Abstract

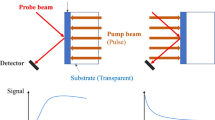

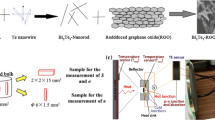

In this work, a measurement system for high-temperature thermal-conductivity measurements has been designed, constructed, and characterized. The system is based on the \(3{\upomega }\) method which is an ac technique suitable for both bulk and thin-film samples. The thermal-conductivity measurements were performed in a horizontal three-zone tube furnace whose sample space can be evacuated to vacuum or alternatively a protective argon gas environment can be applied to prevent undesired oxidation and contamination of the sample material. The system was tested with several dielectric, semiconductor, and metal bulk samples from room temperature up to 725 K. The test materials were chosen so that the thermal-conductivity values covered a wide range from \(0.37\,\hbox {W}\!\cdot \! \hbox {m}^{-1}\!\cdot \! \hbox {K}^{-1}\) to \(150\,\hbox {W}\!\cdot \! \hbox {m}^{-1}\!\cdot \!\hbox {K}^{-1}\). An uncertainty analysis for the thermal-conductivity measurements was carried out. The measurement accuracy is mainly limited by the determination of the third harmonic of the voltage over the resistive metal heater strip that is used for heating the sample. A typical relative measurement uncertainty in the thermal-conductivity measurements was between 5 % and 8 % (\(k=2\)). An extension of the \(3{\upomega }\) method was also implemented in which the metal heater strip is first deposited on a transferable Kapton foil. Utilizing such a prefabricated sensor allows for faster measurements of the samples as there is no need to deposit a heater strip on each new sample.

Similar content being viewed by others

References

E.S. Toberer, L.L. Baranowski, C. Dames, Annu. Rev. Mater. Res. 42, 179 (2012)

D.M. Rowe (ed.), Thermoelectrics Handbook: Macro to Nano (CRC Press, Boca Raton, FL, 2006)

D.G. Cahill, Rev. Sci. Instrum. 61, 802 (1990)

I.K. Moon, Y.H. Jeong, Rev. Sci. Instrum. 67, 29 (1996)

F. Chen, J. Shulman, Y. Xue, C.W. Chu, G.S. Nolas, Rev. Sci. Instrum. 75, 4578 (2004)

S.-M. Lee, Rev. Sci. Instrum. 80, 024901 (2009)

E. Yusibani, P.L. Woodfield, M. Fujii, K. Shinzato, X. Zhang, Y. Takata, Int. J. Thermophys. 30, 397 (2009)

S. Gauthier, A. Giani, P. Combette, Sens. Actuators A 195, 50 (2013)

D.G. Cahill, M. Katiyar, J.R. Abelson, Phys. Rev. B 50, 6077 (1994)

S.-M. Lee, D.G. Cahill, J. Appl. Phys. 81, 2590 (1997)

T. Yamane, N. Nagai, S.I. Katayama, M. Todoki, J. Appl. Phys. 91, 9772 (2002)

A. Jain, K.E. Goodson, J. Heat Trans. 130, 102402 (2008)

J. Alvarez-Quintana, J. Rodríguez-Viejo, Sens. Actuators A 142, 232 (2008)

B. Shen, Z. Zeng, C. Lin, Z. Hu, Int. J. Therm. Sci. 66, 19 (2013)

A. Holtzman, E. Shapira, Y. Selzer, Nanotechnology 23, 495711 (2012)

J. Hu, A.A. Padilla, J. Xu, T.S. Fisher, K.E. Goodson, J. Heat Trans. 128, 1109 (2006)

A. Jacquot, F. Vollmer, B. Bayer, M. Jaegle, D.G. Ebling, H. Böttner, J. Electron. Mater. 39, 1621 (2010)

J. Kimling, S. Martens, K. Nielsch, Rev. Sci. Instrum. 82, 074903 (2011)

JCGM 100:2008, Evaluation of measurement data—guide to the expression of uncertainty in measurement, 1st edn. (2008)

A. Jacquot, B. Lenoir, A. Dauscher, M. Stölzer, J. Meusel, J. Appl. Phys. 91, 4733 (2002)

H. Wang, M. Sen, Int. J. Heat Mass Trans. 52, 2102 (2009)

UQG Ltd., SCHOTT BOROFLOAT thermal properties, http://www.uqgoptics.com/materials_commercial_schott_borofloat.aspx. Accessed 29 November 2013

NTK Technologies Inc., Comparison of ceramic materials, http://www.ntktech.com/AlN/ALN%20for%20web.pdf. p. 8. Accessed 29 November 2013

eFunda Inc., Thermal conductivity of silicon, http://www.efunda.com/materials/elements/TC_Table.cfm?Element_ID=Si. Accessed 29 November 2013

Isabellenhütte Heusler GmbH & Co., ISOTAN properties and application notes, http://www.isabellenhuette.de/fileadmin/content/widerstandslegierungen/ISOTAN-ISABELLENHUETTE-R.pdf. Accessed 29 November 2013

Ferd. Wagner GmbH, ISOTAN technical data sheet, http://www.zapp.com/fileadmin/downloads/01-Produkte/Datenblaetter-Praezisionsprofile-Ferd-Wagner/Werkstoffdatenbl%C3%A4tter%20englisch/engl_isotan%20Cu%20Ni44.pdf. Accessed 29 November 2013

Acknowledgments

This work has received funding from the European Union on the basis of Decision No 912/2009/EC. The research has been carried out in the framework of the European Metrology Research Programme Eng02 - Metrology for Energy Harvesting. The development of the sample preparation techniques was partly funded by the Academy of Finland Project Number 140009, Cleen Ltd. and TEKES (the Finnish Funding Agency for Technology and Innovation).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hahtela, O., Ruoho, M., Mykkänen, E. et al. Thermal-Conductivity Measurement of Thermoelectric Materials Using \(3{{\upomega }}\) Method. Int J Thermophys 36, 3255–3271 (2015). https://doi.org/10.1007/s10765-015-1970-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10765-015-1970-8