Abstract

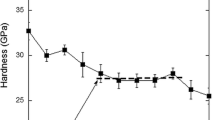

Concentrated heating of titanium by a focused laser beam in ambient atmosphere produces unique dielectric layers with characteristic colors dictated by film thickness and optical properties. A combination of microscopy and diffraction techniques employed to study the phase and microstructure of the oxide coatings showed that nanosecond-pulsed laser irradiation produces polycrystalline TiO films and underlying Ti6O interfacial layers. Mudflat cracking was prevalent in all coatings with most cracks extending through thickness to the metal substrate. Deformation and fracture behavior were probed by traditional nanoindentation methods with accompanying electron microscopy. These mixed titanium oxide coatings have moduli (~200 GPa) and hardnesses (~16 GPa) that are larger than the underlying metallic substrates. Fracture energies and residual stress have also been determined from pre-cracked films; fracture toughness and residual stress tend to decrease with decreasing laser fluence. Electrical contact resistance, measured with conductive nanoindentation, indicates a correlation between laser exposure, current–voltage behavior at constant load, and indentation response. Film conductance increases with decreasing laser fluence, likely due to the presence of defects, which act as a conduction path. Combining techniques provide a unique approach for defining electromechanical behavior and the resulting performance of the films in conditions that cause wear.

Similar content being viewed by others

References

Wautelet M (1990) Appl Phys A 50:131. doi:10.1007/BF00343408

Hongyu Z (2001) SIMTech Technical Report PT/01/005/AM. Singapore Institute of Manufacturing Technology, Singapore

Pérez del Pino A, Fernández-Pradas J, Serra P, Morenza J (2004) Surf Coat Technol 187:106. doi:10.1016/j.surfcoat.2004.02.001

Gyorgy E, Perez del Pino A, Serra P, Morenza JL (2004) Appl Phys A 78:765. doi:10.1007/s00339-002-2054-8

Wong MH, Cheng FT, Man HC (2007) Mater Lett 61:3391. doi:10.1016/j.matlet.2006.11.081

Pérez del Pino A, Serra P, Morenza J (2002) Thin Solid Films 415:201. doi:10.1016/S0040-6090(02)00632-6

Yilbas BS, Shuja SZ, Hashmi MSJ (2003) J Mater Process Technol 136:12. doi:0.1016/S0924-0136(02)00812-9

Drory MD, Thouless MD, Evans AG (1988) Acta Metall 36:2019. doi:10.1016/0001-6160(88)90303-3

Thouless MD (1990) Thin Solid Films 181:270. doi:10.1016/0040-6090(89)90508-7

Thouless MD, Olsson E, Gupta A (1992) Acta Metall Mater 40:1287. doi:10.1016/0956-7151(92)90429-I

Hu MS, Evans AG (1989) Acta Metall 37:917. doi:10.1016/0001-6160(89)90018-7

Thouless M (1990) J Am Ceram Soc 73:2144. doi:10.1111/j.1151-2916.1990.tb05290.x

Schuh CA (2006) Mater Today 9:32. doi:10.1016/S1369-7021(06)71495-X

Oliver WC, Pharr GM (1992) J Mater Res 7:1564. doi:10.1557/JMR.1992.1564

Whitehead A, Page T (1992) Thin Solid Films 220:277. doi:10.1016/0040-6090(92)90585-Y

Gerberich WW, Nelson JC, Lilleodden ET, Anderson P, Wyrobek JT (1996) Acta Mater 44:3585. doi:10.1016/1359-6454(96)00010-9

Hainsworth S, McGurk M, Page T (1998) Surf Coat Technol 102:97. doi:10.1016/S0257-8972(97)00683-X

Bahr DF, Kramer DE, Gerberich WW (1998) Acta Mater 46:3605. doi:10.1016/S1359-6454(98)00024-X

