang JH, Ma AB (2017) A two-step dynamic recrystallization induced by LPSO phases and its impact on mechanical property of severe plastic deformation processed Mg97Y2Zn1 alloy. J Alloys Compd 704:509–517

Abe E, Kawamura Y, Hayashi K, Inoue A (2002) Long-period ordered structure in a high-strength nanocrystalline Mg-1 at% Zn-2 at% Y alloy studied by atomic-resolution Z-contrast STEM. Acta Mater 50:3845–3857

Alizadeh R, Mahmudi R, Ngan AHW, Langdon TG (2017) Microstructural evolution during hot shear deformation of an extruded fine-grained Mg–Gd–Y–Zr alloy. J Mater Sci 52(13):7843–7857. doi:10.1007/s10853-017-1031-8

Li WJ, Deng KK, Zhang X, Nie KB, Xu FJ (2016) Effect of ultra-slow extrusion speed on the microstructure and mechanical properties of Mg–4Zn–0.5Ca alloy. Mater Sci Eng A 677:367–375

Park SH, Kim SH, Kim HS, Yoon JH, You BS (2016) High-speed indirect extrusion of Mg–Sn–Al–Zn alloy and its influence on microstructure and mechanical properties. J Alloys Compd 667:170–177

Quested TE, Dinsdale AT, Greer AL (2005) Thermodynamic modelling of growth-restriction effects in aluminium alloys. Acta Mater 53:1323–1334

Easton MA, Qian M, Prasad A, StJohn DH (2016) Recent advances in grain refinement of light metals and alloys. Curr Opin Solid St M 20:13–24

Men H, Fan Z (2011) Effects of solute content on grain refinement in an isothermal melt. Acta Mater 59:2704–2712

Li D, Zhang JS, Que ZP, Xu CX, Niu XF (2013) Effects of Mn on the microstructure and mechanical properties of long period stacking ordered Mg95Zn2.5Y2.5 alloy. Mater Lett 109:46–50

Wang J, Zhang JS, Zong XM, Xu CX, You ZY, Nie KB (2015) Effects of Ca on the formation of LPSO phase and mechanical properties of Mg–Zn–Y–Mn alloy. Mater Sci Eng A 648:37–40

Zhang JS, Zhang WB, Bian LP, Cheng WL, Niu XF, Xu CX, Wu SJ (2013) Study of Mg–Gd–Zn–Zr alloys with long period stacking ordered structures. Mater Sci Eng A 585:268–276

Li DJ, Zeng XQ, Dong J, Zhai CQ, Ding WJ (2009) Microstructure evolution of Mg–10Gd–3Y–1.2Zn–0.4Zr alloy during heat-treatment at 773 K. J Alloys Compd 468:164–169

Hagihara K, Kinoshita A, Sugino Y, Yamasaki M, Kawamura Y, Yasuda HY, Umakoshi Y (2010) Effect of long-period stacking ordered phase on mechanical properties of Mg97Zn1Y2 extruded alloy. Acta Mater 58:6282–6293

Wu YJ, Lin DL, Zeng XQ, Peng LM (2009) Formation of a lamellar 14H-type long period stacking ordered structures in an as-cast Mg–Gd–Zn–Zr alloy. J Mater Sci 44(6):1607–1612. doi:10.1007/s10853-008-3213-x

Zhu YM, Morton AJ, Nie JF (2012) Growth and transformation mechanisms of 18R and 14H in Mg–Y–Zn alloys. Acta Mater 60:6562–6572

Xu C, Nakata T, Qiao XG, Zheng MY, Wu K, Kamado S (2017) Effect of LPSO and SFs on microstructure evolution and mechanical properties of Mg–Gd–Y–Zn–Zr alloy. Sci Rep UK 7:40846

Du YX, Wu YJ, Peng LM, Chen J, Zeng XQ, Ding WJ (2016) Formation of lamellar phase with 18R-type LPSO structure in an as-cast Mg96Gd3Zn1 (at%) alloy. Mater Lett 169:168–171

Liu H, Bai J, Yan K, Yan JL, Ma AB, Jiang JH (2016) Comparative studies on evolution behaviors of 14H LPSO precipitates in as-cast and as-extruded Mg–Y–Zn alloys during annealing at 773 K. Mater Des 93:9–18

Lv BJ, Peng J, Zhu LL, Wang YJ, Tang AT (2014) The effect of 14H LPSO phase on dynamic recrystallization behavior and hot workability of Mg–2.0Zn–0.3Zr–5.8Y alloy. Mater Sci Eng A 599:150–159

Zhang DL, Jiang L, Schoenung JM, Mahajan S, Lavernia EJ (2015) TEM study on relationship between stacking faults and non-basal dislocations in Mg. Philos Mag 34:3823–3844

Hu WW, Yang ZQ, Ye HQ (2017) 〈c + a〉 dislocations and their interactions with other crystal defects in a Mg alloy. Acta Mater 124:372–382

Tang YZ, El-Awady JA (2014) Formation and slip of pyramidal dislocations in hexagonal close-packed magnesium single crystals. Acta Mater 71:319–332

Liu W, Ma YB, Zhang YG, Fan XX, Xu CX, Zhang JS (2017) Two dynamic recrystallization processes in a high-performance extruded Mg94.5Y2Gd1Zn2Mn0.5 alloy. Mater Sci Eng A 690:132–136

Shao XH, Peng ZZ, Jin QQ, Ma XL (2016) Atomic-scale segregations at the deformation-induced symmetrical boundary in an Mg–Zn–Y alloy. Acta Mater 118:177–186

Janecek M, Cizek J, Gubicza J, Vratna J (2012) Microstructure and dislocation density evolutions in MgAlZn alloy processed by severe plastic deformation. J Mater Sci 47(22):7860–7869. doi:10.1007/s10853-012-6538-4

Xu C, Zhang JH, Liu SJ, Jing YB, Jiao YF, Xu LJ, Zhang L, Jiang FC, Zhang ML, Wu RZ (2015) Microstructure, mechanical and damping properties of Mg–Er–Gd–Zn alloy reinforced with stacking faults. Mater Des 79:53–59

Hagihara K, Kinoshita Sugino Y, Yamasaki M, Kawamura Y, Yasuda HY, Umakoshi Y (2010) Plastic deformation behavior of Mg89Zn4Y7 extruded alloy composed of long-period stacking ordered phase. Intermetallics 18:1079–1085

Yu ZJ, Huang YD, Gan WM, Zhong ZY, Hort N, Meng J (2017) Effects of extrusion ratio and annealing treatment on the mechanical properties and microstructure of a Mg–11Gd–4.5Y–1Nd–1.5Zn–0.5Zr (wt%) alloy. J Mater Sci 52(11):6670–6686. doi:10.1007/s10853-017-0902-3

Acknowledgements

The authors acknowledge Shanxi Key Laboratory of Advanced Magnesium-Based Material, Taiyuan University of Technology (No. 2015-01), Natural Science Foundation of Shanxi Province (Nos. 2009011028-3 and 2012011022-1), Ph.D. Programs Foundation of Ministry of Education of China (20111402110004) and National Natural Science Foundation of China (Nos. 51474153 and 51574175).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, W., Zhang, J., Xu, C. et al. Precipitation behaviors of 14H LPSO lamellae in Mg96Gd3Zn0.5Ni0.5 alloys during severe plastic deformation. J Mater Sci 52, 13271–13283 (2017). https://doi.org/10.1007/s10853-017-1431-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1431-9