Abstract

In this study, [Li0.02(Na0.56 K0.46)0.98](Nb0.81Ta0.15Sb0.04)O3 + x mol% K5.4Cu1.3Ta10O29 ceramics were fabricated by conventional solid-state solution processes. Then, their dielectric and piezoelectric properties were investigated. Sinterability of all samples was enhanced because K5.4Cu1.3Ta10O29 (abbreviated as KCT) acted as sintering aids. As the result of XRD, phase structure showed orthorhombic symmetry when KCT ≤ 0.2 mol%. Whereas, the phase structure changed from orthorhombic symmetry to tetragonal symmetry when KCT ≥ 0.4 mol%. The results suggest that the orthorhombic and tetragonal phases co-exist in the composition ceramics with 0.2 mol% < KCT < 0.4 mol% at room temperature. The effects of the addition of KCT on the dielectric and piezoelectric properties were investigated. As the result, excellent properties of density=4.81[g/cm3], electromechanical coupling factor (kp)=0.48 and piezoelectric constant(d33)=252[pC/N] were obtained in the composition ceramics with 0.4 mol%KCT.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Piezoelectric ceramics have been developed from BaTiO3-based compositions to Pb(Zr,Ti)O3 -based compositions. Among them, Lead zirconate titanate- based (abbreviated as PZT) ceramics have been widely used in actuator, sensors, resonator, transducer, and energy harvesters due to their excellent piezoelectric and dielectric properties. However, these lead- based ceramics can cause serious environmental pollution and damage human health due to generation of toxic PbO during the process of manufacturing. Thus, electrical waste and electronic equipment (WEEE) and restriction of hazardous substances (RoHS) have been enforced to new electronic products for the environmental production and human health. Therefore, lead-free piezoelectric ceramics such as BNT-based materials, and NKN- based materials have been studied during the past decade.

Among these, (N0.5 K0.5)NbO3 (abbreviated as NKN) ceramics is a promising candidate for replacing lead-free ceramics due to their strong piezoelectricity and ferroelectricity. Typically, well sintered KNN ceramics have excellent physical properties such as a piezoelectric constant (d 33 )=80pC/N, electromechanical coupling factor (k p )=36–40 %, mechanical quality factor (Q m )=130 and high curie temperature (Tc~420 °C). However, the physical properties of the ceramics are still weak for application in piezoelectric devices.

Recently, special sintering processes such as Spark Plasma sintering (SPS), Hot pressing, Hot forging, and RTGG (Reactive template grain growth) have been utilized for manufacturing high performance ceramics [1]. However, the methods using these special sintering processes have high manufacturing costs. Therefore, new methods for manufacturing high performance ceramics have been introduced by using sintering aids such as CuO [2], ZnO, Ta2O5, [3–6] KNbO3 [7], LiNbO3,and K5.4Cu1.3Ta10O29 (KCT) [8–14]. They can be added in the basic composition ceramics to form a solid solution. Ta2O5 can be not only good sintering aids by the formation of K5.4Cu1.3Ta10O29 (KCT) [8–14] but also may act as the Ta5+ ion substituted at the B-site of the ABO3 perovskite structure which make phase transition temperature orthorhombic-tetragonal phase transition (TO-T) and tetragonal-cubic phase transition (TC) decrease toward room temperature. In addition, potassium (K) of KCT acted as the compensating material for the volatilization of potassium.

2 Experimental

The specimens were manufactured using a conventional mixed oxide process. The compositions used in this study were as follows [15, 16];

