Abstract

Aqueous extracts from Ascophyllum nodosum brown edible seaweeds were obtained after continuous ultrasound-assisted extraction. The effect of sonication time (from 2 to 6 min), sonication amplitude (from 80 to 100%) and solvent-solid ratio (from 20 to 40 g water g−1 dried seaweed) on the extracts features was studied employing a Box-Behnken experimental design. Extracts were characterised by polyphenols, carbohydrate and uronic acid content. Response surface method (by means of a quadratic model) was successfully employed to relate chemical composition of extracts and operation conditions. Optimal experimental conditions were established to obtain maximal polyphenols content and several polyphenols-carbohydrates ratios together with the conditions that minimise energy consumption per extracted polyphenols amount relationship. Antioxidant capacities of extracts were measured employing different methods (DPPH, FRAP and ABTS). Positive linear correlations between antioxidant activity and total polyphenols content were established.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

High seaweeds content of polysaccharides, polyunsaturated fatty acids, minerals, fibre, vitamins and antioxidant bioactive molecules (Pereira 2011) put algae in the spotlight to be used in several applications such as medicine, pharmaceutics, cosmetics (Holdt and Kraan 2011), fertilisers (Craigie 2011), wastewater treatment (Lawton 2017) and food industry (Leandro et al. 2020). Global seaweed-derived products’ demand generates relevant socio-economic benefits; indeed, the algae consumption trends foresee increases around 10% until 2025 (FAO 2018).

Nowadays, the algae-based refinery concept is promoted. The aim is to develop biorefineries to produce valuable compounds with seaweeds as unique raw material (Herrero and Ibáñez 2015). The extraction of bioactive compounds can be carried out with water as unique solvent; the manufacture does not require high temperatures; and the successive multiple compounds extraction minimises residues generated, concepts that follow green chemistry principles (US EPA 2012).

Brown seaweeds are resource for several industries since they have high contents of polyphenols, fucoidans and alginate (Holdt and Kraan 2011). These nutraceuticals have recently gained relevance for their beneficial health applications since they have shown antioxidant (Koivikko et al. 2005), anticoagulant, antitumor, anti-inflammatory (Cumashi et al. 2007) and anti-viral properties (Damonte et al. 2012). Seaweed biochemical composition is variable and depends on species, season, geographic origin, contaminants and their natural individual variability (Tabassum et al. 2016). Some biomaterials from seaweeds have shown promising features to be employed as food additives for the new formulations of some meals, particularly, gluten-free food products (Zhang et al. 2018). Polyphenols extracted from brown seaweeds are potential food additives that act as competitive inhibitors of digestive α-amylase and α-glucosidase enzymes, inhibiting carbohydrates hydrolysis that cause a reduction of the sugar intake levels (Rodrigues et al. 2015). Extracts from brown edible seaweed Ascophyllum nodosum have also shown antidiabetic effects in mouse models (Lee and Yeon 2013).

Phlorotannins are exclusive secondary polyphenolic metabolites from brown algae. In fact, brown seaweeds owe their colour to high polyphenols contents. Phlorotannins are produced entirely by polymerisation of the phloroglucinol molecule (1,3,5-trihydroxybenzene), and their content in seaweeds depends on environmental parameters, such as tides, currents, salinity, light availability, UV radiation and herbivory intensity (Tabassum et al. 2016). These molecules act as chemical defences against herbivory and UV radiation. Phlorotannins have also structural roles forming part of cell walls together with alginic acids molecules (Koivikko et al. 2005). Alginic acids are a group of uronic polymers derived from polysaccharides, composed of mannuronic and guluronic acids monomers (Rehm 2005). Alginic forms are principally located in cell walls of brown seaweeds and determine algae flexibility (Pereira 2011).

Ultrasound-assisted extraction (UAE) is one of the most widespread polyphenols extraction methods from different natural raw materials (Cikos et al. 2018; Bordoloi and Goosen 2020). This method has recently attracted attention since it is a low-cost equipment and procedure (Kadam et al. 2015a), and it is even considered an eco-friendly technology according with the US EPA (Talmaciu et al. 2015). In comparison to other green techniques, ultrasound technology is simpler and faster than microwave-assisted extraction (Zhu et al. 2017) and less dependent on the algal biochemical composition compared with enzyme-assisted extraction (Hahn et al. 2012).

Several authors have applied UAE to nutraceuticals extraction from marine macroalgae since it has three major extraction benefits: promotes the solvents penetration into cellular materials, improves mass transfer and disrupts plant cell walls facilitating cell content release (Povey and Mason 1998). UAE is more effective to produce enriched antioxidant extracts (Dang et al. 2017). Moreira et al. (2016) studied the effect of fresh seaweed drying temperature on the polyphenols-enriched extracts obtained by UAE and observed total polyphenol content (TPC) and antioxidant activity decreased and uronic acids increased with drying temperature. Additionally, a previous study about air drying effect on three brown seaweeds (Fucus vesiculosus, Bifurcaria bifurcata and A. nodosum) concluded that drying at 50 °C and 30% of relative humidity were the optimal drying conditions to improve antioxidant properties of polyphenols extracts by UAE (Moreira et al. 2017).

Kadam et al. (2015a) compared the efficiency of aqueous and acidic solutions during UAE of laminarin and polyphenols from AN and Laminarina hyperborea. Rodrigues et al. (2015) compared enzymatic and UAE methods on the properties of extracts from three algae species (Osmundea pinnatifida, Sargassum muticum and Codium tomentosum) obtaining the highest TPC from brown seaweed and the highest carbohydrate content from red seaweed. This study obtained the extracts carrying out extractions after seaweed drying at 50 °C and sonication at 400 W for 10 min at 50 °C in a batch process.

