Abstract

As construction activities become more intensive in developing countries, increasing improperly managed construction and demolition waste (CDW) brings serious environmental impacts. Recycling is a beneficial way to dispose of CDW that reduces environmental impact and brings economic benefits, especially for concrete. China is the country that generates the most CDW in the world, but its domestic recycling rate is much lower than that of developed countries. While the efficient technologies in developed regions have helped them to achieve a well-established recycling industry, whether these innovative technologies can be used to improve the concrete debris recycling targets in developing regions is unclear. This study examines whether innovations currently widely used in construction activities and materials can have a positive effect on the recycling of End-of-Life concrete materials in China. Results from modeling system dynamics imply that the introduction of innovative technologies in the recycling system of concrete debris can probably contribute to CO2 reduction (3.6% reduction) and economic benefits (2.6 times increase, but mainly from landfill charges and fines) from 2022 to 2030. Prefabrication and 3D printing significantly impact recycled concrete production and CDW recycling, and they are recommended as a priority for promotion. In contrast, carbonation is not suggested for application due to its minor role. Nevertheless, since the market share of innovative technologies and the basic CDW recycling rates are currently low in China, fluctuations in their usage are hardly to have a substantial positive impact. We suggest that financial support from the government is needed for upcycling by recyclers and technology providers to improve the base recycling rate in order for innovative technologies to make an effective contribution to the sustainable construction industry, creating a win–win situation for both the economy and the environment of the recycling system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

There are currently approximately 7.7 billion people in the world, of which more than half of them are urban populations (Wang et al., 2020). The number of people living in urban areas has more than quadrupled since 1950 to some 4.2 billion by mid-2018, and the United Nations predicts another 2.5 billion will join them in the next three decades (UN, 2019). This amount is the equivalent of adding eight cities the size of New York every single year (USCB, 2020). With the increase in urban population, urban land expands in nearly all cities over time (Xu et al., 2020). Construction activities on urban land for building and infrastructure creation to house the people and maintain the operation of society require prodigious quantities of construction materials and cause the unprecedented generation of construction and demolition waste (CDW). Akhtar and Sarmah (2018) estimated that the generation of CDW around the world reaches approximately 3 billion tons year−1, of which concrete debris can account for 40–60% by weight (Cabral et al., 2010; Zhang et al., 2020), and is the dominant CDW component. Between 1970 and 2022, 361 billion tons of concrete is expected to be produced globally for buildings, accounting for approximately 8.6% of all anthropogenic carbon dioxide (CO2) emissions (Deetman et al., 2020; Di Filippo et al., 2019). These in-use materials become CDW after their service life. Concrete is composed of cementitious materials, aggregates, water, and additives. Due to the cohesion and inertia of concrete, it is almost impossible for the produced concrete material to be broken down into cement and aggregate, instead, it is cemented with some of the bricks and tiles to form debris that are difficult to be completely reused and recovered. Thus, the adoption of a circular economy model into concrete debris can almost only be recycling (Gallego-Schmid et al., 2020). The primary recycling process of concrete debris is multiple crushing and screening to produce recycled aggregates (RA) of different particle sizes and qualities (Dosho, 2007), which is regarded as a common step for further production. Whereas, there are various methods when using RA (secondary materials) to produce recycled concrete (RC) for different application purposes (Guo et al., 2018). For instance, recycled fine aggregates can be used to produce recycled mortar, recycled coarse aggregates are important component materials of pervious concrete, and mixed recycled aggregate can be used to produce general concrete blocks (Verian et al., 2018; Zaetang et al., 2016; Zhu et al., 2015).

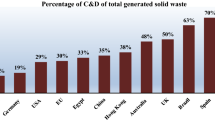

Although the recycling of concrete debris is theoretically and practically available, low recycling rates still occur in most countries. Especially in emerging countries with rapid development and intensive construction, where a vast of CDW has been generated but is sent to landfills for dumping (Bai et al., 2022; Manowong & Brockmann, 2015). As shown in Fig. 1a-b, China is the world's largest contributor to generation of concrete debris with an average recycling rate of less than 10%, and the same high generation and low recycling rates are seen in similar emerging economies, such as India. The global CDW recycling industry is unevenly developed, with high recycling rates concentrated in the more economically developed regions (Fig. 1a). As the major component of construction materials, concrete generation and recycling is representative of the general situation of CDW management.

Even though the land occupation and related environmental impacts caused by the massive landfilling of CDW can be avoided and the shortage of construction materials can be alleviated by adopting recycling methods, only a few developing regions have reasonably developed their recycling industries, due to their imperfect recycling economy facilities, inadequate technological development and immature markets (Duan et al., 2019).

As mentioned above, the recycling status of CDW, especially concrete debris, varies considerably between developed and developing regions. The gap between them in terms of circular economy development needs to be noted and narrowed. The application of efficient technologies and tools in the civil, environmental, and planning fields tends to be concentrated in economically developed regions, which has helped them to achieve a well-established recycling industry. Zhang et al. (2018) describes almost 100% of the concrete waste as being recycled in the Netherlands, 97% of which is crushed into road base filling aggregates and they generally recycle on-site whenever site conditions allow, whereas China currently has few recycling facilities on construction sites. While developed economies are already applying concrete debris recycling technologies such as carbonation, self-healing, and fiber reinforcement to practical projects, China needs to keep pace to avoid the CDW dilemma that comes with being technologically outdated. For China, challenges and opportunities are parallel. The Chinese national government has set a target to increase the recycling rate of CDW to over 35% by 2020 (Zhang et al., 2018). While there is still a gap to this target, it would be good practice to take advantage of ongoing urbanization and urban renewal to develop a circular economy for the built environment. More new technologies are being developed and practiced in developed countries toward the goals of low carbon and circular economy. In order to better manage construction materials in developing regions with intensive construction activities, it is worth exploring whether innovative technologies that have been applied in developed regions can help optimize the design of recycling processes for concrete debris in developing regions. Therefore, this study aims to understand the impact of innovative technologies in construction activities on the recycling chain in China from the perspective of concrete debris, which will help to make appropriate recycling strategies in developing countries for the circular economy transition.

2 Methodology

2.1 System dynamics

System dynamics (SD) was created during the mid-1950s by Professor Jay Forrester to deal with large-scale systems of high complexities (Forrester, 1971). The SD approach can be adopted for visualizing and analyzing complex dynamic feedback systems (i.e., positive or negative feedback loops) with an enhanced understanding of its underlying system behavior and structure (Goodman, 1997). The development of SD has been extended to economic, environmental, construction, and social management from the initial business management to now (Mingers & White, 2010), and specifically includes some applications in the field of CDW management.

For instance, Marzouk and Azab (2014) tried to develop a SD model in order to analytically evaluate the choices of disposing and recycling for CDW. Yuan and Wang (2014) and Mak et al. (2019) developed a SD model for the determination of an effective and appropriate CDW disposal charging fee in Shenzhen and Hong Kong. Ding et al. (2018) facilitated a better understanding of the impact of actions in the design and construction phases on the environmental benefits of CDW management using SD. Au et al. (2018) analyzed CDW effects in a governmental frame by using a SD model. In China, a SD model has been developed by Liu et al. (2020) for understanding how CDW affects on greenhouse gas emission by different variables including landfill disposal and other disposal methods. These studies demonstrate that the application of SD can be extended to the management of CDW. SD is a methodology to see the effects of factors included in the model behaviorally and very effective technique to observe dynamic factors in recycling and remanufacturing (Golroudbary & Zahraee, 2015). Furthermore, by the aid of SD modeling, the comparison of current and proposed model can be obviously done to see different scenarios (Wang et al., 2014). Different scenarios including innovation, new manufacturing systems or additional factors such as economic benefits and losses in short, medium or long term can be apparently taken into consideration by using system dynamics approach (Giannis et al., 2017). Previous papers have examined the management of CDW in China, using the SD approach to model how administrative tools could affect the management of CDW. We believe that the technological means are equally important, because the innovative technologies have been proven to be beneficial to the circular economy in actual projects in other countries. Thus, SD approach has been chosen to evaluate different scenarios of construction waste in China.

