Abstract

This article deals with the application of social life cycle assessment (S-LCA) in the construction sector and explicitly focuses on carbon reinforced concrete (CRC). The publication consists of two parts: (1) a scientific literature review on the current implementation of S-LCA in the construction sector, and (2) the definition of the relevant social hotspots for the cradle-to-gate production of CRC. The literature review was conducted to provide a general overview and compare S-LCA studies in the construction sector; second, countries that provide the relevant input materials needed for CRC were identified. Analysis within the Social Hotspot Database (SHDB) helped determine the relative importance of the CRC supply country for each social category and subcategory. By developing a metric in the form of scores for each risk information, the potential risks indicated by the SHDB were measured. The results show that the focus of the indicators to be highlighted and further used in the indicator catalog is particularly in the area of labor rights and decent work in the health and safety subcategory. Missing data within the SHDB may result in a defined high average score and lead to a lower level of information. In the future, the identified 36 social indicators for CRC should be revised again in cooperation with the manufacturing industry. This study aims to further raise awareness in the construction sector of life-cycle-based sustainability that goes beyond the environmental aspects, and it is the first social hotspot screening using the SHDB for CRC.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Social sustainability is becoming increasingly important. Thus, there is also a growing need in the construction industry and for new trends in sustainable building to assess social impacts and integrate them into decision-making (Abowitz & Toole, 2010). From the perspective of the construction sector, social sustainability means providing a healthy and safe environment for all stakeholders (Wong & Fan, 2013; Zuo & Zhao, 2014), with the focus on globally known certification systems such as DGNB, LEED, or BREEAM mainly only on the use phase and on the single stakeholder building users (Backes & Traverso, 2021a). Especially when developing new building materials, it is important to implement social impacts into the decision-making process from the beginning, in order to create a life-cycle-based sustainable product. Given the high consumption of resources and energy, the construction industry is increasingly called upon to produce more sustainable buildings and building materials (Berardi, 2012; Bork et al., 2015), making carbon reinforced concrete (CRC) an alternative to steel reinforced concrete (SRC) and an alternative new trend in sustainable building. Until now, mainly (and only) the environmental impact of CRC has been evaluated in terms of sustainability (Backes & Traverso, 2021b; Backes et al., 2022).

Concrete is by far the most widely used building material, with a current demand of over 4 billion tons annually (Hilburg, 2019; Meyer, 2005). Demand for concrete could even increase to over 5 billion tons annually by 2050 (Lehne & Preston, 2018). Concrete itself is a mixture of cement, concrete aggregate, and water. Concrete admixtures (e.g., fly ash or granulated blast furnace slag) are often added, for example, to improve the workability of fresh concrete. Concrete aggregates are usually sand or gravel. Although concrete can withstand compressive forces, a reinforcing material must be added to withstand stronger tensile forces. (Wietek, 2019) Combining the high tensile strength of reinforcement material, such as steel or carbon fibers, and the high compressive strength of concrete creates a composite material that combines the useful properties of two materials (Stahr, 2015). Primarily, steel is used as a reinforcing material for concrete (Kortmann, 2020). Despite its affordability, availability, and applicability, steel can corrode (Kortmann, 2020). Therefore, a minimum concrete cover of 20–55 mm must be present to ensure corrosion protection (Otto & Adam, 2019; Stahr, 2015). In recent decades, research and development of alternative reinforcement materials have increased to replace steel as the primary reinforcement material (Rajak et al., 2019). One of these alternatives are carbon fibers, which are less susceptible to corrosion (Kortmann, 2020). This allows for lighter, thinner, and more resource-efficient components (Kortmann, 2020)—mainly by the reduction in concrete. However, these alternative materials are still associated with higher costs, higher energy requirements, consequently with high production emissions, and poorer accessibility (Backes et al., 2022; Otto & Adam, 2019).

As mainly the environmental aspects of CRC were focused, we now open the view and discussion on the social sustainability of CRC. The Social Life Cycle Assessment (S-LCA) is considered as the most effective assessment method for social sustainability of products and organizations (Garrido, 2017). The Social Life Cycle Assessment (S-LCA) represents a methodology to assess the social impacts of products and services along their life cycle. The S-LCA is based on the ISO 14040 and 14,044 standards and thus includes the same four phases as the Life Cycle Assessment (LCA) (ISO 14040, 2006; ISO, 14044, 2018; UNEP, 2020; UNEP Setac Life Cycle Initiative, 2009). Social impacts arise mainly from the behaviors of companies involved in the product life cycle and can affect human well-being (Sala et al., 2015). The S-LCA is considered a component of the Life Cycle Sustainability Assessment (LCSA) and can be conducted alone or in combination with a LCA and/or a Life Cycle Costing (LCC) (Finkbeiner et al., 2010; Garrido, 2017). The S-LCA covers a wide range of applications. First and foremost, it provides relevant information for policy makers and companies and clarifies social conditions in the product life cycle. Thus, the S-LCA seeks to improve the social sustainability of products or services. However, it does not assess whether a product should be produced (Benoît et al., 2010). In 2009, the United Nations Environment Programme (UNEP) and the Society of Environmental Toxicology and Chemistry (SETAC) published the first guidance document for conducting a S-LCA for products (UNEP Setac Life Cycle Initiative, 2009). Together with the methodological sheets published in 2013 (UNEP, 2013), it forms an important basis for the preparation of an S-LCA and has led to an increased application as well as an increase in publications (Ramos Huarachi et al., 2020). The practice has evolved significantly over the past decade, necessitating a revision of the guideline. As a result, a new optimized guideline was recently published by UNEP (UNEP, 2020), reviewed methodological sheets (UNEP, 2021) and the report on the pilot projects (UNEP, 2022). Although S-LCA practice has greatly evolved, to date there is still no standardized approach to S-LCA in the construction sector, and therefore social impacts are often neglected or inadequately assessed as part of a sustainability assessment (Backes & Traverso, 2021b; Berardi, 2012; Bork et al., 2015; Zuo & Zhao, 2014).

The aim of this study is to fill the identified gap and provide relevant social indicators using the Social Hotspot Database in the construction sector, taking carbon reinforced concrete as an example. The research questions of the article are: Does the S-LCA find application in the building sector and if so, what opportunities and risks can be identified with the help of a literature review? If the S-LCA is used, is it based on the UNEP/SETAC Guidelines, which were last updated in 2020? How does social sustainability explicitly apply to the innovation of carbon reinforced concrete? Consequently, our research question aims at the possible social hotspots of CRC. To explicitly name the objectives of this article: on the one hand, this is to continue to raise awareness in the construction sector of life-cycle-based and wider, than purely environmental, sustainability; on the other hand, a social hotspot screening and the SHDB are applied to a construction product and critically analyzed to set up a future survey in cooperation with the industry.

2 Literature Review

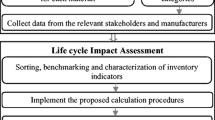

The focus of this systematic literature review is on the two basic building materials of CRC-concrete and carbon fibers. The following databases were used for the detailed search: Scopus, Web of Science, and ScienceDirect. The search was limited to the period from 2010 to June 2022 in order to cover as many studies as possible since the publication of the first guidelines in 2009. The focus was only on English language studies, as these make up the majority and are available internationally. The methodology of this literature search can be presented as follows (Fig. 1). As the search was international, English synonyms for the terms ‘social life cycle assessment,’ ‘concrete,’ and ‘carbon fiber’ were identified (Table 1). Then, in the second step, search combinations were created from these terms and applied to the three databases (Fig. 1).