Ascophyllum nodosum brown edible seaweed was selected for this study for its high polyphenols (14% dry solid, d.s.) content (Holdt and Kraan 2011). The characterisation of seaweeds extracts usually includes the TPC and the evaluation of their antioxidant activity by means of different methods such as DPPH, FRAP and ABTS methods (Dang et al. 2017). DPPH determine free radical scavenging capacity of samples, ABTS determine hydrogen/electron donor capacity of samples, and FRAP evaluates reducing capacity of Fe3+ ion of the samples (Mesa-Vanegas et al. 2015). DPPH, ABTS and FRAP are quick and easy methods with high reproducibility for antioxidant capacities characterisation of aqueous ultrasound-assisted extracted polyphenols from seaweed.

UAE habitually transfers polysaccharides and uronic acids to liquid phase together with polyphenols. This fact demands additional characterisation techniques to evaluate the total carbohydrate content (CHOs) and the total uronic acids content (UA) of the extracts (Leyton et al. 2016; Moreira et al. 2016). Carbohydrates and uronic acids could be considered contaminants of extracted polyphenols, because they can interact forming complexes that could modify chemical and structural polyphenols features (Wang et al. 2016). At these conditions, extracts would require further purification and fractionation treatments.

Water is an efficient solvent for polyphenols extraction (Leyton et al. 2016). Additionally, the use of water reduces subsequent purification stages required when binary solvents are used. However, aqueous blends of acetone (Koivikko et al. 2005), acids (Kadam et al. 2015a) or ethanol (Audibert et al. 2010) improve the extraction of polyphenols since they extract soluble and insoluble fractions of polyphenols. Parameters such as cost, efficiency and feasibility of the process must be considered. Temperature control is a critical parameter since it could significantly reduce extraction of thermal sensitive compounds as polyphenols and some sugars (Tello-Ireland et al. 2011). Operation temperature should be kept under 40 °C to minimise the heat sensitive compound loosing (Li et al. 2017; Catarino et al. 2019).

The aim of this work was to determine the best conditions of aqueous UAE of polyphenols by the evaluation of the effects, following a Box-Behnken (BB) experimental design, of the sonication power measured by amplitude (A, %), sonication time (t, min) and the mass solvent-solid ratio (S, gW gDS−1) using A. nodosum. Extracts were characterised by total polyphenol (TPC, mgPE gDS−1), total carbohydrates (CHOs, mgGE gDS−1) and total uronic acids (UA, mgGE gDS−1) content. Antioxidant capacities (DPPH, ABTS and FRAP methods) of extracts were also measured. The use of several methods was convenient to characterise the antioxidant capacity of the samples since the blends were composed of many reactive species that interact (Koivikko et al. 2005).

Materials and methods

Raw materials, reagents, and pre-treatments

Fresh samples of Ascophyllum nodosum (AN) (73.7 ± 3.8% wet basis) were supplied by Mar de Ardora S.L. company (Ortigueira, Spain), collected from the Galicia’s coasts (NW of Spain) in autumn. The samples were washed with running tap water to remove any trace of sand, shellfishes, epiphytes and sediments.

All chemical reagents used in the treatments and characterisations were analytical grade and were sulfuric acid, glacial acetic acid, phenol and iron sulphate from Merck (Germany). 2,2–Diphenyl-1-picrylhydrazyl (DPPH), 2,4,6-Tris(2-pyridyl)-s-triazine (TPTZ), sulfamic acid, 3-hydroxybiphenyl, glucuronic acid, potassium hydroxide, potassium chloride, iron(III) chloride, sodium chloride, potassium dihydrogen phosphate, sodium phosphate, sodium azide, phloroglucinol and sodium acetate were from Sigma-Aldrich (USA). 2,2′-Azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) diammonium salt (ABTS), sodium carbonate, Folin-Ciocalteu reagent, chlorohydric acid, sodium tetraborate, glucose, trolox, sodium hydroxide and methanol were from Panreac (Spain).

Seaweed samples were dried in a hot air convective dryer at 50 °C, keeping the relative humidity at 30% and the air velocity at 2 m s−1 until the moisture content was 15.5 ± 1.2% (dry solid, d.s.). Then, seaweeds were aerated for 3 days at room temperature (19 ± 1 °C) to achieve a uniform moisture content.

Dried A. nodosum samples were ground in an ultra-centrifugal mill (Retsch GmbH, ZM200, Germany) and sieved using a vibratory sieve (FTL 0200, Cisa, Spain) with standard meshes from 40 to 500 μm. The average particle size of seaweed powder was 276 ± 8 μm. Seaweed flour was sealed in plastic bags with a vacuum packer and stored at 4 °C with final moisture content of 4.3 ± 0.1% (d.s.).

Ultrasound-assisted extraction (UAE) conditions

Aqueous extracts from AN were processed with a 1000 W ultrasound processor (Hielscher, UIP-1000 hdT, Germany) using a 200-mL jacked chamber, controlling the temperature with a cold-water bath to maintain the temperature under 30 °C during the operation. Continuous UAE operation was performed controlling the liquid flow with a peristaltic pump. An initial rest time (15 min) for seaweed rehydration with double distilled water was established (Arufe et al. 2019).