Richardson (2020) formulated system dynamics’ basic structure called as state-determined system, as follows (1)

where \(X\) is a vector belonging to stocks or state variables, \(f\) is a nonlinear vector-valued function while \(p\) is set of parameters.

The main variables in the system dynamics methodology are listed as stocks, dynamic variables, links and flows, respectively. One may explain that stocks are quasi-static part of the systems, implying an accumulation of any type of materials and variables. Furthermore, dynamic variable is defined as a function of stock variables and affected by stocks, flows and linkages between variables (Forrester, 1993). The other type of main variables is a link expressing the positive or negative relationship between variables. The last one is flow defined as the change of variables at a certain rate of change (Forrester, 1993).

The recycling of concrete debris for secondary and recycled materials is a complex process with multiple steps. SD can be introduced to analyze the interaction between internal and external spatial elements from a dynamic perspective. Many previous studies also suggested that SD has great potential to deal with the complicated inter-relationships and dynamics of construction and demolition management (Yuan et al., 2012).

2.2 Development of SD model

2.2.1 Boundary setting

This paper intends to focus on the impact of innovative technologies on concrete debris recycling. The key research object is the innovative technology in construction activities and the research system is the EoL stage and its sequent recycling process of concrete materials. Innovative technologies refer to a range of new technologies with the industrial potential for construction activities and building materials. Since recycling is an applied system rather than basic research, our criteria for selecting innovative technologies are that they need to be widely discussed and accepted in research and already have applications in some engineering. Global performance targets for innovative materials are being pushed toward green, and durability (Park et al., 2017). According to the summary of Soliman et al. (2022), some of the innovative material technologies recently implemented in the construction industry that show great potential are nanomaterials, carbonation, aerogel materials, self-healing, and 3D printing technologies that serve a sustainable and resilient built environment. By combining some actual construction cases or industrial applications occurring in developed countries, we exclude aerogel materials with narrow usage and nanomaterials with high cost. Considering that the Chinese government is currently promoting prefabrication and building information modeling (BIM) technologies, we have included them and radio-frequency identification (RFID), which assists both technologies, in the scope of innovative technologies (Du et al., 2017; Liu et al., 2019). Ultimately, self-healing, prefabrication, BIM, 3D printing, carbonation and RFID are the selections for this study. It is believed that these technologies have potential for development in China and they will be presented in detail in 2.2.4.

The typical recycling process of concrete debris comprises three stages: transportation, production of RA, and production of RC (Fan et al., 2016; Martínez-Lage et al., 2020). First, the transport phase includes the transport of (1) CDW from the construction site to the recycling plant (the recycling plant can be the construction site), (2) RA from the construction site to the recycling plant (the second type of transportation exists only when the RA is produced on-site), and (3) RA or RC from recycling plant to construction site, respectively. Production of RA can be divided into multiple steps of crushing and screening, and the RC is made in a process similar to conventional concrete, except that it uses RA instead of natural aggregates. The boundary of the system refers to the determination of the subsystem of the SD model and the variables contained in the subsystem. The SD model in this study is designed into three subsystems according to the division of the recycling process.

2.2.2 Causal loop structure

Many factors affect the recycling of concrete debris, including environmental, economic, social, and technological aspects, which are interrelated and mutually influential. To demonstrate that this is a comprehensive system, in addition to the technological, environmental and economic aspects discussed, we have brought in the typical social parameters that drive the built environment development, such as population and GDP, which can directly influence the supply, demand and flow of the construction materials. Creating a causal loop diagram (CLD) is an important process that helps to clarify the causal relationships among the factors and identify the feedback relationships in the loops to facilitate the design of relevant variables and parameters in the SD model based on the loops. Vensim software is used here to draw CLD, not only to visualize the CLD structure but also to create complex dynamic models based on CLDs at any level of detail (Sahlol et al., 2021). “ + ” and “−” refer to positive and negative feedback, respectively. The causal loop structure provides the visualizing of relationships and feedback effects between variables, which can be extended further in the SD model. The developed causal loop diagram affecting the recycling industry comprises a total of 11 major loops referring to innovative technology factors, ranging from 4 to 12 in length. The interactions among different loops decide the system’s final behavior. As can be seen in Fig. 2, the recycling system for CDW consists of several common enclosures. CDW is driven by frequent construction activities due to urbanization, and its recycling is aimed at promoting the economy, reducing environmental impacts, and balancing supply and demand, which are the primary concerns of construction management. The main means of promoting recycling considered in this study are innovative technologies.

Besides that, the feedback loops in Fig. 3 also show that there are variables that can be controlled directly or indirectly to improve the recycling rate and increase the generation of recycled products. For instance, frequent construction activities increase the market demand for construction materials, which drives recycling. However, increasing construction activity may also lead to more illegal dumping of CDW. It calls for additional means to control the system with both negative and positive feedback. The diagram shows that material demand and supply, innovative technologies, CDW generation and government management combine to influence recycling. In fact, the supply and demand of materials and the generation of CDW are inevitable in the context of urbanization, so the main tool to promote recycling in this system is innovative technology, which is influenced by government management and economic development.

2.2.3 Model formulation: a case study of China

CLD is a simple mapping of a system and its components and interactions. By capturing the interactions and feedback loops in the CLD, it can reveal the structure of the system (Sterman, 2000). Based on the relationships among the variables in the causal loop diagram of the concrete debris recycling system, the factors and feedback relationships in the causal loop diagram are extended and converted into a stock-flow diagram of the SD model using Vensim software by defining all the main variables affecting the recycling process, as shown in Fig. 3. It contains four types of parameters for the development context, construction and recycling activities, government management, and impact/benefit dimensions, i.e., constants, auxiliary variables, flows (or rate), and stocks (or level). The hollow arrow with the valve represents the flow, the rectangle represents the stock, and the others are constants and auxiliary variables. The parameters in angle brackets are shadow variables, which are set only to avoid the confusion of the arrow lines. Stocks and flows are the core of the SD system, which consists of two main paths from CDW generation (End-of-Life stage) to disposal landfilling and recycling. Other auxiliary variables and constants are used as parameters to influence the flow and stock. We finally measured the multidimensional contribution of the system incorporating the innovative technology in terms of production of RC (outflow of recycled material) and (CDW) recycling rates, economic benefits, and environmental benefits (CO2).

2.2.4 Data sources and parameter setting

The data of parameters in the SD model are obtained from the available previous research, publications, governmental reports and some relevant official websites. The units, values, and sources of the quantitative variables in the model are shown in Table 1.

