Abstract

Magnetic field as a simple and powerful tool is usually applied to electrochemical machining, but the influencing mechanism is a very complicated problem. Ti-48Al-2Cr-2Nb (at. %) alloy dissolution behavior without and with magnetic field was carried out. Open circuit potential (OCP), electrochemical impedance spectroscopy (EIS), cyclic voltammetry (CV), cyclic potentiodynamic polarization (CPP), chronoamperometry (CA), and observation of corrosion morphology combined with energy spectrum analysis were applied. In addition, multifractal spectrum and surface roughness were used to evaluate uniformity and roughness of surface topography of the electrochemical machining (ECM) of Ti-48Al-2Cr-2Nb alloy. The results prove that the magnetic field improves the response rate of adsorption reaction, enhances the decomposition potential and the sensitivity to local corrosion, suppresses the fluctuation of the current density, and reduces the dissolution rate during electrochemical corrosion of Ti-48Al-2Cr-2Nb alloy. The results also verify that the improvement of magnetic field on uniformity of corrosion contributes to obtain an isotropic microscopic surface in the electrochemical machining of Ti-48Al-2Cr-2Nb alloy. The surface roughness of the electrochemical machined surface of Ti-48Al-2Cr-2Nb alloy without and with magnetic field is Ra 2.46 ± 0.14 μm and 1.73 ± 0.28 μm, respectively, which confirms that the deterioration in the preferential corrosion of γ-TiAl phase caused by magnetic field does not become a detrimental factor in obtaining a smooth machined surface. So, magnetic field has a positive effect in the electrochemical machining process of Ti-48Al-2Cr-2Nb alloy and can be applied to the actual production.

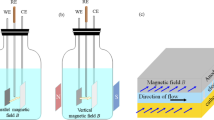

Graphical abstract

The influence of magnetic field on electrochemical dissolution behavior and surface quality of electrochemical machining of Ti-48Al-2Cr-2Nb alloy

Similar content being viewed by others

References

Xu Z, Wang Y (2021) Electrochemical machining of complex components of aero-engines: developments, trends, and technological advances. Chinese J Aeronaut 34:28–53. https://doi.org/10.1016/j.cja.2019.09.016

Pawar A, Kamble D, Ghorpade RR (2021) Overview on electro-chemical machining of super alloys. Mater Today 46:696–700. https://doi.org/10.1016/j.matpr.2020.12.017

Bradley C, Samuel J (2018) Controlled phase interactions between pulsed electric fields, ultrasonic motion, and magnetic fields in an anodic dissolution cell. J Manuf Sci Eng 140:041010–041011. https://doi.org/10.1115/1.4038569

Ayyappan S, Sivakumar K, Kalaimathi M (2015) Electrochemical machining of 20MnCr5 alloy steel with magnetic flux assisted vibrating tool. Proc Inst Mech Eng, Part C 231:1956–1965. https://doi.org/10.1177/0954406215623310

Enache S, Opran C (1989) The mathematical model of the E.C.M. with magnetic field. CIRP Ann 38:207–210. https://doi.org/10.1016/S0007-8506(07)62686-9

Fan Z, Wang T, Zhong L (2004) The mechanism of improving machining accuracy of ECM by magnetic field. J Mater Process Tech 149:409–413. https://doi.org/10.1016/j.jmatprotec.2003.12.025

Frotscher O, Schaarschmidt I, Lauwers D, Paul R, Meinke M, Steinert P, Schubert A, Schröder W, Richter M (2022) Investigation of Lorentz force–induced flow of NaNO3-electrolyte for magnetic field–assisted electrochemical machining. Int J Adv Manuf Technol 121:937–947. https://doi.org/10.1007/s00170-022-09349-z

Li L, Baoji MA (2018) Effect of magnetic field on anodic dissolution in electrochemical machining. Int J Adv Manuf Technol 94:1177–1187. https://doi.org/10.1007/s00170-017-0983-9

Lilong BM, Cheng P, Yun K, Yin P (2019) Effect of magnetic field on the electrochemical machining localization. Int J Adv Manuf Technol 102:949–956. https://doi.org/10.1007/s00170-018-3185-1

Vinod Kumaar JR, Thanigaivelan R (2020) Performance of magnetic field-assisted citric acid electrolyte on electrochemical micro-machining of SS 316L. Mater Manuf Process 35:969–977. https://doi.org/10.1080/10426914.2020.1750630

