Abstract

Expansive clayey soils often pose challenges for construction projects due to their low bearing capacity, swelling, and shrinkage properties. While previous research has explored additives to enhance these soils’ properties, the potential of sand remains underexplored. This study investigates the impact of varying sand percentages on expansive clayey soils’ consistency, compaction, and permeability. This study examines how adding different percentages of sand influences the physical properties of expansive clayey soils. Laboratory tests involved systematic testing of texture, compaction, and permeability. Findings reveal a notable improvement in the physical properties of the soil with the addition of sand. Results from the laboratory tests provided data for empirical equations that facilitate the prediction of soil properties based on the sand content. The enhancement in soil properties underscores the potential of sand as an additive for expansive clayey soils. The empirical equations presented here provide practical benefits to geotechnical engineers and practitioners engaged in construction projects involving these soils, offering them valuable insights into the benefits of sand additives to improve physical characteristics. The insights gained from this research hold promising prospects for improving construction practices and addressing the challenges associated with these soils.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Expansive clayey soils present a worldwide geotechnical problem, causing extensive damage to buildings and infrastructure and requiring costly repairs and delays to construction. Damage from expansive soils, such as structural fractures, building collapse, and road failures, costs billions of dollars annually (Steinberg 1985; Kolay and Ramesh 2016; Goodarzi et al. 2016; Salimi et al. 2018). Nelson and Miller (1997) have contended that expansive soils generate a financial impact more significant than earthquakes or floods. Considering these losses, there is a need to study expansive soils to find effective methods for mitigating their adverse effects on civil infrastructure.

Mineral additives and fibers inclusion have emerged as valuable tools in geotechnical engineering for improving the performance of expansive clayey soils. Table 1 presents the various materials used over many years to make the expansive clayey soils suitable for use in various civil engineering projects.

Sand also provides a beneficial effect on expansive soils. Understanding the relationship between sand percentage in clayey soil and its improved engineering performance requires additional testing and research. A common approach relates soil index properties to shrink-swell performance. Geotechnical laboratories determine Atterberg limits, grain size distribution, maximum dry density, and optimum moisture based on standard tests they perform at a modest cost (Edora et al. 2021; Alavi et al. 2010; Holtz 2001). Engineers then correlate these results to the soil mixtures’ strength, compression, and swell properties. The quantity of added sand may have a profound beneficial influence on the problematic soil.

The primary purpose of this research is to evaluate the laboratory results of such mixtures and to determine the extent to which sand can improve the physical characteristics of expansive soils from Damserkhu, Syria.

Previous researchers have investigated the behavior of expansive soils by adding sand (Kaoua et al. 1994; Louafi and Bahar 2012; Nagaraj 2016; Deng et al. 2017; Phanikumar et al. 2021). Roy (2013) also studied changes in the plasticity, compaction, and strength characteristics of soil mixtures as they improved from adding sand in varying proportions to cohesive soil.

Researchers, including Louafi and Bahar (2012), Roy (2013), Srikanth and Mishra (2019), and Atemimi (2020) have conducted investigations on the impact of adding sand to improve soil consistency. Their findings show that adding sand to expansive soil significantly reduces the liquid limit and plasticity index and highlights the importance of sand in enhancing the engineering characteristics of cohesive soil.

Al Rawi et al. (2018) investigated the effect of adding sand (0–20%) on the characteristics of low plasticity clayey soil. The results revealed that as the percentage of added sand increased, the soil’s liquid limit values and plasticity index values decreased. Furthermore, the soil strength and permeability coefficient increased with increasing percentages of added sand.

The study by Khan et al. (2014) investigated the behavior of clay-sand mixtures with varied sand percentages (0–20–40%) using standard Proctor tests. Their results showed that increasing sand content led to an increase in the maximum dry density (MDD) of the mixtures and a decrease in the optimum moisture content (OMC), which is consistent with studies by Roy (2013) and Gupta and Sharma (2014). Similarly, Prasad and Sharma (2014) reported an improvement in MDD with the addition of sand; however, they studied expansive soils with a high sand content, which may limit the applicability of their findings to mixtures with relatively small percentages of added sand.

Sand particles will tend to form peds within the clay matrix, eventually leading to a more robust support network within the remaining clay. The mixture is less sensitive to moisture, demonstrates some frictional strength, and increases permeability, ultimately leading to a higher bearing capacity when mixed and compacted on-site (Alnmr and Ray 2021).

In summary, while previous studies have shown that adding sand to expansive soil can be an effective and cost-efficient means of improvement, the impact of sand on the physical characteristics of the soil, particularly permeability coefficients, has not been adequately investigated in most published studies. Improved performance varied widely, and a single, general correlation remains elusive. Furthermore, prior studies have only looked at modest percentages of added sand and have not provided equations for predicting the physical characteristics of expansive soil based on widely varying sand content.

This study seeks to address these constraints by looking further into the effects of sand and constructing equations to predict the physical features of expanding soil based on sand content percentages. This is critical since sand content of soil samples taken from project locations can vary significantly and the derived relationships will aid in predicting the physical characteristics of such soils. By conducting thorough testing programs to determine index and performance properties, this study will correlate results between the two sets of test results. Overall, this study will improve our understanding of how sand impacts the physical characteristics of expansive soils and provide essential tools for future research and engineering applications.

2 Research Materials and Methodology

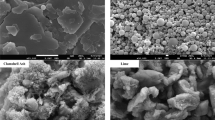

This research adopted an experiment-based approach to fulfill its objectives. The clay soil originated from Damserkhu, Lattakia, Syria, where technicians retrieved samples from a depth of about three meters. Starting from the surface, the geotechnical profile at the site consisted of three layers: (1) an agricultural layer with a thickness of up to 1 m; (2) an expansive soil layer that extended from 1 to 4 m depth; and (3) sandstone interlaced cementitious lime below 4 m. Sand used for mixing came from the Shuqayfat Jibla location in Syria and consisted of fine marine sand that remained on a No. 200 sieve after washing. A summary of physical properties appears in Table 2. Testing details appear in the paragraphs that follow.