Three levels of sonication power were regulated by amplitudes of 80% (72 W cm−2), 90% (81) and 100% (90); three residence times regulated by the pump flow, 2 (1.94 mL s−1), 4 (0.97) and 6 min (0.64); and three liquid–solid ratios 20, 30 and 40 g of water per g of dry seaweed, gW gDS−1, were evaluated. A Box-Behnken (BB) experimental design (Box and Behnken 1960) was employed with coded variables shown in Table 1, generating 17 experimental runs (1–17) summarised in Table 2. Reliability of the obtained models was checked preparing 6 additional extracts (A–F) as shown in Table 2.

Extracts characterisation

Extracts were centrifuged at 8000 × g, 10 min. Then, supernatant was filtered with 0.45 µm microfibre filter (Merck Millipore, USA) and stored at -20 °C. All aqueous extract characterisations were carried out by spectrophotometry (Genesis 10S UV, Thermo Fisher Scientific, USA) at least in triplicate.

Total polyphenol content (TPC) was determined using a calibration (R2 = 0.99) with phloroglucinol as standard following the method proposed by Singleton and Rossi (1965) based on the Folin-Ciocalteu reagent reaction with hydroxyl groups, measured spectrophotometrically at 765 nm. The TPC values were given as g of phloroglucinol equivalents per litre (gPE L−1).

Carbohydrates, in the presence of acids and heat, were transformed into furans that react with phenol giving orange solutions that could be analysed spectrophotometrically at 485 nm (Dubois et al. 1956). The total carbohydrate content (CHOs) was evaluated using a calibration with glucose as reference (R2 = 0.99). CHOs results were given in g of glucose equivalents per litre (gGE L−1).

Uronic acid content (UA) determination was spectrophotometrically at 520 nm (Blumenkrantz and Asboe-Hansen 1973) using a calibration with glucose as reference (R2 = 0.99), and the values are given in g of glucose equivalents per litre (gGE L−1).

DPPH, FRAP and ABTS methods were used to determine the antioxidant activity of extracts. DPPH scavenging activity measures were performed following Brand-Williams et al. (1995). Measurements were taken after a resting time of 30 min in complete darkness at room temperature (19 ± 1 °C) from a DPPH solution of 60 µM. The scavenging activity of samples was determined measuring absorbance at 515 nm and was expressed as DPPH decay percentage (%).

ABTS method was carried out following Re et al. (1999). Extracts-ABTS blends were incubated in darkness for 30 min at room temperature, and absorbance was measured at 734 nm. Data were evaluated using a calibration with Trolox reagent as reference (R2 > 0.99) and expressed as mg of Trolox equivalents per litre (mgTE L−1).

The iron cation reduction capacity (FRAP) of the extracts was performed according to Benzie and Strain (1996). The blends seaweed extracts-FRAP were incubated in darkness for 30 min at room temperature, and absorbance was measured at 593 nm and evaluated using a calibration with Trolox as reference (R2 > 0.99) and expressed as mg of Trolox equivalents per litre (mgTE L−1).

Statistical analysis

Statistical analysis was carried out using IBM SPSS statistics 24 (SPSS Inc., USA) software. A one-way analysis of variance (ANOVA) was assessed based on confidence interval of 95% (p < 0.05) using a Duncan test. The experimental results of Box-Behnken extracts were treated and plotted on MATLAB R2019b software (MathWorks Inc., USA). All experimental results are expressed as mean ± standard deviation of triplicate experiments (n = 3).

Results

Extracts characterisation

The experimental responses of the 17 runs corresponding to BB design, presented as the mean of triplicate experiments, are shown in Table 2. Experimental total polyphenol contents (TPC) ranged from 1.3 ± 0.02 (runs 6, 11, 12, 13 and 17) to 2.8 ± 0.01 gPE L−1 (run 14). Total carbohydrate contents (CHOs) were ranged from 0.5 ± 0.06 (run 6) to 1.5 ± 0.02 gGE L−1 (run 14). Finally, experimental total uronic acids contents (UA) ranged from 0.04 ± 0.02 (run 3) to 0.8 ± 0.05 gGE L−1 (run 14). Maximal TPC, CHOs and UA extracts content were obtained in the run 14 (conditions of A = 100%, t = 2 min and S = 20 gW gDS−1). Globally, it can be observed that the extracts obtained, when low solvent-solid ratios were employed, provided high TPC, CHOs and UA content. The variation of the residence time, between 2 and 6 min, seemed to have slight influence on the TPC and UA content of extracts; however, CHOs increased with increasing residence times. Finally, the power of sonication (amplitude) increased the extraction of polyphenols, carbohydrates and uronic acids.

Response surface modelling

ANOVA was conducted to evaluate the significance of the models for 95% (p < 0.05) confidence interval (Table 3). A crossed reduced quadratic model was selected (model p-value < 0.0001) for TPC, CHOs and UA in the aqueous extracts after backward elimination step to eliminate the non-significant terms. The insignificant lack of fit test of 0.06, 0.09 and 0.05 observed for TPC, CHOs and UA content, respectively, indicated that well-fitting model and models were adequate to describe experimental data. In addition, the values of coefficient of determination, R2, and adjusted R2 were higher than 0.91 and 0.88, respectively, for TPC, CHOs and UA confirming the fit goodness of the respective models.

