Abstract

Zn–1.26 wt% Al alloy was directionally solidified upward with a constant growth rate (V = 16.6 μm/s) in a wide range of temperature gradients (1.94–5.15 K/mm) and with a constant temperature gradient (G = 5.15 K/mm) in a wide range of growth rates (8.3–500 μm/s) with a Bridgman-type directional solidification furnace. The microhardness (HV) and tensile strength (σ) of alloy were measured from directionally solidified samples. The dependency of the microhardness, tensile strength for directionally solidified Zn–1.26 wt% Al alloy on the solidification parameters (G, V) and microstructure parameters (λ1, λ2) were investigated and the relationships between them were experimentally obtained using regression analysis. According to present results, the microhardness and tensile strength of directionally solidified Zn–1.26 wt% Al alloy increase with increasing solidification processing parameters and decrease with the microstructure parameters. Variations of electrical resistivity (ρ) with the temperature in the range of 300–650 K were also measured using a standard dc four-point probe technique for cast samples. The enthalpy of fusion and specific heat for same alloy was also determined by means of differential scanning calorimeter (DSC) from heating trace during the transformation from solid to liquid.

Similar content being viewed by others

References

Yılmaz F, Elliott R (1989) J Mater Sci 24:2065. doi:10.1007/BF02385422

Grugel RN (1995) Metall Mater Trans A 26:496

Çadırlı E, Gündüz M (2000) J Mater Sci 35:3837. doi:10.1023/A:1004829413966

Mullis AM (2003) J Mater Sci 38:2517. doi:10.1023/A:1023977723475

Li L, Zhang Y, Esling C, Zhao Z, Zuo Y, Zhang H, Cui J (2009) J Mater Sci 44:1063. doi:10.1007/s10853-008-3158-0

Kumar A, Dutta P (2009) J Mater Sci 44:3952. doi:10.1007/s10853-009-3539-z

Pandey JP, Prasad BK (1998) Metall Mater Trans A 29:1245

Calayag TS (1986) Zinc–aluminium (ZA) cast alloys. Proc Int Symp CIM, Toronto

Zhu YH, Man HC, Dorantes-Rosales HJ, Lee WB (2003) J Mater Sci 38:2925. doi:10.1023/A:1024457109307

Abou El-khair MT, Daoud A, Ismail A (2004) Mater Lett 58:1754

Ravindranathan P, Patil KC (1987) J Mater Sci 22:3261. doi:10.1007/BF01161190

Zhu Y, Yan B, Huang W (1995) J Mater Sci Tech 11:109

Hung FY, Lui TS, Chen LH, You JG (2007) J Mater Sci 42:3865. doi:10.1007/s10853-006-0463-3

Krupinska B, Dobrzanski LA, Rdzawski ZM, Labisz K (2010) Arch Mater Sci Eng 43:13

Morgan SWK (1985) Zinc and its alloys and compounds. Wiley, New York

Flores OV, Kennedy C, Murr LE, Brown D, Pappu S, Nowak BM, McClure JC (1998) Scr Mater 38:703

Park HS, Kimura T, Murakami T, Nagano Y, Nakata K, Ushio M (2004) Mater Sci Eng A 371:160

Pürcek G (2005) J Mater Process Technol 169:242

Osorio WR, Freire CM, Garcia A (2005) J Mater Sci 40:4493. doi:10.1007/s10853-005-0852-z

Osorio WR, Freire CM, Garcia A (2005) J Alloys Compd 397:179

Santos GA, Neto CM, Osorio WR, Garcia A (2007) Mater Des 28:2425

Ding GL, Tewari SN (2002) J Cryst Growth 236:42

Hui J, Tiwari R, Wu X, Tewari SN, Trivedi R (2002) Metall Mater Trans A 33:3499

Feng J, Huang WD, Lin X, Pan QY, Li T, Zhou YH (1999) J Cryst Growth 197:393

Ganesan S, Chan CL, Poirier DR (1992) Mater Sci Eng A 151:97

Bhat MS, Poirier DR, Heinrich JC (1995) Metall Mater Trans B 26:1049

Smiths FM (1958) Bell Syst Tech J 37:711

Valdes LB (1954) Proc IRE 42:420

Arı M, Saatçi B, Gündüz M, Meydaneri F, Bozoklu M (2008) Mater Charact 59:624

Robinson P (2003) Practical specific heat determination by power compensation DSC. Perkin Elmer, Seer Gren

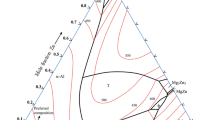

Massalski TB (ed) (1990) Binary alloy phase diagrams, vol 3. ASM International, Materials Park

Böyük U, Kaya H, Çadırlı E, Maraşlı N, Ülgen A (2010) J Alloys Compd 491:143

Kaya H, Çadırlı E, Böyük U, Maraşlı N (2008) App Surf Sci 255:307

Kaya H, Böyük U, Çadırlı E, Ocak Y, Akbulut S, Keşlioğlu K, Maraşlı N (2008) Met Mater Int 14:575

Vnuk F, Sahoo M, Van De Merwe R, Smith RW (1979) J Mater Sci 14:975. doi:10.1007/BF00550730

Vnuk F, Sahoo M, Baragor D, Smith RW (1980) J Mater Sci 15:2573. doi:10.1007/BF00550762

Telli AI, Kısakürek SE (1988) Mater Sci Technol 4:153

Rosenberger MR, Ares AE, Gatti IP, Schvezov CE (2010) Wear 268:1533

Kaya H, Gündüz M, Çadırlı E, Uzun O (2004) J Mater Sci 39:6571. doi:10.1023/B:JMSC.0000044897.98694.be

Kaya H, Çadırlı E, Gündüz M, Ülgen A (2003) J Mater Eng Perform 12:544

Khan S, Ourdjini A, Hamed QS, Najafabadi MAA, Elliott R (1993) J Mater Sci 28:5957. doi:10.1007/BF00365208

Osorio WR, Garcia A (2002) Mater Sci Eng A 325:103

Ares AE, Schvezov CE (2007) Metall Mater Trans A 38:1485

Feng J, Huang WD, Lin X, Pan QY, Li T, Zhou YH (1999) J Mater Sci Lett 18:29

Acknowledgements

This project was supported by the Niğde University Scientific Research Project Unit under Contract No: FEB 2009/02. Authors would like to thank to the Niğde University Scientific Research Project Unit for their financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Çadırlı, E., Şahin, M. Investigation of mechanical, electrical, and thermal properties of a Zn–1.26 wt% Al alloy. J Mater Sci 46, 1414–1423 (2011). https://doi.org/10.1007/s10853-010-4936-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4936-z