In this study, the attention and availability of new technologies were mainly considered when selecting innovative technologies. Table 2 describes the innovative technologies that are currently being widely discussed and focused on for concrete materials and construction. They are BIM, RFID, prefabrication, 3D printing, self-healing technology, and carbonation. BIM is a digital tool that serves the whole life cycle management of construction. Modeling with BIM allows monitoring and management of data and metrics throughout the building lifecycle, which helps optimize the resource consumption and environmental impact of building materials (Meng et al., 2020). RFID is an Internet of Things technology mostly used in the logistics industry. It uses electromagnetic fields to automatically identify and track tags attached to objects. In contrast to bar codes, RFID uses tags that do not need to be in the line of sight of the reader, so it can be embedded in the object being tracked (Landaluce et al., 2020). Based on this feature, RFID has recently been commonly used in the embedding of building structures to track the location of the building components during the construction and in-use phases (Valero & Adán, 2016). RFID has been shown to improve the efficiency of transporting construction materials, the efficiency of utilizing concrete structures, and the percentage of structures that can be recycled at the end of their service life through tracking management. Prefabrication and 3D printing are new technologies that serve to optimize the construction process. Both technologies have a large number of practical examples and are already being used in several global regions. Prefabrication is the practice of assembling structural components at a factory or other manufacturing site and transporting the complete components or subcomponents for assembly to the construction site (Aghasizadeh et al., 2022). By transferring the manufacturing process to a factory, material losses are greatly reduced, and structural modularity increases the ease of construction and demolition, reducing the generation of broken concrete debris that is not conducive to reuse and recycling (Hu et al., 2022). 3D printing is the use of a robotic arm or gantry system to form a building structure by spraying or extruding concrete slurry (El-Sayegh et al., 2020). This highly automated operation is controlled by a computerized system, which can avoid a lot of waste in human operation. Self-healing technology and carbonation are presently used in a smaller range of applications than the previous technologies. Self-healing is typically done using bacteria and fungi added to the concrete material. The mycelium can undergo biomineralization, a metabolic process that metabolizes phosphates, silicates, sulfides and carbonates (Seifan et al., 2016). The mineralized organization fills the cracks created by the concrete material, thus extending the service life of the structure. Carbonation, then, is the process by which the alkaline material in the concrete material reacts with the acidic gas (CO2) in the climatic environment. This process involves a series of chemical reactions that ultimately lead to a reduction in the porosity of the concrete structure resulting in a denser structure (Xuan et al., 2016). Carbonation is particularly suitable for recycled concrete materials since RA structure is considered extremely porous (Zhang et al., 2022a). CO2 and RA utilization can be combined by carbonation, then it can contribute to the reduction of environmental impact (GWP) and increase the efficiency of recycled material use.

2.2.5 Model validation

Due to the complexity of the real system, the model is an abstraction and simplification of the real world under certain conditions, which cannot fully reflect reality. Therefore, the validity of the constructed model needs to be checked to verify its reflection in the real world (Golroudbary & Zahraee, 2015). Only the tested model can be reliable and applicable for the realization of research purposes. In combination with existing literature studies (Schwaninger & Groesser, 2009), the model was checked using the following tests:

Boundary test: This test is concerned with whether the model contains all essential variables that correspond to the research purpose; meanwhile, the test helps assure variables that are irrelevant to the research question are excluded from the model. This test is performed by examining all the variables that have been embodied in the SD model. By adding new stock to the system boundary (in-use stock) and removing the already existing flow (RC outflow), we find that the logic of the system is completely changed. Thus, we concluded that the current system boundary setting is reasonable and each variable is critical for the purpose of the study, which is to evaluate the recycling process of concrete debris.

Structure verification: model structure evaluation is used for evaluating the model logic and its consistency with the practical situation. The information included in the structure and all cause-and-effect chains of the causal loop diagram (shown in Fig. 2) is based on a comprehensive literature review in this domain and CDW management practice. As such, the structure of this model is logical and closely consistent with the practical system. For instance, in China, CDW is transported to landfills and recycling plants after it flows out of the built environment. Since China currently has almost no on-site sorting system for CDW, CDW that has not been landfilled is first collected and then separated at a collection center for the easily recyclable concrete debris and high-value metals within it. Concrete debris is crushed in recycling plants to produce aggregates which are then used in recycled concrete in different scenarios. The structure of this model is realistic and logical.

Dimensional consistency test: this test requires that measurement units of all the variables in the model are dimensionally consistent. The “check model” in software Vensim provides a useful function for checking the consistency of system dimensions. The dimensional consistency test result of the SD model “Units are A.O.K.” indicated that it has passed the dimensional consistency test.

Extreme conditions test: the extreme conditions test is used to determine whether the equations in the model show proper behavior under the extreme conditions in the variable domain. We select the concrete composition (component ratio of the concrete debris in mixed construction waste) and recycling rate as the test variables to evaluate the SD model under extreme conditions. Taking the extreme values of example variables, the normal values of these two ratio variables are within the range of 0 and 1. Three simulations of concrete composition were conducted according to the values of 0.2, 0.9, and 0.57 (the current value), respectively, and the change in the production rate of RC and collected construction waste was obtained as shown in Figs.4a-b. The recycling rate was simulated four times with values of 0.05 (the current value), 0, 0.4, and 0.5, and the results can be seen in Figs.4c-d.

Test of extreme conditions for the production rate of RC and collected construction waste. A Extreme conditions of concrete composition for production rate of RC, B extreme conditions of concrete composition for collected construction waste, C extreme conditions of recycling rate for production rate of RC, and D extreme conditions of recycling rate for collected construction waste

As shown in Fig. 4, these simulation results are consistent with the actual situation. The RC productivity and collected construction waste increases gradually over time as the proportion of concrete debris in CDW rises from 0.2 to 0.9 and the CDW recycling rate increases from 0 to 0.5. For instance, “Recycling rate = 0” refers to the worst-case scenario of no action in the CDW recycling process, and “recovery rate = 0.5” means a relatively high recycling rate (50%) for the current situation in China. One of the values between 0 and 0.5 is the recycling of 5%, representing the actual situation in the recycling process in China. In fact, the increase in “Recycling rate” means the development of technologies and management in construction activities. Advanced technology improves the productivity of secondary materials and thus increases the quantity of recycled products.

In general, the applicability and feasibility of this SD model can be ensured through the above four tests.

3 Simulation results

After running the SD model, the simulation results are analyzed and discussed by dividing them into status quo and 12 scenarios. The 12 scenarios were determined based on setting a ± 30% float for the usage rate (or market share) of the six technologies in the concrete process chain.

3.1 Quantification of major variables

The analysis of the current situation is based on the classification of parameters, including stock, flow and economic and environmental benefits (detailed classification can be found in the supporting information).

3.1.1 Stock and flow

There are six parameters in Fig. 5, containing one stock parameter (CDW stock) and five flow parameters (waste increase, recycling, recycling of concrete debris, production of RA, and production of RC). The results are shown in Fig. 5, which indicates the dynamics of the CDW stock and materials flows from 2010 to 2030. The one stock parameter in the concrete debris recycling system is “CDW stock,” which is characterized by continuous growth and does not tend to slow down over time. The reason for this continued growth in the waste stock is that the increase in waste generation was more than ten times the growth in four types of recycling materials during the same period. Specifically, the trend between 2010 and 2030 of flow parameters is consistent, with the most significant increase from 3.0 to 12 billion tons in the “waste increase” (see Fig. 5). However, since “recycling” has increased rather slowly compared to the increase in “waste increase” over a set period of twenty years, the gap between generation and recycling (landfilling flow) has been gradually enlarged, which actually means that the majority of the generated waste is shipped to landfills. The remaining four flows are different stages of recycled materials. Since the four recycling materials have a sequential production relationship, that is, the former material is the raw material of the latter one, thus they grow in the same trend. It can also be seen from the same changing trend that there is a difference in the rate of growth between the various materials. The growth rate of recycling concrete debris and the production of RA is significantly lower, i.e., the slopes of the lines representing these two materials are the smallest.

