Abstract

The aim of this work was to verify the influence of graphite and wood-based fillers on the flammability of flexible polyurethane foams (FPF). Expandable graphite (EG) and cellulose (C) fillers were added to FPFs to improve their thermal stability and reduce their flammability. Four types of foams have been compared: FPF, FPF with the addition of EG, FPF with the addition of C and FPF with the addition of both fillers. Linear flammability tests and pyrolysis combustion flow calorimetry (PCFC) were performed to assess the flammability of these materials. It was found that the addition of cellulose does not improve the fire reaction, but a combination of both the EG and C fillers mixed together was able to achieve a small reduction in flammability, as confirmed by a linear flammability test and PCFC. The best properties observed by PCFC were from FPFs with EG. Usage of cellulose filler separately is not a good method for the assessment of higher thermal stability and lower flammability of FPFs. Thermal properties were measured by thermogravimetric analysis and dynamic mechanical analysis. These results showed that especially EG addition allows to achieve a positive effect on the thermal stability of the tested materials. Mechanical and physical tests (density, hardness, flexibility and irreversible strain) showed that the presence of graphite or cellulose filler results in changes in the properties of the FPFs, but these changes are not extensive. Fourier transform infrared spectroscopy analysis showed that only small changes exist in the chemical structure with the addition of the fillers. The introduction of EG and EG+C fillers into an FPF may reduce its flammability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Flexible polyurethane foams (FPF) encompass a wide range of polyurethanes and have their largest applications as foams in the automotive, furniture, building and packaging industries. They are commonly used in mattresses, chairs, couches, cleaning products, car and aircraft upholstery [1–5]. These foams have many advantages such as wide range of flexibility and hardness, good cushioning, high durability in use, ease of moulding, assembly and joining, low density and hence low price. Moreover, it is possible to simply changing many parameters, by changing the recipe of foam preparation. These advantages allow to produce foams adjusted to the customer needs. The FPFs used by the transport industry, in public buildings and in residential buildings are required to fulfil all safety standards; the standards related to fire protection and acceptable levels of flammability are particularly important because FPFs tend to have high flammabilities and high degrees of toxic fumes emitted during combustion. The decomposition of polyurethanes starts above 200 °C and is always accompanied by the emission of toxic fumes and smoke. The amount of smoke evolved during combustion depends on many factors including the ambient temperature, the type of ignition, the type of combustion and the availability of oxygen. This smoke is extremely dangerous to human life and health. It is estimated that smoke is the cause of death for about 80 % of fire victims. Currently, every public and residential building is comprised of almost 25 % polymer materials, and consequently, there is a huge risk in the case of fire [6]. For this reason, research is being carried out on the improvement of the fire reaction of FPFs. One very popular method for reduction of the flammability of FPFs is the addition of flame retardants. There are two basic types of these chemicals: reactive flame retardants (introduced during the polymerisation stage and copolymerised with other monomers) and additive flame retardants (introduced during compounding) [7]. In this study, we use additive flame retardants. Expandable graphite (EG) and cellulose (Lignocel C-120) fillers were used to obtain FPFs with reduced flammability. The aim of this work was also to examine the effect of the addition of these fillers on the other properties of the FPFs. Some studies were conducted in this area in last few years, but generally there is not much publications and achievements associated with fire resistant flexible polyurethane foams with cellulose and expandable graphite addition. In recent years, EG has been applied as a flame retardant additive to refractory coatings, bituminous coatings and fireproof sealings. Much research has been carried out regarding the use of EG as a flame retardant in polymer materials [8–15]. The primary advantage of EG is its low price, high resistance and chemical inertness and lack of risk of interaction with materials or catalysts [16]. EG is also environmentally friendly, safe and physiologically neutral. Cellulose is a raw material used in the textile and paper industries as well as in the production of plastics. Lignocel C-120 is a type of cellulose in the form of a soft wood pulp that was designed to modify plastic. In recent years, research has been carried out on the possibility of using cellulose to modify the properties of polyurethanes and polyurethane foams [17–19]. To assess the possibilities of improving the fire reaction of foams, linear flammability tests and pyrolysis combustion flow calorimetry (PCFC) were developed. PCFC is a useful technique for determining the basic fire hazard potential of samples on the mg scale. PCFC was developed by Richard E. Lyon, Richard N. Walters and co-workers at the Federal Aviation Administration (FAA) to assess the flammability of polymer materials. PCFC simulates anaerobic pyrolysis during flaming combustion. Anaerobic pyrolysis occurs in the condensed phase, and the oxidation of volatile pyrolysis products in the gas phase. This technique measures the heat release rate by monitoring the oxygen consumption of samples during combustion [20–26]. Other measurements were also carried out to assess the influence of fillers on the mechanical properties of the foams.

