Abstract

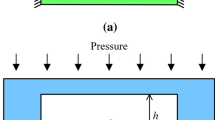

Although silicon is the preferred choice for microelectromechanical systems (MEMS) piezoresistive pressure sensors, such devices are not preferred for application in harsh environmental conditions due to the exponential increase in leakage current with temperature. To alleviate such shortcomings of silicon-based pressure sensors in extreme conditions including elevated temperature and intense vibration, this study strives to shift focus from core complementary metal–oxide–semiconductor (CMOS) materials to silicon carbide. In this work, we adopt an analytical and simulation approach to model and analyze various characteristics of such silicon carbide piezoresistive sensors and determine an optimal design. A square diaphragm is modeled using the analytical expressions for a thin plate in combination with small-deflection theory, providing quick insight for estimation of critical parameters and thus the behavior of the pressure sensor. Both clamped and freely supported edge conditions of the diaphragm are explored. Although many studies and discussions are available on the rigidly supported loading condition, the freely supported edge condition for a square diaphragm has received little attention. The deflection, stress, strain, and sensitivity of the square diaphragm under both loading conditions are reported herein then compared to understand which of the two loading conditions results in more significant outputs.

Similar content being viewed by others

References

Bae, B., et al.: Design optimization of a piezoresistive pressure sensor considering the output signal-to-noise ratio. J. Micromech. Microeng. 14, 1597–1607 (2004)

Bao, M.: Analysis and Design Principles of MEMS Devices. Elsevier, Amsterdam (2005)

Beeby, S.P., Stuttle, M., White, N.M.: Design and fabrication of low cost microengineered silicon pressure sensor with linearized output. IEEE Proc. Sci. Meas. Technol. 147(3), 127–130 (2000)

Jindal, S.K., Raghuwanshi, S.K.: A complete analytical model for circular diaphragm pressure sensor with clamped edge. J. Circuit Syst. 1(2), 19–27 (2013)

Jindal, S.K., Raghuwanshi, S.K.: A complete analytical model for circular diaphragm pressure sensor with freely supported edge. Microsyst. Technol. 21(5), 1073–1079 (2015)

Jindal, S.K., Mahajan, A., Raghuwanshi, S.K.: A complete analytical model for clamped edge circular diaphragm non-touch and touch mode capacitive pressure sensor. Microsyst. Technol. 22(5), 1143–1150 (2015)

Kumar, S.S., Pant, B.D.: Design of piezoresistive MEMS absolute pressure sensor. In: Proceedings of the SPIE 8549 Kumar SS, Pant BD (2013) Effect of Temperature on Etch Rate and Undercutting of (100) Silicon Using 25% TMAH. In: Proceedings of the International Conference on Emerging Technologies Micro to Nano (ETMN), Goa (2012)

Kumar, S.S., Pant, B.D.: Design principles and considerations for the ‘ideal’ silicon piezoresistive pressure sensor: a focused review. Microsyst. Technol. 20, 1213–1247 (2014)

Kumar, S.S., Pant, B.D.: Polysilicon thin film piezoresistive pressure microsensor: design, fabrication and characterization. Microsyst. Technol. (2014). https://doi.org/10.1007/s00542-014-2318-1

Kumar, S.S., Ojha, A.K., Nambisan, R., Sharma, A.K., Pant, B.D.: Design and simulation of MEMS silicon piezoresistive pressure sensor for barometric applications. In: Proceedings of the ARTCom&ARTEE PEIE&itSIP and PCIE, pp 339–345. Elsevier (2013). ISBN978-81-910691-8-3

Kumar, S.S., Ojha, A.K., Pant, B.D.: Experimental evaluation of sensitivity and non-linearity in polysilicon piezoresistive pressure sensors with different diaphragm sizes. Microsyst. Technol. (2014). https://doi.org/10.1007/s00542-014-2369-3

Khakpour, R. et al.: Analytical comparison for square, rectangular and circular diaphragms in MEMS applications. In: International Conference on Electronic Devices. Systems and Applications, pp. 297–299 (2010)

Li, S., Zhang, Z., Tang, J., Ding, D.: A novel signal conditioning circuit for piezoresistive pressure sensor. Unifying Electr. Eng. Electron. Eng. 238, 1707–1713 (2014). https://doi.org/10.1007/978-1-4614-4981-2_187

Li, C., Cordovilla, F., Jagdheesh, R., Ocaña, J.L.: Design and optimization of a novel structural MEMS piezoresistive pressure sensor. Microsyst. Technol. (2016). https://doi.org/10.1007/s00542-016-3187-6

Lin, L., Chu, H.-C., Lu, Y.-W.: A simulation program for the sensitivity and linearity of piezoresistive pressure sensors. J. Microelectromech. Syst. 8, 514–522 (1999). https://doi.org/10.1109/84.809067

Santosh Kumar, S., Pant, B.D.: Polysilicon thin film piezoresistive pressure microsensor: design, fabrication and characterisation. Microsyst. Technol. 21, 1949–1958 (2015)

Sharma, A., Mukhiya, R., Kumar, S.S., Pant, B.D.: Design and simulation of bulk micromachined accelerometer for avionics application. VLSI Des. Test 382, 94–99 (2013). https://doi.org/10.1007/978-3-642-42024-5_12

Song, J.W., Lee, J.-S., An, J.-E., Park, C.G.: Design of a MEMS piezoresistive differential pressure sensor with small thermal hysteresis for air data modules. Rev. Sci. Instrum. 86, 65003 (2015). https://doi.org/10.1063/1.4921862

Smith, C.S.: Piezoresistive effect in germanium and silicon. Phys. Rev. 94, 42–49 (1954)

Timoshenko, S.P., Woinowsky-Kreiger, S.: Theory of Plates and Shells, 2nd edn. McGraw Hill, New York (1959)

Wang, X., Li, B., Lee, S., Sun, Y., Roman, H.T., Chin, K., Farmer, K.R.: A new method to design pressure sensor diaphragm. NSTI Nanotechnol. 1, 324–327 (2004)

Werner, M., Gluche, P., Adamschik, M., Kohn, E., Fecht, H.J.: Review of diamond based piezoresistive sensors. Proc. IEEE Int. Symp. Ind. Electron. 1, 147–152 (1998)

Zhang, Y., Wise, K.D.: Performance of non-planar silicon diaphragms under large deflections. J. Microelectromech. Syst. 3, 59–68 (1994)

Zhang, Y.-H., Yang, C., Zhang, Z.-H., Lin, Z.H.-W., Liu, L.-T., Ren, T.-L.: A novel pressure microsensor with 30-μm-thick diaphragm and meander-shaped piezoresistors partially distributed on high-stress bulk silicon region. IEEE Sens. J. 7, 1742–1748 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jindal, S.K., Magam, S.P. & Shaklya, M. Analytical modeling and simulation of MEMS piezoresistive pressure sensors with a square silicon carbide diaphragm as the primary sensing element under different loading conditions. J Comput Electron 17, 1780–1789 (2018). https://doi.org/10.1007/s10825-018-1223-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10825-018-1223-8