3.1.2 Environmental impacts and economic benefits

The variables related to the environment and economy in this SD model are “environmental impact from the construction sector” and “economic benefits.” The carbon dioxide equivalent (CO2 eq/year) and Chinese Yuan (CNY/year) were chosen to measure the two types of impacts. Figure 6 shows the dynamics of these two parameters after running the model. The trends of the environmental effects and economic benefits in this system are opposite in 2010–2030. The system would have achieved optimistic results in terms of environmental and economic benefits. The environmental benefits come from the increase in “recycling” and the gradual application of innovative technologies in construction activities, resulting in a significant decrease in CO2 emissions. The increase in economic benefits is twofold. It derives from the market benefits created by recycled materials and the charged by legal landfills and the fines from illegal landfills. As shown in Fig. 5, the increment of recycling is much smaller than that of landfilling, so the main reflection of economic benefits is the increased landfilling flow. However, since CO2 emissions from the system are also affected by the landfilling of CDW, the negative environmental impact it contributes will inevitably rise as the landfilled CDW increases.

When the results in Figs.5–6 are combined, it becomes clear that there is an actual dilemma here. With huge quantities of CDW being transported to landfills, it leads to increased emissions of CO2. As the main environmental protection stakeholder, the government will formulate stricter policies to control the capacity of landfills. However, it is difficult for the current technology to provide high profits on a large scale because technological advances cannot match the massive generation of construction waste. Therefore, once the cost of landfills increases and more CDW is forced to be recycled, putting more pressure on the existing CDW disposal industry, the effectiveness of the entire system will be greatly dropped.

3.1.3 Sensitivity analysis

Economic benefits, environmental impact, and waste increase are the most significant factors influencing concrete debris recycling behavior. We performed Monte Carlo simulations to determine the sensitivity of these three indicators to innovative technologies. To maintain consistency with the following scenario simulations, innovative technologies were set as a control variable with ± 30% of the maximum and minimum values. The results are shown in the box plot in Fig. 7. Economic, environmental, and waste generation indicators are all most sensitive to prefabrication technology, which produces hundreds of times higher impacts than other technologies, but only ± 3%. The carbonation technology, on the other hand, has the weakest impact, almost close to zero. Overall, the impact of innovative technology changing on all three indicators is small compared to the current situation, which means that the uncertainty of the results is not high and is reliable in this system.

3.2 Scenario simulation results

To assess the impact of innovative technologies on the recycling process of concrete debris, we conducted a scenario analysis based on the built SD model. Six innovative technologies for construction activities that have been hotly discussed in recent years are selected as the analysis objects. Based on reports from Chinese consultants analyzing the market for these technology applications, they all estimate that these technologies have an annual growth potential of 27–35% (except for carbonation and self-healing, which are still in the laboratory stage in China). Thus, the six variables were set to have fluctuations of 30% of their existing values to evaluate the degree of their impact on the recycling industry. As shown in Fig. 8, the impact of innovative technologies on RC production can be divided into two categories. One type is the increase in market share that favors RC production (prefabrication, 3D printing, RFID, self-healing) and the other type is the decrease in market share that promotes RC production (BIM and carbonation). Interestingly, we can find that (1) only the decrease in “self-healing technology” does not affect RC production compared to the “current” scenario; (2) a 30% increase in market share for carbonation and BIM will instead reduce RC production, and (3) the RFID usage will have a positive impact on RC production no matter how it fluctuates. Suppose the goal is to increase RC production. In that case, the results show that adopting prefabrication and 3D printing are the technologies with the most significant positive impact on RC production. At the same time, BIM and carbonation fail to contribute to the growth of RC.

Figure 9 shows the effect of the innovative technology on the CDW recycling rate. Compared to the “current” scenario, the scenarios that have a negative impact on the recycling rate are BIM − 30%, 3D printing − 30% and prefabrication − 30%. The reduced market shares of self-healing and carbonation technologies have no effect on the recycling rate. The remaining scenarios all can improve the recycling rate. Similar to the results in Fig. 8, both scenarios with + 30% and − 30% fluctuations in RFID provide positive effects, and the settings that cause the most significant impact are also reflected in the + 30% for prefabrication and + 30% for 3D printing scenarios.

Overall, prefabrication and 3D printing have the greatest impact on the RC production and CDW recycling rate compared to the other technologies. But absolutely, changes in the usage of innovative technologies have little effect on RC production and recycling rate. This is mainly because the current adoption rate of these innovative technologies in China is so low that even a 30% change in them would not significantly affect the results. If there is a visible share of the market for these technologies in the future, then we believe the innovative technologies are worthy of being applied on a large scale, especially prefabrication and 3D printing.

The results in Figs. 8–9 both show that the increased market share of prefabrication and 3D printing has the greatest positive impact on concrete recycling. 3D printing can assist in the production of some simple prefabricated structures, indicating that they can be used simultaneously in some scenarios (Volpe et al., 2021). So we set up their mixed-use as a scenario to evaluate the effect of the overlapping use of the technologies. When we try to run the model to get the effect of the hybrid scenario, we instead get similar results to the effects caused by prefabrication in Figs. 8–9. Although compared to other technologies, 3D printing shows a clear effect on RC production and recycling rates, it is still a hundred times worse than prefabrication in the current market situation in China. Their combined use has an impact on this system almost equal to the consequences of using prefabrication individually.

4 Discussions

4.1 Implication and suggestions

The research analyzed the impact of innovative technology in the concrete debris recycling process by using the SD method. The findings provided us with some implications for the management of CDW in China. It can be seen from Fig. 6 that economic and environmental benefits can be achieved simultaneously in the recycling system of concrete by adopting innovative technologies and increasing the recycling rate of CDW. There are many stakeholders involved in CDW management, typical of which are clients, government and policymakers, recyclers (manufacturers and suppliers), architects (designers), structural and civil engineers, and builders (Shooshtarian et al., 2020). But evaluating the concrete recycling chain from the perspective of one of the stakeholders results in a dilemma. The most critical of all actions is the government and recyclers, whose behaviors directly affect the adoption of CDW recycling. The conflict between the government’s concern for environmental benefits and the recycler’s focus on economic benefits is present throughout the CDW recycling process. In the SD model, the economic benefits are mainly derived from landfill charges and fines for illegal landfills. From the government’s perspective, once the construction waste recycling rate is increased to a larger percentage in the future, it will be a sacrifice to the economy to reduce the environmental burden. From a recycler’s perspective, they typically have two paths to recycling concrete debris. When recycling is designed as downcycling and upcycling, it brings different economic and environmental benefits. Downcycling produces low-quality products for narrow applications, while upcycling produces products that can be used in multiple types of constructions. Di Maria et al. (2018) use practical examples to show that upcycling is more sustainable but that the most sustainable solution may be the one with the highest economic cost. Theoretically, priority should be given to upcycling in search of better environmental benefits; most recyclers consider downcycling to make a profit. We, therefore, believe that the development of a CDW recycling industry is predicated on the need to make a trade-off between economics and the environment. To enable recyclers to make financial revenues and governments to obtain low-carbon and sustainable results, we recommend that governors use economic instruments (e.g., subsidy for recycling and purchase of recycled products) to stimulate upcycling activities in plants.