Experimental

Materials

The following materials were examined: flexible polyurethane foam (FPF), flexible polyurethane foam with the addition of 5 wt% expandable graphite (FPF+EG), flexible polyurethane foam with the addition of 5 wt% cellulose Lignocel C-120 (FPF+C) and flexible polyurethane foam with the addition of both fillers—2.5 wt% expandable graphite and 2.5 wt% cellulose (FPF+EG+C). Expandable graphite with a particle size of approximately 0.18 mm and an expansion of approximately 250 was obtained from Sinograf. Other parameters of the expandable graphite are as follows: carbon content—90.98 %, ash content—9.02 %, sulphur content—1,400 ppm, moisture—0.49 % and pH—7.02. The expansion temperature is between 150 and 200 °C, which was confirmed by thermogravimetric analysis (TGA). The expandable graphite can withstand temperatures up to 2,500 °C. The Cellulose Lignocel C-120 was obtained from JRS-J. Rettenmaier and Söhne GMBH+CO.KG. The parameters of this type of cellulose are as follows: particle size is 70–150 μm, humidity ≤6 % and bulk density 100–145 g/l. All foams were produced in Zachem S.A., and they were prepared by the one-shot method. The only difference between producing standard foams and foams with fillers was that part of polyol was mixed with specified quantities of filler using a mechanical stirrer at the beginning of foam production. Then, this mixture was later mixed with the rest of the polyol. All subsequent steps were similar to the foams with and without fillers according to the one-shot method. The components used to prepare the foams used in this study are presented in Table 1. Arcol Polyol 1108 (Bayer Materials Science) is a trifunctional polyether polyol used in the production of polyurethane products; it has a hydroxyl number of 48 ± 2 mg KOH/g (according to PET-11-01), a maximum water content of 0.1 % by wt. (according to PET-19-01), its density at 20 °C is approximately 1.02 g/cm3 (according to DIN 51757) and it has a viscosity at 25 °C of 675 ± 80 mPa*s (according to PET-10-01). Toluene diisocyanate (TDI), surfactants and catalyst were obtained from Zachem S.A.

Measurement and characterisation

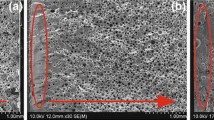

Scanning electron microscopy (SEM)

SEM was used to observe the structure of the fillers used in this study. SEM observations were carried out using a Hitachi TM3000 microscope. The samples of the fillers were covered with a gold layer to obtain better conductivity. A series of images at different magnifications were performed.

Linear flammability

Linear flammability tests were carried out to assess the fire reaction of the flexible polyurethane foams examined in this study. Samples were exposed to the action of a low energy flame. The time taken to extinguish the flame or the time to burn all the foam was determined in this test. Linear flammability tests were carried out in accordance with PN ISO 3795:1996.

Pyrolysis combustion flow calorimeter (PCFC)

The PCFC test was performed to assess the fire behaviour of the FPFs. Samples were heated at a rate of 1 °C/s–750 °C in O2/N2 at a rate of 20/80 cm3/min. The PCFC test was carried out in accordance with ASTM D7309-2007.