Laboratory technicians performed the experiments according to ASTM standards. Sand-clay mixtures were prepared based on dry weight by blending the soil with varying percentages of sand (Fs) (10%, 20%, 30%, 40%, and 50%). Grain Size Distribution experiments (ASTM D6913/D6913M-17, 2017a; ASTM D7928-17, 2017d); produced particle size distribution curves shown in Fig. 1. Note that the shape of the curves suggests a gap-graded mixture with very little material between 0.1 and 0.01 mm in diameter. The percentage of clay particles with a diameter less than 0.002 mm was 73.9%. Table 3 shows the mineral composition of the clay.

The Casagrande method (ASTM D4318-17e1, 2017b) determined the liquid limit (LL). The procedure was repeated for several trials of moisture content to determine the final result. The LL results from a best-fit line of moisture vs. the number of drop impact blows to determine moisture at 25 blows (Casagrande 1932). The plastic limit (PL) test (ASTM D4318-17e1) involves manually rolling a soil thread on a glass plate until it crumbles at a specified diameter, typically about 3 mm. This crumbling is caused by air entry or cavitation within the soil thread (Haigh et al. 2015). Technicians mixed the proper proportions of sand and clay and then performed LL and PL tests on mixtures with % added sand = (0%, 10%, 20%, 30%, 40%, and 50%). The determination of the plasticity index (PI = LL − PL) resulted in the final step of plasticity determination (Bleam 2017). The mixtures are plotted on the Casagrande chart, as shown in Fig. 2. The data point labels show that the points follow the A-line but deviate above it with increasing sand content. The results are discussed further in a later section.

According to the AASHTO (2002) classification system, clean clayey soil (without sand) was classified as A-7-5, while under the USCS (unified soil classification system) (ASTM D2487-17e1, 2017c), it was classified as CH. The specific expansive clay mineral present in the clay was presumed to be illite (Holtz et al. 1981) based on its placement near or above the A-line on Casagrande’s plasticity chart.

According to Prakash and Sridharan (2004), the free swell determined for clean, clayey soil was 127%. The oedometer test revealed that the swelling pressure was equal to 26 tn/m2. Figure 3a presents the glass cylinders employed for determining free swelling. Figure 3b depicts the fixed-load oedometer used in performing consolidation tests (ASTM D2435/D2435M-11, 2020) for clay-sand mixtures to calculate hydraulic conductivity (k).

This study determined the maximum dry density and optimum moisture content of various mixtures using the standard Proctor method (ASTM D698-12e2, 2012). Hydraulic conductivity or the permeability coefficient resulted from back-calculating consolidation vs. time data. Terzaghi’s one-dimensional consolidation theory relates hydraulic conductivity to the two parameters resulting from the test as shown in Eq. (1) below:

where: \(K\): the hydraulic conductivity, \({c}_{v}\): the coefficient of consolidation, determined by Taylor’s method, \({m}_{v}\): the coefficient of volumetric change, \({\gamma }_{w}\): the unit weight of the water.

Watabe et al. (2011) utilized a similar method. They observed that this method’s hydraulic conductivity (k) compared well to the falling head permeability test results, provided the sand content did not exceed 50%.

Specimens mixed with varying sand content, compacted at maximum dry density/optimum moisture content, and tested for consolidation response provided K-values for this study. Each specific mixed specimen was blended, compacted, placed into the oedometer mold, and trimmed during sample preparation. Much care was required to achieve consistent densities and moisture contents. This approach provided improved control over essential parameters such as void ratio, moisture content, percentage of fines, and sand content within the mixed specimen, resulting in a more reliable and consistent experimental setting (Lupogo et al. 2009).

Figure 4 depicts images of the modified sample preparation process employed in the laboratory. First, sand and clay soils were blended to create a homogeneous mixture (a). The mixture was then placed in a sealed plastic bag and isolated for 24 h for a uniform moisture distribution (b). The resultant mixture mass was then placed in a mold with dimensions matching the oedometer ring (c). A hydraulic jack applied static pressure to compress the specimen to the desired unit weight (d). The finished specimen (e) was placed in the oedometer frame.

Figure 5 illustrates the sequence of the oedometer experiment, conducted as follows:

-

1.

Prepare soil samples based on the maximum dry unit weight and optimum moisture content obtained from the standard Proctor test for each sand-clay mixture.

-

2.

Place the prepared samples in the oedometer and apply a vertical load of 25 kPa.

-

3.

Allow 1–2 weeks for the samples to swell (this is 7 days in Fig. 5)

-

4.

Apply the following consolidation load sequence: 50, 100, 200, 400, (200), 400, 800, (400), (200), (100), (50), (25) shown by the green line in Fig. 5.

-

a)

Each load stage lasts approximately 48 h for loading and 24 h for unloading, followed by maintaining the load until it reaches a steady state.

-

b)

The overall duration of the consolidation test can exceed 1 month, extending up to 2 months. Figure 5 illustrates the process with a slightly shorter time line (about 3 weeks) but the stages were the same.

-

a)

-

5.

Remove the samples from the oedometer and dry them to determine their moisture content.

-

6.

Calculate the coefficient of volume compressibility (mv) and the coefficient of consolidation (Cv) depending on the logarithm of time at t90.

Figure 6 shows the compression curve of the clean clay, prepared according to standard Proctor specifications, with a dry unit weight (γd) of 13.95 kN/m3 and an optimum moisture content (wopt) of 31.9%.

3 Results and Discussion

This section presents the results of the laboratory program and discussion on correlating the results of the index tests to performance. The primary focus of the correlations is the effect of added sand. Following sections will address sand’s effect on soil consistency, shrinkage, Proctor density and moisture, oedometric modulus (Eoed), and hydraulic conductivity.

