Abstract

The removal of water from mines was one of the key issues that former miners had to deal with. Roman colonists brought new technology to the Iberian Peninsula that addressed this problem. However, they did not invent this technology because it had already been applied to the growth of other endeavours in the Hellenistic society throughout the Eastern Mediterranean. In the mine, the Archimedes screw, waterwheels, bucket pulleys, and Ctesibius pumps were the primary drainage systems. In this essay, the primary characteristics, and modes of operation of machines are examined. Without leaving out the most significant finds made in the southwest of the Iberian Peninsula, one of the regions with the longest history of mining exploitation. To serve as a foundation for future research in this field, this work compares the primary mining mechanisms in ancient Huelva on a qualitative and quantitative level by the implementation of a TOPSIS methodology, a multi-criteria decision analysis method.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

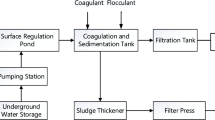

Mining began in the third millennium B.C. with the extraction of copper and precious metals in the southwest of the Iberian Peninsula, where Huelva is currently located (Nocete et al., 2005, 2011). Initially, mining was done with crude technology and a superficial approach. The mining industry didn't become relevant until the second century B.C., with the arrival of the Romans in the south of the Peninsula (Mateo, 2004; Rothenhoefer et al., 2016), developing innovative methods to address the issues that lead to a deeper exploitation of this area due to the introduction of new techniques. One of the major issues that the mining industry had to deal with was water drainage. The capability for extraction increased, and the mining activities frequently reached depths above the water levels. As a consequence, the inundation of underground operations with a subsequent halt of exploitation happened. At that time, the different drainage systems were simple and based on elementary methods, such as manual extraction through buckets, rope baskets or cubes. Additionally, more complex techniques like channels or drainage galleries, as well as the usage of different machinery were gradually adopted. These machines and mechanisms were required to either move the water to a specified location inside the mine and to elevate it outside. It was needed when the terrain’s structure made it impossible to use tunnel systems and galleries taking advantage of gravity force. Instead of using manual transportation, lifting mechanisms were used because due to a lower demand and higher efficiency.

The first drainage systems for mining were discovered in Egypt, coming from the Ptolemaic era. Engineers from Alexandria's School created some wooden mechanisms, such as a wheel to remove water from the mine's interior. Later, in Britannia (currently Great Britain), Dacia (nowadays Romania), as well as in the southwest of Hispania (Riotinto, Tharsis, and Sâo Domingos, Spain, and Portugal), the Romans employed the same technology in their mining operations.

The X books “Architecture of Vitruvius,” by Vitruvius, a Roman architect who lived in the first century B.C and the writings of Gonzalo y Tarin (1888) and Palmer (1927) are some of the principal sources of information regarding mining activities. Palmer noted and illustrated the relics of ancient mining discovered in Huelva. These machines and mechanisms were pricey and they were only found in areas with abundant ore (Gonzalo y Tarín, 1331; Palmer, 1927). The Archimedes screw, the Ctesibius pump, and the water wheel were the three principal pieces of drainage equipment that were recorded throughout Roman times (Garrido et al., 2010). All of these water-related tools had previously been used during the Hellenistic era. Nevertheless, it was the Roman experts who introduced them into the mining industry while also enhancing their efficiency. Because of this reason, the Romans' technical contributions were dependent on the use of machines.

One of the most outstanding predecessors was the inclined gallery. This system was the simplest solution to remedy tunnel flooding. It consisted of the building of an underground channel or gallery with a gentle slope connecting a point from the gallery with the outside of the mine below the water level. In mines located on a hillside, the access galleries were located in the lower part, presenting an outward-facing slope that could even have a gutter dug on one side of the ground to channel water (Fig. 1). Galleries were also laid out and built to collect, guide, and drain the interior of the galleries due to leaks or due to exceeding water table in the area. It could be used on elevations that had a valley into which the water could be poured. It had the drawback that when the excavation work went deeper, its construction was prevented and another system of extracting the water had to be found.

