Abstract

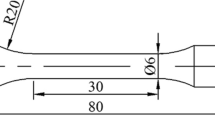

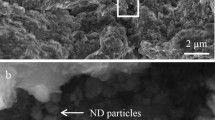

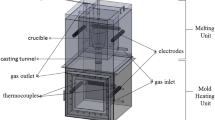

Zinc-nanodiamond (ND) composite is proposed as a novel biodegradable implant material due to its desirable corrosion, mechanical, and biocompatible properties. In this research, the microstructure, corrosion behavior, and mechanical properties of Zn-ND composites were investigated for the first time as a potential implant material in biomedical applications. Powder metallurgy manufacturing processes were used and different sintering conditions were studied. Grain size increased with increasing sintering temperature and longer sintering time. Corrosion resistance was improved 61.0, 65.9, and 70.7 % for 1, 2.5, and 5 % ND compared with pure Zn. Compression and hardness tests were performed to determine the mechanical properties. In the compression tests, Zn-1ND showed the highest Young’s modulus, with 10.95 and 27.32 % more than pure Zn and Zn-5ND. Pure Zn had the highest compressive strength, 11.8 and 29.5 % higher than Zn-1ND and Zn-2.5ND. Zn-1ND and Zn-2.5ND are 55.2 and 68.9 % lower in hardness compared with pure Zn (HV = 27). Compression-molded zinc with low concentrations of nanodiamond offers a promising combination of strength and low corrosion rate, and with strength approaching cortical bone and higher than most biological tissues.

Similar content being viewed by others

References

Zhang Y, Zhang G, Wei M (2009) Controlling the biodegradation rate of magnesium using biomimetic apatite coating. J Biomed Mater Res B Appl Biomater 89B(2):408–414

Witte F et al (2005) In vivo corrosion of four magnesium alloys and the associated bone response. Biomaterials 26(17):3557–3563

Vojtěch D et al (2011) Mechanical and corrosion properties of newly developed biodegradable Zn-based alloys for bone fixation. Acta Biomater 7(9):3515–3522

Tapiero H, Tew KD (2003) Trace elements in human physiology and pathology: zinc and metallothioneins. Biomed Pharmacother 57(9):399–411

Blencowe DK, Morby AP (2003) Zn(II) metabolism in prokaryotes. FEMS Microbiol Rev 27(2–3):291–311

Dardenne M (2002) Zinc and immune function. Eur J Clin Nutr 56:S20–S23

Samman S (2007) Zinc. Nutr Diet 64:S131–S134

Fosmire GJ (1990) Zinc toxicity. Am J Clin Nutr 51(2):225–227

Bowen PK, Drelich J, Goldman J (2013) Zinc exhibits ideal physiological corrosion behavior for bioabsorbable stents. Adv Mater 25(18):2577–2582

Bianco A, Kostarelos K, Prato M (2005) Applications of carbon nanotubes in drug delivery. Curr Opin Chem Biol 9(6):674–679

Bianco A (2004) Carbon nanotubes for the delivery of therapeutic molecules. Expert Opin Drug Deliv 1(1):57–65

Kam NWS, Dai H (2005) Carbon nanotubes as intracellular protein transporters: generality and biological functionality. J Am Chem Soc 127(16):6021–6026

Kam NWS et al (2005) Carbon nanotubes as multifunctional biological transporters and near-infrared agents for selective cancer cell destruction. Proc Natl Acad Sci USA 102(33):11600–11605

Schrand AM, Hens SAC, Shenderova OA (2009) Nanodiamond particles: properties and perspectives for bioapplications. Crit Rev Solid State Mater Sci 34(1–2):18–74

Schrand AM et al (2006) Are diamond nanoparticles cytotoxic? J Phys Chem B 111(1):2–7

Liu K-K et al (2007) Biocompatible and detectable carboxylated nanodiamond on human cell. Nanotechnology 18:32

Yuan Y et al (2010) Pulmonary toxicity and translocation of nanodiamonds in mice. Diam Relat Mater 19(4):291–299

