Abstract

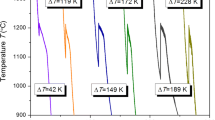

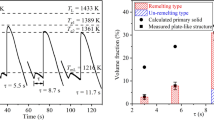

The Ni–38 wt% Si alloy whose eutectic products are two stoichiometric intermetallic compounds (i.e., NiSi and NiSi2) was undercooled by the melt fluxing technique. After in situ observations of the recalescence processes using a high-speed camera and by electron back-scattering diffraction analysis of the solidification microstructures, the crystal growth velocities, phase selection, and microstructure evolutions were studied. Due to a growth-controlled mechanism, the primary phase changes from the NiSi to the NiSi2 phase at a critical undercooling ΔT ≈ 48 K. Even in the absence of the driving force of chemical superheating, the transition from regular eutectics to anomalous eutectics happens. The reason is that the single-phase dendrite of NiSi2 phase solidifies firstly and then the NiSi phase grows epitaxially to form an uncoupled eutectic-dendrite at high undercooling. The present work provides further experimental evidences for the dual origins of anomalous eutectics (e.g., uncoupled eutectic-dendrite growth during the recalescence stage and coupled lamellar eutectic growth at low undercooling during the post-recalescence stage) and is helpful for understanding of non-equilibrium phenomena in undercooled melts.

Similar content being viewed by others

Notes

It should be mentioned that in recent work by Binder et al. [25], the high-speed video data with the help of POV-Ray were fitted assuming a reasonable overall shape of the growing phase (e.g., a spherical envelope) to obtain the growth velocity. Such a method should be more reliable than but is not adopted by the current work.

This is similar to the work by Li et al [27], in which the Co–61.8 at.% Si eutectic alloy was undercooled by both an electromagnetic levitator and an electrostatic levitator. At low undercooling, only a single recalescence event can be found but the microstructure consists of primary CoSi phase and CoSi–CoSi2 eutectics. In subsequent work by Zhang et al. [11], the recalescence behaviors of undercooled Co–61.8 at.% Si eutectic alloy are much more complex; please see their Fig. 1. All these results indicate that the transformation process and the recalescence behaviors may not follow the one-to-one relationship.

It should be noted that for coupled growth, the lamellar spacing of eutectic formed at high undercooling should be smaller than that formed at low undercooling. The present coarse eutectic is formed by uncoupled growth but not coupled growth. Therefore, it is not strange that the lamellar spacing of the present coarse eutectic formed at high undercooling is larger than that of the thin lamellar eutectic formed at low undercooling.

Eutectic-dendrite can be defined as a dendrite on the whole, the solids of which are formed by eutectic solidification. There are two kinds of eutectic-dendrite according to the growth mechanism, i.e., by coupled and uncoupled eutectic growth. For the former, other alloy element should be added to the eutectic alloy or a negative temperature gradient should be improved to the eutectic interface to make the interface unstable to a dendritic morphology. This is the physical basis for the current eutectic-dendrite growth theory [2, 23, 28]. For the latter, the primary dendrite phase is followed by solidification of a second phase.

References

Kurz W, Fisher DJ (1979) Dendrite growth in eutectic alloys: the coupled zone. Int Mater Rev 24:177–204

Li JF, Zhou YH (2005) Eutectic growth in bulk undercooled melts. Acta Mater 53:2351–2359

Li JF, Li XL, Liu L et al (2008) Mechanism of anomalous eutectic formation in the solidification of undercooled Ni–Sn eutectic alloy. J Mater Res 23:2139–2148

Wei XX, Lin X, Xu W et al (2015) Remelting-induced anomalous eutectic formation during solidification of deeply undercooled eutectic alloy melts. Acta Mater 95:44–56

Herlach DM (1994) Non-equilibrium solidification of undercooled metallic melts. Mater Sci Eng Rep R 12:177–272

Liu JM, Zhou YH, Shang BL (1992) Theory and experiments on irregular eutectic growth: investigation on Al–Si eutectic growth. J Mater Sci 27:2067–2074

Wang JT, Kang SB, Kim HW et al (2002) Lamellae deformation and structural evolution in an Al–33 % Cu eutectic alloy during equal-channel angular pressing. J Mater Sci 37:5223–5227

Zhao S, Li JF, Liu L et al (2009) Eutectic growth from cellular to dendritic form in the undercooled Ag–Cu eutectic alloy melt. J Cryst Growth 311:1387–1391

Clopet CR, Cochrane RF, Mullis AM (2013) The origin of anomalous eutectic structures in undercooled Ag–Cu alloy. Acta Mater 61:6894–6902

Yao WJ, Wang N, Wei B (2003) Containerless rapid solidification of highly undercooled Co–Si eutectic alloys. Mater Sci Eng A 344:10–19

Zhang YK, Gao J, Kolbe M et al (2013) Phase selection and microstructure formation in undercooled Co–61.8 at.% Si melts under various containerless processing conditions. Acta Mater 61:4861–4873

Li M, Kuribayashi K (2003) Nucleation-controlled microstructures and anomalous eutectic formation in undercooled Co–Sn and Ni–Si eutectic melts. Metall Mater Trans A 34:2999–3008

Liu L, Wei XX, Huang QS et al (2012) Anomalous eutectic formation in the solidification of undercooled Co–Sn alloys. J Cryst Growth 358:20–28