The results of the scenario analysis provide a more comprehensive perspective. Innovative technologies can help improve the production of recycled materials and the recycling rate of CDW, especially prefabrication and 3D printing, which have the greatest impact on RC production and the recycling rate in Figs.9–10. These technologies with clear effects should be included in the priorities to be promoted in construction activities. However, the results also show that the improvement in the recycling system is inefficient. Innovative technologies need to be adopted with well-established recycling facilities to be considered a significant contribution. The Chinese government has been heavily promoting technologies such as prefabrication and BIM in recent years but has neglected the management of landfills and recycling of CDW. Mitigating China’s sand and gravel shortage and increasing the productivity of RA should start with encouraging the recycling rate and reducing the availability of landfills around the city. The effect of the innovative technology will only be magnified if the basic recycling rate of CDW rises. But we cannot exclude that there may be other technologies that can strongly influence this recycling system. Innovative technologies considered in this study only include easily quantified and applied parameters, there is still a potential to expand the boundary in further research, such as adding some technologies that are cutting-edge and difficult to quantify (e.g., construction robotics, AR, VR, and the metaverse).

Overall, the results of this paper show the contribution of innovative technologies to the concrete recycling industry, including increased recycling rates of CDW, increased production of recycled products, reduced environmental impact and increased economic efficiency. These results can encourage the activities of stakeholders in the CDW recycling industry.

4.2 Limitations and next step

The limitations of this paper are reflected in the data acquisition and model building. The SD model contains a great deal of data, and a large part of them is derived from the literature and statistics. The literature can provide data that are actually limited. We do not deny that local data from the literature were used in the model to represent the national average. China has a vast territory and a very diverse spatial character. The economic development and urbanization levels in western and eastern China are uneven, resulting in spatial differences in CDW generation, recycling rates, and waste management. Local data are hardly representative of the general situation. However, due to the unavailability of national CDW management data, we can only use data directly from publications. These errors cause some uncertainty in the model, and we believe that future studies that analyze quantitative CDW management strategies for multiple spatial regions would reduce the uncertainty in this study.

In the model building, we ignore some not very important details to streamline the system. In the calculation of landfilling, the study used generation minus backfilling and recycling. The actual case of landfilling will be less than the value in this system due to the fact that there are some reuse flows in the circular system in addition to backfilling and recycling. Nevertheless, we believe that reuse is more applicable to the wooden components of buildings and components such as windows and doors and that concrete structures are mostly not left intact during demolition, so the reuse flow of concrete materials is ignored. The reuse of concrete structures is becoming possible with the increased use of prefabrication and modular construction techniques. Future studies are recommended to include reuse considerations to approximate the actual situation in construction and recycling activities.

Besides the incomplete consideration of the circular flow, the deficiency of the system is also manifested in the inadequate consideration of the environmental impact. Environmental impacts are recognized as inclusive indicators in many life cycle assessment studies of the built environment, covering GWP, acidification potential (AP), ozone depletion potential (ODP), etc.(Abd Rashid & Yusoff, 2015). Only CO2 emission is used in this paper to represent the environmental impact. We think that although the environmental impact is multifaceted, controlling greenhouse gas emissions is currently one of the most important environmental tasks for the Chinese government. Carbon peaking and carbon neutrality are among the most pressing goals to achieve in managing the built environment. The Chinese government’s commitment to reach carbon peaking and carbon neutrality by 2030 and 2060, respectively (Zhang & Chen, 2022), requires a joint effort by the construction industry, so CO2 emissions are used here to represent the environmental impact of the construction industry. The inclusion of other significant environmental impacts caused by the construction industry, such as PM2.5, could be taken into account in the following study.

5 Conclusion

In this paper, we model the SD to simulate the effects of recently and frequently discussed construction technological innovations on the recycling system of concrete debris. With the urbanization growth and urban renewal in China, frequent construction activities have made this country the largest generator of CDW in the world. Therefore, the data from China are input into the system to visualize the results. The results include the stock and flow of the concrete materials in the recycling chain at the EoL stage, the economic and environmental benefits resulting from recycling activities, and the analysis of scenarios under set technological fluctuations. The market share of innovative technologies is slowly growing over time, but not keeping pace with the generation growth of CDW in China. Accordingly, from 2010–2030, the stock and flow of recycled concrete materials continues to grow but is still less than the volume of CDW generated and landfilled. The innovative technology has contributed to an increase in the recycling rate of CDW and a consequent reduction in the environmental impact of the system, but the increase in economic benefits is more attributable to charges and fines for (legal and illegal) landfilling that cannot be avoided based on current CDW management policies. The results of this study concluded that while innovative technologies positively impact the recyclability of construction materials, particularly prefabrication and 3D printing, these impacts are not evident due to the very small market share of innovative technologies in China today. In order to enhance the role of technological innovation, we suggest that regulators should primarily use financial instruments to encourage different forms of recycling activities to make the most efficient use of technology in construction and reduce the extraction of virgin resources, thus creating economic and environmental benefits. The results of this paper could be further refined by providing local data and building a more detailed SD system. The analysis of innovative technologies can also be transferred to regions with similar characteristics, such as rapid urbanization and large quantities of generated CDW, but with low recycling rates.

Data availability

Data will be made available on request.

References

Abd Rashid, A. F., & Yusoff, S. (2015). A review of life cycle assessment method for building industry. Renewable and Sustainable Energy Reviews, 45, 244–248. https://doi.org/10.1016/j.rser.2015.01.043

Aghasizadeh, S., Tabadkani, A., Hajirasouli, A., & Banihashemi, S. (2022). Environmental and economic performance of prefabricated construction: A review. Environmental Impact Assessment Review, 97, 106897. https://doi.org/10.1016/j.eiar.2022.106897

Akhtar, A., & Sarmah, A. K. (2018). Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. Journal of Cleaner Production, 186, 262–281. https://doi.org/10.1016/j.jclepro.2018.03.085

Au, L., Ahn, S., & Kim, T. (2018). System dynamic analysis of impacts of government charges on disposal of construction and demolition waste: A Hong Kong case study. Sustainability, 10(4), 1077. https://doi.org/10.3390/su10041077

Bai, J., Kang, P., Zhang, W., Chen, K., Zhang, Y., Zhou, D., & Duan, H. (2022). Feasibility study on using excavated soil and rock to sintering utilization. Circular Economy, 1(1), 100007. https://doi.org/10.1016/j.cec.2022.100007

Bortolini, R., Formoso, C. T., & Viana, D. D. (2019). Site logistics planning and control for engineer-to-order prefabricated building systems using BIM 4D modeling. Automation in Construction, 98, 248–264. https://doi.org/10.1016/j.autcon.2018.11.031

Cabral, A. E. B., Schalch, V., Molin, D. C. C. D., & Ribeiro, J. L. D. (2010). Mechanical properties modeling of recycled aggregate concrete. Construction and Building Materials, 24(4), 421–430. https://doi.org/10.1016/j.conbuildmat.2009.10.011

Cao, Z., Liu, G., Duan, H., Xi, F., Liu, G., & Yang, W. (2019). Unravelling the mystery of Chinese building lifetime: A calibration and verification based on dynamic material flow analysis. Applied Energy, 238, 442–452. https://doi.org/10.1016/j.apenergy.2019.01.106

China Concrete Net (CCN). (2020). 2006–2019 National production of commercial concrete. Shanghai, China. https://www.sohu.com/a/399695541_658567. Accessed 18 January 2022

China Aggregates Net (CAN). (2021b). 2009–2020 China sand and gravel price trends. Hangzhou, China. https://www.chyxx.com/news/2021/0928/976619.html. Accessed 18 January 2022