Combinations were examined in the title, abstract, and keywords of the respective article (Step 3, Fig. 1). Combinations that produced a high number of results were additionally selected according to further keywords, such as ‘social aspects,’ ‘social impacts’ or ‘LCSA,’ in order to capture the most significant studies. The search results were content-checked for S-LCA in relation to concrete and carbon fibers (Step 4, Fig. 1). All studies should follow the UNEP guidelines, to guarantee further comparability.

To the best of the authors’ knowledge, substantiated by the following literature analysis, in scientific literature, the number of papers on the social life cycle concerning the construction sector is relatively low, even though there is a general increase in S-LCA publications. The low number of S-LCA studies in the construction sector is mainly due to the fact that construction materials are complex assemblies of diverse raw materials, and currently there is no consensus on indicators and reference values to compare with. Even more important: The complexity of social impact assessment lies in the collection of primary data along the product life cycle and its comparison with local conditions. Required data include, for example, information on health and safety and working conditions, which is a flashpoint in the construction sector. This makes it difficult for companies to collect and especially publish this data. (Bork et al., 2015; Hossain et al., 2018) For example, construction represents a highly intertwined input–output system, making material flows difficult to determine (Cole, 1998). Furthermore, social conditions are usually dynamic, so social data change more rapidly compared to environmental data (Wu et al., 2014). In addition, the complex stakeholder situation in construction processes complicates the assessment of social sustainability, which means that relevant stakeholders are often not adequately covered in S-LCA studies (Liu & Qian, 2019; Montalbán-Domingo et al., 2019). In this regard, the key difficulties of S-LCA are mainly (1) how to quantitatively relate the social indicators to the functional unit of the system; (2) how to obtain specific regionalized data; (3) how to decide among the large set of indicators; (4) define the benchmark at sector level as well as the reference values; and (5) how to properly evaluate the results. The biggest challenge, however, is the collection of primary data and define benchmarks and reference values at sector level—this to be able to assess negative as well as positive impacts.

For this specific review, it was important that the studies mention the S-LCA and focus on concrete and/or carbon fibers. Thus, in combination with S-LCA, 19 studies could be classified as relevant for concrete and three for carbon fibers. Of the 19 selected studies on concrete, 12 studies were identified after a further detailed analysis that fully apply the S-LCA methodology according to the UNEP guidance (Fig. 1, Table 2). Compared to the status quo of concrete and S-LCA, there is a significant lack of literature for S-LCA of carbon fibers. After a detailed analysis, none of the three studies found performed a S-LCA. The papers neither applied the methodology nor used the S-LCA UNEP guidelines (Helbig et al., 2016; Pillain et al., 2017). While in the study by Pillain et al. (2019), the social sustainability is assessed, it is not clear whether the methodology used is aligned with the UNEP guidelines. The proposed approach is based in part on Hunkeler’s study, which was published in 2006 (Hunkeler, 2006), prior to the publication of the UNEP guideline in 2009. Neither system boundaries nor a functional unit or associated subcategories were defined (Pillain et al., 2019), which is why this study is not further considered. The non-in-detail consideration of other studies (Fig. 1, Step 4) can be generally justified as follows: LCA, LCC, and S-LCA were only elaborated theoretically (e.g., Hu et al., 2013; Scope et al., 2021), categories and indicators from other guidance documents than UNEP Guidelines such as the “Sustainability Reporting Guidelines” of the “Global Reporting Initiative” (Piacenza et al., 2013) or the manual of “Pré Sustainability” (Roh et al., 2018) (UNEP, 2009, 2020) (e.g., Janjua et al., 2021; Josa et al., 2021; Piacenza et al., 2013; Roh et al., 2018), social impacts were not assessed quantitatively or qualitatively (e.g., Piacenza et al., 2013), and it is not clear whether a full S-LCA was conducted or to what extent the methodology followed the guidelines (due to future desired uniformity and for comparison reasons) (e.g., Wang et al., 2017).

The remaining 12 studies identify relevant stakeholders, subcategories as well as indicators and conduct case studies on different concrete types or construction components/projects (Table 2).

The majority of the studies have been published since 2016 (including concrete and carbon fiber), which could be due in part to the increasing importance of sustainability issues in society and the call for the construction sector to produce more sustainable building materials and buildings due to its high energy consumption and greenhouse gas emissions (Bork et al., 2015). In addition, the Sustainable Development Goals set by the United Nations Agenda 2030 in 2015 may have contributed to the increase in publications, as 14 of the 17 goals imply social aspects, and most of them are also included in the guidelines (Backes & Traverso, 2022; Nations, 2015; UNEP, 2020). In this context, the peak of publications is in 2018. Even if an increase in sustainability interest can be explained thanks to the SDGs, it is nevertheless clear in previous studies that no clear combination of LCSA—thus also not for S-LCA-and SDG can be identified for any sector (Backes & Traverso, 2022). The SDGs are better known to the public than the LCSA indicators. Although the SDGs have a 2030 target to address social disparities, still no consensus can be reached on which (S-LCA) indicators should be assigned to which SDGs. Consequently, the SDGs are highly relevant for communication and possibly “attention-grabbing” purposes, but by no means focus in detail on the S-LCA nor explicit industries such as the construction sector or the production chain and thus social hotspots in the construction industry and for carbon reinforced concrete.

In the following, the focus is on the 12 identified studies that mention UNEP’s guidance as the basis of their sustainability assessment (Table 2). From the analysis, it is clear that the products studied, and thus the functional units, vary greatly depending on the case study. In the studies, the functional units were defined either as a quantity of material (kilograms or tons), length (meters), or unit of area (m2). In contrast, there is more agreement on system boundaries and stakeholder categories. The majority used the cradle-to-grave approach as system boundaries, 48% used cradle-to-gate as system boundaries, and other possible system boundaries were not considered. In addition, all 12 studies considered the group of Workers and Local Communities.

Furthermore, Society seems to be relevant as a stakeholder category; children, on the other hand, are not included as stakeholders, which may also be due to the ‘new’ category from 2020 (Fig. 2). Furthermore, there seems to be no consensus regarding the subcategories considered and the indicators used. Thus, the number of subcategories considered in the studies varies. Nevertheless, a more detailed analysis of the subcategories reveals a clear trend. For the stakeholder group workers, ‘Health and Safety,’ ‘Fair Salary,’ and ‘Hours Worked’ represent the most commonly used subcategories. For Local Communities, ‘Safe and healthy living conditions,’ ‘Local employment,’ ‘Access to material resources,’ ‘Cultural heritage,’ and ‘Respect for the rights of indigenous peoples’ were the categories assessed. For the stakeholder group Society, the most frequently used subcategories were ‘Contribution to Economic Development’ and ‘Technical Progress.’ Interestingly, the three stakeholder groups (Society, Local Community and Worker in Fig. 2) are also found in our following case study—this is due to the categorization with the help of the SHDB, which will be further discussed in the following chapters.

