Abstract

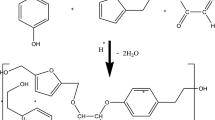

Carbon foam was prepared by submitting birch sawdust to liquefaction, resinification, foaming, carbonization, and activation steps. The foam was characterized by TG and DTG, XRD, SEM, and nitrogen adsorption at 77 K. A mechanism for the formation of the porous carbon foam was proposed. Solid non-graphitized lightweight carbon foams with specific surface areas of 534–555 m2/g and cell sizes of 100–200 μm were obtained, depending on the carbonization or activation temperature used. The intermediate liquefied birch-based resin foam exhibits thermal stability superior to liquefied wood and inferior to phenolic resin, and decomposes rapidly in two stages, at 285.7 and 412.9 °C, respectively. Further activation of the carbon foam in a stream of nitrogen above 800 °C improves the pore structure and homogeneity of the cell size significantly. The matrix of the foams contains a large number of micropores, and the microstructure becomes more ordered as the activation temperature is increased.

Similar content being viewed by others

References

Tondi G, Fierrob V, Pizzia A, Celzard A (2009) Carbon 47:1480. doi:10.1016/j.carbon.2009.01.041

Job N, Pirard R, Marien J, Pirard JP (2004) Carbon 42:619. doi:10.1016/j.carbon.2003.12.072

Biesmans G, Mertens A, Duffours L, Woignier T, Phalippou J (1998) J Non-Cryst Solids 225:64. doi:10.1016/S0022-3093(98)00010-6

Chen C, Kennel EB, Stille AH, Stansberry PG, Zondlo JW (2006) Carbon 44:1535. doi:10.1016/j.carbon.2005.12.021

Inagaki M, Morishita T, Kuno A, Kito T, Hirano M, Suwa T, Kusakawa K (2004) Carbon 42:497. doi:10.1016/j.carbon.2003.12.080

Lorjai P, Wongkasemjit S, Chaisuwan T (2009) Mater Sci Eng 527:77. doi:10.1016/j.msea.2009.07.032

Prabhakaran K, Singh PK, Gokhale NM, Sharma SC (2007) J Mater Sci 42:3894. doi:10.1007/s10853-006-0481-1

Rios RVRA, Martínez-Escandell M, Molina-Sabio M, Rodríguez-Reinoso F (2006) Carbon 44:1448. doi:10.1016/j.carbon.2005.11.028

Rutledge AR, Venditti RA, Pawlak JJ, Patel S, Cibils L (2008) BioResources 3:1063

Eksilioglu A, Gencay N, Yardim MF, Ekinci E (2006) J Mater Sci 41:2743. doi:10.1007/s10853-006-7079-5

Li WQ, Zhang HB, Xiong X (2011) J Mater Sci 46:1143. doi:10.1007/s10853-010-5099-7

Wang M-X, Wang C-Y, Zhang W (2006) J Mater Sci 41:6100. doi:10.1007/s10853-006-0626-2

Gell K, van Groenigen JM, Cayuela ML (2011) J Hazard Mater 186:2017. doi:10.1016/j.jhazmat.2010.12.105

Şensöz S (2003) Bioresour Technol 89:307. doi:10.1016/S0960-8524(03)00059-2

Darmstadt H, Pantea D, Summchen L, Ronald U, Kaliaguine S, Roy C (2000) J Anal Appl Pyrolysis 53:1. doi:10.1016/S0165-2370(99)00051-0

Huang DC, Liu QL, Zhang W, Ding J, Gu JJ, Zhu SM, Guo QX, Zhang D (2011) J Mater Sci 46:5064. doi:10.1007/s10853-011-5429-4

Shulman GP, Lochte HW (1966) J Appl Polym Sci 10:619. doi:10.1002/app.1966.070100407

Katović Z (1967) J Appl Polym Sci 11:85. doi:10.1002/app.1967.070110106

Ozaki J, Ohizumi W, Oya A (2000) Carbon 38:1515. doi:10.1016/S0008-6223(00)00113-5

Mansanray KG, Ghaly AE (1998) Bioresour Technol 65:13. doi:10.1016/S0960-8524(98)00031-5

Shafizadeh F, DeGroote WF (1976) In: Shafizadeh F, Sarkanen KV, Tillman DA (eds) Thermal uses and properties of carbohydrates and lignins. Academic Press, New York, p 1

Doh GH, Lee SY, Kang IA, Kong YT (2005) Compos Struct 68:103. doi:10.1016/j.compstruct.2004.03.004

Chang C, Tackett JR (1991) Thermochimica Acta 192:181. doi:10.1016/0040-6031(91)87160-X

Lin Q, Zheng M, Qin T, Guo R, Tian P (2010) J Anal Appl Pyrol 89:112. doi:10.1016/j.jaap.2010.06.005

Wang Q, Liang X, Zhang R, Liu C, Liu X, Qiao W, Zhan L, Ling L (2009) New Carbon Mater 24:55. doi:10.1016/S1872-5805(08)60036-0

Ma X, Zhao G (2010) Wood Sci Technol 44:3. doi:10.1007/s00226-009-0264-3

Takagi H, Maruyama K, Yoshizawa N, Yamada Y, Sato Y (2004) Fuel 83:2427. doi:10.1016/j.fuel.2004.06.019

Liu CL, Guo QG, Shi JL, Liu L (2004) New Carbon Mater 19:124 (In Chinese with English abstract)

Aso H, Matsuoka K, Sharma A, Tomita A (2004) Carbon 42:2963. doi:10.1016/j.carbon.2004.07.009

Inagaki M, Ibuki T, Takeichi T (1992) J Appl Polym Sci 44:521. doi:10.1002/app.1992.070440316

Prauchner MJ, Pasa VMD, Molhallem NDS, Otani C, Otani S, Pardini LC (2005) Biomass Bioenerg 28:53. doi:10.1016/j.biombioe.2004.05.004

Liu S, Wang R (2011) J Porous Mater 18:99. doi:10.1007/s10934-010-9360-x

Gregg SJ, Sing KSW (1982) Adsorption, surface area and porosity second ed. Academic Press, New York, p 233

Acknowledgement

The present study was financially supported by the Cultivation Project for Promoting Excellence in Research for Ph.D. Degrees from the Northeast Forestry University (GRAP09), Harbin, China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, R., Li, W. & Liu, S. A porous carbon foam prepared from liquefied birch sawdust. J Mater Sci 47, 1977–1984 (2012). https://doi.org/10.1007/s10853-011-5993-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5993-7