Abstract

Cheese-making involves milk coagulation as a crucial step where calf rennet has been used traditionally as the milk-clotting enzyme in the cheese industry. This study investigated milk-clotting enzymes from seven species of seaweed and evaluated the parameters for their isolation and partial purification including post-harvest processing, extraction and purification methods. The saturation degree of ammonium sulphate and the precipitation stages were evaluated to obtain optimal purification conditions, and three desalting methods, namely dialysis, desalting column and the combination of dialysis and desalting column, were investigated to determine the most suitable method for ammonium sulphate removal. Protein extracts of all seven species of seaweeds exhibited some caseinolytic activity, but the extract of unprocessed (whole) dried samples had higher protein yields and stronger caseinolytic activities. The extract from one species, Gracilaria edulis, demonstrated the ability to clot milk. The evaluation of the purification method for G. edulis extract revealed an optimum single step of 50% saturation and ammonium sulphate precipitation with dialysis as the desalting method.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Due to the growing demand in cheese production and limited supply of rennet, a number of rennet substitutes have been explored, including pure chymosin produced by molecular technology, animal pepsin, plant and microbial proteases. However, these milk coagulants still have various drawbacks, including limited availability, low cheese yield, bitterness in cheese produced, and consumer concerns about animal ethics and genetically modified organism (GMO). Rennet substitutes have been explored from diverse marine organisms, and some of them have potential as milk coagulants, including jellyfish, sponges and macroalgae (Rojas and Doolittle 2002; Sharmila et al. 2012). Across the Indo-Pacific region, seaweeds (marine macroalgae) have been widely used as traditional medicine because of their significant bioactivities, as well as raw material for food and agar industries (Torres et al. 2019). It is also reported that seaweeds have great potential nutritional values with components such as polysaccharide, protein, vitamins and minerals, and can be used as a source of nutrients for humans and animals (Sakhthivel and Devi 2015). Moreover, some seaweeds and other types of algae have been found to have a considerable caseinolytic activity (Pérez-Lloréns et al. 2003; Sharmila et al. 2012; Bele et al. 2014; Patil and Rebecca 2014) and thus have the potential to be explored as rennet substitutes for the coagulation of milk in cheese making.

To produce caseinolytic proteases from seaweeds, extraction and subsequent purification of the enzymes from the rather tough algal matrix is the essential first step. The structure of seaweed is quite different from that of terrestial plants with the outer layer being protected by the cell wall, composed of parallel layers of cellulose microfibrils and an outer cuticle of protein (Lobban and Harrison 1997). Rosenthal et al. (1996) reported that some extraction parameters, such as temperature and particle size, could be optimised to assist with protein extraction and avoid protein damage. Cell wall disruption during the extraction process could also increase protein yield. Thus, it is important to assess the effect of extraction conditions, including milling and the resultant particle size of the sample, on the extraction yield, protein content, caseinolytic and milk-clotting activity of obtained extracts.

Protein purification using ammonium sulphate precipitation is an established salting-out method which has been claimed to give high yields and efficiency (Moore and Kery 2009). However, variation exists in enzyme purification, relating to the number of stages in ammonium sulphate precipitation that resulted a good enrichment protein and activity (Pontual et al. 2012; Esposito et al. 2016; Li et al. 2018b). Furthermore, the selection of a suitable desalting procedure is also essential for maintaining the quality of the enzyme (Moore and Kery 2009). Therefore, the evaluation of enzyme preparation methods is crucial to obtain a versatile milk-clotting enzyme with an accessible technique for cheese industry application. In this study we investigated the protein content and proteolytic activity of seven seaweed species, as well as the optimal for the extraction and purification of the enzyme from them.