Depending on the study and subcategory, the type and number of indicators differ greatly among themselves, so there is no consistency. Some studies used up to four indicators to assess a subcategory and others used only one indicator. Qualitative, quantitative as well as semi-quantitative indicators were used. However, there seems to be agreement among practitioners in isolated subcategories, such as Worker ‘health and safety.’ Often this category is considered and consequently includes ‘occupational accidents’ in its assessment. The studies also consistently used ‘gross domestic product’ for ‘measuring contribution to economic development’ (Society). For ‘Technical progress,’ ‘Technological development’ and ‘Technology transfer’ were considered, and for ‘Local employment,’ attention was paid to ‘Job creation’ as well as ‘Use of local workers’ (see also Fig. 2).

2.1 Discussion on Literature Review

A detailed review of the 12 studies that follow UNEP’s guidelines reveals disagreements as well as some trends. All 12 studies consider Workers, Local Communities, and Society as stakeholders. Consumers and Value Chain Actors are often neglected. An explanation of the exact reasons is often missing. However, the analysis of the subcategories also shows that not all studies strictly adhere to the UNEP guidelines. In some cases, some studies assign their subcategories to other stakeholder groups (Hosseinijou et al., 2014; Kono et al., 2018) or use ones that cannot be fully and unambiguously classified with those in the guidelines (Zheng et al., 2019). In particular, neglecting Consumers and Value Chain Actors could lead to an insufficient assessment of social performance and eventually to erroneous results, as the ‘big picture’ in the life cycle is not taken into account (Kühnen & Hahn, 2017). The review of the indicators confirmed that for the most part, there is still no consensus, and the number, as well as the type of indicators chosen, varies greatly across studies. However, there seems to be agreement among practitioners on indicator selection in isolated subcategories (occupational accidents, gross domestic product, etc.). However, a deeper elaboration of the rationale for including S-LCA indicators is generally lacking. Some case studies justify their selection based on existing literature by referring to approaches published by other practitioners and adopting the selection of subcategories and indicators (Balasbaneh & Marsono, 2020; Sánchez et al., 2019). While all studies mention the guidelines as an orientation, the approaches of the S-LCA are insufficiently explained and decisions made are not justified: Even though all studies define the function unit (FU) and the system boundaries (goal and scope), only four studies defined their data collection strategy (3 times questionnaire, once PSILCA) and only two of the analyzed studies defined whether they used S-LCA Type I or Type II.

Short Digression: Two types of social and socioeconomic impact categories can be distinguished: Type I and Type II of S-LCA. Type I impact categories aggregate results for subcategories within a topic of interest to a stakeholder. The so-called Type I approach to S-LCA has a close connection to social reporting—similar to the standards for corporate social responsibility (Sureau et al., 2020). Type II impact categories, on the other hand, model outcomes for subcategories that have a causal relationship to the criteria. (Russo Garrido et al., 2018; UNEP, 2009) Thus, one way to distinguish between these two types of S-LCA is to consider whether the inventory data and the characterized outcome are at the same point along an impact pathway (Type I) or whether they are at different points along the impact pathway (causal relationship) (Type II). (Russo Garrido et al., 2018) Regardless of Type I or Type II of S-LCA, in a globalized world, it is a challenge to track products and all their components and find out under what conditions they were produced. In particular, S-LCAs are relatively new, and there are fewer data sources. Both the SHDB and PSILCA represent possible solutions to the data source problem. PSILCA (Product Social Impact Life Cycle Assessment database) is a social life cycle assessment database developed by GreenDelta. This database provides transparent and up-to-date information on social aspects of products throughout their life cycle for about 15,000 industries and commodities. (GreenDelta, 2016, 2018) The Social Hotspot database (SHDB) is the first database to provide resources for conducting an S-LCA (shdb, 2019). It gives data from over 191 countries and 57 sectors, matching UNEP subcategories. The data are displayed in the form of risk potentials. These risks range from low and medium, to high, to very high. In addition, for some countries, there is no evidence of risk, or no relevant data are given. More than 200 sources of SHDB include the World Health Organization (WHO), the International Labor Organization, and the World Bank. Through the life cycle inventory data, countries can be compared and the potential hotspots identified. (Benoit-Norris et al., 2012) With the help of the databases, calculations, and assessments of the social impacts of products throughout their life cycle, considering global supply chains and services, and the identification of social hotspots are made possible, simplifying the implementation of S-LCA.

As already highlighted, the number of stakeholders and indicators used for the impact assessment varies; nevertheless, a common direction might be visible (Worker: ‘health and safety,’ ‘occupational accidents’; Society: ‘gross domestic product’ for ‘measuring contribution to economic development’; ‘Technical progress,’ ‘Technological development’ and ‘Technology transfer’; ‘Local employment’: ‘Job creation,’ ‘Use of local workers’). Accordingly, the comparison of different approaches with each other and also with the guidelines is made difficult. In addition, the majority of the studies rely on statistical yearbooks and national databases, which reveals a lack of primary data. Two studies use the PSILCA (GreenDelta, 2018) database (Kono et al., 2018; Penadés-Plà et al., 2020), and some others additionally conduct questionnaires or interviews (Balasbaneh et al., 2020; Sánchez et al., 2019; Zheng et al., 2019). Regarding carbon fibers, no study exists yet in the literature that performs a full S-LCA based on the UNEP guidelines. As an increased application of carbon fibers is expected in the coming years (Pillain et al., 2019), there is thus an increasing need to assess the social impacts of these along the entire life cycle.

The review once again shows that in the studies published previously to the actual one the data reference, the quantification of the impacts and, in particular, the selection of suitable indicators appears to pose a challenge. With the following case study, we want to explicitly address the question of how to decide among the large set of indicators. None of the studies performs a social HotSpot analysis (social critical processes, production or working steps) with the Social Hotspot Database (SHDB) and thus independently determines the relevant indicators for a building material—which is what we want to change for CRC in the following chapters with the help of a case study. This can be seen and used as a basis for a future and complete S-LCA for CRC.

3 Case Study: Indicator Identification for CRC

The objective of this case study is to define the socially relevant, elementary phases in the life cycle of CRC and to construct an approach for an assessment framework in the form of a social life cycle assessment. This is done by developing a catalog of indicators based on literature and a subsequent hotspot analysis for the identified production countries with help of the SHDB.

3.1 Goal and Scope

The primary goal of this study is to identify potential main issues via social hotspot analysis of the process at country level—previously having identified the main producers and their production locations. For the assessment of social hotspots, the product system is considered first. In this work, the system boundary is considered from cradle-to-gate—this following a previously published cradle-to-gate LCA on CRC (Backes et al., 2022). Furthermore, no explicit product, no explicit functional unit, is considered in the present work. The reason for this is that so far, no representative component has been defined for CRC, and the finite definition of a component (e.g., a double-wall, a façade panel, a bridge, etc.) is not relevant for carrying out a catalog of indicators based on the producing countries, raw materials, used and general processing steps.