China Aggregates Net (CAN). (2021a). 2010–2020 China sand and gravel aggregate industry market supply and demand. Hangzhou, China. https://www.chyxx.com/industry/202110/978992.html. Accessed 18 January 2022

China RFID Industry Alliance (CFIA). (2021). China RFID industry market status and development trend analysis in 2022. https://www.163.com/dy/article/GS07JF6K051480KF.html. Accessed 18 January 2022

Concrete Association of China (CAC). (2021). 2015–2020 China Ready Mixed Concrete Capacity and Production. Beijing, China. https://www.chyxx.com/industry/202109/974779.html. Accessed 18 January 2022

CSO. (2019). China C&D waste treatment industry 2018 annual development report. China Solid Waste Observation (CSO). https://huanbao.bjx.com.cn/news/20190209/961476.shtml. Accessed 3 June 2021

Deetman, S., Marinova, S., van der Voet, E., van Vuuren, D. P., Edelenbosch, O., & Heijungs, R. (2020). Modelling global material stocks and flows for residential and service sector buildings towards 2050. Journal of Cleaner Production, 245, 118658. https://doi.org/10.1016/j.jclepro.2019.118658

Di Filippo, J., Karpman, J., & DeShazo, J. R. (2019). The impacts of policies to reduce CO2 emissions within the concrete supply chain. Cement and Concrete Composites, 101, 67–82. https://doi.org/10.1016/j.cemconcomp.2018.08.003

Di Maria, A., Eyckmans, J., & Van Acker, K. (2018). Downcycling versus recycling of construction and demolition waste: Combining LCA and LCC to support sustainable policy making. Waste Management, 75, 3–21. https://doi.org/10.1016/j.wasman.2018.01.028

Ding, Z., Yi, G., Tam, V. W. Y., & Huang, T. (2016). A system dynamics-based environmental performance simulation of construction waste reduction management in China. Waste Management, 51, 130–141. https://doi.org/10.1016/j.wasman.2016.03.001

Ding, Z., Zhu, M., Tam, V. W. Y., Yi, G., & Tran, C. N. N. (2018). A system dynamics-based environmental benefit assessment model of construction waste reduction management at the design and construction stages. Journal of Cleaner Production, 176, 676–692. https://doi.org/10.1016/j.jclepro.2017.12.101

Dongtan Consultant. (2020). Development trend and layout characteristics of the assembled building industry. Shanghai, China. https://www.jiemian.com/article/5283607.html. Accessed 18 January 2022

Dosho, Y. (2007). Development of a sustainable concrete waste recycling system: Application of recycled aggregate concrete produced by aggregate replacing method. Journal of Advanced Concrete Technology, 5(1), 27–42. https://doi.org/10.3151/jact.5.27

Du, J., Sugumaran, V., & Gao, B. (2017). RFID and multi-agent based architecture for information sharing in prefabricated component supply chain. IEEE Access, 5, 4132–4139. https://doi.org/10.1109/ACCESS.2017.2665778

Du, Q., Bao, T., Li, Y., Huang, Y., & Shao, L. (2019). Impact of prefabrication technology on the cradle-to-site CO2 emissions of residential buildings. Clean Technologies and Environmental Policy, 21(7), 1499–1514. https://doi.org/10.1007/s10098-019-01723-y

Duan, H., Miller, T. R., Liu, G., & Tam, V. W. Y. (2019). Construction debris becomes growing concern of growing cities. Waste Management, 83, 1–5. https://doi.org/10.1016/j.wasman.2018.10.044

El-Sayegh, S., Romdhane, L., & Manjikian, S. (2020). A critical review of 3D printing in construction: Benefits, challenges, and risks. Archives of Civil and Mechanical Engineering, 20(2), 34. https://doi.org/10.1007/s43452-020-00038-w

Fan, C.-C., Huang, R., Hwang, H., & Chao, S.-J. (2016). Properties of concrete incorporating fine recycled aggregates from crushed concrete wastes. Construction and Building Materials, 112, 708–715. https://doi.org/10.1016/j.conbuildmat.2016.02.154

Forrester, J. W. (1971). Counterintuitive behavior of social systems. Theory and Decision, 2(2), 109–140. https://doi.org/10.1007/BF00148991

Forrester, J. W. (1993). System dynamics and the lessons of 35 years. In K. B. De Greene (Ed.), A Systems-Based Approach to Policymaking (pp. 199–240). Boston: Springer.

Gallego-Schmid, A., Chen, H.-M., Sharmina, M., & Mendoza, J. M. F. (2020). Links between circular economy and climate change mitigation in the built environment. Journal of Cleaner Production, 260, 121115. https://doi.org/10.1016/j.jclepro.2020.121115

Gardner, D., Lark, R., Jefferson, T., & Davies, R. (2018). A survey on problems encountered in current concrete construction and the potential benefits of self-healing cementitious materials. Case Studies in Construction Materials, 8, 238–247. https://doi.org/10.1016/j.cscm.2018.02.002

Giannis, A., Chen, M., Yin, K., Tong, H., & Veksha, A. (2017). Application of system dynamics modeling for evaluation of different recycling scenarios in Singapore. Journal of Material Cycles and Waste Management, 19(3), 1177–1185. https://doi.org/10.1007/s10163-016-0503-2

Golroudbary, S. R., & Zahraee, S. M. (2015). System dynamics model for optimizing the recycling and collection of waste material in a closed-loop supply chain. Simulation Modelling Practice and Theory, 53, 88–102. https://doi.org/10.1016/j.simpat.2015.02.001

Goodman, M. R. (1997). Study notes in system dynamics. Journal of the Operational Research Society, 48(11), 1147–1147. https://doi.org/10.1057/palgrave.jors.2600963

Grigoriadis, K., Whittaker, M., Soutsos, M., Sha, W., Napolano, L., Klinge, A., et al. (2019). Improving the recycling rate of the construction industry. Presented at the Fifth International Conference on Sustainable Construction Materials and Technologies. pp. 400–412. https://doi.org/10.18552/2019/IDSCMT5044

Guangzhou Urban Management and Comprehensive Law Enforcement Bureau (UMLEB). Trial Measures for the Management of Financial Subsidy Funds for the Comprehensive Utilization of C&D Waste in Guangzhou (2015). http://cg.gz.gov.cn/ztzl/srhw/content/post_2801238.html. Accessed 3 June 2021

Guo, H., Shi, C., Guan, X., Zhu, J., Ding, Y., Ling, T.-C., et al. (2018). Durability of recycled aggregate concrete – A review. Cement and Concrete Composites, 89, 251–259. https://doi.org/10.1016/j.cemconcomp.2018.03.008

Han, Y., Yang, Z., Ding, T., & Xiao, J. (2021). Environmental and economic assessment on 3D printed buildings with recycled concrete. Journal of Cleaner Production, 278, 123884. https://doi.org/10.1016/j.jclepro.2020.123884

Hossain, Md. A., Zhumabekova, A., Paul, S. C., & Kim, J. R. (2020). A review of 3D printing in construction and its impact on the labor market. Sustainability, 12(20), 8492. https://doi.org/10.3390/su12208492

Hu, R., Chen, K., Fang, W., Zheng, L., & Xu, J. (2022). The technology-environment relationship revisited: Evidence from the impact of prefabrication on reducing construction waste. Journal of Cleaner Production, 341, 130883. https://doi.org/10.1016/j.jclepro.2022.130883

Huajing Intelligence. (2021). The current state of the market for the architectural 3D printing industry in 2020. Beijing, China. https://caifuhao.eastmoney.com/news/20210409152300980016070. Accessed 18 January 2022