3.1 Effect of Sand on Soil Consistency

3.1.1 Effect of Sand on the Liquid Limit (LL) and Plastic Index (PI)

The results show that as the percentage of added sand (Fs) increases, both LL and PI decrease. While the plastic limit (PL) exhibits a similar trend, the decrease in PL is less steep than that in LL. These findings are consistent with previous soil improvement studies by Shankar et al. (2012), Louafi and Bahar (2012), and Roy (2013).

The effectiveness of sand in improving the characteristics of expansive soils is dependent on the soil’s plasticity index. Previous studies by Louafi and Bahar (2012) and Atemimi (2020), who used high-plasticity bentonite clay, found that adding sand significantly decreased the liquid and plastic limit values. The slope of the relationship between the Atterberg limits and the percentage of added sand was steeper, indicating greater improvement in soil properties. On the other hand, the current study used illite clay, which has a lower plasticity. Figure 7 shows that the plastic indices at 0% added sand were 44.2, 79.7, and 161 for the current, Atemimi, and Louafi and Bahar, respectively. These findings agree with those of Srikanth and Mishra (2019), who used more than 50% sand to improve the properties of high-plasticity soil.

Based on the experimental data, the current study derived Eqs. (2) and (3) for the liquid limit (LL) and plastic index (PI).

where: Fs% is the percentage of added sand.

3.1.2 Effect of Sand on the Shrinkage Limit and Longitudinal Shrinkage

The current study investigated the impact of sand addition on the shrinkage limit (SL) (ASTM D4943, 2008) and longitudinal shrinkage (L.Sh) (BS 1377-2, 1990).

3.1.2.1 Shrinkage Limit Test

The shrinkage limit experiments were carried out using soil samples sieved to pass through a 425-μm sieve. The soil samples were first remolded with distilled water to obtain a soil paste consistency approximating the liquid limit. Following that, the samples were oven-dried for 24 h at approximately 105 °C. A preliminary wax coating was applied to the oven-dried soil samples to reduce water absorption. After immersing the wax-coated samples in water, the weight of the displaced water was carefully measured. After that, the shrinkage limit (SL) was calculated using Eq. (4):

where: \({w}_{1}\) is the initial water content, V is the initial sample volume, \({V}_{d}\) is the volume of the sample after drying, \({m}_{s}\) is the mass of the dried soil, and \({\rho }_{w}\) is the density of water.

3.1.2.2 Shrinkage Limit Results

Shrinkage limit (SL), defined as the moisture content at which soil volume no longer decreases, shows a slight increase with increasing percentage of added sand (Fs), which is consistent with previous research by Srikanth and Mishra (2019). In contrast, as shown in Fig. 8, the shrinkage index (SI), which measures the difference between liquid limit (LL) and SL (Sridharan and Nagaraj 2011), decreases sharply with increasing percentage of added sand (Fs). This suggests that volumetric changes decrease significantly as the percentage of added sand (Fs) increases, potentially alleviating issues associated with expansive soils. Equation (5) was derived for the shrinkage limit (SL) in the current study.

3.1.2.3 Longitudinal Shrinkage Test

The current study also looked into longitudinal shrinkage (L.Sh), which is the change in length of a sample relative to its original length after drying a sample with moisture equal to the liquid limit placed in molds of specific dimensions.

The longitudinal shrinkage test was performed according to BS 1377-2. A 150 g soil sample with particles smaller than a 425-μm sieve was used in each test. The procedure began with remolding the soil samples with distilled water, resulting in a soil paste with a moisture content roughly equal to the soils’ liquid limits. The sample was then placed and leveled within the shrinkage mold. The sample’s initial moisture content and weight were recorded during this phase before subjecting it to natural drying at room temperature for approximately 24 h. Following that, the drying process was continued in an oven at a temperature not exceeding 60 °C until the shrinkage of the sample had significantly ceased. The final drying stage involved keeping the oven at around 105 °C for 24 h to complete the drying process. Finally, the oven-dried soil samples were measured for length and mass.

The percentage of linear shrinkage (L.SH) was calculated using Eq. (6)

where L.SH is the longitudinal shrinkage percentage, L0 is the initial length of the soil sample (mold length), and LD is the length of the dried sample.

3.1.2.4 Longitudinal Shrinkage Results

The results reveal that the longitudinal shrinkage limit decreases as sand content increases, as illustrated in Fig. 9 and defined by Eq. (7).

3.1.3 Proposed equations of LL, PI, L.Sh, and SL

The methods for developing the equations originate from linear regression analysis. This well-known statistical technique models linear relationships between variables. During this analytical procedure:

-

The dependent and independent variables were identified, with the dependent variable representing the particular soil property of interest (e.g., liquid limit, plasticity index) and the independent variable representing the percentage of added sand.

-

Individual linear regression analyses for each soil property under consideration were performed using the combined dataset from this research and relevant prior studies.

-

The equations were then formulated using the coefficients and intercepts derived from the linear regression analysis.

The current study examines the relationships between LL, PI, SL, and L.Sh and the percentage of added sand. Given that the Atterberg limits are known for a specific percentage of added sand, Eqs. (8), (9), (10), and (11) were proposed to predict the Atterberg limits of expansive clayey soils for any percentage of added sand. These equations are a helpful tool for engineering applications, allowing for the estimation of soil consistency under different conditions.

where \({LL}_{Fs}\), \({PI}_{Fs}\), \({SL}_{Fs}\) and \({L.Sh}_{Fs}\) are the unknown Atterberg limits for the desired percentage Fs. \({LL}_{Fs1}\), \({PI}_{Fs1}\), \({SL}_{Fs1}\) \({L.Sh}_{Fs1}\) and \({SL}_{Fs1}\) are the known Atterberg limits that correspond to the sand percentage Fs1.

To predict the liquid limit and plasticity index of expansive clayey soils at any given percentage of added sand using Eqs. (8) and (9), it is recommended to select a value from the stated ranges ( − 0.76 to − 2.47) and ( − 0.42 to − 1.78) for Eqs. (8) and (9), respectively. The selection can be determined with the graphic representation shown in Fig. 7.