Thermogravimetric analysis (TGA)

TGA was carried out using a TA instruments TGA Q500, to assess the thermal stability of the FPFs examined in this study. The TGA data were obtained in N2 with a heating rate of 10 °C/min from room temperature to 600 °C. Initial samples' weights were approximately 10 mg.

Dynamic mechanical analysis (DMA)

Dynamic mechanical analysis was carried out in a DMA Q800 TA instrument. The analyses were performed at a frequency of 5 Hz with a heating rate of 3 °C/min over temperatures from −100 to 60 °C. Samples with dimensions of 10 × 10 × 5 mm were tested using a compression clamp.

Transform infrared spectroscopy (FT-IR)

FT-IR was performed on a Nicolet 6700 FT-IR to assess the influence of the fillers on the chemical structure of the FPFs. The samples were scanned over a wavenumber range of 4,000–400 cm−1. Analysis of the spectra was completed by Omnic spectrum analyser software.

Using the FTIR spectra of the foams, the degree of phase separation (DPS) was determined by analysing the intensities of the carbonyl stretching vibrations of the free and hydrogen-bonded groups. A straight baseline was then drawn on the spectrum between 1,760 and 1,620 cm−1, and the carbonyl stretching zone was corrected by subtracting the baseline. To estimate the signal strengths, peak modelling of the infrared active carbonyl bonds was carried out by the Gaussian curve-fitting method in the Omnic spectrum analyser software. The carbonyl absorption bonds were deconvoluted with a number of iterations to get the best absorbance fits. From the intensities of the characteristic absorbances (A), the degree of phase separation was calculated through Eq. (1), according to Pretsch et al. [27].

Physical and mechanical measurements

The apparent density tests were carried out in accordance with PN-77/C-05012.03 (corresponds to the PN-EN ISO 845:2000). The value of the apparent density was calculated as a mass/volume ratio. Hardness tests were carried out in a Zwick machine in accordance with PN-EN ISO 3386-1:2000. The foams examined had sizes of 100 × 100 × 50 mm. Flexibility tests were carried out in accordance with PN C 04255:1997 (corresponds to the PN-EN ISO 8307:2008). Sample sizes of 80 × 80 × 50 mm were used. Three foams of each material were measured. Irreversible strain tests were carried out in accordance with PN-77/C-05012.10 (corresponds to the PN-EN ISO 1856:2004).

Results and discussion

SEM observations

The structures of the fillers used in this study (EG and C) are shown in Fig. 1. The images presented have magnifications of ×100 and ×500. It can be observed that the expandable graphite occurs in the form of plates with sizes from approximately 100 to 300 μm. Cellulose fillers were found to occur in the form of fibres with different sizes from approximately 50 to 250 μm in length and from 10 to 40 μm in width.

Linear flammability test

The linear flammability results show that the use of expandable graphite or cellulose fillers does not improve the fire reaction of the flexible polyurethane foams, but the addition of both these fillers together allows to obtain lower values of linear flammability (Table 2). Thus, in the case of the combination of EG and C fillers in the foam, it is possible to obtain a synergistic effect of these two fillers. However, this measurement has high level of inaccuracy, so other measurements are needed to confirm these results.