Materials and methods

Seaweed samples

Four red seaweeds (Sarconema filiforme (Sonder) Kylin, Asparagopsis taxiformis (Delile) Trevisan, Gracilaria edulis (S.G.Gmelin) P.C.Silva and Kappaphycus alvarezii (Doty) L.M.Liao) and three green seaweeds (Caulerpa racemosa (Forsskål) J.Agardh, Caulerpa lentillifera J.Agardh, Ulva ohnoi M.Hiraoka & S.Shimada) (Guiry and Guiry 2023) were obtained from commercial producers or aquaculture systems (Fig. 1). The selection of the seven-seaweed species was based on the availability of the sample. After harvesting, the sample was spun to remove the excess water, and then dehydrated in an Ezidri-Ultra FD1000 food dehydrator at 60 °C for 3 days. The moisture content of the samples was determined on unmilled samples according to the AOAC International Official Methods no. 934.01 (AOAC International 2007). After drying, samples were milled, and unmilled samples collected were stored in a freezer (-20 °C) until being processed.

Chemicals and reagents

Liquid calf rennet (Naturen 280 D/S Liquid Chy-Max) was purchased from Chr. Hansen (Victoria, Australia). Bovine whole casein was purchased from Sigma-Aldrich (Australia). All other chemicals used were of analytical grade and purchased from Sigma-Aldrich, unless otherwise stated.

Extraction of crude enzymatic extracts

Of the seven samples, five of them comprise unmilled (whole) and milled sample, while the other two (C. lentilifera and K. alvarezii) only had milled sample. This was because C. lentilifera was only available in the milled form, and the size and hardness of the unmilled sample of K. alvarezii were not appropriate for the homogeniser.

The crude extracts were prepared from samples of seven algal species samples according to the method of Sun et al. (2016) with a slight modification. Algal samples were ground with mortar and pestle to pass to 710 µm mesh sieve. Prior to the milling, the samples were immersed into liquid nitrogen to avoid heat loss of enzymatic activity during the operation. Six gram of the algal sample was homogenised in 20 mM phosphate buffer (pH 7.0) in a ratio of 1:20 (w/v) with an Ultra-Turrax T 25 homogeniser (IKA, Germany) for 1 h at 24 °C, to disrupt algal cell wall and extract the intracellular enzyme (Sun et al. 2016), followed by centrifugation at 5,000 × g for 30 min at 4 °C. The supernatant was filtered with Whatman #1 filter paper and collected as the liquid crude extract (CE). The result of the caseinolytic activity (CA) and protein content (PC) of CE of all sample variation were compared, and the best algae species were selected based on those parameters.

Assay of caseinolytic and milk-clotting activities and protein content

Methods for the assay of caseinolytic and milk-clotting activities were described in our previous publication (Arbita et al. 2020). The protein content of the extracts was determined by the bicinchoninic acid assay (Smith et al. 1985) with bovine serum albumin as the standard, and reported in mg protein per g alga dry matter. The total protein, protein recovery, specific caseinolytic activity (SCA) and purification factor (fold) were calculated with Eq. (1), (2), (3) and (4), respectively.

Partial purification of crude extracts

Evaluation of the saturation and the number of stages of ammonium sulphate precipitation

In order to obtain optimal conditions for the purification of CE by ammonium sulphate precipitation, the concentrations of ammonium sulphate and the precipitation stages used were evaluated, with caseinolytic activity of the obtained fractions as the evaluation criterion. The procedure for the evaluation is outlined in Fig. 2. The ammonium sulphate precipitation procedure followed the method described by Gutiérrez-Méndez et al. (2012) with some modifications.

At the first stage, 10 mL of CE was mixed with ammonium sulphate solutions at 30, 40, 50, 60, and 70% (w/v) saturation. The mixtures were stirred for 30 min at 4 °C, and then centrifuged at 10,000 × g for 10 min at 4 °C. The precipitates were re-dissolved in one-tenth of the initial CE volume of 20 mM phosphate buffer (pH 7.0), followed by dialysis to remove the ammonium sulphate salt. The dialysis was conducted in SnakeSkin Dialysis Tubing 3.5 K MWCO 35 mm (Thermo Scientific, USA) against 1.8 L of the same phosphate buffer at 4 °C for 24 h with constant stirring. The caseinolytic activity (CA) of the purified extracts (PE) were determined and the extract giving the highest activity was selected for the next purification process.