3.2 Life Cycle–Cradle-to-Gate

The life cycle of CRC is taken from a previous study on environmental Life Cycle Assessment (Backes et al., 2022). Currently, PAN is increasingly used as a raw material for the reinforcement of structures (Bergmeister et al., 2010). The PAN fibers and finally the carbon fibers are produced mechanically and usually at a single location. The production of carbon fibers preferably takes place in Asia, North America, and Europe (Gärtner, 2020). Up to this point, however, the carbon fiber can also become another component, so the process up to this point is not specifically geared to the production of CRC. It is only when the finished carbon fibers are transported to another production facility, which is usually located in Europe, that they are processed into reinforcement. This can be produced either in mat form or in bar form. In case study, the reinforcement is then transported to Germany, where the concrete is mixed, placed on the reinforcement, and cured. The composition of the concrete varies depending on the desired properties or components (Fig. 3). CRC has so far been used primarily for repair work, but also to a certain extent for new construction (Textilbetontage, 2017).

3.2.1 Carbon Fiber

More than 90% of the production of carbon fiber (CF) is based on polyacrylonitrile (PAN) (Fig. 3). This is obtained from petroleum via the intermediate stage propene (Witten, 2013). Regular PAN fibers consist of 90–94% acrylonitrile. For fiber production, it is polymerized together with comonomers and spun into precursor fibers. Mainly, PAN fiber production is assumed to take place in Japan. In contrast, the countries to be considered for the origin of petroleum can be determined from statistics: The Global Energy Statistical Yearbook 2020 provides a breakdown of petroleum production by country for 2019 (Enerdata, 2021). According to this, the USA is the largest petroleum producer (745 million tons), followed by Russia (560 million tons) and Saudi Arabia (545 million tons). Thus, the percentage shares are as follows: USA 16.9%, Russia 12.7%, and Saudi Arabia 12.3%, as well as Canada 6.1% and Iraq 5.2%.

For the conversion from PAN fiber to carbon fiber (CF), several energy-intensive process steps take place in succession (Witten, 2013). The composites market report publishes data on the carbon fiber market. The global production capacity of CF was 149.3 kt/a in 2018, of which 45.3 kt/a (30.3%) is located in North America. Japan had a production capacity of 27.1 kt/a (18.2%) and China a capacity of 17.3 kt/a (11.6%) in 2018. Together, these three countries account for 60.1% of CF’s total production capacity in 2018. The remaining production capacity can be distributed among Mexico (6.7%), Europe with France (5.0%), Hungary (4.2%), Germany (3.9%), as well as the United Kingdom (3.3%), Taiwan (5.9%) and South Korea (5.8%). Only about 5.2% are assigned to the rest of the world (Witten et al., 2018; Statista, 2021). To focus on (South American) developing countries in general about the production (supply), it must, unfortunately, be noted that except for Mexico (which is also counted under North America), there is no information on the experience of Latin American developing countries where the industry is booming, such as Brazil or Argentina—these fall under the rest of the world with a very small share. (Statista, 2021) This is even though the construction sector in Latin America is growing by about 6% per year (AlliedMarketResearch, 2018). Also regarding the demand, no further information could be found, except that China seems to provide the largest demand (generally Asia–Pacific) (MordorIntelligence, 2022).

The values named refer to all possible application areas for CF and not explicitly to the construction sector. According to the Composites Market Report of 2018, about 5% of the carbon fibers produced are attributable to the construction sector (Witten et al., 2018). Specifically for the construction sector, the institutes available for the production of CRC can be listed (company headquarters underlined) (C3 CRC composite, 2021) (Table 3).

In contrast to carbon fiber production, the manufacture of carbon fiber reinforcement is not yet an industrialized process (Witten, 2013). General carbon fiber production is followed by bar pultrusion. Subsequently, the surfaces of the reinforcement bars have to be profiled to ensure bonding (Böhm et al., 2018). With the help of the manufacturers’ websites, it was possible to assign the production sites to the listed institutes (Table 3). (C3 CRC composite, 2021) As the majority of PAN fiber production takes place in Japan, this assumption is adopted for the present work. The selection of countries to be considered for the origin of the feedstock petroleum is less clear to analyze. The percentages of total production in 2019 from the USA, Russia, Saudi Arabia, Canada, and Iraq add up to 53.2%, which is more than half of total worldwide production. Thus, these five countries are examined in the following. Carbon fiber production occurs globally, so we weigh countries based on a percentage breakdown of production capacity. Consequently, in the context of this case study, we focus exclusively on the largest producers. If we add the percentage shares of North America, Japan, and China, we arrive at a carbon fiber production capacity of 60.1%.

3.2.2 Concrete

Concrete consists of three to five components: Aggregate, water, and cement, as well as concrete admixtures. Depending on the exposure class and selected compressive strength class, the composition and properties, such as durability and compressive strength, of the concrete vary. The main component of a normal strength concrete for the production of CRC is aggregate. Gravel 2/8 accounts for a total proportion of about 38%, and sand together with the fine sand accounts for about 33%. According to the raw materials report of 2019, the total production of aggregate in Germany in 2019 was about 476 kt. In contrast, imports were only about 12.2 kt and exports were 20.5 kt. The significant proportion of aggregate used in Germany is therefore also produced in Germany. The same applies to cement (Andruleit et al., 2019). Since many of the institutes specify Germany as production location, in this case study, Germany is selected as the reference country for reinforcement production.

3.2.3 Composite Material

As stated at the beginning of the objective formulation, a fictive CRC component built in Germany is considered in this work. Based on the previously stated details concerning fiber production and concrete components, in the following, only the main materials, i.e., crude oil, aggregate, and cement, are considered for further component analysis (Table 4).

3.3 Social Hotspot Database

After researching the producing countries, the Social Hotspot Database is used to conduct a risk analysis of the countries and so of the respective component production. Through this, it can be determined which indicators in the countries have which risk or for which indicators no data are available so far. To use the SHDB, a sector must be selected for each input (shdb, 2019). Although the investigated product of CRC is a building component, which can thus be assigned to the construction sector, the unit processes up to and including carbon fiber production are not explicitly focused on the final product of CRC. These processes have a variety of outputs and therefore do not belong to the construction sector. Following, the petroleum and coal products sector is chosen for petroleum production. Further, for both PAN fiber and carbon fiber production, the sector chemical, rubber, and plastic products are chosen. The raw materials aggregate and cement, which form the main components of concrete, are extracted in Germany. This process step is assigned to the mineral products nec sector. From the reinforcement production onward, the processes can be assigned to the construction sector. Since all processes are carried out in Germany according to the scope of the study, reinforcement production and CRC production are combined under the title CRC production and considered as one process, even if this does not necessarily take place at one single site in Germany. The selected input mask for the SHDB is shown in Table 5, based on Fig. 3.

The risk of individual indicators is indicated with the help of a color code, which is then weighted with the help of a previously defined score so that an average value can be formed for the processes. This weighted average can then be used to determine indicators for the CRC hotspot and relevant indicator catalog. Table 6 shows the color and score scheme of the following risk analysis. The colors from dark red, through red to yellow and green represent the risk potential of the indicators given by the SHDB. Gray and blue also represent ‘no data’ and ‘no evidence.’ The score can then be used to calculate the risk of the main process and to determine the significance of the respective indicator. Since this is a risk assessment, ‘no data’ cannot be set to a score of 0, as this would favor it. Thus, the score for ‘no data’ is set to 4, which is conservatively between ‘medium’ and ‘high.’ The score of ‘no evidence’ is to be equated with low risk. Thus, this heading is given a score of 1 (Table 6).