The significant (p < 0.05) effect on the TPC was contributed by the linear and quadratic terms of liquid–solid ratio (S), and the interaction term between amplitude and liquid–solid ratio (AS). It is worth mentioning the absence of significant effects of the sonication time on the TPC of extracts. The significant effect on the CHOs was contributed by the linear term S, and the interaction terms, amplitude time (At) and time-liquid–solid ratio (tS). Finally, the significant effect on the UA was contributed by the linear terms A and S and interaction terms AS and tS. These results indicated that liquid–solid ratio, as well as their interactions with amplitude and time, played a prominent role in the UAE of polyphenols, carbohydrates and uronic acids, while sonication amplitude and time residence played secondary roles. The final response equations for TPC, CHOs and UA contents, in coded variables, are given in the Eqs. (1), (2) and (3), respectively:

where A is the coded sonication amplitude, t is coded sonication time and S is coded solvent-solid ratio.

Equation (1) estimated the maximum TPC value of 2.8 gPE L−1 at the same operation conditions than those given by run 14. The minimum CHOs content (0.31 gGE L−1) was found (by means of Eq. (2)) at the highest S, the shortest t and an intermediate A value (88%), that is, experimental conditions closer to run 6. Finally,a minimum UA content (0.01 gGE L−1), Eq. (3) was found at intermediate conditions of A (84%) and t (2.5 min), and close to the highest S (38 gW gDS−1).

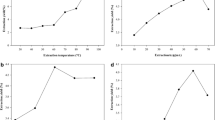

In order to observe the different TPC, CHOs and UA trends, several representative plottings are collected in Fig. 1, where two TPC plots (a and b) are shown as function of t and S at constant amplitudes 80 and 100%, respectively; two CHOS plots (c) as function of t and S at constant A (80%) and (d) as function of A and S at constant t (2 min); and finally two UA plots (e) as function of t and S at constant A (90%) and (f) as function of A and S at constant time (4 min). These plots are also useful to observe the noticeable agreement between experimental data given by the BB design and estimated value for the respective models. Furthermore, several dots corresponding to the additional extracts performed are also included. It can be observed that the response surfaces are very close to these experimental data, verifying again the suitability of the proposed models.

Response surface plots for a,b polyphenols (TPC, gPE L−1); c,d carbohydrates (CHOs, gGE L−1) and e,f uronic acids (UA, gGE L−1) content vs studied variables at constant amplitude (A, %) or time (t, min): a,c A = 80, e A = 90, b A = 100, d t = 2 and f t = 4. Box-Behnken (black box) and additional points (star)

Analysis of TPC ratios

Each experimental run gave aqueous extracts with different compositions from A. nodosum. Maximum TPC can be a criterion to select the optimal extracts conditions (run 14, in this study). Nevertheless, this could imply necessary subsequent operations of polyphenols isolation and purification. It is also important to consider the cost, efficiency and feasibility of the experiment, and the optimal extraction condition must be related to minimise energy consumption and operation time (increase production). Studied TPC ratios are summarised in Table 4.

TPC/UA (gPE gGE−1) ratios varied in a wide range from 3.42 ± 0.1 up to 41.2 ± 0.6 and high values of the corresponded to runs with the tested highest S (40) ratio. Specifically, the highest TPC/UA ratios were obtained in run 3 (A = 80% and t = 4 min) and run 6 (A = 90% and t = 2 min) with ratios of 41.2 ± 0.6 and 21.9 ± 0.7, because UA content of these extracts was less than 0.06 gGE L−1. TPC/CHOs (gPE gGE−1) ratios ranged into a narrow interval from 1.7 ± 0.03 up to 2.7 ± 0.2, and the maximum value was again found in the run 6 where experimental conditions were the least favourable for both polyphenols (1.3 ± 0.1 gPE L−1) and sugars (0.5 ± 0.1 gGE L−1) extractions and corresponding to middle sonication power (90%), the lowest time residence (2 min) and the largest liquid–solid ratio (40 gW gDS−1). The third analysed ratio, TPC/(CHOs-UA) (gPE gGE−1), was the relationship between polyphenols and all those sugars that are not isoforms of alginic acid. With this ratio, it was discerned between the fraction of easily separable alginic extraction procedures, and those sugars whose separation from polyphenols would require alternative methods (Chee et al. 2011). This ratio varied from 2.1 ± 0.1 to 4.0 ± 0.1, and the maximum value was determined in run 7 with intermediate conditions of the Box-Behnken (BB) design (A = 90%, t = 4 min and S = 30 gW gDS−1). This result seemed to indicate that any extreme conditions selected for sonication amplitude, residence time or solvent-solid ratio (within the experimental plan) decreased the ratio value because carbohydrates (not alginic) were more promoted at these conditions to be extracted than polyphenols.

Response surface fittings were used to obtain the corresponding estimated optimal ratios. Maximal (3.25 gPE gGE−1) values of TPC/CHOs and TPC/(CHOs-UA) ratios were determined at the conditions of the shortest t, the highest S and at intermediate A (88%), closed to run 6. Maximal TPC/UA ratio (47 gPE gGE−1) was found at the lowest A, the highest S and intermediate t (4.3 min), close to run 3. These results indicated that some experimental points were close enough to optimal values and consequently no additional experiments to corroborate these theoretical values were necessary.

Energy consumption (J) was evaluated, considering sonication area (6.2 cm2), time and power applied. The energy/TPC ratio (KJ gPE−1 L−1) ranged from 14.6 ± 0.1 up to 96.3 ± 0.1 (run 12), indicating that extracts with the highest energy efficiency for polyphenols extraction were runs 5 and 14. Both extracts achieved relatively high TPC employing the lowest sonication energy (mainly related to short sonication times).