The supernatant from the mixture, whose precipitate gave the highest caseinolytic activity as described above, was subjected for the second stage of ammonium sulphate precipitation. Ten mL of the supernatant was mixed with ammonium sulphate at 70, 75, 80, 85, and 90% (w/v) saturation and the same the procedures for precipitation, re-dissolving and dialysis as for stage one described above was performed. The caseinolytic activity of the purified extracts (PE) were determined and the extract giving the highest activity at this stage was pooled with the PE with the highest CA from the first stage. After that, the caseinolytic activity of the pooled fraction and the best PE from the first and second stage were compared, to decide the best number of stages for ammonium sulphate precipitation.

Evaluation of desalting methods

Three desalting methods: dialysis (DI) (Fig. 3a), desalting column (DE) (Fig. 3b) and the combination of dialysis and desalting column (DIDE) (Fig. 3c), were evaluated to determine the most suitable method for ammonium sulphate removal from extracted protein. The precipitate obtained by XX% ammonium sulphate saturation (which gave the highest CA, details in results and discussion section) was used for the evaluation. The precipitate was re-dissolved in one-tenth of the initial CE volume of 20 mM phosphate buffer (pH 7.0). For the dialysis method, the PE raw (PER, the PE which still contained ammonium sulphate) was dialysed using SnakeSkin Dialysis Tubing 3.5 K MWCO 35 mm (Thermo Scientific) against 1.8 L of the same phosphate buffer at 4 °C for 24 h with constant stirring. The PE from the dialysis was designated as PEDI. For the desalting column method, 1 mL PER was added to PD Minitrap G-10 desalting column (GE Healthcare, Sweden) and allowed to enter the packed bed completely. After that, 0.7 mL of the same phosphate buffer was added and allowed to be absorbed completely into the packed bed. The flow-through up to this point was discarded. Following that, 1.2 mL of the same phosphate buffer was used to elute the column, and the eluate was collected (PEDE1). The elution process was repeated three times, each with 1.2 mL of the same phosphate buffer, to obtain three eluates of purified extract (PEDE1, PEDE2 and PEDE3). The pooled fraction (PEDE) of the purified extract was collected by mixing PEDE1, PEDE2 and PEDE 3. Each solution of PEDE1, PEDE2, PEDE3 and the pooled fraction of PEDE were subjected to CA assay.

For the combination of dialysis and desalting methods, the PER was first dialysed and then further purified by the desalting column method as described above, which yielded three eluates, PEDIDE1, PEDIDE2 and PEDIDE3, as well as a pooled fraction (PEDIDE) by mixing PEDIDE1, PEDIDE2 and PEDIDE 3. All the eluates and fractions assayed for CA.

Data analysis

The data were analysed with Microsoft Excel software. The data were tested for homoscedasticity and one-way ANOVA analysis of each parameter was used to analyse the data. The differences among the mean values were demonstrated using the Tukey comparison test. These analyses were performed using Minitab 17.0 Statistical software (Minitab Inc, USA).

Results

Selection of potential milk-clotting enzymes among seven species of algae

The protein content of crude extracts of seven algae species is presented in Fig. 4a. It is evident that the unmilled samples gave significantly higher protein yields (on average 34% higher) than the milled samples (P < 0.05). The trend is consistent regardless of the species of the algae. The highest protein content reported was unmilled dehydrated S. filiforme (2.294 mg protein mL−1) while the milled K. alvarezii showed the lowest value (0.178 mg protein mL−1).

a) Protein content (mg protein mL−1), (b) caseinolytic activity (units mL−1) and (c) specific caseinolytic activity (units mg−1 protein) of crude extracts of seven algae species. The results were mean values of triplicate experiments with error bars representing one standard deviation. Values sharing the same letter were not significantly different (P < 0.05)

The caseinolytic activity (CA) of the crude extracts is presented in Fig. 4b. Of the seven algal samples, CE from four of the unmilled (whole) samples demonstrated higher CA values than the milled samples, although some of the differences were not statistically significant (P > 0.05), except for G. edulis. Of the milled algal samples, only the extract of S. filiforme showed higher activity than that of the unmilled sample with significant difference (P < 0.05). The highest CA was shown by the extract of unmilled G. edulis (0.113 units mL−1), while K. alvarezii exhibited the lowest activity (0.002 units mL−1).