3.3.1 Metrics

Based on the percentage shares of the production countries shown in Table 4, a weighting is applied and then a weighted average of the risk analysis of the process steps is calculated to ensure the representativeness of the selection of indicators. For this purpose, the percentage shares of the countries \(a_{P,i}\) must be converted. For oil production, the following applies: USA 16.9%, Russia 12.7%, Saudi Arabia 12.3%, Canada 6.1%, and Iraq 5.2% (Enerdata, 2021). For carbon fiber production, in turn, the following applies: USA 30.3%, Japan 18.2%, and China 11.6% (Witten et al., 2018). The conversion to a single weighted value is as follows:

By: \(\overline{X}_{P,w}\): weighted average value of the process \(P\), with \(P \in \left\{ {{\text{Petroleum}};{\text{PANFiber}};{\text{Carbonfiber}};{\text{CRC}}} \right\}\).

\(w_{P,i}\): weighted share of country \(i\), with \(i \in \left\{ {1;2; \ldots ;n} \right\}\)

\(a_{P,i}\): percentage of country \(i\), with \(i \in \left\{ {1;2; \ldots ;n} \right\}\)

\(s_{P,i}\): score from country \(i\), with \(i \in \left\{ {1;2; \ldots ;n} \right\}\)

To determine the weighted mean value \(\overline{X}_{w}\) of a process, the sum of the weightings \(w_{i}\) multiplied by the corresponding score \(s_{i}\) is formed. For the PAN fiber and CRC processes, only one score is available in each case, which is why no conversion is necessary. Those weighted mean values that are greater than or equal to four were marked in red, which represents an increased risk. Thus, these indicators are included in the indicator catalog. The metric of classification was chosen, as score 4 represents the middle of medium and high risk. Moreover, the number 4 itself is included because the score for ‘no data’ was set at 4. Thus, non-existent data cannot favor exclusion from the indicator catalog. Thus, the criteria chosen for inclusion in the indicator catalog was a risk score of at least high or no data available. Indicators for which the SHDB indicates low or medium risk may still have negative impacts in reality, but carry a lower risk of doing so. Combining the process steps into an all-encompassing assessment of CRC does not make sense because no data on the weighting of the process steps are known. In addition, the first three processes do not explicitly take place for the production of CRC. A part for an airplane can be built from carbon fiber just as reinforcement can be produced. Thus, the indicator catalog for CRC is divided into parts according to the process steps (Fig. 3). The formation of an average value per subcategory and process also makes little sense, since the indicators are not weighted in this way. In addition, adding up risks carries the risk of a shifted result. Furthermore, since risk assessment is based on statistical yearbooks (Enerdata, 2021), the values should be netted as little as possible.

3.4 Results

Based on the defined scope of the investigation, a risk analysis of the countries (not processes or materials) identified for the main phases is carried out. This is based on the SHDB and is presented in tabular form. These tables are then evaluated using the color and score scheme presented before, so that the significant indicators can be compiled in the indicator catalog (see Supplementary Material A.1-A.3).

Through the risk analysis, it is clear to see that many data are not given for Saudi Arabia in the SHDB. For example, the subcategories Labor Rights and Decent Work-Social Benefits, Health and Safety-Occupational Toxics and Hazards, and Injuries and Fatalities are without data. Likewise, the subcategory Leadership-Legal System. Data are also sporadically not given in the other subcategories. This is just as true for the country of Iraq. In addition, no data are given for labor rights and decent work wage assessments either. For the other countries, there are only isolated gaps in the data. The fact that no evidence is given for indicators in the respective country often occurs in bundles. Either this applies to one indicator in several countries (see, for example, Health and Safety-Occupational Toxics and Hazards-Miners' Pneumoconiosis DALYs as a Result of Workplace Exposure to Airborne Particulate Matter) or one country increasingly has no evidence for a subcategory (see, for example, Canada, Japan, and Germany: Labor Rights and Decent Work-Child Labor). The latter is also true for Saudi Arabia and Germany in the subcategory Human Rights-Indigenous Rights, or even a majority of countries in the subcategories Labor Rights and Decent Work-Poverty and Community-Small Farmers vs. Commercial Farms (landscape sectors only). Conspicuous in terms of high risk are China in the area of Health and Safety-Occupational Toxics and Hazards and the USA within both process steps in the area of Labor Rights and Decent Work-Social Benefits. Here, a large number of the indicators are indicated as high risk. In addition, the subcategory Labor Rights and Decent Work-Migrant Workers appears to indicate high risks for almost all countries in relation to immigration. The mean values of the processes CRM (Concrete raw material and production) and CCP (CRC production) are identical for each individual indicator. Both processes take place in Germany and can therefore be considered together in the following. (Supplementary Material: Table A.1-A.3) It remains to be seen whether the visual impressions described here are corroborated or relativized by the metrics below. The weighted mean is presented below, which forms a summary of the risk analysis data. This summary can then be used to select based on relevance. The weighted mean value is determined as described in advance (Formula1 & 2). All fields with mean values greater than or equal to four are of relevance. If one of the countries poses a very high risk for the indicator but is not weighted enough, this is indicated by a red dot. This means that the indicator is included in the catalog despite a weighted mean value below the threshold of four.

Example

For carbon fiber production (CFP), the sector average wage is below the living wage for Japan gray (= 4), for the USA green (= 1), and for China gray (= 4) (Table A.1in Supp. Material). Thus, the weighted average is obtained:

⇒ the field will not be filled in red and thus will not be included in the HotSpot catalog (Tables 7 and 8, marked in bold).

In the following, the weighted average value is presented, which forms a summary of the risk analysis data. This summary can then be used to select according to relevance.

Since the SHDB indicators can only be assigned to the three stakeholder categories of Worker, Society, and Local Community, these are listed and considered in detail below. The stakeholder categories Value Chain Actors, Consumers, and Children are therefore omitted in the following tables. This also underpins the most frequently defined stakeholder groups in the literature review (Fig. 2). The following catalog of indicators, however, is detached from the stakeholder categories. Subcategory 7, Health and Safety, in the stakeholder category Worker (Table. A.4), is particularly striking for all process steps. 41% of all indicators are of increasing interest (> 4). In addition, 11 fields are marked with a red dot, i.e., have at least one very high risk. These high risks are primarily attributable to China, which can be seen in Table A.1. The stakeholder category Society is inconspicuous (Table. A.5), but here data are also only given for one subcategory 5. Corruption. The weighted mean scores for the Local Community (Table. A.6) occur less frequently above the threshold of four. Many relevant fields (> 4) can be seen for subcategory 9. Safe living conditions. Sixteen out of 25 fields are marked red here, and there is also one field with a red dot, i.e., a very high risk for one of the countries. In 3. Delocalization and migration, half of the fields are red. In addition, it is noticeable that the weighted mean values exceeding the threshold value are relatively high.