Runs 5 and 14 gave the lowest energy/TPC ratio, and no significant differences were found between their values of TPC/UA, TPC/CHOs and TPC/(CHOs-UA) ratios. Particularly, the last ratio gave a promising high value (3.6 ± 0.1) indicating favourable conditions for the extraction of polyphenols and uronic acids against other carbohydrates. At first, polyphenols of these extracts could be more easily submitted to further purification treatments. Globally, it can be concluded that conditions that maximised polyphenol extraction with low energy consumption corresponded to low S (20 gW gDS−1), short t (2 min) and A above 90%.

Antioxidant activity of extracts

Antioxidant capacity and activity of ultrasound-assisted extracts were studied by DPPH, ABTS and FRAP methods. The DPPH scavenging assays showed antioxidant capacities from 35.69 ± 0.23% (runs 6 and 11) up to 57.24 ± 0.01% (run 14). ABTS values ranged from 43.9 ± 0.7 (run 6) to 92.8 ± 0.1 mgTE L−1 (run 14) and FRAP activities between 39.4 ± 1.4 (run 6) and 63.3 ± 0.4 mgTE L−1 (run 14). The antioxidant capacity of the extracts showed similar trends for the three methods assayed. In fact, independently of the employed method, run 14 (A = 100%, t = 2 min and S = 20 gW gDS−1) showed the highest antioxidant capacity, whereas the weakest antioxidant capacity slightly varied between methods and was always localised at run 6 (A = 90%, t = 2 min and S = 40 gW gDS−1).

IC50 values were calculated for the runs that showed the highest antioxidant activities. Values of 97.5 mgPE mmolDPPH−1 (corresponding to 119.0 mgPE L−1), 106.7 (127.2), 130.5 (147.6) for runs 2, 5 and 14, respectively, were obtained. Linear correlations (R2 > 0.9) between antioxidant responses (DPPH, ABTS and FRAP) and TPC of extracts were found (Fig. 2a, b and c).

Discussion

The obtained results were compared with the literature in which TPC, CHOs and UA of extracts were also determined from A. nodosum or other brown seaweeds using UAE. Other authors found that the extraction conditions that maximise TPC simultaneously increase the extraction of other biocompounds such as carbohydrates or uronic acids resulting in multicomponent solutions (Catarino et al. 2019). Kadam et al. (2015b) working with dried A. nodosum (40 °C for 12 h) and employing longer extraction times (from 5 to 25 min) than those employed in this work, HCl solvent concentration (from 0 to 0.06 M) and ultrasound amplitude (from 22.8 to 114 µm) determined that maximal TPC of 143.0 mgGE gDS−1 (14.3 gGE L−1) expressed in gallic acid equivalents was accompanied with maximal CHOs extraction of 86.6 mgGE gDS−1 (8.7 gGE L−1) and UA of 117.4 mgGE gDS−1 (11.7 gGE L−1) operating at the highest sonication power and acidic concentration and the longest times. Moreira et al. (2016) obtained aqueous extracts with values of 15.6 mgPE gDS−1 (0.5 gPE L−1), 52.0 mgGE gDS−1 (1.7 gGE L−1) and 20.7 mgGE gDS−1 (0.7 gGE L−1) of TPC, CHOs and UA, respectively, from UAE extraction carried out for 4 min, S = 30 gW gDS−1 and 90 W cm−2 employing F. vesiculosus dried at 50° C for 8 h and determined the high impact of the drying temperature (above 50 °C) of seaweeds on TPC and UA content of the extracts.

Alternative non-aqueous extraction methods showed interesting results on polyphenols extraction. Specifically, Zhang et al. (2007) with fresh A. nodosum obtained high TPC of 70.2 mgPE gDS−1 (5.6 gPE L−1) employing low liquid–solid ratios (12.5 gW gDS−1) and water–ethanol (50% v/v) as solvent during very long extraction times (90 min) and at high temperature (80ºC). Ummat et al. (2020) obtained extracts with the highest TPC values of 47.6 mgPE gDS−1 (4.8 gPE L−1) using hydroalcoholic solutions as solvent (ethanol 50% v/v), with a very low solvent-solid ratio (10 gW gDS−1) and very long extraction times (30 min) of UAE from Fucus vesiculosus seaweed previously dried at 50 °C for 9 days. Microwave-assisted extraction of A. nodosum was studied by Yuan et al. (2018) obtaining a TPC of 14.0 mgPE gDS−1 (1.4 gPE L−1) working with fresh algae (S = 15 gW gDS−1) during 15 min and 110 °C using water–methanol (70% (v/v)) solution as extraction solvent. In view of the results, it can be concluded that working at room temperature (below 30 °C) with 100% of sonication amplitude, liquid–solid ratio of 20 gW gDS−1 and very short time, around 2 min (run 14), was obtained a promising TPC value of 55.6 ± 0.2 mgPE gDS−1 (2.8 ± 0.01 gPE L−1).

It must be considered that data collected from literature about seaweed extraction corresponds to batch experiments, working in some cases with different (alcoholic, acidic) solvents, higher temperatures, longer operation times and lower liquid–solid ratios resulting in a wide TPC range. Despite that UAE technology is in the spotlight of seaweed industry and in the research of new antioxidant resources, to carry out a comparison covering all the bibliographic results is difficult since it is necessary to consider that there are several relevant extraction conditions and pre-treatments (mainly drying methods, conditions and procedures) like grinding (mean particle size and particle size distribution), or use of different compounds as quantification standards, could hardly affect to the extracts features.

