Abstract

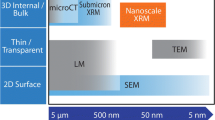

This article presents the results of an investigation of crack nucleation and propagation in a transparent polydimenthylsiloxane (PDMS) elastomer. The main objective of the investigation is to characterize quantitatively the evolution of crack nucleation and propagation behavior not just through the usual macroscopic load and displacement data, but with synchronized optical images at high spatial and adequate temporal resolution that will resolve the evolution of the failure processes. This is augmented with X-ray computed tomography (CT) scans to characterize the three-dimensional geometry of the cracks nucleated in the interior of the elastomer. Towards this goal, we reproduce the classical poker-chip experiment of Gent and Lindley (Proc R Soc Lond A 249(1257):195–205, 1959) in which the specimen’s diameter-to-thickness ratio is varied over a broad range to cover crack nucleation, propagation, and their coalescence. These experiments are performed on transparent PDMS with different compositions, first in a specially built loading machine that is fitted with a high magnification microscopic camera that permits the measurement of the load while simultaneously providing images of the specimen configuration and subsequently in an apparatus built for in situ observations using an X-ray CT scanning system. These experiments reveal that nucleation of multiple microcracks dominates when the diameter-to-thickness aspect ratio \(\alpha \) is sufficiently large, because the incompressibility of the material induces substantial, nearly uniform hydrostatic tension in the specimen. In contrast, specimens with smaller aspect ratio tend to nucleate fewer cracks, and are dominated by the growth of these cracks. At even smaller \(\alpha \), the hydrostatic stress is significantly lowered and failure is dominated by surface flaws. The three-dimensional geometry, and the spatial distribution of the nucleated cracks were evaluated using optical microscopy and X-ray CT scans. This revealed cracks of three different shapes, one of which was confined in a layer near to the upper or bottom boundary of the poker-chip, another was across the thickness, but with a tilt relative to the axis of the specimen, and the last was propagating along the radial direction.

Similar content being viewed by others

Notes

Lindsey et al. (1963) have used a similar approach and observed the nucleation of cracks.

The Young’s moduli of PC and PMMA are 2.4 GPa and 2.9 GPa, respectively, while the PDMS elastomer has an initial modulus on the order of 0.1 MPa.

Lindsey (1966) introduced bubbles and demonstrated that their influence on the response was indeed negligible.

The original tomographic image stack in tiff-format was denoised with Gaussian filter of radius in [10,20] pixels in ImageJ, which was followed by a binarization with the default threshold method; the thresholded images were thereafter imported to 3D Slicer for segmentation and quantitative measurement of each crack of interest via segmentation-related modules and python scripts.

We refrain from calling these cavities because by the time the intrinsic defects of size 10 to 100 nm grow to a visible size of 10 to 100 \(\upmu \)m, it must have transitioned into a crack. Also, it is difficult to achieve higher spatial and temporal resolution; given this limitation, the identified event is an upper bound for the nucleation of the crack.

We know from X-ray CT scans described later that these are actually ellipsoidal.

Since the central region is under a nearly uniform stress state, random nucleation is expected from the weakest point for the first crack. However, the next crack is nucleated, almost always, in the vicinity of the previously nucleated crack - not from the next weakest point globally, but from the weakest point in the neighborhood of the first crack; this is why we refer to the subsequent cracks being “triggered” by the previously nucleated cracks. The nucleation of the first crack causes the stress in the vicinity to drop (due to the increase in the local compliance of the specimen), and shields a certain region from further nucleation; but it must also elevate the stress beyond the region and cause the second nucleation.

References

Ball JM (1982) Discontinuous equilibrium solutions and cavitation in nonlinear elasticity. Philos Trans R Soc Lond Ser A, Math Phys Sci 306(1496):557–611

Baumberger T, Caroli C, Martina D, Ronsin O (2008) Magic angles and cross-hatching instability in hydrogel fracture. Phys Rev Lett 100(17):178303

Bayraktar E, Bessri K, Bathias C (2008) Deformation behaviour of elastomeric matrix composites under static loading conditions. Eng Fract Mech 75(9):2695–2706

Buffiere JY, Maire E, Adrien J, Masse JP, Boller E (2010) In situ experiments with X-ray tomography: an attractive tool for experimental mechanics. Exp Mech 50(3):289–305

Busse WF (1938) Physics of rubber as related to the automobile. J Appl Phys 9(7):438–451

Euchler E, Bernhardt R, Schneider K, Heinrich G, Wießner S, Tada T (2020) In situ dilatometry and X-ray microtomography study on the formation and growth of cavities in unfilled styrene-butadiene-rubber vulcanizates subjected to constrained tensile deformation. Polymer 187:122086

Fond C (2001) Cavitation criterion for rubber materials: a review of void-growth models. J Polym Sci, Part B: Polym Phys 39(17):2081–2096

Gent A (1990) Cavitation in rubber: a cautionary tale. Rubber Chem Technol 63(3):49–53

Gent A, Lindley P (1959) Internal rupture of bonded rubber cylinders in tension. Proc R Soc Lond A 249(1257):195–205

Gent A, Tompkins D (1969) Nucleation and growth of gas bubbles in elastomers. J Appl Phys 40(6):2520–2525

Gent A, Tompkins D (1969) Surface energy effects for small holes or particles in elastomers. J Polym Sci Part A-2: Polym Phys 7(9):1483–1487