3.2 Effect of Sand on Maximum Dry Unit Weight and Optimal Moisture Content

Standard Proctor experiments were performed in this study, as shown in Fig. 10, for determining the maximum dry unit weight and optimal moisture content for each percentage of added sand.

Figure 11 depicts the variation in maximum dry unit weight concerning the percentage of added sand. Note that the maximum dry unit weight of the soil increases continuously as sand content increases, which is similar to the findings of previous studies by Roy (2013), Gupta and Sharma (2014), and Khan et al. (2014). This phenomenon can relate to decreased soil pore volume and suction stress caused by replacing a soft component with a high water retention capacity and a coarse portion with limited water retention capacity. This observation is supported further by the observed trend in the optimal moisture content for the mixtures, which decreases with increasing sand content, as shown in Fig. 12.

3.2.1 Proposed Equations of Maximum Dry Unit Weight and Optimal Moisture Content

Figure 11 demonstrates the linear relationship between the maximum dry unit weight and the percentage of added sand. In contrast, Fig. 12 demonstrates the linear relationship between the optimal moisture content and the percentage of added sand. These relationships can estimate the maximum dry unit weight and optimum moisture content of expansive clayey soils mixed with sand, given that a Proctor experiment is performed for a single sand percentage. The assumption of a constant slope (Fig. 12) is reasonable since the behavior of the soil and added sand is assumed to be the same regardless of the mineral composition of the soil. This assumption, however, needs to be validated by carrying out mixing sand tests with different types of expansive soils. Previous investigations on expansive soils show similar behavior, as shown in Fig. 13. The findings reveal that the slopes are similar with a minor variation, demonstrating the reliability of the equations in estimating the maximum dry unit weight and ideal moisture of expansive soils.

Accordingly, Eqs. (12) and (13), respectively, are given as a means of predicting maximum dry unit weight and optimal moisture content.

where: \({\gamma }_{dmax \left(Fs\right)}\) and \({w}_{opt \left(Fs\right)}\) are maximum dry unit weight (kN/m3) and optimal moisture content (%), respectively, of the required percentage of sand Fs.

\({\gamma }_{dmax \left(Fs1\right)}\) \({\mathrm{W}}_{\mathrm{opt }\left(\mathrm{fs}1\right)}\) \({\mathrm{W}}_{\mathrm{opt}\left(\mathrm{fs}1\right)}\) and \({W}_{opt \left(Fs1\right)}\) are maximum dry unit weight (kN/m3) and optimal moisture content (%), respectively, of the known percentage of sand Fs1.

3.3 Effect of Sand on the Modulus of Oedometric Elasticity

Figure 14 presents the oedometric modulus as a function of the percentage of added sand at three stress levels, namely (1–2), (2–3), and (4–6) kg/cm2. The results demonstrate that increasing the percentage of added sand up to a certain level (about 30%) significantly increases the modulus of oedometric elasticity. At high stress levels, however, the modulus of oedometric elasticity remains constant up to 20% of added sand before increasing noticeably. This finding confirms the beneficial effect of sand on soil stiffness during the plasticity stage, especially when more than 20% sand is added. Nevertheless, expansive soils have a low bearing capacity at high saturation levels, so adding more than 30% sand is most effective to ensure minimum settlement.

3.4 Effect of Sand on Hydraulic Conductivity

The hydraulic conductivity controls the rate of water movement and heave within a region of swelling clays. Values of conductivity in clays may vary over several orders of magnitude, translating to days, months, or years of moisture migration in the field. Previous studies have found that the permeability of clayey soil increases as the percentage of sand increases. Figure 15 illustrates the variation of the permeability coefficient of mixed soil with the percentage of added sand. The results show a steady increase in the permeability coefficient with an increase in the percentage of added sand up to 20%, which is consistent with Al Rawi et al. (2018), followed by a sharp decrease to a minimum of 30% and then a slight increase to 50%. The observed increase in permeability is due to the swelling of the sample during saturation, as shown in Fig. 16. However, after 30% sand addition, the decrease in volume changes and void sizes significantly reduces permeability.

Based on the findings of the experiments, the recommended percentage of added sand in expansive clayey soils for civil engineering purposes, such as earth dams, road construction, and landfill cover layers, should not be less than 30% to meet the desired criteria of low permeability, high stiffness, and minimal volumetric changes.

4 Conclusions

The use of expansive clayey soils in civil engineering applications necessitates careful consideration of their characteristics to ensure stability and long-term durability. Sand is a valuable amendment to improve the characteristics of expansive clayey soils in recent years. This study aimed to look into the effects of different sand percentages on the characteristics of expansive soil and recommend the best sand percentage to achieve the best performance in terms of high stiffness, low permeability, and minimal volumetric changes. The findings of an experimental study of the behavior of expansive soil mixed with various percentages of sand provided the basis for correlations and recommended practice, including the liquid limit, plastic limit, plasticity index, shrinkage limit, shrinkage index, longitudinal shrinkage, maximum dry density, optimal moisture, oedometric elasticity modulus, and hydraulic conductivity. The experimental results of expansive soil mixed with various percentages of sand can be summarized as follows:

-

The liquid limit, plastic limit, and plasticity index all decrease as the percentage of added sand increases. Meanwhile, due to the increase in the shrinkage limit and decrease in the liquid limit, the shrinkage index decreases more sharply than the plasticity index with increasing sand content.

-

The efficacy of sand in expansive soils becomes increasingly significant as the plasticity index increases.

-

The longitudinal shrinkage decreases by about half as the percentage of added sand increases, leading to reduced volumetric changes.

-

The proposed Eqs. (8, 9, 10, 11) can be used to predict the values of the liquid limit, plastic index, shrinkage limit, and longitudinal shrinkage limit if the Atterberg limits for only one of the added percentages of sand are known.