Dewidar M, Yoon H-C, Lim J (2006) Mechanical properties of metals for biomedical applications using powder metallurgy process: a review. Met Mater Int 12(3):193–206

Clark GCF, Williams DF (1982) The effects of proteins on metallic corrosion. J Biomed Mater Res 16(2):125–134

Song G (2007) Control of biodegradation of biocompatable magnesium alloys. Corros Sci 49(4):1696–1701

Kokubo T, Takadama H (2006) How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 27(15):2907–2915

Cai S et al (2012) Effects of Zn on microstructure, mechanical properties and corrosion behavior of Mg–Zn alloys. Mater Sci Eng C 32(8):2570–2577

Wang W et al (2002) Influence of hot pressing sintering temperature and time on microstructure and mechanical properties of TiB2 ceramics. J Eur Ceram Soc 22(7):1045–1049

Yan G et al (1999) The effect of density on the corrosion of NdFeB magnets. J Alloy Compd 292(1–2):266–274

Roy TK et al (2008) Sintering studies of nano-crystalline zinc oxide. Ceram Int 34(1):81–87

Subramaniyan A et al (2011) Sintering studies on 20 mol% yttrium-doped barium cerate. J Am Ceram Soc 94(6):1800–1804

Panigrahi BB, Godkhindi MM (2006) Dilatometric sintering study of Ti–50Ni elemental powders. Intermetallics 14(2):130–135

Fang Z et al (2005) An experimental study of the sintering of nanocrystalline WC–Co powders. Int J Refract Metal Hard Mater 23(4–6):249–257

Fedorchenko IM (2009) Shrinkage of metal ceramic briquettes during sintering. Powder Metall Met Ceram 48(9–10):497–507

Ji CH et al (2001) Sintering study of 316L stainless steel metal injection molding parts using Taguchi method: final density. Mater Sci Eng A 311(1–2):74–82

Sukhanov MV, Pet’kov VI, Firsov DV (2011) Sintering mechanism for high-density NZP ceramics. Inorg Mater 47(6):674–678

Abdoli H et al (2010) Processing and surface properties of Al–AlN composites produced from nanostructured milled powders. J Alloy Compd 490(1–2):624–630

Torres CDS, Schaeffer L (2010) Effect of high energy milling on the microstruture and properties of WC–Ni composite. Mater Res 13:293–298

Hewitt SA, Kibble KA (2009) Effects of ball milling time on the synthesis and consolidation of nanostructured WC–Co composites. Int J Refract Metal Hard Mater 27(6):937–948

Sohn HY, Moreland C (1968) The effect of particle size distribution on packing density. Can J Chem Eng 46(3):162–167

Zhang T et al (2002) Sintering study on commercial CeO2 powder with small amount of MnO2 doping. Mater Lett 57(2):507–512

Yan J et al (2007) High-pressure sintering study of a novel hard material (W0.5Al0.5)C0.5 without binder metal. Int J Refract Metal Hard Mater 25(1):62–66

Stawarczyk B et al (2013) The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin Oral Invest 17(1):269–274

Zhang XG (1996) Corrosion and electrochemistry of zinc. Plenum, New York

Cachet C et al (2002) Relationship between zinc corrosion process and corrosion products: an EIS and Raman spectroscopy study. Electrochim Acta 47:3409–3413

Miao W et al (2007) Pitting corrosion of Zn and Zn–Al coated steels in pH 2 to 12 NaCl solutions. J Electrochem Soc 154(1):C7–C15

Hahn H, Logas J, Averback RS (1990) Sintering characteristics of nanocrystalline TiO2. J Mater Res 5(03):609–614

Jacobs JJ, Gilbert JL, Urban RM (1998) Current concepts review—corrosion of metal orthopaedic implants*. J Bone Joint Surg 80(2):268–282

Frankel GS (1998) Pitting corrosion of metals: a review of the critical factors. J Electrochem Soc 145(6):2186–2198

Kubásek J, Vojtěch D (2012) Zn-based alloys as an alternative biodegradable materials. Metal 5:23–25

Gu X et al (2010) Corrosion of, and cellular responses to Mg–Zn–Ca bulk metallic glasses. Biomaterials 31(6):1093–1103

