Abstract

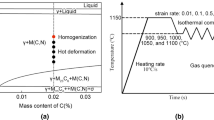

Severe plastic deformation methods include equal-channel angular pressing/extrusion, high-pressure torsion, and plane strain machining. These methods are extremely effective in producing bulk microstructure refinement and are generally initiated at a low homologous temperature. The resulting deformation-induced microstructures exhibit progressively refined cellular dislocation structures during the initial stages of straining that give way to refined, equiaxed grain structures at larger strains. Often, grain refinement appears to saturate but frequently coarsening is observed at the largest strains after a minimum in grain size is attained during SPD. Here, we summarize results on grain refinement by these processing methods and provide an analysis that incorporates adiabatic heating to explain the progressive refinement to intermediate strains and that may be followed either by an apparent saturation in grain refinement or by grain coarsening at the largest strains. This analysis is consistent with continuous dynamic recrystallization in the absence of the formation and long-range migration of high-angle boundaries.

Similar content being viewed by others

References

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Prog Mater Sci 45:103

Segal VM, Reznikov VI, Drobyshevskiy AE, Kopylov VI (1981) Russ Metal 1:99

Valiev RZ, Langdon TG (2006) Prog Mater Sci 51:881

Iwahashi Y, Horita Z, Nemoto M, Langdon TG (1997) Acta Mater 45:4733

Iwahashi Y, Horita Z, Nemoto M, Langdon TG (1998) Acta Mater 46:3317

Zhilyaev AP, Kim BK, Szpunar JA, Baró MD, Langdon TG (2005) Mater Sci Eng A 391:377

Zhilyaev AP, Swisher DL, Oh-ishi K, Langdon TG, McNelley TR (2006) Mater Sci Eng A 429:137

Zhilyaev AP, Langdon TG (2008) Prog Mater Sci 53:893

Bridgman PW (1943) J Appl Phys 14:273

Bridgman PW (1952) Studies in large plastic flow and fracture. McGraw-Hill, New York

Merchant ME (1945) J Appl Phys 16:267

Edalati K, Horita Z (2011) Acta Mater 59:6831

Kim HS (2009) Mater Sci Eng A 503:130

Yamaguchi D, Horita Z, Nemoto M, Langdon TG (1999) Scripta Mater 41:791

Zhilyaev AP, García-Infanta JM, Carreño F, Langdon TG, Ruano OA (2007) Scripta Mater 57:763

Todaka Y, Umemoto M, Yamazaki A, Sasaki J, Tsuchiya K (2008) Mater Trans 49:7

Shaw MC (1984) Metal cutting principles. Oxford University Press, Clarendon

Iwahashi Y, Wang J, Horita Z, Nemoto M, Langdon TG (1996) Scripta Mater 35:143

Polakowski NH, Ripling EJ (1966) Strength and structure of engineering materials. Prentice-Hall, Englewood Cliffs

Onaka S (2010) Phil Mag Let 90:633

Brown TL, Swaminathan S, Chandrasekar S, Compton WD, King AH, Trumble KP (2002) J Mater Res 17:2484

Swaminathan S, Shankar WD, Lee L, Hwang J, King AH, Kezar RF, Rao BC, Brown TL, Chandrasekar S, Compton WD, Trumble KP (2005) Mater Sci Eng A 410–411:358

Swaminathan S, Brown TL, Chandrasekar S, McNelley TR, Compton WD (2007) Scripta Mater 56:1047

Terhune SD, Swisher DL, Oh-ishi K, Horita Z, Langdon TG, McNelley TR (2002) Metall Trans A 33:2173

Oh-ishi K, Zhilyaev AP, McNelley TR (2005) Mater Sci Eng A 410–411:183

Zhilyaev AP, Oh-ishi K, Langdon TG, McNelley TR (2005) Mater Sci Eng A 410–411:277

Zhilyaev AP, Swaminathan S, Raab GI, McNelley TR (2006) Scripta Mater 55:931

Zhilyaev AP, McNelley TR, Langdon TG (2007) J Mater Sci 42:1517. doi:10.1007/s10853-008-2624-z

Zhilyaev AP, Swaminathan S, Gimazov AA, McNelley TR, Langdon TG (2008) J Mater Sci 43:7451. doi:10.1007/s10853-012-6429-8

Korznikova EA, Mironov SY, Korznikov AV, Zhilyaev AP, Langdon TG (2012) Mater Sci Eng A 556:437

Sherby OD, Burke PM (1967) Prog Mater Sci 13:325

Sherby OD, Wadsworth J (1984) Deformation processing and microstructure. ASM International, Materials Park

Vorhauer A, Pippan R (2008) Metall Mater Trans A 39:417

Pippan R, Scheriau S, Taylor A, Hafok M, Hohenwarter A, Bachmaier A (2010) Annu Rev Mater Res 40:319

Hall EO (1951) Proc Phys Soc B 64:742

Petch NJ (1953) J Iron Steel Inst 174:25

Nieh TG, Wadsworth J (1991) Scripta Metall Mater 25:955

Eckert J, Holzer J, Krill C, Johnson W (1992) J Mater Res 7:1751

Greer JR, Dongchan J, Gu XW (2012) J Metals 64:1241

Frost HJ, Ashby MF (1982) Deformation-mechanism maps. Pergamon Press, Oxford

Zhilyaev AP, Lee S, Nurislamova GV, Valiev RZ, Langdon TG (2001) Scripta Mater 44:2753

Zhilyaev AP, Nurislamova GV, Kim B-K, Baró MD, Szpunar JA, Langdon TG (2003) Acta Mater 51:753

Zhilyaev AP, Kim B-K, Nurislamova GV, Baró MD, Szpunar JA, Langdon TG (2002) Scripta Mater 46:575

Zhilyaev AP, Gimazov AA, Soshnikova EP, Révész A, Langdon TG (2008) Mater Sci Eng A 489:207

Acknowledgements

Partial support for this work was provided by the U.S. Air Force Office of Scientific Research (Contract F1ATA06058G001, 2006-09, B. Conner, Scientific Officer). SS acknowledges support under the U.S. National Research Council Postdoctoral Fellowship Program at the Naval Postgraduate School. TGL and APZ acknowledge support by the European Research Council under ERC Grant Agreement No. 267464-SPDMETALS.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhilyaev, A.P., Swaminathan, S., Pshenichnyuk, A.I. et al. Adiabatic heating and the saturation of grain refinement during SPD of metals and alloys: experimental assessment and computer modeling. J Mater Sci 48, 4626–4636 (2013). https://doi.org/10.1007/s10853-013-7254-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7254-4