-

The maximum dry density of mixed soil increases with increasing sand content.

-

The approximate Eqs. (12, 13) predict the maximum dry density and optimal moisture of expansive soil if the results of a Proctor experiment for only one of the added percentages of sand are known.

-

This investigation indicates that the oedometric elasticity modulus increases as the percentage of sand added increases. The optimal percentage of added sand for achieving the best stiffness should not be less than 30%.

Based on the findings, the recommended percentage of sand in expansive clayey soil should be no less than 30% to achieve the best performance, such as low permeability, high stiffness, and minimal volumetric changes. This recommendation applies to civil engineering projects such as earth dams, roads, landfill covers, and other backfilling applications.

In consideration of future research, it is worth noting that previous studies did not thoroughly investigate the effect of sand additives on shrinkage limit (SL), longitudinal shrinkage (L.Sh), and hydraulic conductivity within expansive clay soils. Future investigations into the effect of sand on these specific characteristics would prove beneficial for various types of expansive clay. This approach could lead to developing predictive equations that can effectively extrapolate physical properties based on varying sand content and for different types of expansive clays. It is also important to note that the existing equations, denoted as Eqs. 10 and 11, apply to illite expansive clay. Consequently, future research should aim to develop equations incorporating a broader range of expansive clay types and improve the generality of models in geotechnical engineering along with construction practices involving expansive clayey soils.

Data Availability

I have shared with data in the text of manuscript.

Abbreviations

- Fs:

-

Percentage of added sand (%)

- LL:

-

Liquid limit (%)

- PL:

-

Plastic limit (%)

- PI:

-

Plastic index (%)

- SL:

-

Shrinkage limit (%)

- L.Sh:

-

Longitudinal shrinkage (%)

- \({\mathrm{LL}}_{\mathrm{Fs}}, {\mathrm{PI}}_{\mathrm{Fs}}, {\mathrm{SL}}_{\mathrm{Fs }}\, \mathrm {and } \,{\mathrm{L}.\mathrm{Sh}}_{\mathrm{Fs}}\) :

-

Unknown Atterberg limits for the desired percentage of sand Fs (%)

- \({\mathrm{LL}}_{\mathrm{Fs}1}, {\mathrm{PI}}_{\mathrm{Fs}1}, {\mathrm{L}.\mathrm{Sh}}_{\mathrm{Fs}1}\,\mathrm {and}\, {\mathrm{SL}}_{\mathrm{Fs}1}\) :

-

Well-known Atterberg limits that correspond to the sand percentage Fs1 (%)

- SI:

-

Shrinkage index (%)

- L0 :

-

Initial length of the soil sample (cm)

- LD :

-

Length of the dried sample (cm)

- w:

-

Moisture content (%)

- wopt :

-

Optimal moisture content (%)

- wi :

-

Initial moisture content (%)

- V:

-

Initial sample volume (cm3)

- \({\mathrm{V}}_{\mathrm{d}}\) :

-

Volume of the sample after drying (cm3)

- \({\mathrm{m}}_{\mathrm{s}}\) :

-

Mass of the dried soil (gr)

- \({\uprho }_{\mathrm{w}}\) :

-

Density of water (gr/cm3)

- \({\upgamma }_{\mathrm{d}}\) :

-

Dry unit weight (kN/m3)

- \({\upgamma }_{\mathrm{dmax}}\) :

-

Maximum dry unit weight (kN/m3)

- \({\upgamma }_{\mathrm{dmax }\left(\mathrm{Fs}\right)}\) :

-

Unknown maximum dry unit weight for the desired percentage of sand Fs (kN/m3)

- \({\mathrm{W}}_{\mathrm{opt }\left(\mathrm{Fs}\right)}\) :

-

Unknown optimal moisture content for the desired percentage of sand Fs (%)

- \({\upgamma }_{\mathrm{dmax }\left(\mathrm{Fs}1\right)}\) :

-

Well-known maximum dry unit weight that corresponds to the sand percentage Fs1 (kN/m3)

- \({\mathrm{W}}_{\mathrm{opt }\left(\mathrm{Fs}1\right)}\) :

-

Well-known optimal moisture content that corresponds to the sand percentage Fs1 (%)

- \({\upgamma }_{\mathrm{w}}\) :

-

Unit weight of the water (kN/m3)

- \({\mathrm{m}}_{\mathrm{v}}\) :

-

Coefficient of volumetric compressibility (m2/kN)

- \({\mathrm{c}}_{\mathrm{v}}\) :

-

Coefficient of consolidation (m2/day)

- Cc (compressibility):

-

Compression index (−)

- Cr :

-

Recompression index (−)

- Cu :

-

Coefficient of uniformity (−)

- Cc (grain size):

-

Curvature coefficient (−)

- emax :

-

Maximum voids ratio (−)

- emin :

-

Minimum voids ratio (−)

- K:

-

Hydraulic conductivity (permeability coefficient) (m/day)

- G:

-

Specific gravity (−)

- F200:

-

Percent passing No. 200 sieve (%)

- OMC:

-

Optimal moisture content

- MDD:

-

Maximum dry density

References

AASHTO (2002) Standard method of test for the classification of soils and soilaggregate mixtures for highway construction purposes, test designation M145- 91, standard specifications for transportation materials and methods of sampling and testing

Abdelkader HAM, Ahmed ASA, Hussein MMA et al (2022) An experimental study on geotechnical properties and micro-structure of expansive soil stabilized with waste granite dust. Sustainability 14:6218. https://doi.org/10.3390/SU14106218

Ahmadi Chenarboni H, Hamid Lajevardi S, MolaAbasi H, Zeighami E (2021) The effect of zeolite and cement stabilization on the mechanical behavior of expansive soils. Constr Build Mater 272:121630. https://doi.org/10.1016/J.CONBUILDMAT.2020.121630

Al Rawi OS, Assaf MN, Hussein NM (2018) Effect of sand additives on the engineering properties of fine grained soils. ARPN J Eng Appl Sci 13:3197–3206

