Fibrous materials based on poly(3-hydroxybutyrate) containing the drug dipyridamole were investigated. The structural–dynamic characteristics of the materials were studied by scanning electron microscopy, differential scanning calorimetry, and ESR spectroscopy. The effect of a series of aggressive factors (temperature, water, ozone) on the structure of the poly(3-hydroxybutyrate) fibers with dipyridamole was investigated for the first time. It was established that the enthalpy of fusion of the fibers increases when dipyridamole is added. Complex relationships between the specific enthalpy of fusion of the crystallites and the molecular mobility of the radical are observed during the action of aggressive factors on the fibrous materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Materials for biomedical application based on ultrathin and nanosized fibers of biopolymers and biocomposites are effective in the creation of matrices for cell engineering, antiseptic dressings and plasters, bioresorbable implants of connective tissues, etc. [1,2,3,4]. For the formation of such fibrous materials preference is given to natural polyesters of bacterial origin (polyhydroxyalkanoates). One representative of this type of polymer, poly(hydroxybutyrate) (PHB), is used more than others for the creation of constructive biomedicinal materials and articles (artificial heart components, artificial vessels, catheters, matrices for delivery of drugs). The high biocompatibility with living organisms, controllable biodegradation, and satisfactory physicomechanical characteristics make it possible to regard this polymer as one of the most promising medical polymers [5, 6].

As a rule, nonwoven systems for cell engineering and therapeutic purposes contain various drugs, low-molecular additives, and solid nanoparticles as structure modifiers for the polymer [7, 8]. Earlier we established that liquid and solid substances added to the polymer solution have a significant effect on the structural organization of the PHB during the formation of films and fibers produced from solution, by direct extrusion from the melt, and by electrostatic spinning [9,10,11,12].

In comparison with traditional methods for the production of polymeric fibers by electrospinning (ES) it is possible to spin structured polymers with diameters from 10 nm to 10 μm by stretching a drop of solution or melt formed at the end of a capillary under the influence of mechanical and electrostatic forces applied to the solution or melt. Here, it is possible to control the morphological characteristics, the surface characteristics, the porosity, and the geometry of the fiber by changing the characteristics of the spinning solution (electroconductivity, viscosity), the characteristics of the polymer (molecular mass and molecular-mass distribution), and the technological parameters of ES (the electrode potential, the distance between the electrodes, the productivity) [13].

In [10, 14, 15] the physicochemical and dynamic characteristics of fibrous biopolymeric materials based on PHB containing solid nanoparticles of various titanium dioxide modifications, nanocrystalline silicon dioxide in a silicon dioxide shell, and chitosan were studied. It was found that the set of physicomechanical and diffusion characteristics, the dynamics of reabsorption in the organism, and proliferation of living cells in the fibrous biomaterials depend on the degree of crystallinity and also on the morphology of the amorphous phase of PHB. It was established that the addition of nanodisperse particles to the spinning solution of PHB in small concentrations (0.1-0.5%) leads to substantial changes in the structure of the polymer at the supramolecular level [10, 16]. Analogous changes in the crystal structure of PHB fibers were obtained in [17,18,19], where gelatin [17], calcite [18], and an L-lactide and ε-caprolactone copolymer [19] were used as modifying additives. The mutual effect of the crystalline and intercrystalline (primarily amorphous) regions in biodegradable polymers and their composites remains a complex little studied problem of polymeric materials science.

It is of particular interest in terms of the present investigation to study the effect of external factors (heat, water, ozone) on the structure of the ultrathin PHB fibers. These external factors arise during the production and use of articles for medical purposes based on unwoven fibrous materials during autoclaving, under the influence of physiological media, in various methods of sterilization, etc.