Schrand AM et al (2007) Differential biocompatibility of carbon nanotubes and nanodiamonds. Diam Relat Mater 16(12):2118–2123

Sun J, Xie G (2011) Tissue distribution of intravenously administrated hydroxyapatite nanoparticles labeled with < sup > 125 </sup > I. J Nanosci Nanotechnol 11(12):10996–11000

Ruedi TP, Murphy WM, Principles AO (2001) Principles of fracture management. Thieme Medical, New York

Xu L et al (2007) In vivo corrosion behavior of Mg–Mn–Zn alloy for bone implant application. J Biomed Mater Res Part A 83A(3):703–711

Zhang S et al (2010) Research on an Mg–Zn alloy as a degradable biomaterial. Acta Biomater 6(2):626–640

Zhang E et al (2008) Microstructure, mechanical properties and corrosion properties of Mg–Zn–Y alloys with low Zn content. Mater Sci Eng A 488(1–2):102–111

Chang J-W et al (2011) Influence of Nd and Y additions on the corrosion behaviour of extruded Mg–Zn–Zr alloys. Int J Miner Metall Mater 18(2):203–209

Gu X-N, Zheng Y-F (2010) A review on magnesium alloys as biodegradable materials. Front Mater Sci China 4(2):111–115

Zhang BP, Wang Y, Geng L (2011) Research on Mg–Zn–Ca alloy as degradable biomaterial. In: Pignatello R (ed) Biomaterials—Physics and chemistry. InTech, pp 183–204

Hansen N (2004) Hall–Petch relation and boundary strengthening. Scripta Mater 51(8):801–806

Razavi M, Fathi MH, Meratian M (2010) Microstructure, mechanical properties and bio-corrosion evaluation of biodegradable AZ91–FA nanocomposites for biomedical applications. Mater Sci Eng A 527(26):6938–6944

Zadražil T, Vodák F, Kapičková O (2004) Effect of temperature and age of concrete on strength–porosity relation. Acta Polytech 44:1

Mahfuz H et al (2007) Reinforcement of nylon-6 filaments with SiO2 nanoparticles and comparison of Young’s modulus with theoretical bounds. Macromol Mater Eng 292(4):437–444

Vijh A (1975) The influence of metal–metal bond energies on the adhesion, hardness, friction and wear of metals. J Mater Sci 10(6):998–1004. doi:10.1007/bf00856987

Yanson KA et al (1973) Hardness of the human tibia. Polym Mech 9(6):966–971

Porter FC (1991) Zinc handbook: properties, processing, and use in design. Mechanical engineering. Marcel Dekker, New York

Cheng J et al (2013) Comparative in vitro study on pure metals (Fe, Mn, Mg, Zn and W) as biodegradable metals. J Mater Sci Technol 29(7):619–627

Brar HS, Wong J, Manuel MV (2012) Investigation of the mechanical and degradation properties of Mg–Sr and Mg–Zn–Sr alloys for use as potential biodegradable implant materials. J Mech Behav Biomed Mater 7:87–95

Hänzi AC, Sologubenko AS, Uggowitzer PJ (2009) Design strategy for new biodegradable Mg–Y–Zn alloys for medical applications. Int J Mater Res 8:1127–1136

Hung F-Y et al (2007) Vibration behavior of light metals: Al–Zn alloy and Mg–Al–Zn alloy. J Mater Sci 42(13):5020–5028. doi:10.1007/s10853-006-0595-5

He S-Y et al (2011) Microstructure and properties of biodegradable β-TCP reinforced Mg–Zn–Zr composites. Trans Nonferr Met Soc China 21(4):814–819

Acknowledgements

The authors would like to express the sincere appreciation to Dr. Haifeng (Frank) Ji and Dr. Richard Chiou at Drexel University for providing experimental facilities, assistance, and thoughtful scientific discussions in this Project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, M., George, C., Cao, Y. et al. Microstructure, corrosion, and mechanical properties of compression-molded zinc-nanodiamond composites. J Mater Sci 49, 3629–3641 (2014). https://doi.org/10.1007/s10853-014-8066-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8066-x