Abstract

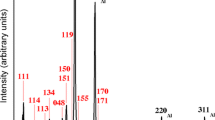

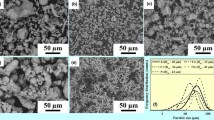

There has been considerable interest in Al-rich Al–Mn–Ce alloys due to the variety of crystalline and quasi-crystalline metastable phases that can be formed. Here we report a study of the effects of heat treatment on an Al–5Mn–2Ce (at.%) alloy processed by gas atomization and consolidated by warm extrusion. Characterization using X-ray diffraction and electron microscopy showed that the powder microstructure consists mainly of an amorphous phase, FCC Al, and a previously unreported phase, Al20Mn2Ce. The extrudate is fully devitrified and contains a mixture of FCC Al, Al20Mn2Ce, and Al6Mn, with a small amount of Al12Mn and Al11Ce3. Upon heat-treatment at up to 450 °C, the Al20Mn2Ce and Al6Mn phases decompose to give a hard stable phase mixture with 72–73 % Al12Mn plus 13–14 % each of Al11Ce3 and FCC Al. Heat treatments at 500 °C give a much softer phase mixture consisting of 60 % FCC Al, 22 % of an unknown Al3(Mn,Ce) phase, 9 % Al12Mn, 8 % Al6Mn, and 1 % Al11Ce3. The formation of large volume fractions of Al12Mn for heat-treatments at up to 450 °C suggests that the presence of Ce may stabilize this phase, and that more dilute Al–Mn–Ce compositions could form the basis for new high-strength, low-density Al-based alloys with enhanced elevated temperature properties.

Similar content being viewed by others

References

Saito Y, Tsuji N, Utsunomiya H, Sakai T, Hong RG (1998) Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process. Scripta Mater 39:1221–1227

Gholinia A, Prangnell PB, Markushev MV (2000) The effect of strain path on the development of deformation structures in severely deformed aluminum alloys processed by ECAE. Acta Mater 48:1115–1130

Furukawa M, Horita Z, Nemoto M, Langdon TG (2001) Review: processing of metals by equal-channel angular pressing. J Mater Sci 36:2835–2843. doi:10.1023/A:1017932417043

Valiev RZ, Langdon TG (2006) Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog Mater Sci 51:881–981

Zhilyaev AP, McNelley TR, Langdon TG (2007) Evolution of microstructure and microtexture in fcc metals during high-pressure torsion. J Mater Sci 42:1517–1528. doi:10.1007/s10853-006-0628-0

Parker BA, Zhou ZF, Nolle P (1995) The effect of small additions of scandium on the properties of aluminum-alloys. J Mater Sci 30:452–458. doi:10.1007/BF00354411

Norman AF, Prangnell PB, McEwen RS (1998) The solidification behavior of dilute aluminum–scandium alloys. Acta Mater 46:5715–5732

Marquis EA, Seidman DN (2001) Nanoscale structural evolution of Al3Sc precipitates in Al(Sc) alloys. Acta Mater 49:1909–1919

Novotny GM, Ardell AJ (2001) Precipitation of Al3Sc in binary Al–Sc alloys. Mater Sci Eng A 318:144–154

Royset J, Ryum N (2005) Scandium in aluminum alloys. Int Mater Rev 50:19–44

Belov NA, Alabin AN, Eskin DG, Istomin-Kastrovskii VV (2006) Optimization of hardening of Al–Zr–Sc cast alloys. J Mater Sci 41:5890–5899. doi:10.1007/s10853-006-0265-7

He Y, Poon SJ, Shiflet GJ (1988) Synthesis and properties of metallic glasses that contain aluminum. Science 241:1640–1642

Chen H, He Y, Shiflet GJ, Poon SJ (1991) Mechanical properties of partially crystallized aluminum based metallic glasses. Scripta Metal Mater 25:1421–1424

Greer AL (1995) Metallic glasses. Science 267:1947–1953

Inoue A, Kimura H (1997) High-strength Al-based nanostructure alloys. Curr Op Sol State Sci 2:305–310

Battezzati L, Kusy M, Rizzi P, Ronto V (2004) Devitrification of Al–Ni–rare earth amorphous alloys. J Mater Sci 39:3927–3934. doi:10.1023/B:JMSC.0000031473.19334.5b

Inoue A, Kimura H (2000) High-strength aluminum alloys containing nanoquasicrystalline particles. Mater Sci Eng, A A286:1–10

Shechtman D, Blech I, Gratias D, Cahn JW (1984) Metallic phase with long-range orientational order and no translational symmetry. Phys Rev Lett 53:1951–1953

Shechtman D, Blech I (1985) The microstructure of rapidly solidified Al6Mn. Met Trans 16A:1005–1012

Takeuchi S (1992) Mechanical properties of quasicrystals. Tetsu to Hagane 78:1517–1522

Hiraga K, Hirabayashi M, Inoue A, Masumoto T (1985) Icosahedral quasicrystals of a melt-quenched Al–Mn alloy observed by high-resolution electron microscopy. Sci Rep Res Inst Tohoku Univ 32:309–314

Kimura K, Hashimoto T, Suzuki K, Nagayama K, Ino H, Takeuchi S (1985) Stoichiometry of quasicrystalline Al-Mn. J Phys Soc 54:3217–3219