During the work we used PHB of 16F series from Biomer® (Germany) with mean-viscosity molecular mass of 2.06·105 g/mole, density 1.248 g/cm3, melting point 177°C, and degree of crystallinity 45%. As functional additive (drug) we used dipyridamole (DPD): (2,22,23,24-[(4,8-di-1-piperidinylpyrimido[5,4-d]pyrimidine-2,6-diyl)]dinitrilotetrakis[ethanol]) with a molecular mass of 504.53 g/mole. The pharmacological group to which dipyridamole, antiaggregants, angioprotectors, and microcirculation protectors belong consists of adenosinergic agents. The ultrathin PHB fibers were obtained by electrospinning [21]. Spinning solutions of PHB and of PHB with DPD in chloroform were prepared for production of the fibers. The concentration of PBH in the solution amounted to 7 wt. %. The content of dipyridamole in the composite with the polymer amounted to 1, 3, and 5% in relation to the mass of PHB. The spinning solutions of PHB with DPD were prepared with an automatic magnetic stirrer. The ESR spectra (the X range) were recorded on an EPR-V (Institute of Chemical Physics, Russian Academy of Sciences) automatic ESR spectrometer. The ESR probe was the stable 2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO). The procedure was described in [15, 20, 21]. The samples were annealed at 70 ± 1 °C in a dry-air oven with various holding times. Before the introduction of the radical the samples, which had been subjected to the action of water, were dried to constant weight. Ozone oxidation of the samples was conducted in an ozone–air mixture with partial ozone concentration of 5·10−5 M. The samples were investigated by DSC on a Netzsch DSC 204 F1 instrument in an inert argon medium with a heating rate of 10 deg/min. The average statistical error was ±3%. The enthalpy of fusion was calculated by Netzsch Proteus software [22]. The morphology of the fibrous materials was investigated by electron microscopy (SEM) on a Hitachi TM-1000 scanning electron microscope (Japan) at an accelerating potential of 20 kV. The surface of the unwoven fibrous material was coated with a layer of gold 100-200 Å thick.

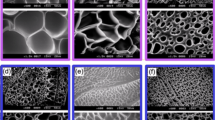

Figure 1 shows typical photomicrographs of the fibrous materials based on PHB and DPD. For pure PHB and PHB with 1% DPD there are a significant number of spindle-like bulges, which in our opinion result from the insufficient electric conductivity and viscosity of the spinning solution. Another reason for the formation of bulges on the fiber may be the appearance of intermolecular interaction in the solution between the polymer and the modifying additives, leading to disruption of the steady flow of the spinning solution and to decrease in the rate of the relaxation processes in the spun fiber [13].

As seen from Fig. 1a, the unwoven PHB material consists of a combination of cylindrical fibers 1-3 μm in diameter and spindle-like elements with maximum diameter of 10-15 μm and length of 30-50 μm. The addition of 3-5% of DPD to the spinning solution (Fig. 1b) leads to complete disappearance of the bulges on the fibers. In this case the average diameter of the fiber varies from 2 to 4 μm.

The appearance of the characteristic bulges on the PHB fibers in the electrospinning process and their disappearance when DPD is added are due to a lesser degree to change in electric conductivity in so far as DPD in chloroform solution consists of nonionogenic molecules, where the functional groups that dissociate into ions are absent. The addition of 100-400 mg of DPD to 100 ml of the PHB spinning solution leads to practically no changes in the general conductivity of the solution. On the other hand, when between 1 and 5% of DPD was added to a solution of PHB with initial viscosity ~ 7 Ps the viscosity decreased from 6.5 to 4.5 Ps.

Earlier it was shown [10, 23, 24] that the spinning process for the polymeric fiber only becomes stable after a specific viscosity value has been reached where the polymer becomes capable of plastic deformations. In our case, therefore, at a viscosity value below 6.5 Ps plastic (irreversible) deformation of the PHB fibers evidently occurs under the influence of the electrostatic and gravitational forces in the electrospinning process, and the bulges on the fiber are stretched. Since the DPD molecules are comparatively large, during spinning of the fiber they lead to an increase of the free volume between the polymer chains. As a result the polymer chains obtain an additional degree of freedom, and a forced elasticity effect, i.e., the ability to undergo larger deformations, can arise [25].