PCFC measurements

The results of the PCFC measurements are presented in Fig. 2. The heat release rate curves were determined in relation to time for this test. It can be observed that both peaks in the curves are shifted towards higher values for testing times of foams modified by the addition of EG, C or EG+C. In addition, the time to start the first decomposition step (first peak on curves) is slightly longer for the modified foams in comparison to the pure foam (FPF). FPFs release heat in two decomposition steps. The first peak (peak 1) occurs over 150–250 s and the second peak occurs over 270–370 s. These data correspond to the thermograms obtained from TGA, which are presented in the next part of this study in Fig. 4. Some characteristic values were obtained from the PCFC measurements, including the heat release rate (HRR), the time that we can observe the peak of the heat release rate (tHRR) and the temperature that we can observe the peak of the heat release rate (THRR). The heat release rates are proportional to the mass loss rate represented by the steepness in the TGA curves during decomposition of the material [2, 25]. Values for the heat release capacity (HRC) were also obtained. The HRC describes the potential of a material to release heat while burning, and is considered as a key parameter in determining the fire reaction of materials tested by PCFC [25, 26]. These results are presented in Table 3. The longest time needed to achieve peak 1 (tHRR1) was obtained with FPF+C and FPF+EG+C (including the standard deviations values). FPF+EG had tHRR1 value higher than FPF, but it was within the standard deviations value. The temperature required to achieve peak 1 (THRR1) was the highest for foams with cellulose, but the THRR1 value for FPF+EG+C was only 0.17 % lower than that of FPF+C. However, including the standard deviations, only FPF+EG+C obtained THRR1 value higher than FPF. The heat release capacity for peak 1 (HRC1) increased in foams with additives (the highest was observed to FPF+C, but including standard deviations only FPF+EG+C obtained higher HRC1 value than FPF). Similar results were observed for peak 2. The HRC value is higher in foams with additives; only the addition of EG leads to a decrease in this value. When comparing the THRRmax values, the addition of any filler leads to a decrease in this value. However, this measurement does not indicate the best way to modify the FPFs. Taking HRC values as the primary criterion for assessment, the best modification is through the addition of an EG filler. However, looking at the whole of the results, the best properties come from FPF+EG+C. These results may be caused by different properties of tested fillers. Cellulose filler tends to be easily burning, while expandable graphite is known as a filler, which absorbs heat and leads to the reduction of the HRRmax value. The addition of 5 wt% of EG is not sufficient to form intumescent char layer in FPF during combustion, but it seems to be some kind of barrier which protect material against fast burning.

Thermogravimetric analysis (TGA)

The thermal stability of polymer materials can be estimated using TGA. TG curves of the foams are shown in Fig. 3, and DTG curves are shown in Fig. 4. FPFs display two main steps during degradation. The first step occurs around 280 °C, and the second step occurs around 380 °C. The first degradation step correlates with the maximum rate of decomposition of the hard domains (Tmax1), and the second degradation step correlates with the maximum rate of soft domain decomposition (Tmax2). It can be observed in Fig. 4 that the DTG curves of the modified foams have similar characteristics. The results of Tmax1 and Tmax2 of the foams are presented in Table 4. It is observed that addition of EG or C into FPF results in only slight changes in the values of these temperatures. This finding is most likely related to the small amount of filler used in this study. However, including standard deviations, it can be observed, that FPF+C has Tmax1 and Tmax2 values lower than FPF. The 5 % mass loss and 50 % mass loss temperatures were also determined from the TG curves presented in Fig. 3, and the data are listed in Table 4. The temperature corresponding to a 5 % mass loss is considered the temperature of the beginning of the sample decomposition process [28], but some sources claim that the 50 % mass loss is the correct value to establish the structural decomposition of the material under investigation [29]. The addition of EG, C or EG+C leads to a decrease in value of 5 % mass loss, implying that foams modified in this way have lower thermal stability than foams without modification. The temperature corresponding to a 50 % mass loss is correlated with the temperature of decomposition of the soft domains. Modified foams have higher value for this temperature, than FPF. The worst thermal stability was observed in foams with the addition of the cellulose filler. It is possible that the appearance of this type of filler in FPF causes an acceleration in the decomposition of the hard and soft segments in polyurethane foams via some impurities in this filler. It is also possible that cellulose makes some changes in structure of the polymer, which weakness interaction between polymer chains and leads to faster degradation. Better results obtained to FPF+EG, can be related to some kind of the impediment provided by EG, which starts expanding in temperatures between 150 and 200 °C and makes decomposition process being harder (low amount of EG used in these studies is not sufficient to form typical char layer and provide the barrier effect) [10].