Watanabe M, Inoue A, Kimura HM, Aiba T, Masumoto T (1993) High mechanical strength of rapidly solidified Al92Mn6Ln2 (Ln = Lanthanide Metal) alloys with finely mixed icosahedral and Al phases. Mat Trans JIM 34:162–168

Schurack F, Eckert J, Schultz L (2003) Al–Mn–Ce quasicrystalline composites: phase formation and mechanical properties. Phil Mag 83:807–825

Schurack F, Eckert J, Schultz L (2001) Synthesis and mechanical properties of cast quasicrystalline-reinforced Al-alloys. Acta Mater 49:1351–1361

Schurack F, Eckert J, Schultz L (2000) Quasicrystalline Al-alloys with high strength and good ductility. Mater Sci Eng A 294:164–167

Inoue A, Watanabe M, Kimura HM, Takahashi F, Nagata A, Masumoto T (1992) High mechanical strength of quasicrystalline phase surrounded by fcc-Al phase in rapidly solidified Al–Mn–Ce alloys. Mater Trans JIM 33:723–729

Gordillo MA, Zhang LC, Watson TJ, Aindow M (2013) Effect of upset forging on microstructure and tensile properties in a devitrified Al–Y–Ni–Co alloy. J Mater Sci 48:3841–3851. doi:10.1007/s10853-013-7185-0

Villars P, Calvert LD (1991) Pearson’s handbook of crystallographic data for intermetallic phases. ASM, Materials Park

Nicol ADI (1953) The structure of MnAl6. Acta Cryst 6:285–293

Kontio A, Coppens P (1981) New study of the structure MnAl6. Acta Crystallogr A 37B:433–435

Adam J, Rich JB (1954) The crystal structure of WAl12, MoAl12 and (Mn, Cr)Al12. Acta Cryst 7:813–816

Buschow KHJ, van Vucht JHN (1967) Systematic arrangement of the binary rare–earth–aluminium systems. Philips Res Reports 22:233–245

Samson S (1958) The crystal structure of the intermetallic compound Mg3Cr2Al18. Acta Cryst 11:851–857

Black PJ (1955) The structure of FeAl3.1. Acta Cryst 8:43–45

Kontio A, Stevens ED, Coppens P, Brown RD, Dwight AE, Williams JM (1980) New investigation of the structure of Mn4Al11. Acta Cryst 36B:435–436

Krypyakevich PI, Zarechnyuk OS (1968) RCr2Al20 compounds in systems of rare earth metals and calcium, and their crystal structures. Dopov Akad Nauk Ukr RSR 30:364–367

McAlister AJ, Murray JL (1990) Al–Mn (Aluminum–Manganese). In: Massalski TB, Subramanian PR, Okamoto H, Kacprzak L (eds) Binary alloy phase diagrams, vol 1, 2nd edn. ASM International, Materials Park, pp 171–174

Ran Q (1991) Aluminium–cerium–manganese. In: Petzow G, Effenberg G (eds) Ternary alloys volume 4 Al–Cd–Ce to Al–Dy–Zr: a comprehensive compendium of evaluated constitutional data and phase diagrams. Wiley, Weinheim, pp 78–79

Little K, Raynor GV, Hume-Rothery W (1946) A new aluminum-rich phase in the alloys of aluminium and manganese. J Inst Met 73:83–90 and related correspondence with Marchand G, ibid: 747–749

Murray JL, McAlister AJ, Schaefer RJ, Bendersky LA, Biancaniello FS, Moffat DL (1987) Stable and metastable phase-equilibria in the Al–Mn system. Metal Trans A 18:385–392

McAlister AJ, Bendersky LA, Schaefer RJ, Biancaniello FS (1987) Transformation of the icosahedral phase in rapidly quenched Al-rich Al–Mn alloys. Scripta metal 21:103–106

Nes E, Naess SE, Hoier R (1972) Decomposition of an aluminium–manganese alloy. Z Metal 63:248–252

Shechtman D, Schaefer RJ, Biancaniello FS (1984) Precipitation in rapidly solidified alloys. Metal Trans 15A:1987–1997

Hansen V, Andersson B, Tibballs JE, Gjønnes J (1995) Metallurgical reactions in two industrially strip-cast aluminum–manganese alloys. Met Trans 26B:839–849

Jansson A (1992) A thermodynamic evaluation of the Al–Mn system. Met Trans 23A:2953–2962

Liu XJ, Ohnuma I, Kainuma R, Ishida K (1998) Thermodynamic assessment of the aluminum–manganese (Al–Mn) binary phase diagram. J Phase Equil 20:45–56

Schaefer RJ, Biancaniello FS, Cahn JW (1986) Formation and stability range of the G phase in the Al–Mn system. Scripta metal 20:1439–1444

Mula S, Ghosh S, Pabi SK (2009) On the formation of phases by mechanical alloying and their thermal stability in Al–Mn–Ce system. Powder Tech 191:176–181

Acknowledgements

This research was supported by Pratt & Whitney and the University of Connecticut Research Foundation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gordillo, M.A., Cernatescu, I., Aindow, T.T. et al. Phase stability in a powder-processed Al–Mn–Ce alloy. J Mater Sci 49, 3742–3754 (2014). https://doi.org/10.1007/s10853-014-8086-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8086-6