Abstract

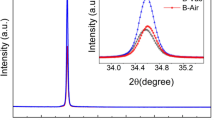

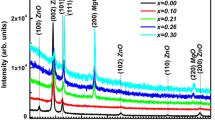

In order to gain a deeper understanding of the relationship between defects and luminescent properties in thin films, ZnO films containing 0 to 8 at % Mg were prepared on amorphous quartz substrates by room temperature radio-frequency (RF) magnetron sputtering, followed by annealing in air at 400 °C. X-ray diffraction (XRD) results indicate that the ZnMgO film is a solid solution with a hexagonal close-packed wurtzite structure and preferential c-axis growth direction. With the increase in Mg concentration, the intensity of the (002) diffraction peak gradually decreases. Field emission scanning electron microscopy (FESEM) observations reveal a transition in surface particle shapes from approximately circular to a mixture of circular and irregular polygonal shapes. The optical bandgap (Eg), obtained from optical transmittance measured using a UV–visible spectrophotometer, decreases first and then increases with increasing Mg concentration. Photoluminescence (PL) spectra show a strong violet peak and a weak near-infrared (NIR) peak. Gaussian fitting of the two peaks reveals that the violet peak mainly originates from the radiative recombination of electrons bound to shallow donor interstitial zinc (Zni) with holes in the valence band. The NIR peak primarily arises from the radiative recombination of electrons captured by shallow donor interstitial zinc (Zni) with holes captured by deep-level acceptor interstitial oxygen (Oi).

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author, upon reasonable request.

References

P. Shimpi, Y. Ding, E. Suarez, J. Ayers, P.-X. Gao, Appl. Phys. Lett.Lett. 97, 200 (2010)

D. Fang, C. Li, N. Wang, P. Li, P. Yao, Cryst. Res. Technol. 48, 265–272 (2013)

M. Boshta, M.O. Abou-Helal, D. Ghoneim, N.A. Mohsen, R.A. Zaghlool, Surf. Coat. Technol. 205, 271–274 (2010)

V.V. Petrov, V.V. Sysoev, A.P. Starnikova, M.G. Volkova, Z.K. Kalazhokov, V.Y. Storozhenko, S.A. Khubezhov, E.M. Bayan, Chemosensors 9, 124 (2021)

N. Siregar, J.H. Motlan, M. Panggabean, J. Sirait, N.S. Rajagukguk, F.K. Gultom, J.C. Sabir, Int. J. Photoenergy 2021, 1–7 (2021)

S. Aksoy, Y. Caglar, S. Ilican, M. Caglar, J. Alloys Compd. 512, 171–178 (2012)

H. Benali, B. Hartiti, F. Lmai, A. Batan, S. Fadili, P. Thevenin, Mater. Today. Proc. 66, 212–216 (2022)

R. Dhawan, E. Panda, J. Alloys Compd. 788, 1037–1047 (2019)

P.F.H. Inbaraj, J.J. Prince, J. Mater. Sci. Mater. Electron. 29, 935–943 (2017)

T. Ivanova, A. Harizanova, T. Koutzarova, B. Vertruyen, R. Closset, Materials 15, 8883 (2022)

A. Rana, A. Sharma, S.P. Khanna, R. Srivastava, C.K. Suman, J. Mater. Sci. Mater. Electron. 34, 1379 (2023)

S. Talu, S. Boudour, I. Bouchama, B. Astinchap, H. Ghanbaripour, M.S. Akhtar, S. Zahra, Microsc. Res. Tech. 85, 1213–1223 (2022)

A. Das, P. Guha Roy, A. Dutta, S. Sen, P. Pramanik, D. Das, A. Banerjee, A. Bhattacharyya, Mat. Sci. Semicon. Proc. 54, 36–41 (2016)

M. Caglar, Y. Caglar, S. Ilican, Physica B 485, 6–13 (2016)

Y. Hu, C. Mao, Proceedings of the 3rd International Conference on Material, Mechanical and Manufacturing Engineering. June 27–28, 2015. Guangzhou, China. Paris, France: Atlantis Press, 2015: 1771–1776. https://doi.org/10.2991/ic3me-15.2015.342

F. Kayaci, S. Vempati, I. Donmez, N. Biyikli, T. Uyar, Nanoscale 6, 10224–10234 (2014)

C.C. Singh, E. Panda, J. Appl. Phys. 123, 165106 (2018)

C.-Y. Chang, J. Shieh, Y.-L. Kuo, J.-Y. Guo, S.-Y. Chen, C.-L. Kuo, Appl. Surf. Sci. 638, 158018 (2023)

J. Varghese, S.K. Saji, N.R. Aswathy, R. Vinodkumar, Eur. Phys. J. Plus. 136, 1–13 (2021)

X. Long, X. Li, P.T. Lin, X.W. Cheng, Y. Liu, C.B. Cao, Chinese Phys. B 19, 027202 (2010)

P. Giri, P. Chakrabarti, Superlattices and Microstruct. 93, 248–260 (2016)

Z.K. Heiba, M.B. Mohamed, J. Mol. Struct. 1181, 507–517 (2019)