To compare the CA of the extracted enzymes in the extracts, the specific caseinolytic activity of the extracted protein was calculated (Fig. 4c). By this measure, the extract from unmilled G. edulis also showed the highest activity (0.093 units mg−1 protein) while K. alvarezii gave the lowest activity (0.011 units mg−1 protein).

In this study it was found that only the extract from the unmilled sample of G. edulis showed the ability to clot milk (Fig. 5).

Milk-clotting ability crude extracts of the seven species of unmilled algae. (1) Sarconema filiforme; (2) Caulerpa racemosa; (3) Caulerpa lentillifera; (4) Gracilaria edulis; (5) Asparagopsis taxiformis; (6) Ulva ohnoi; (7) Kappaphycus alvarezii. Milk coagulation occurred only in (4), shown as the milk curdle remained on top of the tube after being inverted

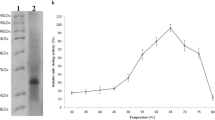

Evaluation of the saturation and the number of stages in ammonium sulphate precipitation

To obtain the optimum yield and activity of the algal protease, we investigated the effect of ammonium sulphate concentration and the number of purification stages on protease yield and specific activity and the results are presented in Table 1. Protein loss was indeed a consequence in the AS precipitation method. However, the CA was expected to increase along the purification process. In the first stage of ammonium sulphate precipitation, the protein yield ranged from 0.65 to 1.78 mg protein g−1 algal dry matter. The highest protein recovery (12.3%) was obtained at 60% saturation of ammonium sulphate, although statistically the value was not significant different from those at 50 and 70% saturation. The specific caseinolytic activities (SCA) of PEs from the first stage of precipitation was increased compared to CE, with the highest activity (0.13 units mg−1 protein) and purification factor (2.3) obtained at 50% saturation. The protein yield in the second stage ranged from 0.83 to 1.13 mg protein g−1 alga. The average protein recovery of the second stage was also lower than that of in the first stage. At 85% saturation, the values of PC, CA and SCA were at the highest among the those of other fractions at the second stage. This fraction was further evaluated in the pooled fraction.

The pooled fraction was a mixture of the PE obtained from the 50% saturation in the first stage and second stage, and the protein recovery and caseinolytic activities of the pooled PE were determined.

Comparison of desalting methods

Three desalting methods, dialysis, desalting column and the combination of two, were evaluated to determine the most efficient process for removing ammonium sulphate from the protease solution, and Table 2 shows the results. For protein yield, the highest value (1.406 mg protein g−1 alga d.m.) was obtained by dialysis (PEDI), which was substantially higher (P < 0.05) than those by the other two methods. Although the desalting column method gave a higher total amount and recovery of protein, particularly in its pooled fraction PEDE (11.4 mg and 13%, respectively), the protein yield (0.635 mg protein g−1 alga) was still lower than dialysis (PEDI).

In regard to the SCA, the combined methods (DIDE) gave the highest values, especially for the second fraction PEDIDE2 (0.171 units mg−1 protein). However, due to the large volume of eluent used, which resulted in the very diluted solution of the PEDIDE, the CA values for the fractions obtained either by the desalting column or the combined methods (ranging from 0 to 0.057 units mL−1) were significantly (P < 0.05) lower than that of the dialysis method (0.133 units mL−1).