Intelligence Research Group (IRG). (2020a). RFID market size and growth trend in China from 2010–2019. Beijing, China. https://www.chyxx.com/industry/2020a09/894097. Accessed 18 January 2022

Intelligence Research Group (IRG). (2020b). Analysis of China’s assembled building market structure, new area forecast, development advantages and bottlenecks in 2019. https://www.chyxx.com/industry/2020b05/866738.html. Accessed 18 January 2022

Jalaei, F., Zoghi, M., & Khoshand, A. (2021). Life cycle environmental impact assessment to manage and optimize construction waste using building information modeling (BIM). International Journal of Construction Management, 21(8), 784–801. https://doi.org/10.1080/15623599.2019.1583850

Kazmi, S. M. S., Munir, M. J., Wu, Y.-F., Patnaikuni, I., Zhou, Y., & Xing, F. (2019). Influence of different treatment methods on the mechanical behavior of recycled aggregate concrete: A comparative study. Cement and Concrete Composites, 104, 103398. https://doi.org/10.1016/j.cemconcomp.2019.103398

Landaluce, H., Arjona, L., Perallos, A., Falcone, F., Angulo, I., & Muralter, F. (2020). A review of IoT sensing applications and challenges using RFID and wireless sensor networks. Sensors, 20(9), 2495. https://doi.org/10.3390/s20092495

Liu, Y., Qi, L., & Ji, Y. (2019). Initial Logistics Management System of Prefabricated Component Based on BIM and RFID Technology. In ICCREM 2019 (pp. 135–143). Presented at the International Conference on Construction and Real Estate Management 2019, Banff, Alberta, Canada: American Society of Civil Engineers. https://doi.org/10.1061/9780784482308.015

Liu, J., Liu, Y., & Wang, X. (2020). An environmental assessment model of construction and demolition waste based on system dynamics: A case study in Guangzhou. Environmental Science and Pollution Research, 27(30), 37237–37259. https://doi.org/10.1007/s11356-019-07107-5

Lu, G. (2021). 2021 China BIM Industry Research Report. LeadLeo. https://pdf.dfcfw.com/pdf/H3_AP202111041526978655_1.pdf?1636022757000.pdf. Accessed 18 January 2022

Lu, W., & Yuan, H. (2013). Investigating waste reduction potential in the upstream processes of offshore prefabrication construction. Renewable and Sustainable Energy Reviews, 28, 804–811. https://doi.org/10.1016/j.rser.2013.08.048

Mak, T. M. W., Chen, P.-C., Wang, L., Tsang, D. C. W., Hsu, S. C., & Poon, C. S. (2019). A system dynamics approach to determine construction waste disposal charge in Hong Kong. Journal of Cleaner Production, 241, 118309. https://doi.org/10.1016/j.jclepro.2019.118309

Manowong, E., & Brockmann, C. (2015). Construction waste management in newly industrialized countries (pp. 12–24). Presented at the W107-Special Track 18th CIB World Building Congress, Salford, United Kingdom. https://www.irbnet.de/daten/iconda/CIB_DC24555.pdf. Accessed 17 February 2022

Martínez-Lage, I., Vázquez-Burgo, P., & Velay-Lizancos, M. (2020). Sustainability evaluation of concretes with mixed recycled aggregate based on holistic approach: Technical, economic and environmental analysis. Waste Management, 104, 9–19. https://doi.org/10.1016/j.wasman.2019.12.044

Marzouk, M., & Azab, S. (2014). Environmental and economic impact assessment of construction and demolition waste disposal using system dynamics. Resources, Conservation and Recycling, 82, 41–49. https://doi.org/10.1016/j.resconrec.2013.10.015

Meng, Q., Zhang, Y., Li, Z., Shi, W., Wang, J., Sun, Y., et al. (2020). A review of integrated applications of BIM and related technologies in whole building life cycle. Engineering, Construction and Architectural Management, 27(8), 1647–1677. https://doi.org/10.1108/ECAM-09-2019-0511

Mingers, J., & White, L. (2010). A review of the recent contribution of systems thinking to operational research and management science. European Journal of Operational Research, 207(3), 1147–1161. https://doi.org/10.1016/j.ejor.2009.12.019

National Bureau of Statistics of China (NBSC). (2021). China Statistical Yearbook 2021. China Statistics Press.

Park, J., Yoon, J., & Kim, K.-H. (2017). Critical review of the material criteria of building sustainability assessment tools. Sustainability, 9(2), 186. https://doi.org/10.3390/su9020186

Ping An Insurance Company (Pingan). (2019). 3D printing industry chain panorama. Shenzhen, China. http://pdf.dfcfw.com/pdf/H3_AP201908061342397689_1.pdf. Accessed 18 January 2022

Richardson, G. P. (2020). Core of System Dynamics. In B. Dangerfield (Ed.), System Dynamics (pp. 11–20). New York: Springer.

Sahlol, D. G., Elbeltagi, E., Elzoughiby, M., & Abd Elrahman, M. (2021). Sustainable building materials assessment and selection using system dynamics. Journal of Building Engineering, 35, 101978. https://doi.org/10.1016/j.jobe.2020.101978

Schiller, G., Gruhler, K., & Ortlepp, R. (2017). Continuous material flow analysis approach for bulk nonmetallic mineral building materials applied to the German building sector: Continuous MFA for nonmetallic mineral materials. Journal of Industrial Ecology, 21(3), 673–688. https://doi.org/10.1111/jiec.12595

Schwaninger, M., & Groesser, S. (2009). System Dynamics Modeling: Validation for Quality Assurance. In R. A. Meyers (Ed.), Complex Systems in Finance and Econometrics (pp. 767–781). New York, NY: Springer New York. https://doi.org/10.1007/978-1-4419-7701-4_42

Seifan, M., Samani, A. K., & Berenjian, A. (2016). Bioconcrete: Next generation of self-healing concrete. Applied Microbiology and Biotechnology, 100(6), 2591–2602. https://doi.org/10.1007/s00253-016-7316-z

Shooshtarian, S., Caldera, S., Maqsood, T., & Ryley, T. (2020). Using recycled construction and demolition waste products: A review of stakeholders’ perceptions, decisions, and motivations. Recycling, 5(4), 31. https://doi.org/10.3390/recycling5040031

Soliman, A., Hafeez, G., Erkmen, E., Ganesan, R., Ouf, M., Hammad, A., et al. (2022). Innovative construction material technologies for sustainable and resilient civil infrastructure. Materials Today Proceedings. https://doi.org/10.1016/j.matpr.2022.01.248

Song, Z. (2015). Research on guarantee mechanism of waste concrete recycling logistics mode in Beijing city. In 2015 International Conference on Logistics, Informatics and Service Sciences (LISS) (pp. 1–4). Presented at the 2015 International Conference on Logistics, Informatics and Service Sciences (LISS), Barcelona, Spain: IEEE. https://doi.org/10.1109/LISS.2015.7369781

Stanaszek-Tomal, E. (2020). Bacterial concrete as a sustainable building material? Sustainability, 12(2), 696. https://doi.org/10.3390/su12020696

Sterman, J. (2000). Business Dynamics: Systems Thinking and Modeling for a Complex World. McGraw -Hill Education Ltd.