Seaweeds scavenging activities have been studied by several authors such as Goswami et al. (2016) employing phloroglucinol standard molecule reported values around 46 mgPE mmolDPPH−1. Wang et al. (2009) studied extracts from A. nodosum by a liquid–solid extraction (20 gW gDS−1) using two different solvents, water and acetone 70% (v/v), during 24 h at room temperature, and the highest IC50 (43.50 mgPE mmolDPPH−1) was obtained with acetone blends. Kirke et al. (2017) reported IC50 values between 20 and 40 mgPE L−1 at room temperature and 70 and 80 mgPE L−1 at 50 °C measured from purified fractions extracts obtained from F. vesiculosus carrying out extractions with a liquid–solid ratio of 10 gW gDS−1 using water–methanol 80% (v/v) solution for 24 h. Audibert et al. (2010) presented IC50 values around 19 mgPE mmolDPPH−1 from purified polyphenols fractions obtained from A. nodosum after liquid–solid extraction with methanol at 4 gW gDS−1, 3 h at 40 °C.

Matanjun et al. (2008) studied several seaweed species and obtained ABTS values from 375 to 475 mmolTE L−1 mgDE−1 and FRAP capacities of 63 and 92 mgTE mgDE−1 for extracts obtained from Dictyota dichotoma, Sargassum polycystum and Padina species, employing methanol or diethyl ether as solvents at ratios of 10 gW gDS−1 for 72 h. Audibert et al. (2010) reported ABTS values around 235–540 mgTE L−1. FRAP values obtained by Ummat et al. (2020) were around 50 mgTE L−1.

Briefly, in comparison to above mentioned studies, obtained IC50 values from DPPH assays in this study showed lower scavenging activities than phloroglucinol, A. nodosum extracts or purified fractions from F. vesiculosus. Furthermore, reported that ABTS values were higher than those obtained here and, finally, FRAP values were in the same range. It is worthy to note that despite lower antioxidant responses of extracts were determined in this study, they were obtained after very short times of extraction with low energy consumption without further purification or fractionizing processes of the extracts.

In relation to the linear correlations of DPPH, ABTS and FRAP with TPC, other authors also found these trends with other seaweeds. Moreira et al. (2016) obtained these linear relationships with F. vesiculosus extracts and Matanjun et al. (2008) for red (Eucheuma cottonii, Eucheuma spinosum, Halymenia durvillaei), green (Caulerpa lentillifera, Caulerpa racemosa) and brown (Dictyota dichotoma, Sargassum polycystum, Padina sp.) algae. This linear trend suggested that polyphenols present in the extracts, regardless of extraction conditions, remained chemically similar (Connan et al. 2004) and TPC gave the main antioxidant responses of the extracts.

Conclusions

Continuous UAE extraction modelling of Ascophyllum nodosum carried out at room temperature indicated that TPC of extracts depended on sonication amplitude (power) and solvent-solid ratio (with no dependence of sonication time). Carbohydrate and uronic acid content depended on sonicated time, amplitude and solvent-solid ratio following a quadratic model. Maximal TPC (55.6 ± 0.2 mgPE gDS−1 or 2.8 ± 0.01 gPE L−1) were obtained at 100% of sonication amplitude, solvent-solid ratio of 20 gW gDS−1 and 2 min. Experimental data modelling (TPC, CHOS and UA) allowed to determine the optimal (3.25 gPE gGE−1) values of TPC/CHOs and TPC/(CHOs-UA) ratios being obtained at intermediate amplitude (88%), solvent-solid ratio of 20 gW gDS−1 and 2 min. The conditions that minimised the consumption of energy per gram of extracted polyphenols corresponded to low solvent-solid ratio (20 gW gDS−1), short sonication time (2 min) and amplitude above 90%. Aqueous extracts with high TPC were obtained indicating that UAE is a promising technology to produce extracts with bioactive molecules employing short extraction times and with low energy consumption in relation to other techniques. Antioxidant capacity values (DPPH, ABTS and FRAP) of extracts using water as solvent and sonication technology were comparable to those extracts obtained after very long extractions (> 5 h) and employing organic solvents. Antioxidant capacities were linearly correlated with the total polyphenol contents of the extracts.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Change history

27 November 2021

This article contains funding note, which has been added.

References

Arufe S, Sineiro J, Moreira R (2019) Determination of thermal transitions of gluten-free chestnut flour doughs enriched with brown seaweed powders and antioxidant properties of baked cookies. Heliyon 5:e01805

Audibert L, Fauchon M, Blanc N, Hauchard D, Ar Gall E (2010) Phenolic compounds in the brown seaweed Ascophyllum nodosum: distribution and radical-scavenging activities. Phytochem Anal 21:399–405

Benzie IFF, Strain JJ (1996) The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: The FRAP assay. Anal Biochem 239:70–76

Blumenkrantz N, Asboe-Hansen G (1973) New method for quantitative determination of uronic acids. Anal Biochem 54:484–489

Bordoloi A, Goosen N (2020) Green and integrated processing approaches for the recovery of high-value compounds from brown seaweeds. Adv Bot Res 95:369–413

Box GEP, Behnken DW (1960) Some new three level designs for the study of quantitative variables. Technometrics 2:455–475