Discussion

The results of both protein content and caseinolytic activity analysis demonstrated that extraction from unmilled (whole) algal sample was more effective in extracting the proteins and maintaining the caseinolytic activity. According to Saftig (2005) protease is a part of lysosomal enzymes located in the tissue cells, which needs to be disrupted to facilitate the extraction of protease. The tissue cells of the unmilled algal samples were largely intact before being broken by homogenisation; thus, the materials including the protease inside were likely to be intact before being extracted into the solvent. Meanwhile, for the milled samples, the milling process may expose the cellular material to degradation, leading to a lower protein content in the crude extract. Moreover, exposure of the cellular content to the cold temperature of liquid nitrogen (below -190 °C) could lead to protein damage (Di et al. 2018). The sharp temperature drop to -65 °C could decrease protein flexibility, and protein disfunction could occur at the lower temperature, which might lead to a partial loss of caseinolytic activity (More et al. 1995). These could be the reasons for the lower protein content and CA for extracts obtained from the milled samples.

The CA result was in agreement with Bele et al. (2014) who also found that G. edulis harvested from Pulicat Lake (Chennai, India) showed significant caseinolytic activity. A preliminary study by Pérez-Lloréns et al. (2003) qualitatively investigated the caseinolytic activity of algae from Chlorophyta, Rhodophyta and Phaeophyta phylum, which showed that some species exhibited high activities, including Ulva lactuca, Corallina officinalis, Peyssonnelia sp., Fucus vesiculosus, Pelvetia canaliculata and Stypocaulon scoparium (current name Halopteris scaparia).

Because the extracted protease was intended to be used as a milk coagulant in cheese-making, its milk-clotting activity (MCA) was also evaluated. Despite the presence of caseinolytic activities in the seven algae species, only the extract from the unmilled sample of G. edulis showed the ability to clot the milk. Therefore, according to this result, G. edulis was selected as the potential milk-clotting enzyme and was further evaluated in the subsequent purification process. In addition to caseinolytic activity, milk-clotting activity plays an important role in determining the suitability of an enzyme for cheese making. This is because the coagulation ability of an enzyme strongly affects the degradation of casein and has major impact on the yield and quality of cheese (Shah and Mir 2014). An early study by Abdel-Fattah and Edrees (1973) revealed that U. lactuca, a green marine alga, has milk-clotting ability. They found that the water extract of U. lactuca was able to clot milk within 5 h. Recent studies about algal proteases have focused on the analysis of their proteolytic and caseinolytic activities, but ignored their milk-clotting properties (Pérez-Lloréns et al. 2003; Sharmila et al. 2012; Bele et al. 2014; Patil and Rebecca 2014).

The G. edulis protease was purified by ammonium sulphate precipitation, which is one of the most commonly used method for protein purification and is able to maintain protein structure and functionalities (Burgess 2009). This method has been used to purify milk-clotting enzymes from Withania coagulans and the red seaweed Petrocladia capillacea (El-Shora et al. 2016; Salehi et al. 2017). Previous studies have shown that the concentration of ammonium sulphate as well as the number of purification stages can affect both the yield and specific activities of the extracted enzymes (Burgess 2009). Several studies conducted only single stage of ammonium sulphate precipitation, e.g., for enzymes extracted from Moringa oleifera and tamarillo fruit (Pontual et al. 2012; Li et al. 2018a). Meanwhile, other studies performed multiple stage ammonium sulphate precipitation, e.g., for proteases extracted from artichoke leaves and alpine thistle flowers (Esposito et al. 2016).

By comparing the protein content and SCA of each concentration of ammonium sulphate precipitation, solution at 50% saturation was selected as the best option for purification of the algal protease, and its supernatant was used in the second stage ammonium sulphate precipitation. However, the second stage of ammonium sulphate precipitation did not increase the protein yield, it also neither improved the CA nor the SCA. As expected, the protein recovery in the pooled PE was higher than the CE and its two source PE fractions. However, the values of CA and SCA of the pooled fraction were lower than those of the PE from the 50% saturation of the first stage. Based on the above results, it was concluded that a single stage purification of algal protease by precipitation with ammonium sulphate at 50% saturation was optimum in the overall consideration of protein recovery, caseinolytic activity and procedure simplicity.