Gallery with side gutter to channel water a Graphical representation (Foto del mes de mayo. Río Tinto - Rotae Romanas, 2020). b Galleries found in Sotiel Coronada’s mine

This topic has been covered by various works, who analysed the historical evolution of different mechanisms for water drainage (Garrido et al., 2010; Rodríguez-Pérez et al., 2022). Nevertheless, this article's main purpose is to examine and compare the mechanical water extraction techniques and mechanisms used in the South West (SW) mines of the Iberian Peninsula in Roman times. After the description of the primary techniques, a comparison of the systems' efficacy is made considering each system's characteristics: lifting capability, flow, and energy usage during operation. The main novelty of this article is the methodology adopted to compare the mechanisms’ characteristics in order to determine which one represents the biggest technological advantage between them. The comparison is performed by implementing the TOPSIS technique, which is founded on the premise that by hierarchizing the problem stated, a decision-making dilemma with several criteria can be solved. The relevance of this work corresponds to develop a quantitative comparison among different ancient mechanisms. In contrast with previous works.

2 Materials and Methods

The bibliographic review consist of a large number of documentary sources. On the one hand, the firms who used the mines located in Riotinto and other spots in Huelva saved a vast quantity of information. This is available in the Historical Mining Archive of the Riotinto Foundation in Huelva. Regarding the mines, the Andalusian Historical Heritage Institute (IAPH) was also consulted. Furthermore, a bibliographic search was conducted using the main research databases, including Scopus, Google Scholar, Web of Science, and Journal Citation Reports. For this purpose, the keywords “water lifting machinery,” “Iberian pyrite belt,” “water wheel,” “Ctesibius pump,” and “Archimedes screw” were used as a filter. After applying several combinations, the records were sorted back to Roman times and ranged in size from 1850 to 160 records. The design, construction, applications, and lifting capacity of the water lifting machines employed in the SW mines of the Iberian Peninsula during Roman times were also considered and included. Additionally, on-site research was carried out in the local archives and museums of the villages and towns where the discovers took place, i.e.: in Minas de Tharsis, Minas de Riotinto, Zalamea, El Cerro del Andévalo, and Valdelamusa.

After the arranged literature review, all necessary calculations are carried out in order to enable performing the Technique for Order Preference by Similarity to an Ideal Solution (TOPSIS).

2.1 Archimedes’ Screw

Despite some similar devices were discovered in ancient Egypt, it was during the third century B.C. when it was created. Archimedes built this mechanism, to allow the transport and lifting water, flour, grains, or dug debris (Ceccarelli, 2008; Chon, 2010). This tool, a helical gravimetric machine, was built using an endless screw and a hollow cylinder (see Fig. 2).

Description of the composition and operation of the Archimedes’ screw (Tamain, 1966)

The interior helix was occasionally made of metal, but typically, it was built out of wood because of the availability of materials and the easier capacity to manufacture and model the machine elements. Eight parallel lines were drawn in a trunk at equal distances. In some cases, it was also cut with equidistant lines that separated them by an eighth of the axis' radius. Slats of flexible wood that were firmly secured and cemented together to add pitch were passing at the intersection places of some lines. These strips of wood were used to create the snail or screw by being fastened spirally to the trunk. Finally, wooden slats (convex tables) resembling the envelope cylinder of the prior sculpture were placed on top of this one.

A rolled rope was used to firmly hold the entire set, which had been tarred. Although the high of elevation was not great, the capacity of moving water was.

Vitruvius advised eight divisions for his structure, iron was used in the ends of the axis once attached, and pitch for the casing to prevent leaks. According to Vitruvius, a 36.8° angle was the ideal inclination based on the Pythagorean Theorem. The water was loaded from a lower tank to an upper tank, from which it was covered by another screw, and they were arranged in rows, as shown in Fig. 3.

Human force was used to power it on. As it is possible to observe in the Fig. 3. Additionally, Fig. 4 shows a representation of the operation of an Archimedes’ screw.

