Abstract

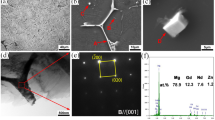

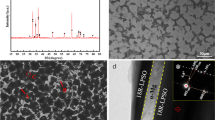

In this paper, a large-sized ingot of Mg−9Gd−3Y−1.5Zn−0.5Zr (wt%) alloy with a diameter of 600 mm was successfully prepared by the semi-continuous casting method. The alloy was subsequently annealed at a relatively low temperature of 430°C for 12 h as a homogenization treatment. The microstructure and room-temperature mechanical properties of the alloy were investigated systematically. The results show that the as-cast alloy contained a mass of discontinuous lamellar-shaped 18R long-period stacking ordered (LPSO) phases with a composition of Mg10ZnY and an α-Mg matrix, along with net-shaped Mg5(Y,Gd) eutectic compounds at the grain boundaries. Most of the eutectic compounds dissolved after the homogenization treatment. Moreover, the amount and dimensions of the lamellar-shaped LPSO phase obviously increased after the homogenization treatment. The structure of the phase transformed into 14H-type LPSO with composition Mg12Zn(Y,Gd). The mechanical properties of the heat-treated large-sized alloy ingot are uniform. The ultimate tensile strength (UTS) and tensile yield strength (TYS) of the alloy reached 207.2 MPa and 134.8 MPa, respectively, and the elongation was 3.4%. The high performances of the large-sized alloy ingot after the homogenization treatment is attributed to the strengthening of the α-Mg solid solution and to the plentiful LPSO phase distributed over the α-Mg matrix.

Similar content being viewed by others

References

Q.D. Wang, J. Chen, Z. Zhao, and S.M. He, Microstructure and super high strength of cast Mg−8.5Gd−2.3Y−1.8Ag− 0.4Zr alloy, Mater. Sci. Eng. A, 528(2010), No. 1, p. 323.

C. Xu, M.Y. Zheng, S.W. Xu, K. Wu, E.D. Wang, S. Kamado, G.J. Wang, and X.Y. Lv, Ultra high-strength Mg−Gd−Y−Zn−Zr alloy sheets processed by large-strain hot rolling and ageing, Mater. Sci. Eng. A, 547(2012), p. 93.

D.J. Li, X.Q. Zeng, J. Dong, C.Q. Zhai, and W.J. Ding, Microstructure evolution of Mg−10Gd−3Y−1.2Zn−0.4Zr, J. Alloys Compd., 468(2009), No. 1-2, p. 164.

D. Griffiths, Explaining texture weakening and improved formability in magnesium rare earth alloys, Mater. Sci. Technol., 31(2015), No. 1, p. 10.

X. Liu, Q.C. Le, Z.Q. Zhang, L. Bao, Z.X. Fan, and J.Z. Cui, Effects of casting process on microstructures and flow stress behavior of Mg−9Gd−3Y−1.5Zn−0.8Zr semi-continuous casting billets, J. Magnesium Alloys, 2(2014), No. 4, p. 342.

J.W. Chang, J. Duo, Y.Z. Xiang, H.Y. Yang, W.J. Ding, and Y.H. Peng, Influence of Nd and Y additions on the corrosion behavior of extruded Mg−Zn−Zr alloys, Int. J. Miner. Metall. Mater., 18(2011), No. 2, p. 203.

T. Itoi, K. Takahashi, H. Moriyama, and M. Hirohashi, A high-strength Mg−Ni−Y alloy sheet with a long-period ordered phase prepared by hot-rolling, Scripta Mater., 59(2008), No. 10, p. 1155.

Y. Kawamura, K. Hayashi, A. Inoue, and T. Masumoto, Rapidly solidified powder metallurgy Mg97Zn1Y2 alloys with excellent tensile yield strength above 600 MPa, Mater. Trans., 42(2001), No. 7, p. 1172.

J.F. Nie, Precipitation and hardening in Magnesium alloys, Metall. Mater. Trans. A, 43A(2012), No. 11, p. 3891.

M. Yamasaki, K. Hashimoto, K. Hagihara, and Y. Kawamura, Effect of multimodal microstructure evolution on mechanical properties of Mg−Zn−Y extruded alloy, Acta Mater., 59(2011), No. 9, p. 3646.

