Abstract

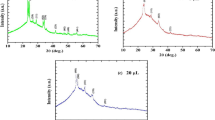

To find the percolation threshold for the electrical resistivity of metallic Ag-nanoparticle/titania composite thin films, Ag-NP/titania composite thin films, with different volumetric fractions of silver (0.26 ≤ φAg ≤ 0.68) to titania, were fabricated on a quartz glass substrate at 600 °C using the molecular precursor method. Respective precursor solutions for Ag-nanoparticles and titania were prepared from Ag salt and a titanium complex. The resistivity of the films was of the order of 10−2 to 10−5 Ω cm with film thicknesses in the range 100–260 nm. The percolation threshold was identified at a φAg value of 0.30. The lowest electrical resistivity of 10−5 Ω cm at 25 °C was recorded for the composite with the Ag fraction, φAg, of 0.55. X-ray diffraction (XRD), field-emission scanning electron microscope (FE-SEM), and transmission electron microscopic (TEM) evaluation of the effect of the morphology and the nanostructures of the Ag nanoparticles in the composite thin films on the electrical resistivity of the film revealed that the films consist of rutile, anatase, and metallic Ag nanoparticles homogeneously distributed in the titania matrix. It could be deduced that the electrical resistivity of the thin films formed at 600 °C was unaffected by the anatase/rutile content within the thin film, whereas the shape, size, and separation distance of the Ag nanoparticles strongly influenced the electrical resistivity of the Ag-nanoparticle/titania composite thin films.

Similar content being viewed by others

References

Li H, Zhao G, Song B, Han G (2008) J Cluster Sci 19:667. doi:10.1007/s10876-008-0207-4

Cattin L, Morsli M, Dahou F, Yapi Abe S, Khelil A, Bernède JC (2010) Thin Solid Films 518:4560

Kumpika T, Thongsuwan W, Singjai P (2008) Thin Solid Films 516:5640

Fujishima A, Rao TN, Tryk DA (2000) J Photochem Photobiol 1:1

Nagai H, Mochizuki C, Hara H, Takano I, Sato M (2008) Sol Energy Mat Sol Cell 92:1136

Lee H, Chou K, Shih Z (2005) Int J Adhes Adhes 25:437

Ambrozic M, Dakskobler A, Valant M, Kosmac T (2005) Mater Sci-Pol 23(2):535

Zhang W, Dehghani-Sanij AA, Blackburn RS (2007) J Mater Sci 42:3408. doi:10.1007/s10853-007-1688-5

Hanisch C, Ni N, Kulkarni A, Zaporojtchenko V, Strunskus T, Faupel F (2011) J Mater Sci 46:438. doi:10.1007/s10853-010-4887-4

Gupta A, Choudhary V (2011) J Mater Sci 46:6416. doi:10.1007/s10853-011-5591-8

Ho L, Nishikawa H, Takemoto T (2011) Electron 22:538. doi:10.1007/s10854-010-0174-z

Shin S (2010) Electron Mater Lett 6(2):65. doi:10.3365/eml.2010.06.065

Macwan DP, Dave PN, Chaturvedi S (2011) J Mater Sci 46:3669. doi:10.1007/s10853-011-5378-y

Hong C, Park H, Moon J, Park H (2006) Thin Solid Films 515(3):957

Lo CT, Chou K, Chin W (2001) J Adhes Sci Technol 15(7):783

Wang Z, Helmersson U, Kall P (2002) Thin Solid Films 405:50

Addamo M, Augugliaro V, Di Paola A, García-López E, Loddo V, Marcì G, Palmisano L (2008) Thin Solid Films 516:3802

Traversa E, Di Vona M, Nunziante P, Via Licoccia S (2000) J Sol-Gel Sci Technol 19:733

Miao L, Jin P, Kaneko K, Terai A, Nabatova-Gabain N, Tanemura S (2003) Appl Surf Sci 212:255

Sancaktar E, Bai L (2011) Polymers 3:427. doi:10.3390/polym3010427

Ren P, Fan∗ H, Wang X, Shi J (2011) J Alloy Compd 509:6423

McNaught AD, Wilkinson A (1997) IUPAC compendium of chemical terminology, 2nd edn. Blackwell Science, Oxford, p 267. ISBN 0-86542-6848

Sato M, Tanji T, Hara H, Nishide T, Sakashita Y (1999) J Mater Chem 9:1539

Takahashia K, Hayakawa T, Yoshinari M, Hara H, Mochizuki C, Sato M, Nemoto K (2005) Thin Solid Films 484:1

Sato M, Hara H, Nishide T, Sawada Y (1996) J Mater Chem 6:1767

Sato M, Hara H, Kuritani H, Nishide T (1997) Sol Energ Mat Sol C 45:43

Nishide T, Sato M, Hara H (2000) J Mater Chem 34:465

Spurr RA, Myers H (1957) Anal Chem 29:760. doi:10.1021/ac60125a006

Powder Diffraction File (1987) In: Joint Committee on Powder Diffraction Standards International Center for Diffraction Data, Swarthmore, JCPDS card 4-783

Powder Diffraction File (1987) In: Joint Committee on Powder Diffraction Standards International Center for Diffraction Data, Swarthmore, JCPDS card 21-1272

Powder Diffraction File (1987) Joint Committee on Powder Diffraction Standards International Center for Diffraction Data, Swarthmore, JCPDS card 21-1276

Powder Diffraction File (1987) Joint Committee on Powder Diffraction Standards International Center for Diffraction Data, Swarthmore, JCPDS card 40-909

Zhang H, Banfield JF (2009) Am Mineral 84:528

Nishide T, Sato M, Hara H (2000) J Mater Sci 35:465. doi:10.1023/A:1004731804075

Nagai H, Aoyama S, Hara H, Mochizuki C, Takano I, Baba N, Sato M (2009) J Mater Sci 44:861. doi:10.1007/s10853-008-3185-x

Deepa KS, Kumari Nisha S, Parameswaran P, Sebastian MT, James J (2009) Appl Phys Lett 94:142902. doi:10.1063/1.3115031

Elechiguerra JL, Burt JL, Morones JR, Camacho-Bragado A, Gao X, Lara HH, Yacaman MJ (2005) J Nanobiotechnol 3(6):1. doi:10.1186/1477-3155-3-6

Standridge SD, Schatz GC, Hupp JosephT (2009) Langmuir 25:2596

Ye L, Lai Z, Liu J, Tholen A (1999) IEEE T Electron Pack Manuf 22:299

Jeonga SH, Lim DC, Boo J-H, Lee SB, Hwang HN, Hwang CC, Kim YD (2007) Appl Catal A-Gen 320:152

Kim WJ, Taya M, Nguyen MN (2009) Mech Mater 41:1116

Acknowledgements

This study was supported by the “Energy Conversion Ecomaterials Center” project (2011–2016): Matching fund subsidy from MEXT (Ministry of Education, Culture, Sports, Science and Technology), Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Likius, D.S., Nagai, H., Aoyama, S. et al. Percolation threshold for electrical resistivity of Ag-nanoparticle/titania composite thin films fabricated using molecular precursor method. J Mater Sci 47, 3890–3899 (2012). https://doi.org/10.1007/s10853-011-6245-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-6245-6