Consequently, in conclusion, the desired catalog of indicators for the production (cradle-to-gate) of a CRC component can be summarized-from the tables in the appendix and the weighted mean values. We use the SHDB again and focus on processes and impact categories, which is why the perspective on stakeholders selected in advance is now changed (stakeholders are no longer explicitly named). Since the indicator selection for raw material procurement concrete and carbon concrete production is identical, the resulting catalog is presented only once (Table eleven). The mean values are ≥ 5, and the corresponding indicator per production step is marked with an X as relevant process and placed in the CRC’s risk catalog for social aspects. In the following (Tables 8, 9, 10 and 11), all critical indicators are marked per defined process with an X—to be used in future potential surveys. A detailed discussion of the indicator catalogs follows in the discussion chapter.

4 Discussion

At this point, we come back to the goal of this article: to further raise awareness in the construction sector of life-cycle-based sustainability and sustainability that goes beyond the purely environmental aspect, and to conduct a social hotspot screening to create a future survey in collaboration with, for example, the construction industry. The catalog of 36 indicators identified (Tables 8, 9, 10 and 11) provides a basis for recognizing the relevant social issues for the life cycle of CRC (Table. A.1-A.3) and can further be used to build up and share a questionnaire used in the industry. However, additional information can be gained from the tables of weighted mean values (Table. A.4-A.6), as it becomes clear here where values are given in the database and where they are not (no data/no evidence). In the following, not every indicator will be discussed, but the totality will be examined for anomalies, so that conclusions on the life cycle and relevant social aspects of carbon reinforced concrete are permissible. The impact category of health and safety will be examined in particular, as this is where the most reference to the processes can be made (Table 12).

-

In general, it can be seen at a glance that for all processes, the area of Labor rights and decent work contains a large proportion of the indicators (X) noted as relevant (Table 12).

The focus in Labor rights and decent work is particularly on the subcategories: Freedom of Association, Collective Bargaining, Right to Strike; Migrant Labor; Social Benefits and Labor Laws/Conventions. For concrete production and the manufacture of the final CRC component, indicators in the health and safety subcategory are of particular relevance.

-

The most important processes, due to the explicit assignment to the production of CRC, are the raw material procurement and production of (carbon reinforced) concrete (Table. A.6).

For (carbon reinforced) concrete production (Table. A.6), increased risks are shown for the indicators of the impact category health and safety. Ten of the 19 indicators are included in the catalog, two of which have a very high risk (can also be seen in Table. A.1). For the subcategory labor rights and decent work-migrant workers, three of seven risks are at least high. A very high risk for Germany is also found for the indicator Human Rights-High Conflict Zones UNDP (Table. A.3 and Table. A.6). Here, it is important to check what this indicator explicitly assesses, as there is currently no indication for Germany, at least with regard to war conflicts or similar. For all other indicators, Germany predominantly has a score of 1, occasionally a score of 3, which corresponds to a low or medium risk, or no data are available (see Table. A.1–A.3).

-

In the risk analysis of Saudi Arabia, a large number of indicators are missing. In particular, there is a complete lack of data in the health and safety impact category. The scores in the impact category of labor rights and decent work are all between medium risk and very high risk. Only the indicators remittances and workers’ compensation per immigrant (USD) (Table. A.3)—calculated using the total number of immigrants with R&D / number and the risk that the average wage is below the country’s minimum wage are marked with low risk. The latter should be viewed with caution, however, as the risk here is based on a value set by the country itself, the minimum wage, and thus cannot be put into perspective. The lack of data for Saudi Arabia poses a high risk in itself. However, the country accounts for only 12.3% of oil production. It should be noted, however, that the Middle East has the world’s largest oil resources (Pablo & Alfonso, 2007). Thus, Saudi Arabia offers the potential to play a major role in oil production in the future. This has to be considered for such a future-oriented material as carbon fibers. The USA forms the largest share in both oil production and carbon fiber production (Table seven). Therefore, to differentiate, we look at the risk analysis tables to consider this country individually. For petroleum production, the USA predominantly shows high to very high risk in the subcategories of Labor Rights and Decent Work-Freedom of Association, Collective Bargaining, Right to Strike, and Labor Rights and Decent Work-Social Benefits (Table. A.1). This is also consistent with the risk data for carbon fiber manufacturing, which is assigned to a different sector. Thus, these subcategories need to be looked at more closely for the USA, regardless of the process step. This is also true for the subcategory Labor Rights and Decent Work-Migrant Workers. The single given indicator risk of child labor by sector (qualitative) indicates a very high risk for China (Table. A.1). For China, this phenomenon is also given in the same impact category for the subcategory freedom of association, collective bargaining, and right to strike (Table. A.1& Table ten). Again, risk values for indicators are not given, but a trend can be seen due to the high risk of other indicators. China accounts for about 11.6% of carbon fiber production.

-

The weighted averages often give the impression of increased risk due to the chosen threshold of four, but in many cases, this impression is based on non-existent data.

A good example of this is the indicator Human Rights-Human Health Problems-Communicable Diseases-Dengue Fever, Incidence Rate (per 100,000 population) (Table. A.3). As can be seen in Table A.3, no data are given here except for China. Thus, the indicators are given a score of four and are transferred to the indicator catalog. This shows the impact of the metric, as this is a risk assessment. No data does not equate to no risk and therefore the indicators need to be revisited. At most, this approach adds too many indicators to the catalog but does not omit any that are potentially important.

In summary, it can be said that for Germany as well as for the other process countries, the issue of employee health and safety stands out above all. Therefore, a focus should be set here for further consideration and a future survey (based on the selected indicators). For all five process steps, several indicators in the subcategory of migrant workers are also assigned at least a high risk. Due to a lack of data in some cases, indicators were also included in the catalog for which there is no known risk. This named data leak can also be explicitly countered in the future with surveys in and in cooperation with the industry. Furthermore, limitations are explicitly addressed in the following, which must be dealt with in the future in relation to the preceding discussion.

5 Limitation

In order to address the increasing interest in the field of sustainable construction, especially social sustainability, with a clear framework, systematic studies were used, as they provide an objective overview of the state of the art through strict inclusion and exclusion rules. The presented research results of S-LCA in the construction sector are based on only 12 studies, mainly published between 2018 and 2021. Journals or articles in languages other than English and before 2010 were not included in the study. A clear focus in the conducted literature review was on the UNEP Guidelines, which completely excludes other potential approaches. The named restrictions can be extended in a further research. Nevertheless, the main focus of this study was on the development of a catalog of indicators for carbon reinforced concrete: The approach chosen in this paper is a process-oriented approach, which is based on official and published statistics (e.g., yearbooks (Enerdata, 2021)). This entails a certain degree of uncertainty, as the interrelationships between the individual processes are not clearly differentiated. Thus, the weighted averages and the resulting selection of indicators are not based on all countries involved in the processes. However, the goal of this work is to identify potential hotspots through a social hotspot analysis. These potentials are identified through the approach of this work. This risk analysis is based on the previously identified process countries. While this provides the prerequisite for identifying the potential hotspots, this approach focuses more on the countries than on the processes themselves. A comprehensive expert survey, based on the catalog identified, on the process steps would therefore be a useful addition. A survey itself or even a cooperation with the producing industry did not exist for the creation of the catalog-which is why indicators, explicitly those that were created through non-existing data, should be questioned again.