Three devices from this mechanism were discovered in Huelva next to the San Juan pit, at Sotiel Coronada’s mine (Calañas, Huelva) (Pérez & Delgado-Domínguez, 2015). They were all connected to a bucket pulley. Only one of these three (preserved in the Museum of Huelva) remains largely undamaged. The British Museum, the Musée des Arts et Métiers in Paris, the Provincial Museum of Huelva, and the Museum of Transport in Glasgow, they all house pieces from the other collections. It was at Cerro Muriano’s mine, Cordoba Copper Co., and the Centenillo and Castulo Group’s mine (Jaen), where the best-preserved screws were discovered. Vitruvius’ model has a different size than the one at the museum. This one has a ratio of 1/15, the partitions that form the spiral are three instead of eight and they are formed by twenty-five layers of wood sheets in 12 m of height (Arboledas-Martínez, 2013). Bronze nails greased on the cylinder fixed these plates, and it is covered in pitch together with a rope covered in pitch too, to secure its sealing. Its inclination was of approximately 17°.

2.2 Water Wheels (Rotae Aquae)

The water wheel is a device that raises water and that is made up of several buckets that are fastened to a big wheel. The water is raised from the bottom to the top. This kind of wheel resembles a carriage wheel but it is larger and features buckets to catch water in addition to its larger size.

Many cultures lay claim to have created the wheel. Joseph Needham thought that the wheel was invented in India around the fifth or fourth century B.C., and there exist Indian manuscripts from 350 B.C. (Pérez & Delgado-Domínguez, 2015). By the first century B.C., Needham believed it had expanded to the west, and that by the second century A.D., it had reached China. However, Chinese historical sources tell us that there were not water wheels as water-lifting devices in China before the seventh century. Namely, there is absolutely evidence of the exist of water wheels in China before the seventh century. Nevertheless, water wheels were popular in China in the tenth century. Needham idea was followed by widespread use of the wheel in the Eastern Mediterranean in the fifth century A.D., before reaching North Africa and the Iberian Peninsula in the eleventh century. Other possibilities related to the origin of this mechanism include locations like the Near East 200 B.C. As an example, Philo of Byzantium (ca. 230 B.C.), who was a Hellenic engineer, showed different sketches and draws which corresponded to different types of water wheels (Yannopoulos et al., 2015).

The main structure of these mechanisms was made entirely of wood, but the axes were made of copper as it is shown in the Fig. 5. The water wheels were preferably placed in pairs, forming batteries, as it possible to observe in the Fig. 6 a. They were placed in different steps. They lifted the water from one step to the next, communicating with each other through short galleries and channels. The couples of water wheels turned in the opposite direction, powered by mining workers as it is possible to be observed in the Fig. 6b. So, water wheels put the water in the channel always in the same direction. Its assembly was made in situ due to its large diameters.

Historical reports state that the wood was taken from oak in Sâo Domingo (Portugal). Regarding the water wheel preserved in Huelva, it has three types of wood, walnut for the cube, pine for the buckets and fir for the radios.

The ends of the spokes were joined by some boards that were attached to the running surface. The worker who worked it, seated at a higher height on the wall in front of the wheel, used these tables as steps, transferring the force from their foot. Another worker who was situated at the area of the wheel's axis where the spokes were being moved by ropes assisted with this. Water wheels were able to raise significant volumes of water to a height of 3–4 m, demonstrating a relatively high level of performance.

The water wheels found in the Iberian Pyrite Belt, have been defined as “Hispanic type” and they are characterized by being taller, slender and narrower. They have a diameter that varies between 3.60 and 4.65 m. They have a bucket with a width between 20 and 30 cm. Their weight ranges around 200 kg and their number of buckets and spokes are between 22 and 30 (Domínguez, 2015). Between 1850 and 1860 ten wheels were found in Sâo Domingo’s mine (Mértola, Portugal) the wheel is currently kept in the Musée des Arts et Métiers in Paris (Domergue & Binet, 1999).

About the 50% of water wheels discovered in the Iberian Peninsula have been discovered in Huelva. Ten water wheels were discovered in 1875 in Filón Norte’s mine. Two fifths of the wheel are preserved in the Museum of Transport in Glasgow. Later in 1886 at the Lagunazo’s mine (Alosno), a pair of wheels similar to those was found in Tharsis (Domínguez, 2015).

