Abstract

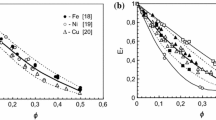

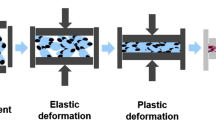

General approaches for developing models to describe the elastic properties of granular and porous materials are discussed, with emphasis on their application to predicting the elastic properties of powders undergoing uniaxial compaction. Both particle-based, and pore-based models were considered so as to reflect the transition in compact response with decreasing porosity; being particle-dominated at high porosity, then pore-dominated at low porosity. Pore-based models were further subdivided into: mechanistic models, which consider the effects of porosity on internal mechanical fields; and geometric models, for which the elastic response is assumed to correlate with a microstructural feature (e.g. load-bearing area). A selection of models suggested in the literature, considered representative of these approaches, was applied to experimental measurements of the elastic moduli of powders during compaction. In general, the geometric pore-based models show most promise, as these are able to approximate the transition in pore character during compaction. However, further developments are required for application to uniaxially compacted powders. In particular, it is necessary to develop the ability to predict more than one elastic modulus, handle irregular powder particles, and accommodate powders comprised of brittle solid phase materials.

Similar content being viewed by others

References

Hentschel ML, Page NW Elastic properties of powders during compaction. Part 1: Pseudo-isotropic moduli. J Mater Sci (accepted)

Hentschel ML, Page NW Elastic properties of powders during compaction. Part 2: Elastic anisotropy. J Mater Sci (accepted)

Dean EA, Lopez JA (1983) J Am Ceram Soc 66:366

Wang JC (1984) J Mater Sci 19:801

Timoshenko SP, Goodier JN (1970) Theory of elasticity, 3rd edn. McGraw-Hill, Singapore

Duffy J, Mindlin RD (1957) J Appl Mech 24:585

Deresiewicz H (1958) Adv Appl Mech 5:233

Kendall K, Alford NMCN, Birchall JD (1987) Proc R Soc Lond A 412:269

Iida K (1939) Bull Earthq Res Inst 17:783

Takahashi T, Satô Y (1949) Bull Earthq Res Inst Japan 27:11

Duffy J (1959) Trans ASME J Appl Mech 26:88

Rice RW (1998) Porosity of ceramics. Marcel Dekker, New York

Dantu P (1957) Proceedings of the 4th International Conference on Soil Mechanics and Foundations Engineering, vol 1. p 144

Liu C-H, Nagel SR, Schecter DA, Coppersmith SN, Majumdar S, Narayan O, Witten TA (1995) Science 269:513

Brandt H (1955) J Appl Mech 22:479

Digby PJ (1981) J Appl Mech Trans ASME 48:803

Walton K (1987) J Mech Phys Solids 35:213

Emeriault F, Chang CS (1997) J Eng Mech 123:1289

Endres AL (1990) J Appl Mech Trans ASME 57:330

Chang CS, Chao SJ, Chang Y (1995) Int J Solids Struct 32:1989

Chang CS, Liao CL (1994) Appl Mech Rev 47:S197

Dong J-J, Pan Y-W (1999) Int J Num Anal Meth Geomech 23:1075

Bathurst RJ, Rothenburg L (1988) J Appl Mech Trans ASME 55:17

Misra A, Chang CS (1993) Int J Solids Struct 30:2547

Kruyt NP, Rothenburg L (2001) Int J Solids Struct 38:4879

Kruyt NP, Rothenburg L (1998) Int J Eng Sci 36:1127

Mackenzie JK (1950) Proc Phys Soc Lond 63B:2

Hashin Z (1962) J Appl Mech Trans ASME 29:143

Zimmerman RW (1991) Mech Mater 12:17

Sayers CM, Smith RL (1982) Ultrasonics 20:201

Rossi RC (1968) J Am Ceram Soc 51:433

Kreher W, Ranachowski J, Rejmund F (1977) Ultrasonics 14:70

Mazilu P, Ondracek G (1990) In: Herrmann KP Olesiak ZS (eds) Thermal effects in fracture of multiphase materials. Proceedings of the Euromech Colloquium 255, Oct. 31–Nov. 2, 1989. Panderburn, FRG, pp 214–226. Springer-Verlag. Berlin. (1990)

Dean EA (1983) J Am Ceram Soc 66:847

Zhao YH, Tandon GP, Weng GJ (1989) Acta Mech 76:105

Kachanov M, Tsukrov I, Shafiro B (1994) Appl Mech Rev 47:151

Eshelby JD (1957) Proc R Soc Lond A 241:367

Bert CW (1985) J Mater Sci 20:2220

Nielsen LF (1984) J Am Ceram Soc 67:93

Nielsen LF (1982) Mater Sci Eng 52:39

Hill R (1963) J Mech Phys Solids 11:357

Hashin Z, Shtrikman S (1963) J Mech Phys Solids 11:127

Balendran B, Nemat-Nasser S (1995) J Mech Phys Solids 43:1825

Nemat-Nasser S, Hori M (1993) Micromechanics: overall properties of heterogeneous materials. Elsevier, Amsterdam

Ramakrishnan N, Arunachalam VS (1993) J Am Ceram Soc 76:2745

Martin LP, Dadon D, Rosen M (1996) J Am Ceram Soc 79:1281

Rice RW (1996) In: Liu D-M (ed) Porous ceramic materials: fabrication, characterisation, applications. Trans Tech Publications, Zurich, p 1

Rice RW (1996) J Mater Sci 31:102

Roberts AP, Garboczi EJ (2000) J Am Ceram Soc 83:3041

Budiansky B (1965) J Mech Phys Solids 13:223

Wu TT (1966) Int J Solids Struct 2:1

Mori T, Tanaka K (1973) Acta Metall 21:571

Dvorak GJ, Srinivas MV (1999) J Mech Phys Solids 47:899, 2207

Dunn ML, Ledbetter H (1995) J Mater Res 10:2715

Luo J, Stevens R (1996) J Appl Phys 79:9047

Ferrari M, Filipponi M (1991) J Am Ceram Soc 74:229

Ponte Castañeda P, Willis JR (1995) J Mech Phys Solids 43:1919

Rice RW (1996) J Mater Sci 31:1509

Cytermann R (1987) Powder Metall Int 19:27

Phani KK, Niyogi SK (1987) J Am Ceram Soc 70:362

Boccaccini AR, Ondracek G, Mazilu P, Windelberg D (1993) J Mech Behav Mater 4:119

Arnold M, Boccaccini AR, Ondracek G (1996) J Mater Sci 31:1643

Abdel-Ghani M, Petrie JG, Seville JPK, Clift R, Adams MJ (1991) Powder Technol 65:113

Skriver HL, Rosengaard NM (1992) Phys Rev B 46:7157

Hentschel ML (2002) PhD thesis. The University of Newcastle

German RM (1996) Sintering theory and practice. Wiley, New York

Rice RW (2005) J Mater Sci 40:983

Acknowledgement

The authors gratefully acknowledge scholarship support for MLH through the Australian Research Council Small Grants Scheme.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hentschel, M.L., Page, N.W. Elastic properties of powders during compaction. Part 3: Evaluation of models. J Mater Sci 41, 7902–7925 (2006). https://doi.org/10.1007/s10853-006-0875-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0875-0