To investigate the effect of DPD on the formation of the supramolecular structure of the PHB fiber we used the SCR method. As seen from Table 1, the melting points of the samples have similar values of ~169°C. The constancy of the melting points with various contents of the drug indicates that it does not affect the morphology or size of the crystalline formations of PHB (i.e., its energy of cohesion). Here the specific enthalpy of fusion (ΔH) of PHB increases by almost twice—from 42.9 J/g in the initial PHB to 79.7 in the PHB with a DPD content of 5%—indicating an increase of the crystalline part in the PHB phase. Thus, the presence of the drug in the PHB fibers accelerates the crystallization process. The largest proportion of the crystallization part is observed for the samples of PHB with 5% of DPD. As the PDP content decreases the degree of crystallinity of the PHB decreases and reaches a value of only 30% for the fibers of the initial PHB. On the basis of the foregoing we suppose that the changes of crystallinity and form of the fiber with increase of the DPD content arise from increase in the segmental mobility of the PHB with increase of the free volume of intermolecular space. That is, there is an analogy with the increase of crystallinity in crystallized polymers with a small plasticizer content.

Thus, the differences in the morphology of the fibers and the increase of the crystallinity of the PHB can be explained by decrease in the viscosity of the polymer solution with the addition of DPD and also by an increased degree of crystallinity in the PHB during production of the fibers.

During investigation of the structural organization of the intercrystallite space (the amorphous regions) of the fibers of the initial PHB and of PHB with DPD it is important to understand that the structure of such regions is directly related to the spatial orientation of the through chains, which are subject to conformational restrictions in the fairly narrow intercrystallite space. With the addition of dipyridamole to the PHB the increase in the degree of crystallinity, i.e., the decrease of the intercrystallite space in the unit fibril, must lead to change in the structural and dynamical state of the amorphous regions. We investigated the structural state and the molecular dynamics of these regions by ESR with the use of stable radicals.

The ESR spectra of the radical (TEMPO) and PHB have complex form and represent the superimposition of two spectra corresponding to two populations of radicals with different correlation times τ1 and τ2, where τ1 characterizes the molecular mobility in the less dense a τ2 in the more dense intercrystallite regions (Fig. 2).

The concentration ratios for the regions with different densities were estimated by mathematical treatment of the spectra using a special NLSL program similar to the previously described procedure [20]. The calculations showed that the fraction of the dense regions in the intercrystallite space of PHB is substantially larger than the fraction of the less dense regions. It amounts to 90% in the PHB fibers, 93.5% in the PHB fibers with 1% DPD, 94.3% with 3% DPD, and 95.2% with 5% DPD. The specific enthalpy of fusion of PHB, which as indicated above reflects its degree of crystallinity, varies in a similar way.

With increase in the fraction of dense intercrystallite regions of PHB there is a corresponding decrease in the mobility of the radical present in them. This indicates indirectly that the molecular mobility of the polymer is reduced, i.e., the flexibility of its chains is reduced. Using the program mentioned above we calculated the correlation times of the fast and slow components of the rotation of the molecule. For the slow component of the spectrum the correlation time increases with increase of the DPD content of the fiber: 66·10−10 s in PHB, 71·10−10 s in PHB with 1% DPD, 88·10−10 s in PHB with 3% DPD, and 90·10−10 s I PHB with 5% DPD. This indicates a decrease in the mobility of the radical and, accordingly, a decrease in the molecular mobility or flexibility of the PHB chains. The correlation time for the fast component in all the samples except PHB with 5% DPD (7·10−10 s) amounted to 2.4·10−10 s.

Elevated temperatures (above 100°C) in the treatment of medical articles and instruments are used, for example, for the disinfection of surfaces during autoclaving. It is well known that heat treatment (annealing) of crystallizing samples of polymer at temperatures 20-30° below the melting point (melting point of PHB ~175°C) removes a series of internal stresses and promotes further crystallization.

For this reason PHB–DPD fibers were heated up isothermally at 140°C for times ranging from 0 to 2 h. The dynamic characteristics were obtained for each heat-treated sample (Fig. 3). It is important to note that the radical was introduced after heat treatment. The enthalpies of fusion of the ultrathin fibers of PHB with DPD in the original state and after heat treatment at 140°C for 2 h were obtained in parallel by the DSC method.