Around 50 wheels have been discovered in Riotinto, but only two of them are still in good condition. A bronze axis is also still present in the British Museum.

A wooden axis is also preserved in the Riotinto Mining Museum, and the Museum of Huelva displays eight bronze axes, three wooden discs, and a complete wheel discovered in Masa Planes (see Fig. 7) (Manzano-Beltrán et al., 2010).

Apart from these remains that have been maintained, several pairs of wheels have also been found, as the battery of eight pairs found in Filón Sur or Nerva. These 16 wheels allowed them to move the water a total hight of 29.6 m from level 309.3–338.9 above sea level (Fig. 8).

Roman wheels in Riotinto (Delgado-Domínguez & Pérez-Macías, 2013)

For the purpose of calculating the flow of a water wheel, the number of buckets, the diameter of the wheel, and the rotational speed must all be known. It is a variation of the previous one that was employed when the depth or low water level in the wheel's loading area prohibited the buckets from properly loading water, rendering the wheel ineffective. It consists of a hydraulic wheel with a double chain of metal on which were suspended some 3.5-L bronze buckets. Today, only a small number of the copper buckets discovered in the Cabeza del Agua (Riotinto) and Sotiel Coronada's mine (Calaas) have been preserved. This item was discovered with asset of Archimedes’ screws.

2.3 Bucket Pulley

The bucket pulley is a variant of the wheel for situations in which the amount of the water extracted was very small, Fig. 9.

Left, Illustration of a bucket pulley. Right, Roman bronze bucket preserved in the Mining Museum (Huelva) (Arboledas-Martínez, 2013)

It must be remembered that the bucket’s previous volume was 3.5 L. The few machines that remain also have 20–25 buckets. Despite the fact that just a little portion of it has been preserved, the bucket pulley constructed by Sotiel Coronada’s is one piece rather than the typical two. Additionally, the engravings “Q.CORNELLIV (s)” and “L.VIBI. AMARANTI. P. XII S.” are visible (Arboledas-Martínez, 2013). These inscriptions are thought to have been created by the pulley manufacturers.

2.4 Ctesibius’ Pump

Vitruvius claims that the Hellenistic Alexandrian Ctesibius made his innovation in the middle of the third century B.C. This pump comprises of two cylinders with pistons that are moved by connecting rods coupled to the ends of a single lever, which are located on either side of the pump (Ceballos et al., 2013). These pistons come together in a single chamber with non-return valves in the entrances, allowing the water to flow in only one direction. The driven water exits through a nozzle that is connected to the central chamber. Due to the narrowing part, the nozzle can be directed to increase the water speed by around 25 times. Lead or copper can be used to make these. To manufacture the perfectly cylindrical pistons they used the procedure of lost wax.

The pump was hand-moved, operating a wooden lever with a swinging motion. Then the water ascends by the piston. The other piston impelled the water contained in the central pipe. Securing in that way a continuous flow. By their operation mode, they worked only with clean water.

On the third level, sleeper 25, of Sotiel Coronada’s mine in Calañas, (Huelva, Spain), masonry work revealed one of the two pumps of this type that are still in existence there (Arboledas-Martínez, 2013). This is the most significant Roman artifact still in existence (Fig. 10). It is presently housed in the Madrid National Archaeological Museum.

Sotiel Coronada’s pump, Calañas a Archaeological National Museum, (Madrid). b Draw of a Ctesibius pump (Delgado-Domínguez & Pérez-Macías, 2013)

This pump was found in Huelva. Built in bronze and with a size of 0.95 m high and 0.41 m wide. It had a flexible tube with the form of a T placed at the end of the main tube. Due to their characteristics, it is believed that the main use of this pump was not to drain water but to pulverize it and cool the pyrite in the demolition system of the hard rock, where the action of the fire was complemented by the water (Suarez-Suarez et al., 2017).