The lower protein yield of PEDE might be caused by the numerous elution steps that used a much higher amount of solvent, resulting in a lower protein concentration. Dialysis is a common but also highly efficient method for salt removal in the protocol for protease purification. Several studies have used this method for the purification of milk-clotting enzymes from plant sources such as Withania coagulans (Beigomi et al. 2014) and Solanum dubium (Ahmed et al. 2009). Duong-Ly and Gabelli (2014) also recommended dialysis in protein purification protocol instead of the desalting column for removing high concentrations of ammonium sulphate. Our results agreed with those previous findings. Our results demonstrated that the desalting column and the combination of dialysis and desalting column were not efficient for protein yield and recovery and were more cumbersome than dialysis. For these reasons, dialysis was concluded to be the appropriate desalting method for the purification of G. edulis protease.

Conclusion

To search for alternative milk coagulants to animal rennet, this study evaluated proteolytic enzymes from seven algal species and found that only Gracilaria edulis contained a protease with significant caseinolytic activity. Extraction from unmilled whole algal sample was higher than the milled samples in the overall protein yield and caseinolytic activity. One stage ammonium sulphate precipitation followed by dialysis was found to be the optimum procedure for purifying the enzymatic extract of G. edulis.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Abdel-Fattah AF, Edrees M (1973) Seasonal changes in the constituents of Ulva lactuca. Phytochemistry 12:481–485

Ahmed IAM, Morishima I, Babiker EE, Mori N (2009) Characterisation of partially purified milk-clotting enzyme from Solanum dubium Fresen seeds. Food Chem 116:395–400

AOAC International (2007) Official Methods of Analysis of AOAC International, 8th edn. AOAC International, Gaithersburg

Arbita AA, Paul NA, Cox J, Zhao J (2020) Extraction, partial purification and characterization of proteases from the red seaweed Gracilaria edulis with similar cleavage sites on κ-casein as calf rennet. Food Chem 330:127324

Beigomi M, Mohammadifar MA, Hashemi M, Rohani MG, Senthil K, Valizadeh M (2014) Biochemical and rheological characterization of a protease from fruits of Withania coagulans with a milk-clotting activity. Food Sci Biotechnol 23:1805–1813

Bele SD, Patil SS, Sharmila S, Rebecca LJ (2014) Isolation and partial purification of lipase and protease from marine algae. J Chem Pharm Res 6:1153–1156

Burgess RR (2009) Protein precipitation techniques. Meth Enzymol 463:331–342

Di W, Jiang X, Xu J, Jia M, Li B, Liu Y (2018) Stress and damage mechanisms in Dendrobium nobile Lindl. protocorm-like bodies during pre- and post-liquid nitrogen exposure in cryopreservation revealed by iTRAQ proteomic analysis. Vitr Cell Dev Biol - Plant 54:253–272

Duong-ly KC, Gabelli SB (2014) Salting out of proteins using ammonium sulfate precipitation. Meth Enzymol 541:85–94

El-Shora HM, Abou-El-Wafa GS, Kadhim AI (2016) Purification and biochemical characteristic of protease from the red seaweed Petrocladia capillacea. Int J Curr Microbiol Appl Sci 5:297–308

Esposito M, Di Pierro P, Dejonghe W, Mariniello L, Porta R (2016) Enzymatic milk clotting activity in artichoke (Cynara scolymus) leaves and alpine thistle (Carduus defloratus) flowers. Immobilization of alpine thistle aspartic protease. Food Chem 204:115–121

Guiry MD, Guiry GM (2023) AlgaeBase. World-wide electronic publication, National University of Ireland, Galway. https://www.algaebase.org Accessed 2 Apr 2023

Gutiérrez-Méndez N, Chávez-Garay DR, Jiménez-Campos H (2012) Exploring the milk-clotting properties of a plant coagulant from the berries of S. elaeagnifolium var. cavanilles. J Food Sci 77:89–94

Li Z, Scott K, Hemar Y, Otter D (2018a) Protease activity of enzyme extracts from tamarillo fruit and their specific hydrolysis of bovine caseins. Food Res Int 109:380–386