Al-Akhras NM, Attom MF, Al-Akhras KM, Malkawi AIH (2015) Influence of fibers on swelling properties of clayey soil. Geosynth Int 15:304–309. https://doi.org/10.1680/GEIN.2008.15.4.304

Alavi AH, Gandomi AH, Mollahassani A et al (2010) Modeling of maximum dry density and optimum moisture content of stabilized soil using artificial neural networks. J Plant Nutr Soil Sci 173:368–379. https://doi.org/10.1002/JPLN.200800233

Al-Baidhani AF, Al-Taie AJ (2020a) Recycled crushed ceramic rubble for improving highly expansive soil. Transp Infrastruct Geotechnol 7:426–444. https://doi.org/10.1007/S40515-020-00120-Z

Al-Baidhani AF, Al-Taie AJ (2020b) Shrinkage and strength behavior of highly plastic clay improved by brick dust. J Eng 26:95–105. https://doi.org/10.31026/J.ENG.2020.05.07

Alnmr A, Ray RP (2021) Review of the effect of sand on the behavior of expansive clayey soils. Acta Tech Jaur 14:521–552. https://doi.org/10.14513/ACTATECHJAUR.00611

Amadi AA, Lubem S (2014) Assessing stabilization effectiveness of combined cement kiln dust and quarry fines on pavement subgrades dominated by black cotton soil. Geotech Geol Eng 32:1231–1238. https://doi.org/10.1007/S10706-014-9793-0/FIGURES/4

Asgari MR, Baghebanzadeh Dezfuli A, Bayat M (2015) Experimental study on stabilization of a low plasticity clayey soil with cement/lime. Arab J Geosci 8:1439–1452. https://doi.org/10.1007/S12517-013-1173-1

Ashango AA, Patra NR (2014) Static and cyclic properties of clay subgrade stabilised with rice husk ash and Portland slag cement. Int J Pavement Eng 15:906–916. https://doi.org/10.1080/10298436.2014.893323

ASTM International. ASTM D4943 (2008) Standard test method for shrinkage factors of soils by the wax method. American Society for Testing and Materials (ASTM)

ASTM International. ASTM D698-12e2 (2012) Standard test methods for laboratory compaction characteristics of soil using standard effort. https://doi.org/10.1520/D0698-12E02

ASTM International. ASTM D6913/D6913M-17 (2017a) Standard test method for particle-size analysis of soils. https://doi.org/10.1520/D6913_D6913M-17

ASTM International. ASTM D4318-17e1 (2017b) Standard test methods for liquid limit, plastic limit, and plasticity index of soils. https://doi.org/10.1520/D4318-17E01

ASTM International. ASTM D2487-17e1 (2017c) Standard practice for classification of soils for engineering purposes (unified soil classification system). https://doi.org/10.1520/D2487-17E01

ASTM International. ASTM D7928-17 (2017d) Standard test method for particle-size distribution (gradation) of fine-grained soils using the sedimentation (hydrometer) analysis. https://doi.org/10.1520/D7928-17

ASTM International. ASTM D2435 / D2435M - 11 (2020) Standard test methods for one-dimensional consolidation properties of soils using incremental loading. https://doi.org/10.1520/D2435_D2435M-11R20

Atemimi YK (2020) Effect of the grain size of sand on expansive soil. In: Key engineering materials. Trans Tech Publications Ltd, pp 367–373

Bandopadhyay A, Giri D (2023) Improvement of expansive soils mixed with red mud and phosphogypsum. Arab J Geosci 16:1–15. https://doi.org/10.1007/S12517-023-11384-3

Bleam W (2017) Clay mineralogy and chemistry. Soil Environ Chem. https://doi.org/10.1016/B978-0-12-804178-9.00003-3

BS 1377-2 (1990) British standard methods of test forsoils for civil engineering purposes: part 2. Classification tests. British Standard Institute, London

Casagrande A (1932) Research on the Atterberg limits of soils. Publ Roads 13:121–136

Celik E, Nalbantoglu Z (2013) Effects of ground granulated blastfurnace slag (GGBS) on the swelling properties of lime-stabilized sulfate-bearing soils. Eng Geol 163:20–25. https://doi.org/10.1016/J.ENGGEO.2013.05.016

Dang LC, Khabbaz H, Ni BJ (2021) Improving engineering characteristics of expansive soils using industry waste as a sustainable application for reuse of bagasse ash. Transp Geotech 31:100637. https://doi.org/10.1016/J.TRGEO.2021.100637

Deng Y, Wu Z, Cui Y et al (2017) Sand fraction effect on hydro-mechanical behavior of sand-clay mixture. Appl Clay Sci 135:355–361. https://doi.org/10.1016/j.clay.2016.10.017

Eberemu A, Amadi A, Lawal M (2012) The geotechnical properties of black cotton soil treated with crushed glass cullet. Niger J Technol Res. https://doi.org/10.4314/NJTR.V7I2.83788

Edeh JE, Tyav ST, Osinubi KJ (2014) Cassava peel ash stabilized lateritc soil as highway pavement material. Pavement Mater Struct Perform. https://doi.org/10.1061/9780784413418.037

Edora AB, Ann M, Adajar Q (2021) Strength and permeability characteristics of expansive soil with gypsum and rice husk ash. Geomate J 21:28–34. https://doi.org/10.21660/2021.88.gxi251

Ene E, Okagbue C (2009) Some basic geotechnical properties of expansive soil modified using pyroclastic dust. Eng Geol 107:61–65. https://doi.org/10.1016/J.ENGGEO.2009.03.007

Gadouri H, Meziani B (2023) Strength improvement using polypropylene fiber as reinforcement in natural pozzolana-lime-stabilized expansive clayey soil artificially contaminated by sulfates. Period Polytech Civ Eng 67:1152–1175. https://doi.org/10.3311/PPCI.21388