The raw materials, Na2CO3 (99.5 %), K2CO3 (99.5 %), Sb2O5 (99.9 %), Nb2O5 (99.9 %), CuO (99.9 %), Li2CO3 (99 %) and Ta2O5 (99.95 %) for the given composition were weighted by mole ratio and the powders were ball-milled for 24 h. After drying, they were calcined at 900 °C and 950 °C for 6 h and 5 h, respectively. Thereafter, KCT was added as sintering aids and then the specimens were ball-milled and dried again. Polyvinyl alcohol (PVA: 5 wt.% aqueous solution) was subsequently added to the dried powders. The powders were molded under pressure of 2,000 kg/cm2, burned out at 600 °C for 3 h, and then sintered at 1100~1120 °C for 5 h. The dimensions of the specimens were 17.2 Φ (diameter)× 1 mm(thickness). Poling was carried out at 100 °C in a silicon oil bath by applying a field of 3 kV/mm for 30 min. In order to investigate the dielectric properties, capacitance was measured at 1 kHz using an LCR meter (ANDO AG-4034) and the dielectric constant (ε r ) was calculated. Piezoelectric constants were obtained using a d 33 meter (APC 8000 piezo d 33 tester). For investigating the piezoelectric properties, the resonant and anti-resonant frequencies were measured by an Impedance Analyzer (Agilent 4294A) according to the IEEE standard and then k p and Q m were calculated [17].

An X-ray diffractometer (XRD) (Rigaku, D/MAX 2500V) with CuKα1 radiation (λ = 1.5406 Å) was utilized to identify the crystal structure.

3 Results and discussion

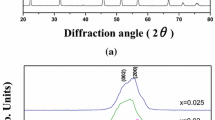

Figure 1 presents the X-ray diffraction pattern as a function of KCT addition. The XRD analysis showed a typical peroveskite structure. The XRD pattern of the ceramics in the range of 2θ from 43° to 48° indicated that the specimens have orthorhombic symmetry when KCT ≤ 0.2 mol%, and then phases structure was changed from orthorhombic symmetry to tetragonal symmetry when KCT ≥ 0.4 mol% because of the excess addition of KCT. At room temperature, the crystal structures of all samples showed the pure perovskite without any secondary phases (indexed by JCPDS card no. 71–2171).

Figure 2 illustrates the microstructures of specimens as a function of KCT addition. It was observed that all samples had dense microstructures. The grain size gradually increased from 0 mol%KCT to 0.8 mol%KCT. The average grain size was obtained as approximately 2.6 μm, 2.89 μm, 3.86 μm, 3.94 μm and 4.5 μm, respectively. The grain size reached the maximum value at 0.8 mol%KCT. The pores were gradually decreased by KCT addition. This may be due to the liquid phase that formed during the sintering process.

Figure 3 shows the bulk density and relative density of specimens as a function of KCT addition. As shown in Fig. 3, the (bulk) density gradually increased from 4.71 g/cm3 to 4.81 g/cm3. This can be due to the improved sinterability as a function of KCT addition, and then little changed. The little change of density above 0.4 mol%KCT was attributed to the suppression of grain growth by excess KCT. The densities were researched as 4.71 g/cm3, 4.81 g/cm3, 4.82 g/cm3 and 4.83 g/cm3, respectively.

Figures 4 and 5 show the electromechanical coupling factor (k p ) and piezoelectric constant (d 33 ) as a function of KCT addition. The k p values showed similar d 33 values. k p and d 33 gradually increased. k p and d 33 showed the maximum values of 0.48 and 252[pC/N], respectively, at 0.4 mol%KCT addition. However, k p and d 33 decreased above 0.4 mol%KCT addition due to pores formed by the excess addition of KCT.

Figure 6 shows the dielectric constant (ε r ) as a function of KCT addition. The dielectric constant (ε r ) gradually increased from 1693 at 0.2 mol% KCT to 2789 at 0.6 mol% KCT, and then decreased. It is found that the dielectric constant (ε r ) was increased due to the To-t shifted toward room temperature by Ta substitution.

Figure 7 shows the mechanical quality factor (Q m ) according to the amount of KCT addition. The mechanical quality factor (Q m ) increased from 80 at 0.2 mol%KCT to 141 at 0.4 mol% KCT because of the oxygen vacancies formed by Cu2+ ion substituted into the B-site in the ABO3 perovskite structure. A similar tendency was observed for k p and d 33 .

Figure 8(a) shows the temperature dependence of the dielectric constant at 10 kHz. The Curie temperature T c shifted toward the lower temperature region as a function of KCT addition. The orthorhombic–tetragonal phase transition temperature (To-t) appeared at room temperature as shown in Fig. 8(b). The substitution of Ta5+ ions in the B-site caused the phase transition shift toward the lower temperature range.