Liu L, Li JF, Zhou YH (2011) Solidification interface morphology pattern in the undercooled Co–24.0 at.%Sn eutectic melt. Acta Mater 59:5558–5567

Yang C, Gao J, Zhang YK et al (2011) New evidence for the dual origin of anomalous eutectic structures in undercooled Ni–Sn alloys: in situ observations and EBSD characterization. Acta Mater 59:3915–3926

Xing LQ, Zhao DQ, Chen XC (1993) Solidification of undercooled Ni–32.5 wt%Sn eutectic alloy. J Mater Sci 28:2733–2737

Kattamis TZ, Flemings MC (1970) Structure of undercooled Ni–Sn eutectic. Metall Trans 1:1449–1451

Cao YQ, Lin X, Wang ZT et al (2015) Three-dimensional reconstruction of anomalous eutectic in laser remelted Ni–30 wt%Sn alloy. Sci Technol Adv Mater 16:1–11

Powell GL, Hogan LM (1965) Undercooling in silver-copper eutectic alloys. J Inst Metals 93:505–512

Jones BL (1971) Growth mechanisms in undercooled eutectic. Metall Trans 2:2950–2951

Wei BB, Yang GC, Zhou YH (1991) High undercooling and rapid solidification of Ni–32.5%Sn eutectic alloy. Acta Metall Mater 39:1249–1258

Li JF, Jie WQ, Zhao S et al (2007) Structural evidence for the transition from coupled to decoupled growth in the solidification of undercooled Ni–Sn eutectic melt. Metall Mater Trans A 38:1806–1816

Goetzinger R, Barth M, Herlach DM (1998) Mechanism of formation of the anomalous eutectic structure in rapidly solidified Ni–Si, Co–Sb and Ni–Al–Ti alloys. Acta Mater 46:1647–1655

Nash P, Nash A (1987) The Ni–Si (Nickel–Silicon) system. Bull Alloy Phase Diagr 8:6–14

Binder S, Galenko PK, Herlach DM (2014) The effect of fluid flow on the solidification of Ni2B from the undercooled melt. J Appl Phys 115:053511

Wang HF, Liu F, Chen Z et al (2007) Effect of non-linear liquidus and solidus in undercooled dendrite growth: a comparative study in Ni–0.7 at.%B and Ni–1 at.%Zr systems. Scr Mater 57:413–416

Li MJ, Nagashio K, Ishikawa T et al (2008) Microstructure formation and in situ phase identification from undercooled Co–61.8 at.%Si melts solidified on an electromagnetic levitator and an electrostatic levitator. Acta Mater 56:2514–2525

Kuang WW, Wang HF, Liu F et al (2016) Modeling of eutectic dendrite growth in undercooled binary alloys. J Mater Sci 51:2141–2152

Boettinger WJ, Coriell SR, Greer AL et al (2000) Solidification microstructures: recent developments, future directions. Acta Mater 48:43–70

Wei XX, Xu W, Kang JL et al (2016) Metastable Co23B6 phase solidified from deeply undercooled Co79.3B20.7 alloy melt. J Mater Sci 51:6436–6443

Tatsuya T, Kazumasa N, Hiroshi O et al (2003) Thermodynamic assessment of the Ni–Si system by incorporating ab initio energetic calculations into the CALPHAD approach. CALPHAD Comput Coupling Phase Diagr Thermochem 27:161–168

Ahmad R, Cochrane RF, Mullis AM (2012) The formation of regular αNi-γ(Ni31Si12) eutectic structures from undercooled Ni–25 at.%Si melts. Intermetallics 22:55–61

Cao LG, Cochrane RF, Mullis AM (2014) Lamella structure formation in drop-tube processed Ni–25.3 at.%Si alloy. J Alloys Compd 615:S599–S601

Dutra AT, Milenkovic S, Kiminami CS et al (2004) Microstructure and metastable phase formation in a rapidly solidified Ni–Si eutectic alloy using a melt-spinning technique. J Alloys Compd 381:72–76

Cao LG, Cochrane RF, Mullis AM (2015) Microstructural evolution and phase formation in rapidly solidified Ni–25.3 at.%Si alloy. Metall Mater Trans A 46:4705–4715

Schwarz M, Karma A, Eckler K et al (1994) Physical mechanism of grain refinement in solidification of undercooled melts. Phys Rev Lett 73:1380–1383

Karma A (1998) Model of grain refinement in solidification of undercooled melts. Int J Non-Equilib Process 11:201–233

Wang HF, Liu F, Tan YM (2011) Modeling grain refinement for undercooled single-phase solid-solution alloys. Acta Mater 59:4787–4797

Cline HE (1971) Shape instabilities of eutectic composites at elevated temperatures. Acta Metall 19:481–490

Acknowledgements

The authors would like to thank the Natural Science Foundation of China (Nos. 51371149, 51134011 and 51431008), the China National Funds for Distinguished Young Scientists (No. 51125002), Huo Yingdong Young Teacher Fund (No. 151048), the Aeronautical Science Foundation of China (No. 2015ZF53066), the Free Research Fund of State Key Lab. of Solidification Processing (No. 92-QZ-2014) and the project of Shaanxi Young Stars of Science and Technology (No. 2015KJXX-10).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Lai, C., Wang, H., Pu, Q. et al. Phase selection and re-melting-induced anomalous eutectics in undercooled Ni–38 wt% Si alloys. J Mater Sci 51, 10990–11001 (2016). https://doi.org/10.1007/s10853-016-0312-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0312-y