Brand-Williams W, Cuvelier ME, Berset C (1995) Use of a free radical method to evaluate antioxidant activity. LWT-Food Sci Technol 28:25–30

Catarino MD, Silva AMS, Mateus N, Cardoso SM (2019) Optimization of phlorotannins extraction from Fucus vesiculosus and evaluation of their potential to prevent metabolic disorders. Mar Drugs 17:162–185

Chee SY, Wong P, Wong CL (2011) Extraction and characterisation of alginate from brown seaweeds (Fucales, Phaeophyceae) collected from Port Dickson, Peninsular Malaysia. J Appl Phycol 23:191–196

Cikos AM, Jokic S, Subaric D, Jerkovic I (2018) Overview on the application of modern methods for the extraction of bioactive compounds from marine macroalgae. Mar Drugs 16:348–368

Connan S, Goulard F, Stiger V, Deslandes E, Ar Gall E (2004) Interspecific and temporal variation in phlorotannin levels in an assemblage of brown algae. Bot Mar 47:410–416

Craigie JS (2011) Seaweed extract stimuli in plant science and agriculture. J Appl Phycol 23:371–393

Cumashi A, Ushakova NA, Preobrazhenskaya ME, D’Incecco A, Piccoli A, Totani L, Tinari N, Morozevich GE, Berman AE, Bilan MI, Usov AI, Ustyuzhanina NE, Grachev AA, Sanderson CJ, Kelly M, Rabinovich GA, Iacobelli S, Nifantiev NE (2007) A comparative study of the anti-inflammatory, anticoagulant, antiangiogenic, and antiadhesive activities of nine different fucoidans from brown seaweeds. Glycobiology 17:541–552

Damonte E, Matulewicz M, Cerezo A (2012) Sulphated seaweed polysaccharides as antiviral agents. Curr Med Chem 11:2399–2419

Dang TT, Vuong QV, Schreider MJ, Bowyer MC, Altena IAV, Scarlet CJ (2017) Optimisation of ultrasound-assisted extraction conditions for phenolic content and antioxidant activities of the alga Hormosira banksii using response surface methodology. J Appl Phycol 29:3161–3173

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

FAO (2018) The global status of seaweed production, trade, and utilization. Globefish Research Programme 124:120–132

Goswami SK, Gangadarappa SK, Vishwanath M, Razdan R, Jamwal R, Bhadri N, Inamdar MN (2016) Antioxidant potential and ability of phloroglucinol to decrease formation of advanced glycation end products increase efficacy of sildenafil in diabetes-induced sexual dysfunction of rats. Sex Med 4:106–114

Hahn T, Lang S, Ulber R, Muffler K (2012) Novel procedures for the extraction of fucoidan from brown algae. Process Biochem 47:1691–1698

Herrero M, Ibáñez E (2015) Green processes and sustainability: An overview on the extraction of high added-value products from seaweeds and microalgae. J Supercrit Fluid 96:211–216

Holdt SL, Kraan S (2011) Bioactive compounds in seaweed: Functional food applications and legislation. J Appl Phycol 23:543–597

Kadam SU, O’Donnell CP, Rai DK, Hossain MB, Burgess CM, Walsh D, Tiwari BK (2015a) Laminarin from Irish brown seaweeds Ascophyllum nodosum and Laminaria hyperborea: ultrasound assisted extraction, characterisation, and bioactivity. Mar Drugs 13:4270–4280

Kadam SU, Tiwari BK, Smyth TJ, O’Donnell CP (2015b) Optimization of ultrasound assisted extraction of bioactive components from brown seaweed Ascophyllum nodosum using surface methodology. Ultrason Sonochem 23:308–316

Kirke DA, Smyth TJ, Rai DK, Kenny O, Stengel DB (2017) The chemical and antioxidant stability of isolated low molecular weight phlorotannins. Food Chem 221:1104–1112

Koivikko R, Loponen J, Honkanen T, Jormalainen V (2005) Contents of soluble, cell-wall-bound, and exuded phlorotannins in the brown alga Fucus vesiculosus, with implications on their ecological functions. J Chem Ecol 31:195–212

Lawton RJ (2017) The industrial ecology of freshwater macroalga for biomass applications. Algal Res 24:486–491

Leandro A, Pacheco D, Cotas J, Marques JC, Pereira L, Gonçalves AMM (2020) Seaweed’s bioactive candidate compounds to food. Life 10:140

Lee SH, Yeon YJ (2013) Anti-diabetic effects of brown algae derived phlorotannins, marine polyphenols through diverse mechanisms. Fitoterapia 86:129–136

Leyton A, Pezoa-Conte P, Barriga A, Buschmann AH, Maki-Arvela P, Mikkola JP, Lienqueo ME (2016) Identification and efficient extraction method of phlorotannins from the brown seaweed Macrocystis pyrifera using an orthogonal experimental design. Algal Res 16:201–208

Li Y, Fu X, Duan D, Liu X, Xu J, Gao X (2017) Extraction and identification of phlorotannins from the brown alga, Sargassum fusiforme (Harvey) Setchell. Mar Drugs 15:49–64

Matanjun P, Mohamed S, Mustapha NM, Muhammad K, Ming CH (2008) Antioxidant activities and phenolics content of eight species of seaweeds from north Borneo. J Appl Phycol 20:367–373