Zhai K, Tang L, Liu J, Zhang X, Yan Y, Feng X (2021) Study on improving the surface roughness of multi-stage internal cone hole by rotating magnetic field assisted electrochemical machining. Int J Adv Manuf Technol 115:1227–1236. https://doi.org/10.1007/s00170-021-06930-w

Ling S, Jia Y, Ning F, Li H, Xiao Q, Lu Z (2018) Effect of magnetic field on anodic dissolution of nickel in an alkaline solution with chloride ions. ECS Trans 85:615–623. https://doi.org/10.1149/08513.0615ecst

Klocke F, Herrig T, Zeis M, Klink A (2015) Experimental research on the electrochemical machinability of selected γ-TiAl alloys for the manufacture of future aero engine components. Procedia CIRP 35:50–54. https://doi.org/10.1016/j.procir.2015.08.050

Li HY, Klocke F, Zeis M, Herrig T, Heidemanns L (2018) Experimental study on the ECM and PECM of pressed and casted γ-TiAl alloys for aero engine applications. Procedia CIRP 68:768–771. https://doi.org/10.1016/j.procir.2017.12.135

Wang Y, Xu Z, Hu J, Zhang A (2020) Surface integrity analysis of electrochemical machining of γ-TiAl alloys. Mater Today Commun 25:101686. https://doi.org/10.1016/j.mtcomm.2020.101686

Wang Y, Xu Z, Meng D, Liu L, Fang Z (2022) Study on surface roughness of large size TiAl intermetallic blade in electrochemical machining. J Manuf Process 76:1–10. https://doi.org/10.1016/j.jmapro.2022.01.035

Wang X, Zhao J, Hu Y, Li L, Wang C (2014) Effects of the Lorentz force and the gradient magnetic force on the anodic dissolution of nickel in HNO3+NaCl solution. Electrochim Acta 117:113–119. https://doi.org/10.1016/j.electacta.2013.11.100

Liu S, Shao Y, Yan C, Yuan B, Li L, Wang C (2020) Effects of the magnetic field on the anodic dissolution of Ni│H3PO4 + KSCN system. Corros Sci 169:108614. https://doi.org/10.1016/j.corsci.2020.108614

Luo S, Elouarzaki K, Xu ZJ (2022) Electrochemistry in magnetic fields. Angew Chem Int Ed 61:e202203564. https://doi.org/10.1002/anie.202203564

Li X, Zhang M, Yuan B, Li L, Wang C (2016) Effects of the magnetic field on the corrosion dissolution of the 304 SS│FeCl3 system. Electrochim Acta 222:619–626. https://doi.org/10.1016/j.electacta.2016.11.017

Zhang X, Wang Z, Zhou Z, Xu J (2017) Effects of magnetic field and rare earth addition on corrosion behavior of Al-3.0 wt% Mg alloy. J Alloys Compd 698:241–249. https://doi.org/10.1016/j.jallcom.2016.12.184

Zhang X, Wang Z-H, Zhou Z-H, Xu J-M, Zhong Z-J, Yuan H-L (2017) Corrosion behavior of Al–3.0 wt%Mg alloy in NaCl solution under magnetic field. Rare Met 36:627–634. https://doi.org/10.1007/s12598-016-0785-5

Zhang X, Wang Z, Zhou Z, Yang G, Cai X (2021) Impact of magnetic field on corrosion performance of Al–Mg alloy with different electrode potential phases. Intermetallics 129:107037. https://doi.org/10.1016/j.intermet.2020.107037

Buteau S, Dahn DC, Dahn JR (2018) Explicit conversion between different equivalent circuit models for electrochemical impedance analysis of lithium-ion cells. J Electrochem Soc 165:A228–A234. https://doi.org/10.1149/2.0841802jes

Westerhoff U, Kurbach K, Lienesch F, Kurrat M (2016) Analysis of lithium-ion battery models based on electrochemical impedance spectroscopy. Energy Technol 4:1620–1630. https://doi.org/10.1002/ente.201600154

Pirnát A, Mészáros L, Lengyel B (1990) Study of the formation of chromate layer on zinc by impedance technique. Electrochim Acta 35:515–522. https://doi.org/10.1016/0013-4686(90)87038-4

Liao CJ, Liu Q, Ma XZ, Liu JH (2019) Relationship between surface heterogeneity and electrochemical interface behavior of the TiAl alloy electrode. J Phys Chem C 123:473–484. https://doi.org/10.1021/acs.jpcc.8b09123

