Abstract

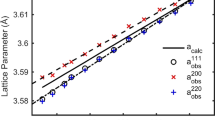

Effect of Al content on the stacking fault energy (SFE) was investigated in the austenitic Fe–25Mn–(1.16–9.77)Al–0.68C (at%) alloys by X-ray diffraction line profile analysis and thermodynamic estimation, and was discussed on the basis of anomaly in shear modulus caused by the antiferromagnetic transition. The experimental results show that the stacking fault probability decreases with increasing Al content, the observed SFE increases linearly when Al content is lower than 6.27 at%, and markedly as it is more than 6.27 at%. The thermodynamic estimation indicates that the non-magnetic component of SFE increases faster than the observed one with increasing Al content in the antiferromagnetic state, and both are almost equal in the paramagnetic state. The magnetic order increases SFE in the antiferromagnetic state, and the magnetic component of SFE depends on the average magnetic moment and Néel temperature. The increases in the localized magnetic moment and the decrease in the Néel temperature are caused by the addition of Al atoms into the austenitic Fe–Mn alloys and are accompanied by the anomaly in shear modulus, which affects SFE in the antiferromagnetic state. The anomalous drop in shear modulus leads to the inconsistency for the variations of the observed SFE and non-magnetic component with Al content in the antiferromagnetic state.

Similar content being viewed by others

References

Ye CS (1977) Acta Metall Sin 13:149 (in Chinese)

Shih CH, Zhang YS et al (1984) Adv Cryog Eng Mater 31:161

Zhang YS, Su LJ (1983) Acta Metall Sin 19:A253 (in Chinese)

Zhang YS (1983) Acta Metall Sin 19:A262 (in Chinese)

Brüx U, Frommeyer G, Gràssel O, Meyer LW, Weise A (2002) Steel Res 73:294

Frommeyer G, Brüx U (2006) Steel Res 77:627

Tian X, Zhang YS, Shih CH (1986) Acta Metall Sin 22:A101 (in Chinese)

Sato K, Ichinase M, Hirotsu Y, Inoue Y (1989) ISIJ Inter 29:868. doi:https://doi.org/10.2355/isijinternational.29.868

Takaki S, Furuya T, Tokunaga Y (1990) ISIJ Inter 30:632. doi:https://doi.org/10.2355/isijinternational.30.632

Tian X, Zhang YS (1993) Scr Metall Mater 28:1219. doi:https://doi.org/10.1016/0956-716X(93)90457-4

Zhu XM, Zhang YS (1998) Corrosion 54:3

Zhang YS, Lu X, Tian X, Qin ZX (2002) Mater Sci Eng A 334:19. doi:https://doi.org/10.1016/S0921-5093(01)01781-6

Tian X, Tian R, Wei X, Zhang Y (2004) Can Metall Q 43:183

Zhang YS (1985) Acta Metall Sin 21:A295 (in Chinese)

Zhang YS (1986) Acta Metall Sin 22:A470 (in Chinese)

Sato A, Yamaji Y, Mori T (1986) Acta Metall 34:287. doi:https://doi.org/10.1016/0001-6160(86)90199-9

Yang JH, Chen H, Wayman CM (1992) Metall Trans 23A:1445

Yang WS, Wan CM (1990) J Mater Sci 25:1821. doi:https://doi.org/10.1007/BF01045392

Oh BW, Cho SJ, Kim YG et al (1995) Mater Sci Eng A 197:147. doi:https://doi.org/10.1016/0921-5093(94)09751-8

Ruff AW Jr (1970) Metall Trans 1:2391

Gallagher PCJ (1970) Metall Trans 1:2429

Adler RPI, Otte HM, Wagner CNJ (1970) Metall Trans 1:2375

Reed RP, Schramm RE (1974) J Appl Phys 45:4705. doi:https://doi.org/10.1063/1.1663122

Schramm RE, Reed RP (1975) Metall Trans 6A:1345

Mukherjee P, Sarkar A, Barat P et al (2004) Acta Mater 52:5687. doi:https://doi.org/10.1016/j.actamat.2004.08.030

Kapoor K, Lahiri D et al (2005) Mater Charact 54:131. doi:https://doi.org/10.1016/j.matchar.2004.09.009

Dey SN, Chatterjee P, Sen Gupta SP (2005) Acta Mater 53:4635. doi:https://doi.org/10.1016/j.actamat.2005.06.017

Warren RE (1969) X-ray diffraction. Addison-Wesley, Reading, MA, p 251

Hirth JP (1970) Metall Trans 1:2367. doi:https://doi.org/10.1007/BF02642816

Miodowink AP (1978) Calphad 2:207. doi:https://doi.org/10.1016/0364-5916(78)90010-X

Ferreira PJ, Müllner P (1998) Acta Mater 46:4479. doi:https://doi.org/10.1016/S1359-6454(98)00155-4

Lee YK, Choi CS (2000) Metall Mater Trans 31A:355. doi:https://doi.org/10.1007/s11661-000-0271-3

Olson GB, Cohen M (1976) Metall Trans 7A:1897

Ishida K (1976) Phys Stat Solids 36:717. doi:https://doi.org/10.1002/pssa.2210360233

Hirllert M, Jar M (1978) Calphad 2:227. doi:https://doi.org/10.1016/0364-5916(78)90011-1

Tian X, Zhang YS (1991) Mater Sci Prog 5:48 (in Chinese)

Stepakoff GL, Kaufman L (1968) Acta Metall 16:13. doi:https://doi.org/10.1016/0001-6160(68)90066-7

Breedis JF, Kaufman L (1971) Metall Trans 2:2359. doi:https://doi.org/10.1007/BF02814874

Kaufman L, Nesor H (1978) Calphad 2:295. doi:https://doi.org/10.1016/0364-5916(78)90018-4

Murr LE (1975) Interfacial phenomenon in metal and alloys. Addison-Wesley, Reading, MA, p 130

Ericsson T (1969) Acta Metall 14:1073. doi:https://doi.org/10.1016/0001-6160(66)90195-7

Ishida K, Nishizawa T (1974) Trans Jpn Inst Met 15:225

Fernández Guillerment A (1987) High Temp High Press 19:477

Petrov Yu N, Yakubtsov IA (1986) Phys Met Metall 62(2):34

Ohno H, Mekata M (1971) J Phys Soc Jpn 31:102. doi:https://doi.org/10.1143/JPSJ.31.102

Zhang YS (1988) J Phys Met Phys 18:L229

Qin ZX, Zhang YS (1998) Hyperfine Interact 116:225. doi:https://doi.org/10.1023/A:1012670705310

Remy L, Pineau A (1977) Mater Sci Eng 28:99. doi:https://doi.org/10.1016/0025-5416(77)90093-3

Umebayashi H, Ishikawa Y (1966) J Phys Soc Jpn 21:1281. doi:https://doi.org/10.1143/JPSJ.21.1281

Acknowledgement

The authors thank Professor Shuzhi LIN for his valuable help in the XRD testing and for the profitable discussion.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tian, X., Li, H. & Zhang, Y. Effect of Al content on stacking fault energy in austenitic Fe–Mn–Al–C alloys. J Mater Sci 43, 6214–6222 (2008). https://doi.org/10.1007/s10853-008-2919-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2919-0