It follows from Fig. 3 that if the heating time in PHB fibers is increased sharply, by approximately three times, the correlation time is increased by approximately two times in the samples of PHB with 1% DPD, while such changes in PHB fibers with 5% DPD are less significant and amount to ~40%. Here, the relationships differ in nature: in the fibers of PHB and of PHB with 1% DPD a strong increase of correlation time with increase of heating time is observed, for fibers of PHB with 3 and 5% DPD the time at first increases to some degree, but after heating for 40 min it decreases a little. In our opinion such dependence of the correlation time for the samples with 3-5% of DPD is due to the comparatively large content of DPD in the amorphous phase of the PHB. In view of the comparatively high degree of crystallinity of PHB in the fibers the proportion of its amorphous part is small, and the effect of the PHB is therefore particularly significant when its content lies in this region. In our opinion the decrease of the correlation time during heat treatment in samples of PHB with 3 and 5% of DPD may be a consequence of intermolecular interaction of the DPD, which has polar hydroxyl groups, with the molecules of the TEMPO radical in the amorphous phase of PHB. If the DPD molecules (with 3-5% contents) are concentrated in the intercrystallite regions of the PHB steric hindrances are created for free rotational movement of the radical.

By the DSC method we obtained data on the change of the crystallinity of the fibers after heat treatment at 140°C. As seen from Table 2, ΔH for the PHB and PHB with 1% DPD fibers is increased by more than twice whereas the value for the PHB with 3% fibers was practically unchanged, while the value for PHB with 5% DPD was increased by 10 J/g. A distinct correlation is observed during comparison of the τ and ΔH data: in the PHB and PHB with 1% DPD samples the molecular mobility decreased by 2-3 times, and the enthalpy of fusion increased by ≈ times whereas heat treatment in fibers of PHB with 3 and 5% DPD did not lead to any significant changes in τ and ΔH. In our opinion it is the DPD that prevents additional crystallization processes at 140°C. The sharp increase of τ in the amorphous phase of the PHB and PHB with 1% DPD fibers with increase of the heating time indicates a significant increase in the rigidity of the polymer chains as a result of the increased proportion of crystallites in the volume. Conversely, the extremely weak changes of τ in the PHB with 3 and 5% DPD samples are due to the insignificant changes of ΔH. The fact that the crystallinity changes little in the PHB polymers with 3 and 5% DPD indicates an extremely low relaxation rate and accordingly flexibility of the molecular chains in these fibers under the influence of the drug.

Experiments in a phosphate buffer at 70°C are often used for investigation of the effect of water on the structure of biomedical fibrous and film matrices. There are also methods of evaluating the biological resistance of polymeric materials to various microorganisms for long periods in aqueous media at 28-30°C. Under these conditions the structure of the polymer undoubtedly undergoes appreciable changes at the molecular and supramolecular levels.

In order to asses the effect of the aqueous medium on the ultrafine fibers of the PHB-DPD composite the ESR spectra of samples exposed in distilled water at 70°C were recorded. The radical was added to the samples after holding in the aqueous suspension. The results from calculation of the correlation times are presented in Fig. 4.

As seen from Fig. 4, the action of water and temperature for a short time (up to 1.5 h) leads to a decrease of the correlation time, which is the result of increased molecular mobility in the polymer. The correlation time for all the fibers increases monotonically with more prolonged action of these factors.

It was previously shown [15, 17] that for film and fiber samples the addition of polar chitosan and gelatin to the PHB leads to hydrophilization of the composites materials. Their sorption capacity is greatly increased due to the high affinity of water to the molecules of the given polysaccharides, and this at the same time leads to increase of the plasticizing action of water on the PHB. Similar processes evidently arise in the amorphous regions of the PHB–DPD fibers under the influence of water heated to 70°C. On account of the plasticizing action of water on the moderately hydrophilic (weakly polar) PHB at the first moment of time (up to 30 min) the free volume of the amorphous phase of PHB is increased and, accordingly, the rotation of the molecules of the TEMPO radical is accelerated (the correlation time is reduced). Increase of the free volume of the amorphous phase of the polymer is also favored by diffusion of the individual hydrated molecules of the DPD. The water molecules, their associates, and the hydrated molecules of DPD are built into the intermolecular space of the PHB with the formation of hydrogen bonds between the carbonyl groups of the PHB, leading to increase of the distance between the neighboring macromolecules [26]. To judge from the curves in Fig. 4, the largest decrease in the correlation time is observed in the original PHB fibers. When DPD is added and its content is increased the correlation time decreases to a lesser degree. In all probability the DPD molecules, being concentrated in the amorphous regions of the PHB create steric hindrances for rotational motion of the TEMPO radical.