Mesa-Vanegas AM, Zapata-Uribe S, Arana LM, Zapata IC, Monsalve Z, Rojano B (2015) Antioxidant activity of different polarity extracts from Ageratum conyzoides L. Bol Latinoam Caribe Plant Med Aromat 14:1–10

Moreira R, Chenlo F, Sineiro J, Arufe S, Sexto S (2016) Drying temperature effect on powder physical properties and aqueous extract characteristics of Fucus vesiculosus. J Appl Phycol 28:2485–2494

Moreira R, Sineiro J, Chenlo F, Arufe S, Díaz-Varela D (2017) Aqueous extracts of Ascophyllum nodosum obtained by ultrasound-assisted extraction: effects of drying temperature of seaweed on the properties of extracts. J Appl Phycol 29:3191–3200

Pereira L (2011) A review of the nutrient composition of selected edible seaweeds. In: Pomin VH (ed) Seaweed: Ecology, Nutrient Composition and Medicinal Uses. Nova Science Publishers, New York, pp 15–50

Povey MJW, Mason TJ (1998) Ultrasound in food processing, the Way Forward. Blackie Academic & Professional, London

Re R, Pellegrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radical Bio Med 26:1231–1237

Rehm BHA (2005) Biosynthesis and applications of alginates. In: Wnek G, Bowlin G (eds) Biosynthesis and applications of alginates. CRC Press, Boca Raton, Encyclopaedia of Biomaterials and Biomedical Engineering, pp 1–9

Rodrigues D, Sousa S, Silva A, Amorim M, Pereira L, Rocha-Santos TAP, Gomes AMP, Duarte AC, Freitas AC (2015) Impact of enzyme- and ultrasound-assisted extraction methods on biological properties of red, brown, and green seaweeds from the central west coast of Portugal. J Agr Food Chem 63:3177–3188

Singleton VL, Rossi JA (1965) Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Enol Viticult 16:144–158

Tabassum MR, Xia A, Murphy JD (2016) Seasonal variation of chemical composition and biomethane production from the brown seaweed Ascophyllum nodosum. Bioresource Technol 216:219–226

Talmaciu AI, Volf I, Popa VI (2015) A comparative analysis of the “green” techniques applied for polyphenols extraction from bioresources. Chem Biodivers 12:1635–1651

Tello-Ireland C, Lemus-Mondaca R, Vega-Gálvez A, López J, Di Scala K (2011) Influence of hot-air temperature on drying kinetics, functional properties, colour, phycobiliproteins, antioxidant capacity, texture, and agar yield of alga Gracilaria chilensis. LWT-Food Sci Technol 44:2112–2118

Ummat V, Tiwari BK, Jaiswal AK, Condon K, Garcia-Vaquero M, O’Doherty J, O’Donnell C, Rajauria G (2020) Optimization of ultrasound frequency, extraction time and solvent for the recovery of polyphenols, phlorotannins and associated antioxidant activity of brown seaweeds. Mar Drugs 18:250–265

US EPA (2012) Green Chemistry. United States Environmental Protection Agency, Washington. https://www.epa.gov/greenchemistry/basics-green-chemistry#twelve; Searched on 3 November 2020

Wang T, Jónsdóttir R, Ólafsdóttir G (2009) Total phenolic compounds, radical scavenging and metal chelation of extracts from Icelandic seaweeds. Food Chem 116:240–248

Wang J, Hu S, Nie S, Yu Q, Xie M (2016) Reviews on mechanisms of in vitro antioxidant activity of polysaccharides. Oxid Med Cell Longev 2016:5692852

Yang Z, Han Y, Gu Z, Fan G, Chen Z (2008) Thermal degradation kinetics of aqueous anthocyanins and visual color of purple corn (Zea mays L.) cob. Innov Food Sci Emerg 9:341–347

Yuan Y, Zhang J, Fan J, Clark J, Shen P, Li Y, Zhang C (2018) Microwave assisted extraction of phenolic compounds from four economic brown macroalgae species and evaluation of their antioxidant activities and inhibitory effects on α-amylase, α-glucosidase, pancreatic lipase and tyrosinase. Food Res Int 113:288–297

Zhang J, Tiller C, Shen J, Wang C, Girouard GS, Dennis D, Barrow CJ, Miao M, Stewart HS (2007) Antidiabetic properties pf polysaccharide- polyphenolic- enriched fractions from the brown seaweed Ascophyllum nodosum. Can J Physiol Pharm 85:1116–1127

Zhang D, Wang C, Shen L, Shind HC, Lee KB, Jif B (2018) Comparative analysis of oxidative mechanisms of phloroglucinol and dieckol by electrochemical, spectroscopic, cellular and computational methods. RSC Adv 8:1963–1972

Zhu Z, Wu Q, Di X, Li S, Barba FJ, Koubaa M, Roohinejad S, Xiong X, He J (2017) Multistage recovery process of seaweed pigments: investigation of ultrasound assisted extraction and ultra-filtration performances. Food Bioprod Process 104:40–47

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. This work was supported by the Ministry of Science and Innovation of Spain and European Regional Development Fund (ERDF) of European Union by the research project (RTI2018-095919-B-C2) and Xunta de Galicia, Spain (Consolidation Project ED431B 2019/01).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gisbert, M., Barcala, M., Rosell, C.M. et al. Aqueous extracts characteristics obtained by ultrasound-assisted extraction from Ascophyllum nodosum seaweeds: effect of operation conditions. J Appl Phycol 33, 3297–3308 (2021). https://doi.org/10.1007/s10811-021-02546-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-021-02546-5