M. Wang, Y. Zhou, Y. Zhang, E.J. Kim, S.H. Hahn, S.G. Seong, Appl. Phys. Lett.Phys. Lett. 100, 101906 (2012)

K. Panturotai, C. Krataithong, P. Pluengphon, E. Wongrat, A. Tubtimtae, B. Inceesungvorn, Opt. Mater. 126, 112179 (2022)

P.S. Shewale, S.H. Lee, Y.S. Yu, J. Alloys Compd. 774, 461–470 (2019)

M. Singh, A.K. Ambedkar, S. Tyagi, V. Kumar, P. Yadav, A. Kumar, Y.K. Gautam, B.P. Singh, Optik 257, 168860 (2022)

P.J. Kelly, R.D. Arnell, Vacuum 56, 159–172 (2000)

A. Goktas, A. Tumbul, Z. Aba, M. Durgun, Thin Solid Films 680, 20–30 (2019)

R. Cebulla, R. Wendt, K. Ellmer, J. Appl. Phys. 83, 1087–1095 (1998)

V. Kumar, V. Kumar, S. Som, A. Yousif, N. Singh, O.M. Ntwaeaborwa, A. Kapoor, H.C. Swart, J. Colloid Interf. Sci. 428, 8–15 (2014)

S. Shi, J. Xu, L. Li, Mater. Lett.Lett. 229, 178–181 (2018)

Y. Hu, H. Zeng, J. Du, Z. Hu, S. Zhang, Mater. Chem. Phys. 182, 15–21 (2016)

C.J. Gawlak, C.R. Aita, J. Vac. Sci. Technol. 1, 415–418 (1983)

J. Luo, H.Y. Liu, W.J. Deng, R.G. Zhang, C. He, J. Mater, Sci. Mater. El. 34, 2172 (2023)

M. Wang, J. Yi, S. Yang, Z. Cao, X. Huang, Y. Li, H. Li, J. Zhong, Appl. Surf. Sci.Surf. Sci. 382, 217–224 (2016)

H. Zhang, W. Li, G. Qin, H. Ruan, Z. Huang, F. Wu, C. Kong, L. Fang, Appl. Surf. Sci.Surf. Sci. 492, 392–398 (2019)

J. Sengupta, A. Ahmed, R. Labar, Mater. Lett. 109, 265–268 (2013)

C. Singh, E. Panda, RSC Adv. 6, 48910–48918 (2016)

B. Panigrahy, M. Aslam, D.S. Misra, M. Ghosh, D. Bahadur, Adv. Funct. Mater. 20, 1161–1165 (2010)

M. Bedrouni, B. Kharroubi, A. Ouerdane, Mh. Bouslama, Mh. Guezzoul, Y. Caudano, K.B. Bensassi, M. Bousmaha, M.A. Bezzerrouk, A. Mokadem, M. Abdelkrim, Opt. Mater.Mater. 111, 110560 (2021)

S. Vempati, J. Mitra, P. Dawson, Nanoscale Res. Lett. 7, 1–10 (2012)

M. Abdelkrim, Mh. Guezzoul, M. Bedrouni, Mh. Bouslama, A. Ouerdane, B. Kharroubi, J. Alloys Compd. 920, 165703 (2022)

B. Pal, D. Sarkar, P.K. Giri, Appl. Surf. Sci. 356, 804–811 (2015)

Q.P. Wang, D.H. Zhang, H.L. Ma, X.H. Zhang, X.J. Zhang, Appl. Surf. Sci. 220, 12–18 (2003)

F. Stavale, N. Nilius, H.J. Freund, J. Phys. Chem. Lett.Lett. 4, 3972–3976 (2013)

A. Janotti, C.G. Van de Walle, Rep. Prog. Phys. 72, 126501 (2009)

T.M. Borseth, B.G. Svensson, A.Y. Kuznetsov, P. Klason, Q.X. Zhao, M. Willander, Appl. Phys. Lett. 89, 26 (2006)

Acknowledgements

This work is supported by National Natural Science Foundation of China (Project No. 11975173).

Funding

National Natural Science Foundation of China, 11975173, Jing Luo

Author information

Authors and Affiliations

Contributions

Hongyu Liu provided ideas and guided the design of research plans, and Jing Luo implemented the research process, collected and sorted out data and wrote a thesis. During the experiment, technical was supported by Rengang Zhang, Weijie Deng and Chen He.

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Luo, J., Liu, H., Deng, W. et al. The effect of Mg doping concentration and annealing on the structure and luminescence properties of ZnO thin films. J Mater Sci: Mater Electron 35, 744 (2024). https://doi.org/10.1007/s10854-024-12520-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12520-9