Since PHB is a hard-center polymer the size of its kinetic segment is extremely large (it can amount to 5-10 monomer units), and the duration of the relaxation processes in the macromolecular chains of PHB is correspondingly long. Spatial movement of the segments (flexibility of the chains) requires additional free volume. The action of water and elevated temperature leads to an increase in the free volume of the amorphous phase of the PHB and, consequently, to increased flexibility in its macromolecular chains. The structurization processes in the polymer are thus accelerated. As seen from Fig. 4, the maximum increase in the free volume of the amorphous regions of PHB under the given experimental conditions is reached after approximately 1-1.5 h. At the moment when the free volume of the polymer becomes commensurable with the size of the kinetic segment of PHB the conditions necessary for increase of the segmental mobility of sections of the macromolecular chains in the amorphous phase of the polymer are reached. That is, conditions are created for additional crystallization of PHB in the intercrystallite regions. This will lead to a decrease in the volume of the polymer in the amorphous intercrystallite regions. From Fig. 4 we therefore see a further increase of the correlation time (decrease of the rotation rate) of the radical with increase of the holding time for the fibrous materials in water to more than 1.5 h. The obtained data agree well with our dynamic and diffusion results obtained for film-type PHB–polyurethane [11] and PHB–chitosan [15] composites.

An essential operation before medical materials are packed is sterilization. Various methods are used for sterilization: UV irradiation, γ irradiation, corona discharge treatment, chemical treatment, etc. In certain types of sterilization the antiseptic factor is the appearance of ozone during treatment of the material in air. Ozone is capable of exerting a substantial effect on the structure and segmental mobility of the polymers and composites. Study of the effect of this external factor is therefore a topical issue.

Figure 5 shows the dependence of the correlation time for rotation of the probe on the DPD content of the fiber for various lengths of treatment in the ozone–air mixture.

As seen from the figure, increase of the ozonation time leads to increase of the correlation time in the PHB–DPD fiber materials. An analogous relationship is observed in the dependence of the correlation time on the DPD content of the fiber without the ozone treatment (curve 1). During ozonation, however, the decrease in the rotating ability of the radical in the samples is substantially greater compared with the effect of the DPD content on this property. Judged from the nature of the curves in Fig. 5, the correlation time for various ozonation times increases with increase of the DPD content. More significant increase is observed at DPD contents greater than 3%.

The increased correlation time for the rotational motion of the TEMPO probe arises from the increased density of the amorphous phase of PHB and the reduced flexibility of its macromolecules during the action of ozone. In our opinion, this action involves the formation of cross links between the PHB macromolecules in the amorphous regions on account of the appearance of a network of chemical bonds initiated by the formation of hydroperoxides during the interaction of ozone with the functional groups (methyl, hydroxyl) of the PHB. During ozonation physicochemical structurization of the macromolecules occurs in parallel with the chemical process that leads to breakdown of the polymeric bonds, and a system of hydrogen bonds is formed. The decrease of the flexibility of the chains can also result from the accumulation of oxygen-containing groups in the side chains of the PHB, leading to increased intermolecular interaction between the segments of the polymeric chains. Similar results were obtained earlier in [15], where fibrous materials based on PHB and chitosan and the effect of ozone on the molecular-dynamic characteristics of the materials were studied.

References

D. Bomba, M. Brojan, et al., RMZ – Materials and Geoenvironment, 54, No. 4, 471-499 (2007).

A. Jaros, A. Smola, et al., Chemik, 64, No. 2, 87-96 (2010).

Sokolowski W., Metcalfe A., et al., Biomedical Materials, 2, No. 1, S23- S27 (2007). (DOI: 10.1088/1748-6041/2/1/S04).

