Abstract

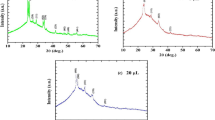

TiN nanolayers with different thicknesses were inserted in TiSiN nanocomposite film by magnetron-sputtering technique. The influences of TiN insertion nanolayers with different thicknesses on microstructure and mechanical properties of TiSiN film were investigated X-ray diffraction, high-resolution transmission electron microscopy, scanning electron microscopy, and nanoindentation techniques. When the TiN insertion layer thickness is <0.5 nm, TiN nanolayers can coordinate the misorientations between TiN nanocrystallites in adjacent TiSiN layers, leading to the transformation from the nanocomposite structure with TiN nanocrystallites encapsulated by SiN x interfacial phase into columnar crystal structure, and disappearance of the strengthening effect from the nanocomposite structure. When the TiN insertion layer thickness increases to 1.0 nm, the film is strengthened with the epitaxial growth structures between TiSiN and TiN layers. As the TiN insertion layers further thicken, the hardness and elastic modulus evidently decrease, which can be attributed to the breakage of epitaxial growth structures between TiSiN and TiN layers.

Similar content being viewed by others

References

Veprek S, Veprek-Heijman MGJ, Karvankova P, Prochazka J (2005) Different approaches to superhard coatings and nanocomposites. Thin Solid Films 476:1–29

Niederhofer A, Bolom T, Nesladek P, Moto K, Eggs C, Patil DS, Veprek S (2001) The role of percolation threshold for the control of the hardness and thermal stability of super- and ultrahard nanocomposites. Surf Coat Technol 146–147:183–188

Veprek S, Veprek-Heijman MJG (2008) Industrial applications of superhard nanocomposite coatings. Surf Coat Technol 202:5063–5073

Andrievski RA (2007) Nanostructured superhard films as typical nanomaterials. Surf Coat Technol 201:6112–6116

Li SZ, Shi YL, Peng HR (1992) Ti–Si–N films prepared by plasma-enhanced chemical vapor deposition. Plasma Chem Plasma Process 12:287–297

Nesladek P, Veprek S (2000) Superhard nanocrystalline composites with hardness of diamond. Phys Status Solidi A 177:53–62

Veprek S, Argon AS (2001) Mechanical properties of superhard nanocomposites. Surf Coat Technol 146–147:175–182

Veprek S, Prilliman SG, Clark SM (2010) Elastic moduli of nc-TiN/a-Si3N4 nanocomposites: compressible, yet superhard. J Phys Chem Solids 71:1175–1178

Veprek S, Veprek-Heijman MGJ (2012) Limits to the preparation of superhard nanocomposites: impurities, deposition and annealing temperature. Thin Solid Films 522:274–282

Veprek S, Niederhofer A, Moto K, Bolom T, Mannling HD, Nesladek P, Dollinger G, Bergmaier A (2000) Composition, nanostructure and origin of the ultrahardness in nc-TiN/a-Si3N4/a- and nc-TiSi2 nanocomposites with HV = 80 to ≥105 GPa. Surf Coat Technol 133–134:152–159

Veprek S, Reiprich S, Li SZ (1995) Superhard nanocrystalline composite materials: the TiN/Si3N4 system. Appl Phys Lett 66:2640–2642

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Li W, Liu P, Zhao YS, Zhang K, Ma FC, Liu XK, Chen XH, He DH (2013) SiN x thickness dependent morphology and mechanical properties of CrAlN/SiN x nanomultilayers. Thin Solid Films 534:367–372

Kong M, Zhao WJ, Wei L, Li GY (2007) Investigations on the microstructure and hardening mechanism of TiN/Si3N4 nanocomposite coatings. J Phys D Appl Phys 40:2858–2863

Hultman L, Bareno J, Flink A, Soderberg H, Larsson K, Petrova V, Oden M, Greene JE, Petrov I (2007) Interface structure in superhard TiN–SiN nanolaminates and nanocomposites: film growth experiments and ab initio calculations. Phys Rev B 75(155437):1–6

Zhang XD, Meng WJ, Wang W, Rehn LE, Baldo PM, Evans RD (2004) Temperature dependence of structure and mechanical properties of Ti–Si–N coatings. Surf Coat Technol 177–178:325–333

Kauffmann F, Dehm G, Schier V, Schattke A, Beck T, Lang S, Arzt E (2005) Microstructural size effects on the hardness of nanocrystalline TiN/amorphous-SiN x coatings prepared by magnetron sputtering. Thin Solid Films 473:114–122

Patscheider J (2003) Nanocomposite hard coatings for wear protection. MRS Bull 28:180–183

Koehler JS (1970) Attempt to design a strong solid. Phys Rev B 2:547–551

Kato M, Mori T, Schwartz LH (1980) Hardening by spinodal modulated structure. Acta Metall 28:285–290

Acknowledgements

The present study was financially supported by the National Natural Science Foundation of China under Grant No. 51101101; the State Key Laboratory Program for Mechanical Behavior of Materials under Grant No. 20131305; the“Shanghai Municipal Natural Science Foundation” under Grant No. 11ZR1424600, sponsored by Shanghai Municipal Science and Technology Commission; and the “Innovation Program of Shanghai Municipal Education Commission” under Grant No. 12YZ104.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, W., Liu, P., Zhu, X. et al. Influence of TiN-nanolayered insertions on microstructure and mechanical properties of TiSiN nanocomposite film. J Mater Sci 49, 4127–4132 (2014). https://doi.org/10.1007/s10853-014-8107-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8107-5