Tam, V. W. Y., & Hao, J. J. L. (2014). Prefabrication as a mean of minimizing construction waste on site. International Journal of Construction Management, 14(2), 113–121. https://doi.org/10.1080/15623599.2014.899129

United Nations (UN). (2019). 2018 Revision of World Urbanization Prospects (p. 126). New York, the US: The Population Division of the Department of Economic and Social Affairs of the United Nations. https://population.un.org/wup/Publications/Files/WUP2018-Report.pdf. Accessed 26 May 2021

USCB. (2020). American Community Survey 5-Year Data (2009-2019). Washington, DC, the US: United States Census Bureau (USCB). https://www.census.gov/data/developers/data-sets/acs-5year.html. Accessed 26 May 2021

Valero, E., & Adán, A. (2016). Integration of RFID with other technologies in construction. Measurement, 94, 614–620. https://doi.org/10.1016/j.measurement.2016.08.037

Verian, K. P., Ashraf, W., & Cao, Y. (2018). Properties of recycled concrete aggregate and their influence in new concrete production. Resources, Conservation and Recycling, 133, 30–49. https://doi.org/10.1016/j.resconrec.2018.02.005

Volpe, S., Sangiorgio, V., Petrella, A., Coppola, A., Notarnicola, M., & Fiorito, F. (2021). Building envelope prefabricated with 3D printing technology. Sustainability, 13(16), 8923. https://doi.org/10.3390/su13168923

Wang, H., Abbas, K. M., Abbasifard, M., Abbasi-Kangevari, M., Abbastabar, H., Abd-Allah, F., et al. (2020). Global age-sex-specific fertility, mortality, healthy life expectancy (HALE), and population estimates in 204 countries and territories, 1950–2019: A comprehensive demographic analysis for the Global Burden of Disease Study 2019. The Lancet, 396(10258), 1160–1203. https://doi.org/10.1016/S0140-6736(20)30977-6

Wang, J., Zhang, Y., & Wang, Y. (2018). Environmental impacts of short building lifespans in China considering time value. Journal of Cleaner Production, 203, 696–707. https://doi.org/10.1016/j.jclepro.2018.08.314

Wang, Y., Chang, X., Chen, Z., Zhong, Y., & Fan, T. (2014). Impact of subsidy policies on recycling and remanufacturing using system dynamics methodology: A case of auto parts in China. Journal of Cleaner Production, 74, 161–171. https://doi.org/10.1016/j.jclepro.2014.03.023

Won, J., Cheng, J. C. P., & Lee, G. (2016). Quantification of construction waste prevented by BIM-based design validation: Case studies in South Korea. Waste Management, 49, 170–180. https://doi.org/10.1016/j.wasman.2015.12.026

Xu, G., Zhou, Z., Jiao, L., & Zhao, R. (2020). Compact Urban Form and Expansion Pattern Slow Down the Decline in Urban Densities: A Global Perspective. Land Use Policy, 94, 104563. https://doi.org/10.1016/j.landusepol.2020.104563

Xuan, D., Zhan, B., & Poon, C. S. (2016). Development of a new generation of eco-friendly concrete blocks by accelerated mineral carbonation. Journal of Cleaner Production, 133, 1235–1241. https://doi.org/10.1016/j.jclepro.2016.06.062

Yuan, H., Chini, A. R., Lu, Y., & Shen, L. (2012). A dynamic model for assessing the effects of management strategies on the reduction of construction and demolition waste. Waste Management, 32(3), 521–531. https://doi.org/10.1016/j.wasman.2011.11.006

Yuan, H., & Wang, J. (2014). A system dynamics model for determining the waste disposal charging fee in construction. European Journal of Operational Research, 237(3), 988–996. https://doi.org/10.1016/j.ejor.2014.02.034

Zaetang, Y., Sata, V., Wongsa, A., & Chindaprasirt, P. (2016). Properties of pervious concrete containing recycled concrete block aggregate and recycled concrete aggregate. Construction and Building Materials, 111, 15–21. https://doi.org/10.1016/j.conbuildmat.2016.02.060

Zhang, C., Hu, M., Dong, L., Xiang, P., Zhang, Q., Wu, J., et al. (2018). Co-benefits of urban concrete recycling on the mitigation of greenhouse gas emissions and land use change: A case in Chongqing metropolis, China. Journal of Cleaner Production, 201, 481–498. https://doi.org/10.1016/j.jclepro.2018.07.238

Zhang, N., Duan, H., Miller, T. R., Tam, V. W. Y., Liu, G., & Zuo, J. (2020). Mitigation of carbon dioxide by accelerated sequestration in concrete debris. Renewable and Sustainable Energy Reviews, 117, 109495. https://doi.org/10.1016/j.rser.2019.109495

Zhang, N., Xi, B., Li, J., Liu, L., & Song, G. (2022a). Utilization of CO2 into recycled construction materials: A systematic literature review. Journal of Material Cycles and Waste Management. https://doi.org/10.1007/s10163-022-01489-4

Zhang, N., Zhang, D., Zuo, J., Miller, T. R., Duan, H., & Schiller, G. (2022). Potential for CO2 mitigation and economic benefits from accelerated carbonation of construction and demolition waste. Renewable and Sustainable Energy Reviews, 169, 112920. https://doi.org/10.1016/j.rser.2022.112920

Zhang, N., Zhang, H., Schiller, G., Feng, H., Gao, X., Li, E., & Li, X. (2021). Unraveling the global warming mitigation potential from recycling subway-related excavated soil and rock in china via life cycle assessment. Integrated Environmental Assessment and Management, 17(3), 639–650. https://doi.org/10.1002/ieam.4376

Zhang, N., Zheng, L., Duan, H., Yin, F., Li, J., & Niu, Y. (2019). Differences of methods to quantify construction and demolition waste for less-developed but fast-growing countries: China as a case study. Environmental Science and Pollution Research, 26(25), 25513–25525. https://doi.org/10.1007/s11356-019-05841-4

Zhang, S., & Chen, W. (2022). Assessing the energy transition in China towards carbon neutrality with a probabilistic framework. Nature Communications, 13(1), 87. https://doi.org/10.1038/s41467-021-27671-0

Zhang, Z., & Wang, B. (2016). Research on the life-cycle CO2 emission of China’s construction sector. Energy and Buildings, 112, 244–255. https://doi.org/10.1016/j.enbuild.2015.12.026

Zhao, W., Ren, H., & Rotter, V. S. (2011). A system dynamics model for evaluating the alternative of type in construction and demolition waste recycling center––The case of Chongqing, China. Resources, Conservation and Recycling, 55(11), 933–944. https://doi.org/10.1016/j.resconrec.2011.04.011

Zhu, L., Dai, J., Bai, G., & Zhang, F. (2015). Study on thermal properties of recycled aggregate concrete and recycled concrete blocks. Construction and Building Materials, 94, 620–628. https://doi.org/10.1016/j.conbuildmat.2015.07.058

Zhu, W., Feng, W., Li, X., & Zhang, Z. (2020). Analysis of the embodied carbon dioxide in the building sector: A case of China. Journal of Cleaner Production., 269, 122438. https://doi.org/10.1016/j.jclepro.2020.122438

Acknowledgements

This research was supported by the PhD program of the Leibniz Institute of Ecological Urban and Regional Development (IOER).

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

NZ: conceptualization, writing–original draft, visualization; AKK: validation, methodology; HD: writing–review & editing, resources; HF: writing–review & editing; HL: resources.

Corresponding author

Ethics declarations

Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, N., Konyalıoğlu, A.K., Duan, H. et al. The impact of innovative technologies in construction activities on concrete debris recycling in China: a system dynamics-based analysis. Environ Dev Sustain 26, 14039–14064 (2024). https://doi.org/10.1007/s10668-023-03178-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-023-03178-0