Li Z, Scott K, Hemar Y, Zhang H, Otter D (2018b) Purification and characterisation of a protease (tamarillin) from tamarillo fruit. Food Chem 256:228–234

Lobban CS, Harrison PJ (1997) Seaweed Ecology and Physiology. Cambridge University Press, New York

Moore PA, Kery V (2009) High-throughput protein concentration and buffer exchange: comparison of ultrafiltration and ammonium sulfate precipitation. Meth Mol Biol 498:309–314

More N, Daniel RM, Petach HH (1995) The effect of low temperatures on enzyme activity. Biochem J 305:17–20

Patil SS, Rebecca LJ (2014) Isolation and characterization of protease from marine algae. Int J Pharm Sci Rev Res 27:188–190

Pérez-Lloréns JL, Benítez E, Vergara JJ, Berges JA (2003) Characterization of proteolytic enzyme activities in macroalgae. Eur J Phycol 38:55–64

Pontual EV, Carvalho BEA, Bezerra RS, Coelho LCBB, Napoleão TH, Paiva PMG (2012) Caseinolytic and milk-clotting activities from Moringa oleifera flowers. Food Chem 135:1848–1854

Rojas A, Doolittle RF (2002) The occurrence of type S1A serine proteases in sponge and jellyfish. J Mol Evol 55:790–794

Rosenthal A, Pyle DL, Niranjan K (1996) Aqueous and enzymatic processes for edible oil extraction. Enzyme Microb Technol 19:402–420

Saftig P (ed) (2005) Lysosomes. Springer, New York

Sakhthivel R, Devi KP (2015) Evaluation of physicochemical properties, proximate and nutritional composition of Gracilaria edulis collected from Palk Bay. Food Chem 174:68–74

Salehi M, Aghamaali MR, Sajedi RH, Asghari SM, Jorjani E (2017) Purification and characterization of a milk-clotting aspartic protease from Withania coagulans fruit. Int J Biol Macromol 98:847–854

Shah MA, Mir SA (2014) Plant proteases as milk-clotting enzymes in cheesemaking : a review. Dairy Sci Technol 94:5–16

Sharmila S, Rebecca LJ, Susithra G, Dhanalakshmi V, Saduzzaman (2012) Partial Purification of protease from seaweed. Int J Appl Biotech Biochem 2:81–85

Smith PK, Krohn RI, Hermason GT et al (1985) Measurement of protein using bicinchoninic acid. Anal Biochem 150:76–85

Sun Q, Zhang B, Yan Q-J, Jiang Z-Q (2016) Comparative analysis on the distribution of protease activities among fruits and vegetable resources. Food Chem 213:708–713

Torres P, Santos JP, Chow F, dos Santos DYAC (2019) A comprehensive review of traditional uses, bioactivity potential, and chemical diversity of the genus Gracilaria (Gracilariales, Rhodophyta). Algal Res 37:288–306

Acknowledgements

We thank C Morris from the University of the South Pacific for the supply of the dried seaweed from Fiji and S. Tiitii from the Ministry of Agriculture and Fisheries for the supply of the dried seaweed from Samoa under the ACIAR Project FIS/2010/098.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions This study was supported by a full PhD scholarship of AA Arbita, provided by the Indonesian Endowment Fund for Education (LPDP).

Author information

Authors and Affiliations

Contributions

Ariestya Arlene Arbita: methodology development, experimentation, data analysis, manuscript drafting and revision; Jian Zhao: project conceptualisation, primary supervision, manuscript reviewing and editing; Nicholas A. Paul: providing algae samples, co-supervision and manuscript editing; Julian Cox: contributing to conceptualisation and co-supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest in this study.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Arbita, A.A., Paul, N.A., Cox, J. et al. Screening and isolation of milk-clotting enzymes from seaweed. J Appl Phycol 36, 887–896 (2024). https://doi.org/10.1007/s10811-023-02975-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-023-02975-4