Gadouri H, Harichane K, Ghrici M (2016) Effects of Na2SO4 on the geotechnical properties of clayey soils stabilised with mineral additives. Int J Geotech Eng 11:500–512. https://doi.org/10.1080/19386362.2016.1238562

Gadouri H, Harichane K, Ghrici M (2017) A comparison study between CaSO4·2H2O and Na2SO4 effects on geotechnical properties of clayey soils stabilised with mineral additives to recommend adequate mixtures as materials for road pavements. Int J Geotech Eng 13:61–82. https://doi.org/10.1080/19386362.2017.1320850

Gadouri H, Harichane K, Ghrici M (2019) Effect of the interaction between calcium sulphate and mineral additives on shear strength parameters of clayey soils. J Eng Res 7:66–88

Gautam KK, Sharma RK, Sharma A (2021) Effect of municipal solid waste incinerator ash and lime on strength characteristics of black cotton Soil. Lect Notes Civ Eng 113:115–123. https://doi.org/10.1007/978-981-15-9554-7_10/COVER

Goodarzi AR, Akbari HR, Salimi M (2016) Enhanced stabilization of highly expansive clays by mixing cement and silica fume. Appl Clay Sci 132:675–684. https://doi.org/10.1016/j.clay.2016.08.023

Gupta C, Sharma RK (2014) Influence of marble dust, fly ash and beas sand on sub grade characteristics of expansive soil. J Mech Civ Eng 13:13–18

Haigh SK, Vardanega PJ, Bolton MD (2015) Plast Limit of Clays Géotech 63:435–440. https://doi.org/10.1680/GEOT.11.P.123

Harichane K, Ghrici M, Kenai S (2012) Effect of the combination of lime and natural pozzolana on the compaction and strength of soft clayey soils: a preliminary study. Environ Earth Sci 66:2197–2205. https://doi.org/10.1007/S12665-011-1441-X/FIGURES/6

Harichane K, Ghrici M, Kenai S (2018) Stabilization of Algerian clayey soils with natural pozzolana and lime. Periodica Polytech Civ Eng 62:1–10. https://doi.org/10.3311/PPCI.9229

Hasan H, Dang L, Khabbaz H et al (2016) Remediation of expansive soils using agricultural waste bagasse ash. Procedia Eng 143:1368–1375. https://doi.org/10.1016/J.PROENG.2016.06.161

Hastuty IP, Sembiring IS, Abidin MI (2017) The Utilization of volcanic ash and high rusk ash as material stabilization in clay by unconfined compression test (UCT) and California bearing ratio (CBR). IOP Conf Ser Mater Sci Eng 180:012141. https://doi.org/10.1088/1757-899X/180/1/012141

Holtz RD (2001) Construction materials: soil and natural materials. Science and Technology, Encyclopedia of Materials. https://doi.org/10.1016/B0-08-043152-6/00278-3

Holtz R, Kovacs W, Sheahan T (1981) An introduction to geotechnical engineering. Prentice-Hall, Incorporated, New Jersey

Hossain KMA, Lachemi M, Easa S (2007) Stabilized soils for construction applications incorporating natural resources of Papua new Guinea. Resour Conserv Recycl 51:711–731. https://doi.org/10.1016/J.RESCONREC.2006.12.003

Jain AK, Jha AK, Shivanshi (2020) Improvement in subgrade soils with marble dust for highway construction: a comparative study. Indian Geotech J 50:307–317. https://doi.org/10.1007/S40098-020-00423-5

James J, Vijayasimhan S, Eyo E (2023) Stress–strain characteristics and mineralogy of an expansive soil stabilized using lime and phosphogypsum. Appl Sci 13:123. https://doi.org/10.3390/APP13010123

Kaoua F, Derriche Z, Laradi N (1994) Contribution à l’étude de la stabilisation des sols gonflants par ajouts de sable. Algérie Equipement: Revue De L’ecole Nationale Des Travaux Publics 15:12–15

Khan FS, Azam S, Raghunandan ME, Clark R (2014) Compressive strength of compacted clay-sand mixes. Adv Mater Sci Eng 2014:1–6. https://doi.org/10.1155/2014/921815

Kolay PK, Ramesh KC (2016) Reduction of expansive index, swelling and compression behavior of kaolinite and bentonite clay with sand and class C fly ash. Geotech Geol Eng 34:87–101. https://doi.org/10.1007/s10706-015-9930-4

Kumar S, Singh RP, Paswan SK (2022) Strength and impact of rice husk ash on expansive soil by using soil stabilization. Lect Notes Civ Eng 154:73–80. https://doi.org/10.1007/978-981-16-1993-9_9

Louafi B, Bahar R (2012) Sand: an additive for stabilzation of swelling clay soils. Int J Geosci 03:719–725. https://doi.org/10.4236/ijg.2012.34072

Lupogo K, Ngan-Tillard D, Vos B, de Jager R (2009) Effects of fines on mechanical behaviour of sandy soils. Delft University of Technology

Maliakal T, Thiyyakkandi S (2013) Influence of randomly distributed coir fibers on shear strength of clay. Geotech Geol Eng 31:425–433. https://doi.org/10.1007/S10706-012-9595-1/FIGURES/10

Meziani B, Gadouri H (2023) Swelling suppressing by using polypropylene fibre as reinforcement in natural pozzolana-lime-stabilised expansive grey clayey soil artificially contaminated by sulphates. Multiscale Multidiscip Model Exp Des. https://doi.org/10.1007/S41939-023-00157-W

Mistry MK, Shukla SJ, Solanki CH (2021) Reuse of waste tyre products as a soil reinforcing material: a critical review. Environ Sci Pollut Res 28:24940–24971. https://doi.org/10.1007/S11356-021-13522-4

Modarres A, Nosoudy YM (2015) Clay stabilization using coal waste and lime—technical and environmental impacts. Appl Clay Sci 116–117:281–288. https://doi.org/10.1016/J.CLAY.2015.03.026