Dynamic mechanical analysis (DMA)

DMA is a measurement of the mechanical properties of materials as a function of temperature or frequency. In this study, the storage modulus and glass transition temperature (Tg) were estimated. These results were obtained from DMA curves (Fig. 5) and are presented in Table 5. The addition of expandable graphite or cellulose fillers leads to an increase in the storage modulus value, especially in comparison with foam without any fillers. This parameter gives an indication of a materials ability to store energy, and the results obtained in this study show that the additives in the FPF help improve the overall energy absorption. From tan δ curves, Tg values were obtained. It was observed that the Tg values change over a very small temperature range, and all these changes are within standard deviation values. Therefore, only slight changes in the chemical structure of the tested foams are observed in this measurement.

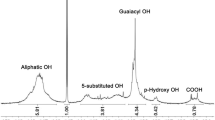

Fourier transform infrared spectroscopy (FT-IR)

The influence of added fillers on changes in the chemical structure of the foams was researched by Fourier transform infrared spectroscopy (FT-IR). The FT-IR spectra of the investigated materials are presented in Fig. 6. The addition of cellulose or expandable graphite into the flexible polyurethane foam does not have a great influence on the chemical structure of the tested foams. Some characteristic peaks are observed in these spectra, including the peak at 3,300 cm−1 (assigned to the stretching vibrations of the N–H bond), the peaks at 2,965 and 2,865 cm−1 (assigned to the vibrations of the asymmetric and symmetric C–H bond in CH2 groups, respectively), the peak at 1,730 cm−1 (assigned to stretching vibrations of hydrogen bonded C=O groups, amide I) and the peak at 1,085 cm−1 (assigned to the C–O–C stretching vibrations) [18, 30]. An additional peak at 2,270 cm−1 is observed in the spectra of each foam. This peak is assigned to the N=C=O bond, and it comes from unreacted isocyanates. However, it should be noted that these peaks show very small absorbances.

The introduction of EG brings about an increase in the degree of phase separation, while the introduction of C does not change DPS (Table 6). This finding indicates that EG helps to form a larger number of hydrogen bonds that link the carbonyl groups of urethane. The introduction of C does not change this bonding. When both additives are introduced, the DPS of the resulting foam is larger than that of the foam in its initial state.

Physical and mechanical measurements

Measurements of the physical and mechanical properties were carried out and the results are tabulated in Table 7. The addition of EG or C leads to a decrease in the value of the apparent density. This is a positive effect, especially when considering potential applications. Analysis of hardness results, allows to conclude that no significant changes are observed in foams with cellulose and expandable graphite addition. It could be related with relatively low amount of fillers used in this work, insufficient to modify this parameter. The flexibility of FPF decreases with the addition of any filler. This deterioration is lowest in FPF+EG and highest in FPF+C. The irreversible strain value decreases only for foam with the addition of EG. Addition of C or EG+C fillers leads to increasing in this value. The changes in values of physical and mechanical measurements, observed in foams with fillers, can be caused by influence of fillers on polyurethane properties. Fillers can be a barrier to macromolecules movement, but further researches are needed to verify this theory. Summarising the physical and mechanical measurements of the fillers tested in this study, the most optimal characteristics are obtained for modifications with EG or EG+C fillers; however, all the modification results in measurements are within acceptable norms.

Conclusions

The introduction of EG as a filler in polyurethane foams allows the achievement of the same level of thermal stability as found in PUR foams. The best properties observed from PCFC were with FPF+EG. Thus, the EG filler could be considered as an effective material for the improvement of the fire reaction in flexible polyurethane foams. The combination of EG and cellulose can reduce the flammability of FPF while maintaining the desired mechanical properties. This result was confirmed by linear flammability tests and partially through PCFC. TG analysis showed that mainly EG addition allows to achieve a positive effect on the thermal stability of the tested materials. Usage of the cellulose filler did not prove to be a good method to achieve higher thermal stability and better fire reaction for FPF. The introduction of EG and EG+C fillers into a flexible polyurethane foam may reduce its flammability, but further research is needed to verify these results.