Sun B, Ni X, Cao Y, Cao G (2017) Electrochemical sensor based on magnetic molecularly imprinted nanoparticles modified magnetic electrode for determination of Hb. Biosens Bioelectron 91:354–358. https://doi.org/10.1016/j.bios.2016.12.056

Esmailzadeh S, Aliofkhazraei M, Sarlak H (2018) Interpretation of cyclic potentiodynamic polarization test results for study of corrosion behavior of metals: a review. Prot Met Phys Chem 54:976–989. https://doi.org/10.1134/S207020511805026X

Bellezze T, Giuliani G, Roventi G (2018) Study of stainless steels corrosion in a strong acid mixture. Part 1: cyclic potentiodynamic polarization curves examined by means of an analytical method. Corros Sci 130:113–125. https://doi.org/10.1016/j.corsci.2017.10.012

Wang X-Z, Ye C-P, Shi D-D, Fan H-Q, Li Q (2021) Potential polarization accelerated degradation of interfacial electrical conductivity for Au/TiN coated 316L SS bipolar plates used in polymer electrolyte membrane fuel cells. Corros Sci 189:109624. https://doi.org/10.1016/j.corsci.2021.109624

Nikulov AV, Dubonos SV, Koval YI (1997) Destruction of the phase coherence by magnetic field in the fluctuation region of thin superconducting films. J Low Temp Phys 109:643–652. https://doi.org/10.1023/A:1022207216763

Tacken RA, Janssen LJJ (1995) Applications of magnetoelectrolysis. J Appl Electrochem 25:1–5. https://doi.org/10.1007/BF00251257

Qingdong XU, Kejian LI, Zhipeng CAI, Yao WU (2019) Effect of pulsed magnetic field on the microstructure of TC4 titanium alloy and its mechanism. Acta Metall Sin 55:489–495. https://doi.org/10.11900/0412.1961.2018.00257

Kelly EJ (1977) Magnetic field effects on electrochemical reactions occurring at metal/flowing-electrolyte interfaces. J Electrochem Soc 124:987–994. https://doi.org/10.1149/1.2133514

Liu ZJ, Zhong X, Walton J, Thompson GE (2015) Anodic film growth of titanium oxide using the 3-electrode electrochemical technique: effects of oxygen evolution and morphological characterizations. J Electrochem Soc 163:E75–E82. https://doi.org/10.1149/2.0181603jes

Arockiasamy A, Eliezer D, Wang PT, Horstemeyer MF, King RL (2010) Electrochemical hydrogenation and corrosion studies of Ti-48Al-2Cr-2Nb alloy in acidic solution. Anti-Corros Method M 57:280–289. https://doi.org/10.1108/00035591011087136

Nasehnejad M, Gholipour Shahraki M, Nabiyouni G (2016) Atomic force microscopy study, kinetic roughening and multifractal analysis of electrodeposited silver films. Appl Surf Sci 389:735–741. https://doi.org/10.1016/j.apsusc.2016.07.134

Chen X, Tang B, Liu D, Wei B, Zhu L, Liu R, Kou H, Li J (2021) Dynamic recrystallization and hot processing map of Ti-48Al-2Cr-2Nb alloy during the hot deformation. Mater Charact 179:111332. https://doi.org/10.1016/j.matchar.2021.111332

Yim S, Bian H, Aoyagi K, Chiba A (2021) Effect of multi-stage heat treatment on mechanical properties and microstructure transformation of Ti–48Al–2Cr–2Nb alloy. Mater Sci Eng A 816:141321. https://doi.org/10.1016/j.msea.2021.141321

Wang K, Liao C, Wang W, Xiao Y, Liu X, Zuo Y (2020) Removal of gas bubbles on an electrode using a magnet. ACS Appl Energy Mater 3:6752–6757. https://doi.org/10.1021/acsaem.0c00890

Li Y-H, Chen Y-J (2021) The effect of magnetic field on the dynamics of gas bubbles in water electrolysis. Sci Rep 11:9346. https://doi.org/10.1038/s41598-021-87947-9

Acknowledgements

The work was financially supported by the National Natural Science Foundation of China (No. 22072040) and the National Natural Science Foundation of Hunan Province, China (No. 2020JJ4271).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liao, C.J., Zhang, X.M. & Luo, Z.J. Magnetic field effects on electrochemical dissolution behavior and surface quality of electrochemical machining of Ti-48Al-2Cr-2Nb alloy. J Appl Electrochem 53, 49–63 (2023). https://doi.org/10.1007/s10800-022-01756-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-022-01756-0