Gent AN, Wang C (1991) Fracture mechanics and cavitation in rubber-like solids. J Mater Sci 26(12):3392–3395

Green AE, Zerna W (1992) Theoretical elasticity. Courier Corporation, Chelmsford

Hao S, Suo Z, Huang R (2022) Why does an elastomer layer confined between two rigid blocks grow numerous cavities? Submitted

Horgan C, Abeyaratne R (1986) A bifurcation problem for a compressible nonlinearly elastic medium: growth of a micro-void. J Elast 16(2):189–200

James RD, Spector SJ (1991) The formation of filamentary voids in solids. J Mech Phys Solids 39(6):783–813

Kikinis R, Pieper SD, Vosburgh KG (2014) 3D Slicer: a platform for subject-specific image analysis, visualization, and clinical support. Intraoperative imaging and image-guided therapy, pp 277–289

Kumar A, Lopez-Pamies O (2021) The poker-chip experiments of Gent and Lindley (1959) explained. J Mech Phys Solids 150:104359

Lakrout H, Sergot P, Creton C (1999) Direct observation of cavitation and fibrillation in a probe tack experiment on model acrylic pressure-sensitive-adhesives. J Adhes 69(3–4):307–359

Lefèvre V, Ravi-Chandar K, Lopez-Pamies O (2015) Cavitation in rubber: an elastic instability or a fracture phenomenon? Int J Fract 192(1):1–23

Lin YY, Hui CY (2004) Cavity growth from crack-like defects in soft materials. Int J Fract 126(3):205–221

Lindsey GH (1966) Hydrostatic tensile fracture of a polyurethane elastomer. Tech. rep, CALIFORNIA INST OF TECH PASADENA GRADUATE AERONAUTICAL LABS

Lindsey G, Schapery R, Williams M, Zak A (1963) The triaxial tension failure of viscoelastic materials. Tech. rep, CALIFORNIA INST OF TECH PASADENA GRADUATE AERONAUTICAL LABS

Liu R, Sancaktar E (2018) Identification of crack progression in filled rubber by micro X-ray CT-scan. Int J Fatigue 111:144–150

Lopez-Pamies O (2010) A new \(I_1\)-based hyperelastic model for rubber elastic materials. CR Mec 338(1):3–11

Lopez-Pamies O, Nakamura T, Idiart MI (2011) Cavitation in elastomeric solids: II-Onset-of-cavitation surfaces for Neo-Hookean materials. J Mech Phys Solids 59(8):1488–1505

Müller S, Spector SJ (1995) An existence theory for nonlinear elasticity that allows for cavitation. Arch Ration Mech Anal 131(1):1–66

Pham K, Ravi-Chandar K (2017) The formation and growth of echelon cracks in brittle materials. Int J Fract 206(2):229–244

Poulain X, Lefèvre V, Lopez-Pamies O, Ravi-Chandar K (2017) Damage in elastomers: nucleation and growth of cavities, micro-cracks, and macro-cracks. Int J Fract 205(1):1–21

Poulain X, Lopez-Pamies O, Ravi-Chandar K (2018) Damage in elastomers: healing of internally nucleated cavities and micro-cracks. Soft Matter 14(22):4633–4640

Rivlin R, Saunders D (1951) Large elastic deformations of isotropic materials vii. Experiments on the deformation of rubber. Philos Trans R Soc Lond Ser A, Math Phys Sci 243(865):251–288

Schindelin J, Arganda-Carreras I, Frise E, Kaynig V, Longair M, Pietzsch T, Preibisch S, Rueden C, Saalfeld S, Schmid B, Tinevez JY, White DJ, Hartenstein V, Eliceiri K, Tomancak P, Cardona A (2012) Fiji: an open-source platform for biological-image analysis. Nat Methods 9(7):676–682

Shull KR, Creton C (2004) Deformation behavior of thin, compliant layers under tensile loading conditions. J Polym Sci, Part B: Polym Phys 42(22):4023–4043

Sivaloganathan J (1986) Uniqueness of regular and singular equilibria for spherically symmetric problems of nonlinear elasticity. Arch Ration Mech Anal 96(2):97–136

Toda H, Maire E, Yamauchi S, Tsuruta H, Hiramatsu T, Kobayashi M (2011) In situ observation of ductile fracture using x-ray tomography technique. Acta Mater 59(5):1995–2008

Williams ML, Schapery RA (1965) Spherical flaw instability in hydrostatic tension. Int J Fract Mech 1(1):64–72

Yerzley FL (1939) Adhesion of neoprene to metal. Ind Eng Chem 31(8):950–956

Acknowledgements

The financial support of the US National Science Foundation through Grant Number 1900191 is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

J.G: Conceptualization, Methodology, Data analysis, Data interpretation, Writing—Original Draft, Writing—Review & Editing. K.R-C: Conceptualization, Methodology, Data interpretation, Writing—Original Draft, Writing—Review & Editing, Supervision, Funding acquisition

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file 1 (avi 223544 KB)

Supplementary file 2 (avi 104323 KB)

Supplementary file 3 (avi 117337 KB)

Supplementary file 4 (avi 84805 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, J., Ravi-Chandar, K. On crack nucleation and propagation in elastomers: I. In situ optical and X-ray experimental observations. Int J Fract 243, 1–29 (2023). https://doi.org/10.1007/s10704-023-00714-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-023-00714-x