The S-LCA methodology is designed to evaluate existing structures. However, the carbon fiber reinforced plastic/product (CFRP) market is in constant growth and includes the development of new fields, such as the recycling of CFRPs (Backes et al., 2022). Thus, new activities are always added, which are not yet fully definable and calculable. The results of this work can therefore serve as a construct for a yet-to-be-performed S-LCA or as a review of an already existing S-LCA of CRC.

Finally, it should be noted at this point that the production process and the named process countries are based on official statistics—an explicit consideration of developing countries is not made here—especially since these countries are not explicitly named as producers or customers. Nevertheless, a look at these developing countries can change the perspective and also the social risks in the future, especially since in these countries, for example in Latin America, the construction industry is experiencing a boom.

6 Conclusion

The intended goal of this work was (1) a literature review and the identification of chances and challenges of S-LCAs in the construction sector and (2) a risk analysis of the cradle-to-gate life cycle of carbon reinforced concrete (CRC) in order to create the prerequisite for an effective and complete S-LCA, with help of a future questionnaire, based on the created indicator catalog—specially to answer the question on how to decide among the large set of possible indicators.

Only a rather small number of studies (literature review) integrate the S-LCA according to the UNEP/SETAC Guidelines into the building sector. Depending on the study and subcategory, the type and number of indicators differ greatly, so there is no uniformity (challenge). Furthermore, qualitative, quantitative, and semi-quantitative indicators were used. However, for a few individual subcategories, such as ‘worker health and safety,’ practitioners seem to agree (chances).

For the purpose of the case study (risk analysis for carbon reinforced concrete), the cradle-to-gate part of life cycle was divided into five major process steps in this work: (1) petroleum production, (2) PAN fiber production, (3) carbon fiber production, (4) raw material procurement concrete, and (5) CRC production. The process countries relevant to these processes were identified with help of official statistical yearbooks and risk analysis of the countries was performed based on the Social Hotspots Database (SHDB). Since a majority of relevant countries were identified for the petroleum production and carbon fiber manufacturing process steps, the proportions of countries were weighted and used to group the risk potentials together. This resulted in a weighted average value as an evaluation criterion. As a metric, an individually defined threshold value was discussed, above which the risk potential of an indicator is considered relevant.

The result of this case study is a catalog of initial risk assessment of the entire production process (36 critical hotspots) and thus forms the basis for an S-LCA of CRC to be carried out in the next step. The main focus of indicators to be highlighted and further used in the indicator catalog are in the area of labor rights and decent work in the health and safety subcategory.

Critically, some missing data can lead to a high average value, which is then also included in the catalog as a relevant indicator, but may not be considered critical. On the other hand, missing data can also lead to a lower level of information, as in the case of Saudi Arabia, for example. In the future, the identified indicators can and should again be revised and possibly shortened or expanded in cooperation with the manufacturing industry to set up a survey.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Abowitz, D. A., & Toole, T. M. (2010). Mixed method research: fundamental issues of design, validity, and reliability in construction research. Journal of Construction Engineering and Management, 136(1), 108–116. https://doi.org/10.1061/(asce)co.1943-7862.0000026

Allied market research. (2018). Carbon fiber market. retrieved from https://www.alliedmarketresearch.com/carbon-fiber-market

Andruleit, H., Elsner, H., Henning, S., Homberg-heumann, D., Kreuz, A., Kuhn, K., Wilken, H. (2019). Deutschland–Rohstoffsituation.

Backes, J. G., & Traverso, M. (2022). Life cycle sustainability assessment as a metrics towards SDGs Agenda 2030. Current Opinion in Green and Sustainable Chemistry. 100683.

Backes, J. G., Traverso, M., & Horvath, A. (2022b). Sustainability assessment of a disruptive innovation: comparative cradle-to-gate life cycle assessment of carbon reinforced concrete. International Journal of Life Cycle Assessment, submitted(In Revision). Retrieved from tbd

Backes, J. G., del Rosario, P., Petrosa, D., Traverso, M., Hatzfeld, T., & Guenther, E. (2022a). Building sector issues in about 100 years: End-of-life scenarios of carbon-reinforced concrete presented in the context of a life cycle assessment, focusing the carbon footprint. Processes, 10, 1791.

Backes, J. G., & Traverso, M. (2021a). Application of life cycle sustainability assessment in the construction sector: A systematic literature review. Processes., 9(7), 1248.

Backes, J. G., & Traverso, M. (2021b). Life cycle sustainability assessment—a survey based potential future development for implementation and interpretation. Sustainability (switzerland), 13(24), 13688. https://doi.org/10.3390/su132413688

Balasbaneh, A. T., & Marsono, A. K. (2020). Applying multi-criteria decision-making on alternatives for earth-retaining walls: LCA, LCC, and S-LCA. The International Journal of Life Cycle Assessment. https://doi.org/10.1007/s11367-020-01825-6

Balasbaneh, A. T., Yeoh, D., Juki, M. I., Gohari, A., Abidin, A. R. Z., & MarsonoBin, A. K. (2021). Applying three pillar indicator assessments on alternative floor systems: Life cycle study. International Journal of Life Cycle Assessment, 26(7), 1439–1455. https://doi.org/10.1007/s11367-021-01881-6

Benoît, C., Norris, G. A., Valdivia, S., Ciroth, A., Moberg, A., Bos, U., & Beck, T. (2010). The guidelines for social life cycle assessment of products: Just in time! International Journal of Life Cycle Assessment, 15(2), 156–163. https://doi.org/10.1007/s11367-009-0147-8

Benoit-Norris, C., Traverso, M., Valdivia, S., Vickery-Niederman, G., Franze, J., Azuero, L., Aulisio, D. (2013). The methodological sheets for sub-categories in Social Life Cycle Assessment. Retrieved from https://www.lifecycleinitiative.org/wp-content/uploads/2013/11/S-LCA_methodological_sheets_11.11.13.pdf#:~:text=The Methodological Sheets for Subcategories in Social Life,public resource to guide the application of S-LCA.

Benoit-Norris, C., Cavan, D. A., & Norris, G. (2012). Identifying social impacts in product supply chains: Overview and application of the social hotspot database. Sustainability, 4(9), 1946–1965. https://doi.org/10.3390/su4091946

Berardi, U. (2012). Sustainability assessment in the construction sector: Rating systems and rated buildings. Sustainable Development, 20(6), 411–424. https://doi.org/10.1002/sd.532

Bergmeister, K., Fingerloos, F., & Wörner, J.-D. (2010). Beton Kalender (Vol. 1).

Berriel, S. S., Ruiz, Y., Sánchez, I. R., Martirena, J. F., Rosa, E., & Habert, G. (2018). Introducing low carbon cement in Cuba-A life cycle sustainability assessment study. RILEM Bookseries, 16(October), 415–421. https://doi.org/10.1007/978-94-024-1207-9_67

Böhm, R., Thieme, M., Wohlfahrt, D., Wolz, D. S., Richter, B., & Jäger, H. (2018). Reinforcement systems for carbon concrete composites based on low-cost carbon fibers. Fibers., 6(3), 56. https://doi.org/10.3390/fib6030056

Bork, C. A. S., De Barba, D. J., & De Oliveira Gomes, J. (2015). Social life cycle assessment of three companies of the furniture sector. Procedia CIRP, 29, 150–155. https://doi.org/10.1016/j.procir.2015.02.191

C3 carbon concrete composite. (2021). Stoffkreislauf Carbonbeton. Retrieved from https://www.bauen-neu-denken.de/stoffkreislauf-carbonbeton/

Caruso, M. C., Pascale, C., Camacho, E., & Ferrara, L. (2022). Comparative environmental and social life cycle assessments of off-shore aquaculture rafts made in ultra-high performance concrete (UHPC). International Journal of Life Cycle Assessment, 27(2), 281–300. https://doi.org/10.1007/s11367-021-02017-6

Enerdata. (2021). Crude oil production. retrieved from https://yearbook.enerdata.net/crude-oil/world-production-statistics.html

ISO 14040. (2006). Environmental management–Life cycle assessment–Principles and framework.