B. Jeong, Y.K. Choi, et al., J. Control Release, 62, No. 1-2, 109-114 (1999).

A. A. Ol’khov, A. L. Iordanskii, et al., Plast. Massy, No. 9, 61-64 (2010).

B. Saraswathi, A. Balaji, M.S. Umashankar, Int. J. Pharm. Pharm. Sci., 5, No. 3, 423-430 (2013).

M. Chasin, R. Langer (Eds.), Biodegradable Polymers as Drug Delivery Systems,: Marcel Dekker, New York (1990), 347 pp.

W. Badri1, R. Eddabra, et al., J. Coll. Sci. Biotechnol., 3, 141-149 (2014).

A. A. Ol’khov, S. Markin, et al., Russian J. Appl. Chem., 88, No. 2, 308-313 (2015).

A. A. Ol’khov, A. L. Iordanskii, et al., Khim. Volokna, No. 5, 8-24 (2015).

Ol’khov A. A., Staroverova O.V., et al., Polymer Sci. Ser. D, 8, No. 2, 100-109 (2015).

Ol’khov A. A., R. Yu. Kosenko, et al., 49, No. 6, 671-677 (2015).

Yu. N. Filatov, Electrospinning of Fibrous Materials (EVF Process) [in Russian] (Ed. V. N. Kirichenko), Neft’ i Gaz (1997), 298 pp.

S. G. Karpova, A. L. Iordanskii, et al., Vysokomol. Soed., 57, No. 2, 128-135 (2015).

S. G. Karpova, A. A. Ol’khov, et al., 58, No. 1, 61-72 (2016).

A. A. Ol’khov, O. V. Staroverova, Vestnik Kazansk. Tekhnol. Un-ta, 16, No. 8, 157-161 (2014).

T. Nuge, M.E. Hoque, et al., Regenerative Res., 2, No. 2, 39-42 (2013).

D. H. Guan, C. P. Huang, et al., Key Eng. Materials, 330-332, 695-698 (2007).

D. Daranarong, R. T. H. Chan, et al., Biomed Res. Int., 2014. Vol. 2014. Article ID 741408, 12 p. http://dx.doi.org/10.1155/2014/741408.

V. P. Timofeev, Yu. A. Misharin, Ya. V. Tkachev, Biofizika, 56, No. 3, 420-432 (2011).

A. L. Buchachenko, A. M. Vasserman, Stable Radicals [in Russian], Khimiya, Moscow (1973), 408 pp.

J. Opfermann, Rechentechnik Datenverarbeitung, 23, No. 3, 26 (1985).

S. P. Papkov, Physicochemical Principles of Treatment of Polymer Solutions [in Russian], Khimiya, Moscow (1971) 372 pp.

M. Shen (Ed.), Viscoelastic Relaxation in Polymers, Intersci. Publ. a Division of John Wiley and Sons Inc., New York (1971).

V. N. Kuleznev, V. A. Shershnev, Chemistry and Physics of Polymers [in Russian], 2nd Edition, rev. and sup., KolosS, Moscow (2007), 367 pp.

A. L. Iordanskii, A. A. Ol’khov, et al., Desalination, No. 126, 139-145 (1999).

The authors express their gratitude to the company Biomer (Krailling, Germany) and especially to Prof. U. J. Haenggi for providing the poly(3-hydroxybutyrate) for the investigation.

The work was carried out with financial support from the Russian Fundamental Research Fund. Project Nos. 13-02-12407_m2 and 15-59-32401 RT-omi.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskie Volokna, No. 4, pp. 24-32, July-August, 2016.

Rights and permissions

About this article

Cite this article

Ol’khov, A.A., Karpova, S.G., Staroverova, O.V. et al. Effect of External Factors on the Structure of Ultrathin Fibers of Poly(3-Hydroxybutyrate) and Dipyridamole. Fibre Chem 48, 284–291 (2016). https://doi.org/10.1007/s10692-017-9784-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10692-017-9784-z