2.5 TOPSIS Method

When resolving election conflicts, it is typical to use multi-criteria decision-analysis (MCDA) methods, which objectively find the ideal solution for certain options proposed and analyse the priority attributed to the multiple conditioners used (Roszkowska, 2011). TOPSIS approach has some advantages over other methods, such as its simplicity, logic, and comprehensibility, effectiveness when embedded in multiple software, ability to assimilate measurements of varying magnitudes for each alternative, and a simple mathematical formulation (Ceballos et al., 2013).

The TOPSIS technique is founded on the premise that by hierarchizing the problem stated, a decision-making dilemma with several criteria can be solved. As shown in Fig. 11, this methodology handles the difficulty of constructing an order among the alternatives by utilizing the concept of distance to the ideal alternative and the anti-ideal alternative.

Be alternatives Ai, i = 1, 2, …, m, criteria Cj, j = 1, 2, …, n, the weights of the criteria Wj and an Uj. Where U is the utility function of the decider, operating on the basis of a decision matrix with xij = Uj (Ai), and all criteria are to maximize/minimize as gains or costs are considered, respectively.

It is known as a positive ideal point at point A+, which is the best conceivable option, and A−, which is the worst possible option, at point A. A logical decision maker would always select A+, and if this value did not correspond to any of the options, he would select the one that was closest to it.

1°—Construction of the decision matrix: Starting from m alternatives Ai, i = 1, 2, …, m that will be evaluated from the criteria Cj, j = 1, 2, …, in the following decision matrix is obtained (Table 1, Ceballos et al., 2013).

2°—Standardization of the decision matrix: The elements of the decision matrix may not be defined in the same domain and should therefore be standardized. The standard used is given by the Eq. 1:

3°—Construction of the weighted standardized decision matrix: The elements of the weighted standardized decision matrix V shall be calculated with the expression:

Vij = wj x nij, \(j=1, \dots , n; i=1,\dots , m\), where wj is the weight associated with each criterion.

4°—Obtaining the positive ideal solution (PIS) and the negative ideal solution (NIS): The positive and negative ideal values (A+ and A−) are determined by the expressions:

where J is associated with the benefit criteria and Jʹ is associated with cost criteria.

5°—Calculation of distance measures: the distance of each alternative to the positive ideal solution, d+, and to the negative ideal solution, d−, is given by the equations:

6°—Calculation of the relative proximity to the ideal solution: the relative proximity Ri to the positive ideal solution shall be calculated by the expression:

So, the closer the value of R is to the unit, 1, the closer the i-th alternative to the ideal solution will be.

7°—Organization of preferences: the alternatives will be ordered in a decreasing way, starting with the one that comes closest to the ideal solution (greater relative proximity).

3 Results and Discussion

Once the main water extraction machines Roman times mines in the SW of the Iberian Peninsula have been seen, their performance and capacity are analysed and compared.

Humans have a limited physical power output, which can be in the range of 0.08–0.10 HP. This power can be considered to lift water elevation machinery (0.08–0.1 HP gives between 60 and 75 watts).

-

Archimedes’ screw

Focusing on the size and according the literature (Landels, 1981), in the formulation of helical screws mentioned in “Elevators: Principles and innovations” (Miravete & Larrodé, 2007) the main operating parameters of Archimedes’ screw can be calculated. For this purpose, the following data are required: hb = 1.16 m (Lifting height), L = 2.4 m (Screw length), φ = 36.8° (Inclination angle). These values and the following expressions (Eqs. 7–9), it is possible to obtain the water flow that the Archimedes’ screw was able to raise.

where Q = Flow [l/h], V = Peripheral speed [m/s], S = Area [m2], ρ = Water density [kg/m3], i = Inclination parameter, D = Screw diameter [m], P = Step [m], N = Angular speed [rpm].

The usual diameter of similar machines studied is about 0.5 m, the distance between blades can be assumed approximately 0.13 m (Luzón, 1968) and the inclination parameter is 0.6 for a mechanism’s inclination of approximately 20° (Galbarro, 2022). This machine was activated by people so it is assumed a rotation speed of 10–14 rpm. Equations (7), (8) and (9) are used.

The results obtained are these.