M. Yamasaki, T. Anan, S. Yoshimoto, and Y. Kawamura, Mechanical properties of warm-extruded Mg−Zn−Gd alloy with coherent 14H long periodic stacking ordered structure precipitate, Scripta Mater., 53(2005), No. 7, p. 799.

J.F. Nie, Y.M. Zhu, and A.J. Morton, On the structure, transformation and deformation of long-period stacking ordered phase in Mg-Y-Zn alloys, Metall. Mater. Trans. A, 45(2014), No. 8, p. 3338.

Y.X. Du, Y.J. Wu, L.M. Peng, J. Chen, X.Q. Zeng, and W.J. Ding, Formation of lamellar phase with 18R-type LPSO structure in an as-cast Mg96Gd3Zn1(at%) alloy, Mater. Lett., 169(2016), p. 168.

C. Xu, M.Y. Zheng, K. Wu, E.D. Wang, G.H. Fan, S.W. Xu, S. Kamado, X.D. Liu, G.J. Wang, and X.Y. Lv, Effect of cooling rate on the microstructure evolution and mechanical properties of homogenized Mg−Gd−Y−Zn−Zr alloy, Mater. Sci. Eng. A, 559(2013), p. 364.

M. Yamasaki, K. Hagihara, S. Inoue, J.P. Hadorn, and Y. Kawamura, Crystallographic classification of kink bands in an extruded Mg−Zn−Y alloy using intragranular misorientation axis analysis, Acta Mater., 61(2013), No. 6, p. 2065.

T. Homma, N. Kunito, and S. Kamado, Fabrication of extraordinary high-strength magnesium alloy by hot extrusion, Scripta Mater., 61(2009), No. 6, p. 644.

L. Zhang, Z. Liu, and P.L. Mao, Effect of annealing on the microstructure and mechanical properties of Mg−2.5Zn−0.5Y alloy, Int. J. Miner. Metall. Mater., 21(2014), No. 8, p. 779.

Z.Q. Wang, B. Zhang, D.J. Li, R. Fritsch, X.Q. Zeng, H.J. Roven, and W.J. Ding, Effect of heat treatment on microstructures and mechanical properties of high vacuum die casting Mg-8Gd-3Y-0.4Zr magnesium alloy, Trans. Nonferrous Met. Soc. China, 24(2014), No. 12, p. 3762.

J. D. Robson, Effect of rare-earth additions on the texture of wrought magnesium alloys: the role of grain boundary segregation, Metall. Mater. Trans. A, 45(2014), No. 8, p. 3205.

F.M. Lu, A.B. Ma, J.H. Jiang, D.H. Yang, and Q. Zhou, Review on long-period stacking-ordered structures in Mg−Zn−RE alloys, Rare Met., 31(2012), No. 3, p. 303.

J.C. Li, Z.L. He, P.H. Fu, Y.J. Wu, L.M. Peng, and W.J. Ding, Heat treatment and mechanical properties of a high-strength cast Mg−Gd−Zn alloy, Mater. Sci. Eng. A, 651(2016), p. 745.

G.D. Zhang, X.G. Li, M.L. Ma, Y.J. Li, G.L. Shi, J.W. Yuan, and K. Zhang, Homogenization heat treatment of Mg−7.68Gd−4.88Y−1.32Nd−0.63Al−0.05Zr alloy, J. Rare Earths, 32(2014), No. 5, p. 445.

Acknowledgements

This work is supported by the Youth Science Fund Project of the National Natural Science Fund of China (No. 51401070), the Program for New Century Excellent Talents in Universities (No. NCET-12-0849), and the Fundamental Research Funds for the Central Universities (No. 2014ZZD03).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xue, Zy., Ren, Yj., Luo, Wb. et al. Microstructure evolution and mechanical properties of a large-sized ingot of Mg−9Gd−3Y−1.5Zn−0.5Zr (wt%) alloy after a lower-temperature homogenization treatment. Int J Miner Metall Mater 24, 271–279 (2017). https://doi.org/10.1007/s12613-017-1405-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-017-1405-6