Mujtaba H, Aziz T, Farooq K et al (2018) Improvement in engineering properties of expansive soils using ground granulated blast furnace slag. J Geol Soc India 92:357–362. https://doi.org/10.1007/S12594-018-1019-2/METRICS

Munirwan RP, Mohd Taib A, Taha MR et al (2022) Utilization of coffee husk ash for soil stabilization: a systematic review. Phys Chem Earth Parts a/b/c 128:103252. https://doi.org/10.1016/J.PCE.2022.103252

Nagaraj HB (2016) Influence of gradation and proportion of sand on stress–strain behavior of clay–sand mixtures. Int J Geo-Eng 7:1–10. https://doi.org/10.1186/s40703-016-0033-8

Nalbantoglu Z, Tawfiq S (2006) Evaluation of the effectiveness of olive cake residue as an expansive soil stabilizer. Environ Geol 50:803–807. https://doi.org/10.1007/S00254-006-0252-Y

Nelson J, Miller DJ (1997) Expansive soils: problems and practice in foundation and pavement engineering. Wiley, New York

Okeke CAU (2020) Engineering behaviour of lime- and waste ceramic dust-stabilized expansive soil under continuous leaching. Bull Eng Geol Env 79:2169–2185. https://doi.org/10.1007/S10064-019-01648-2/TABLES/5

Oriola F, Moses G (2010) Groundnut shell ash stabilization of black cotton soil. Electron J Geotech Eng 15:415–428

Oyekan GL, Meshida EA, Ogundalu AO (2013) Effect of ground polyvinyl waste on the strength characteristics of black cotton clay soil. J Eng Manuf Technol 1:1–10

Phanikumar BR, Dembla S, Yatindra A (2021) Swelling behaviour of an expansive clay blended with fine sand and fly ash. Geotech Geol Eng 39:583–591. https://doi.org/10.1007/s10706-020-01480-6

Prakash K, Sridharan A (2004) Free swell ratio and clay mineralogy of fine-grained soils. Geotech Test J 27:220–225. https://doi.org/10.1520/GTJ10860

Prasad CRV, Sharma RK (2014) Influence of sand and fly ash on clayey soil stabilization. IOSR J Mech Civ Eng 334:36–40

Rabab’ah S, Al Hattamleh O, Aldeeky H, Abu Alfoul B (2021) Effect of glass fiber on the properties of expansive soil and its utilization as subgrade reinforcement in pavement applications. Case Stud Construct Mater 14:e00485. https://doi.org/10.1016/J.CSCM.2020.E00485

Roy TK (2013) Influence of sand on strength characteristics of cohesive soil for using as subgrade of road. Procedia Soc Behav Sci 104:218–224. https://doi.org/10.1016/j.sbspro.2013.11.114

Salimi M, Ilkhani M, Vakili AH (2018) Stabilization treatment of Na-montmorillonite with binary mixtures of lime and steelmaking slag. Int J Geotech Eng 14:295–301. https://doi.org/10.1080/19386362.2018.1439294

Shankar AU, Chandrasekhar A, Bhat HP (2012) Experimental investigations on lithomargic clay stabilized with sand and coir. Indian Highw 40:21–31

Singh P, Dash HK, Samantaray S (2020) Effect of silica fume on engineering properties of expansive soil. Mater Today Proc 33:5035–5040. https://doi.org/10.1016/J.MATPR.2020.02.839

Sridharan A, Nagaraj HB (2011) Compressibility behaviour of remoulded, fine-grained soils and correlation with index properties. Can Geotech J 37:712–722. https://doi.org/10.1139/T99-128

Srikanth V, Mishra AK (2019) Atterberg limits of sand-bentonite mixes and the influence of sand composition. Geotech Charact Geoenviron Eng. https://doi.org/10.1007/978-981-13-0899-4_17

Steinberg ML (1985) Controlling expansive soil destructiveness by deep vertical geomembranes on four highways. Transportation Research Board

Sudhakar S, Duraisekaran E, Dilli Vignesh G, Kanna GD (2021) Performance evaluation of quarry dust treated expansive clay for road foundations. Iran J Sci Technol Trans Civ Eng 45:2637–2649. https://doi.org/10.1007/S40996-021-00645-4

Watabe Y, Yamada K, Saitoh K (2011) Hydraulic conductivity and compressibility of mixtures of Nagoya clay with sand or bentonite. Géotechnique 61:211–219. https://doi.org/10.1680/geot.8.P.087

Yi Y, Gu L, Liu S (2015) Microstructural and mechanical properties of marine soft clay stabilized by lime-activated ground granulated blastfurnace slag. Appl Clay Sci 103:71–76. https://doi.org/10.1016/J.CLAY.2014.11.005

Zada U, Haleem K, Saqlain M et al (2023) Reutilization of eggshell powder for improvement of expansive clayey soil. Iran Jof Sci Technol Trans Civ Eng 47:1059–1066. https://doi.org/10.1007/S40996-022-00938-2

Ziari H, Moniri A, Imaninasab R, Nakhaei M (2017) Effect of copper slag on performance of warm mix asphalt. Int J Pavement Eng 20:775–781. https://doi.org/10.1080/10298436.2017.1339884

Acknowledgements

The authors would like to express their heartfelt gratitude to the Faculty of Civil Engineering at Tishreen University in Latakia, Syria, particularly the Department and Laboratory of Geotechnical Engineering. Prof. Mounzer Omran Alzawi and Dr. Safwan Abdallah are also thanked for their invaluable support and guidance.

Funding

Open access funding provided by Széchenyi István University (SZE). This research received no external funding. Funding for open access granted by Szechenyi István University (SZE).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Alnmr, A., Ray, R. Investigating the Impact of Varying Sand Content on the Physical Characteristics of Expansive Clay Soils from Syria. Geotech Geol Eng 42, 2675–2691 (2024). https://doi.org/10.1007/s10706-023-02698-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-023-02698-w