These results are similar to Landel’s, who obtained a value of 10.000 l/h. Landel’s used the same size so it can be considered as a valid calculation method (Landels, 1981). Using these values, the theoretical power can be calculated and compared later with the other devices studied using the Eq. 10:

where \(\rho\) = Fluid density [kg/m3], g = Gravity [m/s2], Q = Flow [m3/s], hb = Lifting Height [m].

For water density of 1000 kg/m3 and 9.81 m/s2. The power value is 30.69 W. Finally, the Eq. (11) is used.

where Pr = Real power [W], Pt = Theoretical power [W], η = performance.

These machines were manufactured in wood and knowing that their power came from human power, the performance was too low. In this case a performance of 70% is assumed according to literature (Stein, 2007). So that, and by implementing the Eq. 11, the real power developed in these conditions provides value of 43.84 W.

-

Water wheels

According to the bibliography, the usual volume of a bucket reached a capacity of 7 L (Beltrán et al., 2010) and the number of buckets, 30 units. The total volume will never be covered so a coefficient of 0.75 is applied (Palmer, 1927). “Note on some Ancient Mine Equipment and Systems”.

In a complete rotation, it would provide approximately, 157.5 litters of water. Considering that the diameter of the wheel was approximately 4.5 m it can be assumed that the drive speed per person should not be too high. For this study one complete lap per minute has been assumed.

A slightly higher value is obtained, compared with the proposed one by Palmer but of the same order of magnitude (Palmer, 1927). The difference is due to the performance used by the author or to various losses that are not discussed in this article. Knowing that the lifting height for a wheel is 4,5 m and using the expression (10), the obtained power is:

In the same way, considering the same performance in the section of Archimedes’ screw (11) the real power of a water wheel is calculated. Obtaining a power of 163.95 W.

-

Bucket pulley

Using the same formulation as in the wheel (7), (8), (9) and assuming a diameter of the wheel of 1 m. driven by a person at a rate of 3–4 turns per minute and with a lifting height similar to 4.5 m and with about 25 buckets:

Using (10) the power is:

Again, using Eq. 11 to calculate the power of a pumping machine, with a performance of 70%, 201.8 W are obtained.

-

Ctesibius’ pump

In this case for the calculation of the real and theoretical powers, the data collection begins with the flow data previously established (Martínez Luengo, 2012). These values are 3320 L/h for the flow and 2 m. of lifting height (Urteaga et al., 2010).

With these values the theoretical power is obtained from the Eq. (10).

Applying again a performance of 70% the real power obtained is 25.71 W.

If the rocker arm operates at 15 cycles per minute, the pump supplies 23 L. per minute and requires an input power of 54 watts. Working with a rocker, a man can probably produce between 40 and 50 watts (Stein, 2007), so it would be difficult for a man to handle this pump. However, two men could do it easily.

However, if it is considered that they have control of the vehicle, they could be able to accelerate it more quickly (for example 20 cycles per minute). The power production will rise to 31 L per minute, while the power consumption will rise to 71 watts.

The next stage is to assess which equipment was the most successful in extracting water from the Iberian Peninsula's mines using all of this data.

Applying the TOPSIS methodology, results are shown below. The following table shows the experimental values to be compared in a clear way, Table 2. Furthermore, Table 3 represents the first matrix of the TOPSIS methodology, with set parameters according to the previous calculations. Table 4 also includes random values for the weights of each characteristic. This corresponds to one of the multiple iterations of the general process to evaluate the different mechanisms.

TOPSIS process performs successes mathematical transformations to the initial matrix. These intermediate steps result into the final matrix, where the relative distance between each option and the ideal and anti-ideal solutions shows the optimal mechanism. The final matrix of a random process among the ones performed in this study is shown in Table 5. Where it is possible to observe that the best option is the Archimedes’s screw.