Rodriguez-Marek D, Bahr D, Pang M (2003) Metall Mater A 34:1291. doi:10.1007/s11661-003-0240-8

Boxley CJ, White HS, Gardner CE, Macpherson JV (2003) J Phys Chem 107:9677. doi:10.1021/jp034874u

Pang M, Eakins DE, Norton MG, Bahr DF (2001) Corrosion 57:523. doi:10.5006/1.3290378

Jiang HG, Rühle M, Lavernia EJ (2011) J Mater Res 14:549. doi:10.1557/JMR.1999.0079

Scherrer P (1918) Nachr Ges Wiss Göttingen 26:98

Bartkowski S, Neumann M, Kurmaev E, Fedorenko V, Shamin S, Cherkashenko V, Nemnonov S, Winiarski A, Rubie D (1997) Phys Rev B 56:10656. doi:10.1103/PhysRevB.56.10656

Kramer D, Huang H, Kriese M, Robach J (1998) Acta Mater 47:333. doi:10.1016/S1359-6454(98)00301-2

Tabor D (1951) The hardness of metals. Clarendon Press, Oxford

Morasch KR, Bahr DF (2007) Thin Solid Films 515:3298. doi:10.1016/j.tsf.2006.01.043

Bahr DF, Woodcock CL, Pang M, Weaver KD, Moody NR (2003) Int J Fract 119(120):339. doi:10.1023/A:1024979030155

Li J, Forberg S, Hermansson L (1991) Biomaterials 12:438. doi:10.1016/0142-9612(91)90015-3

Latella BA, Gan BK, Li H (2007) Surf Coat Technol 201:6325. doi:10.1016/j.surfcoat.2006.11.037

Thouless MD (1995) Annu Rev Mater 25:69. doi:10.1146/annurev.ms.25.080195.000441

Khan RHU, Yerokhin AL, Matthews A (2008) Philos Mag 88:795. doi:10.1080/14786430801968603

Lee C-C, Chen H-C, Jaing C-C (2006) Appl Opt 45:3091. doi:10.1364/AO.50.001945

Major B, Ebner R, Zieba P, Wolczynski W (1999) Appl Phys A 923:921. doi:10.1007/s003399900273

Kennedy MS, Moody NR, Adams DP, Clift M, Bahr DF (2008) Mater Sci Eng A 493:299. doi:10.1016/j.msea.2007.09.081

Nowak R, Chrobak D, Nagao S (2009) Nat Nanotechnol 4:287. doi:10.1038/nnano.2009.49

Holleman AF, Wiberg E (2001) Inorganic chemistry. Academic Press, San Diego

Kofstad P (1972) Nonstoichiometry, diffusion, and electrical conductivity in binary metal oxides. Wiley-Interscience, New York

Lawrence SK, Stauffer DD, Major RC, Adams DP, Gerberich WW, Bahr DF, Moody NR (2012) MRS Proc 1424:73. doi:10.1557/opl.2012.819

Huisman L, Carlsson A, Gelatt CD Jr, Ehrenreich H (1980) Phys Rev B 22:991. doi:10.1103/PhysRevB.22.991

Valeeva A, Rempel A, Sprengel W, Schaefer H-E (2007) Phys Rev B 75:3. doi:10.1103/PhysRevB.75.094107

Acknowledgements

This work was supported by the Defense Threat Reduction Agency, Basic Research Award # IACRO 10-4257I and by Sandia National Laboratories, a Lockheed Martin Company for the USDOE NNSA under contract DE-AC04-94AL85000. The authors would like to thank Mark Rodriguez, Paul Kotula, Vitalie Stavila, and Ray Friddle for their work and helpful discussions on microscopy and XRD.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lawrence, S.K., Adams, D.P., Bahr, D.F. et al. Deformation and fracture of a mudflat-cracked laser-fabricated oxide on Ti. J Mater Sci 48, 4050–4058 (2013). https://doi.org/10.1007/s10853-013-7217-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7217-9