References

Lefebvre J, Bastin B, Le Bras M, Duquesne S, Ritter C, Paleja R, Poutch F (2004) Polym Test 23:281

Krämer RH, Zammarano M, Linteris GT, Gedde UW, Gilman JW (2010) Polym Degrad Stab 95:1115

You KM, Park SS, Lee CS, Kim JM, Park GP, Kim WN (2011) J Mater Sci 46:6850. doi:10.1007/s10853-011-5645-y

Lefebvre J, Bastin B, Le Bras M, Duquesne S, Paleja R, Delobel R (2005) Polym Degrad Stab 88:28

Mello D, Pezzin SH, Amico SC (2009) Polym Test 28:702

Janowska G, Przygocki W, Włochowicz A (2007) Palność polimerów i materiałów polimerowych. WNT, Warszawa

NN (2003) Plast Addit Compd 2:18

Fukushima K, Murariu M, Camino G, Dubois P (2010) Polym Degrad Stab 95:1063

Kuan C-F, Yen W-H, Chen C-H, Yuen S-M, Kuan H-C, Chiang C-L (2008) Polym Degrad Stab 93:1357

Modesti M, Lorenzetti A (2002) Polym Degrad Stab 78:167

Shiha Y-F, Wang Y-T, Jeng R-J, Wei K-M (2004) Polym Degrad Stab 86:339

Duquesne S, Delobel R, Le Bras M, Camino G (2002) Polym Degrad Stab 77:333

Modesti M, Lorenzetti A (2003) Eur Polym J 39:263

Modesti M, Lorenzeti A, Simioni F, Camino G (2002) Polym Degrad Stab 77:195

Zhu H, Zhu Q, Li J, Tao K, Xue L, Yan Q (2011) Polym Degrad Stab 96:183

Duquesne S, Le Bras M, Bourbigot S, Delobel R, Camino G, Eling B, Lindsay C, Roels T (2001) Polym Degrad Stab 74:493

Rivera-Armenta JL, Heinze Th, Mendoza-Martinez AM (2004) Eur Polym J 40:2803

Abdel Hakim AA, Nassar M, Emam A, Sultan M (2011) Mater Chem Phys 129:301

Özgür Seydibeyoğlu M, Oksman K (2008) Compos Sci Technol 68:908

Lyon RE, Walters RN (2004) J Anal Appl Pyrolysis 71:27

Westmoreland PR, Inguilizian T, Rotem K (2001) Thermochim Acta 367–368:401

Jurs JL, Tour JM (2003) Polymer 44:3709

Shi Y, Kashiwagi T, Walters RN, Gilman JW, Lyon RE, Sogah DY (2009) Polymer 50:3478

Morgan AB, Douglas Wolf J, Guliants EA, Shiral Fernando KA, Lewis WK (2009) Thermochim Acta 488:1

Schartel B, Pawlowski KH, Lyon RE (2007) Thermochim Acta 462:1

Perret B, Schartel B (2009) Fire behaviour. Polym Degrad Stab 94:2204

Pretsch T, Jakob I, Muller W (2009) Polym Degrad Stab 94:61

Ge XG, Wang DY, Wang C, Qu MH, Wang JS, Zhao CS, Jing XK, Wang YZ (2007) Eur Polym J 43:2882

Mahfuz H, Rangari VK, Islam MS, Jeelani S (2004) Composites 35:453

Chunjing H, Guodong L, Haoxiong N, Jiaxiang N (2010) J Wuhan Univ Technol Mater Sci Ed. doi:10.1007/s11595-010-0134-8

Acknowledgements

These studies were supported by the National Center of Research and Development as a grant No N R15 0024 06/2009. Special thanks are directed to ZACHEM S.A. in Bydgoszcz and Institute of Natural Fibers and Medicinal Plants in Poznań for help in the realization of these studies.

Open Access

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Wolska, A., Goździkiewicz, M. & Ryszkowska, J. Influence of graphite and wood-based fillers on the flammability of flexible polyurethane foams. J Mater Sci 47, 5693–5700 (2012). https://doi.org/10.1007/s10853-012-6394-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6394-2