Performing the previous study requires setting the value of the different weights of each parameter. Since providing equal values for each parameter turns out to be a coarse simplification. To solve this issue, an iterative process has been implemented in RStudio. This process shed the most relevant mechanism in general after evaluating all possible combinations of weights for the different parameters. Every iteration represents a variation of 0.05 over 1 from a bottom value of 0.1 to a top value of 0.9 in the weight of the parameters. After this process, the results are shown below:

As it is represented in the Fig. 12 and Table 5, the mechanism with a higher rate of favourable situations is the Archimedes’ screw representing the 37,5% over the total favourable cases.

4 Conclusions

After the historical research and the analysis of the studied mechanisms, the main conclusions that can be stated are the following ones. The evolution of mechanisms throughout the history followed the optimization of the work, focusing not in the reduction of power requirements but in the reduction of number of stages in the chain of mechanisms to remove water from inside of the galleries during mining activities.

These mechanisms allowed to perform relevant mining activities which developed the industry and economy of the areas where these activities took place. Water drainage is critical for mining activities, thus, these mechanisms where a key element, especially in the SW region of the Iberian Peninsula, where the pyrite belt turns the region into one of the most relevant areas for cooper and gold mining in Europe.

About the main mechanisms analysed, Archimedes' screw allowed a large flow of water supply up to a limited height, although the consumed power for this purpose was considerably low. Next, water wheels were able to raise large amounts of water to a considerable height, although the power consumed represents a significant value to consider. Therefore, this mechanism was oriented to more complex facilities. The bucket pulley was a variant of the wheel for situations in which the amount of the water extracted was very small, with comparable characteristics. Finally, Ctesibius’ pump made use of high amount of metal and this mechanism was mainly pyrite pulverization oriented. Therefore, lower flow was compensated with low power. After the application of the TOPSIS methodology, considering the multiple possible cases in a wide range, while evaluating flow, power and height parameters, it is concluded that higher rate of favourable situations (37.5%) is represented by the Archimedes’ screw mechanism.

References

Arboledas-Martínez, L. (2013). Tesis Doctoral: Minería y Metalurgia romana en el Alto Guadalquivir. Universidad de Granada.

Beltrán, P., Calvo, R., & Trobajo, E. (2010). Las ruedas de achique romanas de Riotinto a la luz de la intervención en la “Rota aquaria” del Museo de Huelva. Las técnicas y las construcciones en la ingeniería romana (pp. 347–380). Fundación de la Ingeniería Técnica de Obras Públicas.

Ceballos, B., Jiménez, M., Mochcovsky, D., & Sanchez, J. (2013). El método TOPSIS relativo vs absoluto. Rect@: Revista Electrónica de Comunicaciones y Trabajos de ASEPUMA, 14(2), 181–192.

Ceccarelli, M. (2008). Renaissance of machines in Italy: From Brunelleschi to Galilei through Francesco di Giorgio and Leonardo. Mechanism and Machine Theory., 43, 1530–1542.

Chon, T. G. (2010). Archimedes life works and machines. Mechanism and Machine Theory, 45(11), 1766.

Delgado-Domínguez, A., & Pérez-Macías, J. (2013). El duro trabajo de los mineros en Hispania. National Geographic, 115, 16–19.

Domergue, C., & Binet, B. J. (1999). La roué de Sâo Domingos. La revue. Musée des Arts et Nétiers, 27, 49–59.

Domínguez, A. D., & Santamaría, P. S. G. (2015). La noria del museo de Huelva, un Unicum en la Arqueología Romana. De Re Metallica, 24, 33–43.

Foto del mes de mayo. Río Tinto - Rotae Romanas. [Film]. Andalusía, Spain: Fundación Patrimonio Industrial de Andalucía., 2020.

Galbarro, H. R. (2022) ingemecanica. [Online]. https://ingemecanica.com/tutorialsemanal/tutorialn143.html

Garrido, J. F., Castilla, L. S., Fortes, B., Dávila, J. M., & Salmerón, I. (2010). Máquinas de desagües utilizadas por la minería romana en la provincia de Huelva. Una Apuesta por el Desarrollo Local Sostenible, Huelva: Universidad de Huelva.

Gonzalo y Tarín, J. (1888). Descripción física, geológica, y minera de la provincial de Huelva (p. 1331). Imp M Tell.

