Abstract

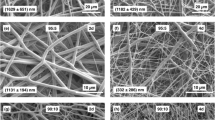

Non-woven structures of cellulose acetate (CA) fibres of 90 nm–5 μm in diameter (spinning parameters 90 nm beaded fibres: 12% CA in EtOH-DMSO 1/1, 22 kV, 30 cm, 0.5 mL/h; maximum 5 μm diameter fused fibres spun with 14% CA in Ac-BenzOH 2/1, 22 kV, 24 cm, 13 mL/h) were produced by electrospinning. On the basis of Hansen solubility theory, composition of binary solvent mixtures (ketones—acetone, methyl ethyl ketone (MEK), and alcohols—benzyl alcohol, propylene glycol and dimethylsulphoxide) was optimized with respect to control of fibre felt morphology. Fibre networks of high packing density were obtained with binary low-volatile alcohols/MEK solvent mixtures, a decreased spinning distance and an increased feed rate. Substituting MEK by acetone in the solvent mixture resulted in the formation of nanofibre felt with a low degree of fibre cross-links. Thus, solvent control is a key aspect for control of electrospun fibre felt structures, which may serve as scaffolds for tissue engineering.

Similar content being viewed by others

References

Subbiah T, Bhat GS, Tock RW, Pararneswaran S, Ramkumar SS (2005) J Appl Polym Sci 96:557

Li D, Xia YN (2004) Adv Mater 16:1151

Huang Z-M, Zhang Y-Z, Kotaki M, Ramakrishna S (2003) Compos Sci Technol 63:2223

Reneker DH, Yarin AL, Fong H, Koombhongse S (2000) J Appl Phys 87:4531

Shin YM, Hohman MM, Brenner MP, Rutledge GC (2001) Appl Phys Lett 78:1149

Yoshimoto H, Shin YM, Terai H, Vacanti JP (2003) Biomaterials 24:2077

Laurencin CT, Ambrosio AMA, Borden MD, Cooper JA (1999) Ann Rev Biomed Eng 1:19

Kumbar SG, Nukavarapu SP, James R, Nair LS, Laurencin CT (2008) Biomaterials 29:4100

Schiffman JD, Schauer CL (2008) Polym Rev 48:317

Liu HQ, Tang CY (2007) Polym J 39:65

Carrizales C, Pelfrey S, Rincon R, Eubanks TM, Kuang A, McClure MJ, Bowlin GL, Macossay J (2008) Polym Adv Technol 19:124

Inai R, Kotaki M, Ramakrishna S (2005) Nanotechnology 16:208

Courtney T, Sacks MS, Stankus J, Guan J, Wagner WR (2006) Biomaterials 27:3631

Teo WE, Ramakrishna S (2006) Nanotechnology 17:R89

Greiner A, Wendorff JH (2007) Angew Chem Int Ed 46:5670

Ma ML, Hill RM, Lowery JL, Fridrikh SV, Rutledge GC (2005) Langmuir 21:5549

Liu H, Hsieh Y-L (2002) J Polym Sci Part B: Polym Phys 40:2119

Son WK, Youk JH, Lee TS, Park WH (2004) J Polym Sci Part B: Polym Phys 42:5

Tungprapa S, Puangparn T, Weerasombut M, Jangchud I, Fakum P, Semongkhol S, Meechaisue C, Supaphol P (2007) Cellulose 14:563

Jarusuwannapoom T, Hongrojjanawiwat W, Jitjaicham S, Wannatong L, Nithitanakul M, Pattamaprom C, Koombhongse P, Rangkupan R, Supaphol P (2005) Eur Pol J 41:409

Barton AFM (1985) Handbook of solubility parameters and other cohesion parameters. CRC Press Inc., Boca Raton, FL

Hoernschemeyer D (1974) J Appl Polym Sci 18:61

Shenoy SL, Bates WD, Frisch HL, Wnek GE (2005) Polymer 46:3372

Gupta P, Elkins C, Long TE, Wilkes GL (2005) Polymer 46:4799

Colby RH, Rubinstein M, Daoud M (1994) J Phys II 4:1299

Fong H, Chun I, Reneker DH (1999) Polymer 40:4585

McKee MG, Wilkes GL, Colby RH, Long TE (2004) Macromolecules 37:1760

McKee MG, Elkins CL, Long TE (2004) Polymer 45:8705

He JH, Wan YQ, Yu MY (2004) Int J Nonlin Sci Num 5:243

Baumgarten PK (1971) J Colloid Interf Sci 36:71

Yarin AL, Koombhongse S, Reneker DH (2001) J Appl Phys 89:3018

Reneker DH, Fong H (2005) Polymeric nanofibers. American Chemical Society, Washington, DC

Eda E, Shivkumar S (2007) J Appl Polym Sci 106:475

Choktaweesap N, Arayanarakul K, Aht-ong D, Meechaisue C, Supaphol P (2007) Polym J 39:622

Tan SH, Inai R, Kotaki M, Ramakrishna S (2005) Polymer 46:6128

Lee SJ, Oh SH, Liu J, Soker S, Atala A, Yoo JJ (2008) Biomaterials 29:1422

Acknowledgements

Special thanks go to Dr. Jochen Kaschta from the chair of polymer materials for helpful discussions. Financial support from German Science Foundation (DFG) under contract number GR 961/26-1 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Haas, D., Heinrich, S. & Greil, P. Solvent control of cellulose acetate nanofibre felt structure produced by electrospinning. J Mater Sci 45, 1299–1306 (2010). https://doi.org/10.1007/s10853-009-4082-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-4082-7