Figure 9 presents the P-E hysteresis loop of LKNTNS ceramics with x = 0, 0.2, 0.4 0.6 and 0.8 mol% sintered at 1100–1120 °C. The remnant polarization (P r) rapidly increased from 3.54 μC/cm2 to 12.95 μC/cm2, and then gradually decreased from 12.95 μC/cm2 to 6.26 μC/cm2 as a function of KCT.

Table 1 shows the physical characteristics of the specimens as a function of KCT addition.

4 Conclusion

Lead-free [Li0.02(K0.5Na0.5)0.98](Nb0.81Ta0.15Sb0.04)O3 piezoelectric ceramics were prepared as a function of KCT addition by the conventional solid state reaction and normal sintering processes. Their piezoelectric and dielectric properties were investigated as a function of KCT addition. The results obtained from the experiment are as follows:

-

1.

The grain size gradually increased from 0 mol%KCT to 0.8 mol%KCT.

-

2.

The density gradually increased from 4.71 g/cm3 to 4.81 g/cm3 due to the improved sinterability with KCT addition.

-

3.

The Curie temperature T c shifted toward the lower temperature region with KCT addition.

-

4.

Excellent physical properties of density=4.81[g/cm3], the electromechanical coupling factor (kp)=0.48 and the piezoelectric constant(d33)=252[pC/N] were obtained in the composition ceramics with 0.4 mol%KCT.

References

Y. Guo, K. Kakimoto, H. Ohsato, Solid State Commun. 129, 279 (2004)

Y. Oh, J. Noh, J. Yoo, J. Kang, L. Hwang, Trans. Ultrason. Ferroelectr. Freq. Control 58, 1860 (2011)

Y. Guo, K. Kakimoto, H. Ohsato, Appl. Phys. Lett. 85, 4121 (2004)

M. Matsubara, K. Kikuta, S. Hirano, J. Appl. Phys. 97, 114105 (2005)

Y. Guo, K. Kakimoto, H. Ohsato, Mater. Lett. 59, 241 (2005)

Y. Lee, J. Yoo, K. Lee, I. Kim, J. Song, Y.-W. Park, J. Alloys Comp. 506, 872 (2010)

P. Zhao, B.P. Zhang, J.F. Li, Appl. Phys. Lett. 90, 242909 (2007)

M. Matsubara, T. Yamaguchi, K. Kikuta, S. Hirano, Jpn. J. Appl. Phys. 44, 6618–23 (2005)

B. Park, I. Hong, H. Jang, V. Tran, W. Tai, J. Lee, Mater. Lett. 64, 1577 (2010)

D. Lin, M. Guo, K. Lam, K. Kwok, H. Chan, Smart Mater. Struct. 17, 035002 (2008)

M. Matsubara, T. Yamaguchi, K. Kikuta, S. Hirano, Jpn. J. Appl. Phys. 43, 7159 (2004)

M. Matsubara, T. Yamaguchi, W. Sakamoto, K. Kikuta, T. Yogo, S. Hirano, J. Am. Ceram. Soc. 88, 1190 (2005)

M. Matsubara, K. Kikuta, S. Hirano, J. Appl. Phys. 97, 114105 (2005)

J. Noh, J. Yoo, Y. Jung, J. KIEEME 23, 397 (2010)

J. Noh, J. Yoo. International Conference on Advanced Electromaterials (2011) FM778

J. Noh, J. Yoo, J. KIEEME 24, 627 (2011)

IEEE Standards on Piezoelectricity, The Institute of Electrical and Electronics Engineers Inc, IEEE Standard 176 (1978)

Acknowledgments

This work was supported by the Power Generation & Electricity Delivery of the Korea Institute of Energy Technology Evaluation and Planning (KETEP) grant funded by the Korea government Ministry of Knowledge Economy (No. 2010T100100282) and was partially supported by Basic Science Research Program through NRF funded by the Ministry of Education, Science and Technology (No. 2010-0022117)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Noh, J., Yoo, J. Dielectric and piezoelectric properties of KCT added (Li0.02(Na0.56 K0.46)0.98(Nb0.81Ta0.15Sb0.04)O3 ceramics. J Electroceram 30, 139–144 (2013). https://doi.org/10.1007/s10832-012-9775-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10832-012-9775-7