Landels, J. (1981). Engineering in the Ancient World. University of California. Edited in 1981 and Revised Edition 2000.

Luzón, J. (1968). Los sistemas de desagüe en minas romanas del suroeste peninsular. Consejo Superior de Investigaciones Científicas.

Manzano-Beltrán, R., Ojeda-Calvo, R., & Rodríguez Trobajo, E. (2010). Las Ruedas de achique romanas de riotinto. IAPH. Junta de Andalucía, Sevilla.

Martínez Luengo, L. (2012). Revista Anales. [Online]. https://revista-anales.icai.es/web/n_14/seccion_4.html

Mateo, M. O. (2004). La minería antigua de Riotinto (Huelva). De re metallica (Madrid): revista de la Sociedad Española para la Defensa del Patrimonio Geológico y Minero, 3, 23–32.

Miravete, E., & Larrodé, A. (2007). Elevadores: Principios e Innovaciones. Reverté.

Nocete, F., Alex, E., Nieto, J., Sáez, R., & Bayona, M. (2005). An archaeological approach to regional environmental pollution in the south-western Iberian Peninsula related to Third millennium BC mining and metallurgy. Journal of Archaeological Science, 32(10), 1566–1576.

Nocete, F., Saez, R., Bayona, M., Peramo, A., Inacio, N., & Abril, D. (2011). Direct chronometry (14C AMS) of the earliest copper metallurgy in the Guadalquivir Basin (Spain) during the Third millennium BC: First regional database. Journal of Archaeological Science, 38(12), 3278–3295.

Palmer, R. E. (1927). Notes on some ancient mining equipments and system. Transactions of the Institution of Mining and Metallurgy, 36(1926–1927), 299–336.

Pérez, G., & Delgado-Domínguez, A. (2015). La noria del museo de Huelva, un Unicum en la Arqueología Romana. De Re Metallica, 24, 33–43.

Rodríguez-Pérez, A., Caparrós-Mancera, J., Hernández-Torres, J., Fortes-Garrido, J., Dávila-Martín, J., & Castilla-Gutiérrez, J. (2022). Power and performance the water lifting machines used in ancient mining in the southwest of the Iberian Peninsula. In International symposium on history of machines and mechanisms (pp. 184–196) No. Springer.

Roszkowska, E. (2011). Multi-criteria decision making models by applying the TOPSIS method to crisp and interval data. Multiple Criteria Decision Making, 6(1), 200–230.

Rothenhoefer, P., Bode, M., & Hanel, N. (2016). Old Finds-New Insights: Remarks on two Roman lead ingots from Minas de Riotinto (Huelva, España). Onoba. Revista de Arqueología y Antigüedad. https://doi.org/10.33776/onoba.v0i4.2824

Stein, R. (2007). Roman Wooden Force Pumps. Use and Performance. Brun J.P, Fiches.

Suarez-Suarez, J., Puche-Riart, O., & Delgado-Dominguez, A. (2017). Gonzalo y Tarin and the Physical, Geological and Mining Description of the Province of Huelva 1886–1888. Boletin Geológico y Miniro, 128(1), 111–128.

Tamain, G. (1966). Las minas antiguas de El Centenillo (Jaén). Oretania, 8(23–24), 285–303.

Urteaga, M., Schiöler, T., Noain, M., & de Munain, D. (2010). La válvula de la bomba Ctesibio de Oiasso, Irun (Gipuzkoa). Boletín Arkeolan, 2009(40), 16.

Yannopoulos, S. I., Lyberatos, G., Theodossiou, N., Li, W., Valipour, M., Tamburrino, A., & Angelakis, A. N. (2015). Evolution of water lifting devices (pumps) over the centuries worldwide. Water, 7(9), 5031–5060.

Funding

Open access funded by Universidad de Huelva/CBUA.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fortes-Garrido, J.C., Rodríguez-Pérez, A.M., Hernández-Torres, J.A. et al. Comparative Analysis of Water Extraction Mechanism in Roman Mines. Found Sci 29, 185–203 (2024). https://doi.org/10.1007/s10699-022-09891-9

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10699-022-09891-9