Finkbeiner, M., Schau, E. M., Lehmann, A., & Traverso, M. (2010). Towards life cycle sustainability assessment. Sustainability, 2(10), 3309–3322. https://doi.org/10.3390/su2103309M4-Citavi

Garrido, S. R. (2017). Social Life-Cycle Assessment: An Introduction. In Encyclopedia of Sustainable Technologies (Vol. 1). https://doi.org/10.1016/B978-0-12-409548-9.10089-2

Gärtner, C. (2020). Fragen und antworten–carbon concrete composite e.V. Hg. V. carbon concrete composite E.V. retrieved from https://www.bauen-neu-denken.de/faq/#s03

GreenDelta. (2018). PSILCA-Understanding social impacts. Retrieved from https://psilca.net/

GreenDelta. (2016). PSILCA–A Product Social Impact Life Cycle Assessment database. Database version 1.0. Documentation. (March), 1–99. Retrieved from http://www.openlca.org/documents/14826/6d439d91-ddf5-480f-9155-e4787eaa0b6b

Helbig, C., Gemechu, E. D., Pillain, B., Young, S. B., Thorenz, A., Tuma, A., & Sonnemann, G. (2016). Extending the geopolitical supply risk indicator: Application of life cycle sustainability assessment to the petrochemical supply chain of polyacrylonitrile-based carbon fibers. Journal of Cleaner Production, 137, 1170–1178. https://doi.org/10.1016/j.jclepro.2016.07.214

Hilburg, J. (2019). Concrete production produces eight percent of the world’s carbon dioxide emissions. The Architect’s Newspaper.

Hosseinijou, S. A., Mansour, S., & Shirazi, M. A. (2014). Social life cycle assessment for material selection: A case study of building materials. International Journal of Life Cycle Assessment, 19(3), 620–645. https://doi.org/10.1007/s11367-013-0658-1

Hu, M., Kleijn, R., Bozhilova-Kisheva, K. P., & Di Maio, F. (2013). An approach to LCSA: The case of concrete recycling. The International Journal of Life Cycle Assessment, 18(9), 1793–1803. https://doi.org/10.1007/s11367-013-0599-8

Hunkeler, D. (2006). Societal LCA methodology and case study. International Journal of Life Cycle Assessment, 11(6), 371–382. https://doi.org/10.1065/lca2006.08.261

ISO 14044. (2018). Environmental management–Life cycle assessment–Requirements and guidelines.

Janjua, S. Y., Sarker, P. K., & Biswas, W. K. (2021). Sustainability implications of service life on residential buildings–An application of life cycle sustainability assessment framework. Environmental and Sustainability Indicators., 10, 100109. https://doi.org/10.1016/j.indic.2021.100109

Josa, I., de la Fuente, A., Casanovas-Rubio, M. D. M., Armengou, J., & Aguado, A. (2021). Sustainability-oriented model to decide on concrete pipeline reinforcement. Sustainability Switzerland, 13(6), 1–25. https://doi.org/10.3390/su13063026

Kono, J., Ostermeyer, Y., & Wallbaum, H. (2018). Trade-off between the social and environmental performance of green concrete: The case of 6 countries. Sustainability., 10(7), 2309. https://doi.org/10.3390/su10072309

Kortmann, J. (2020). Verfahrenstechnische Untersuchungen zur Recyclingfähigkeit von Carbonbeton. Retrieved from https://doi.org/10.1007/978-3-658-30125-5

Kühnen, M., & Hahn, R. (2017). Indicators in social life cycle assessment: A review of frameworks, theories, and empirical experience. Journal of Industrial Ecology, 21(6), 1547–1565. https://doi.org/10.1111/jiec.12663

Lehne, J., & Preston, F. (2018). Making concrete change (C. H. R. Y.-15. 05. 202. M. Citavi, Ed.). Retrieved from https://www.chathamhouse.org/sites/default/files/publications/research/2018-06-13-making-concrete-change-cement-lehne-preston.pdf

Martínez-Muñoz, D., Martí, J. V., & Yepes, V. (2022). Social impact assessment comparison of composite and concrete bridge alternatives. Sustainability., 14(9), 5186. https://doi.org/10.3390/su14095186

Meyer, C. (2005). Concrete as a Green Building Material (Columbia University).

MordorIntelligence. (2022). Carbon fiber market-growth, trendS, COVID-19 impact, and forecasts (2022–2027). Retrieved from https://www.mordorintelligence.com/industry-reports/carbon-fiber-market

Nations, U. (2015). THE 17 GOALS | Sustainable Development. Retrieved from https://sdgs.un.org/goals

Navarro, I. J., Yepes, V., & Martí, J. V. (2018). Social life cycle assessment of concrete bridge decks exposed to aggressive environments. Environmental Impact Assessment Review, 72(May), 50–63. https://doi.org/10.1016/j.eiar.2018.05.003

Oladazimi, A., Mansour, S., Hosseinijou, S. A., & Majdfaghihi, M. H. (2021). Sustainability identification of steel and concrete construction frames with respect to triple bottom line. Buildings, 11(11), 1–21. https://doi.org/10.3390/buildings11110565

Otto, J., & Adam, R. (2019). Carbonbeton und Stahlbeton im wirtschaftlichen Vergleich/Textile-reinforced concrete and reinforced concrete in an economic comparison. Bauingenieur, 94, 246–253.

Pablo, J., & Alfonso, P. (2007). Crude Oil. In N. C. Schofield (Ed.), Commodity Derivatives: Markets and Applications.

Penadés-Plà, V., Martínez-Muñoz, D., García-Segura, T., Navarro, I. J., & Yepes, V. (2020). Environmental and social impact assessment of optimized post-tensioned concrete road bridges. Sustainability Switzerland, 12(10), 1–18. https://doi.org/10.3390/su12104265

Piacenza, J. R., Tumer, I. Y., Haapala, K. R., & Hoyle, C. (2013). Detc2013–12267 Comparison of Sustainability Performance for Cross Laminated. 1–11.

Pillain, B., Gemechu, E., & Sonnemann, G. (2017). Identification of Key Sustainability Performance Indicators and related assessment methods for the carbon fiber recycling sector. Ecological Indicators, 72, 833–847. https://doi.org/10.1016/j.ecolind.2016.08.056

Pillain, B., Viana, L. R., Lefeuvre, A., Jacquemin, L., & Sonnemann, G. (2019). Social life cycle assessment framework for evaluation of potential job creation with an application in the French carbon fiber aeronautical recycling sector. International Journal of Life Cycle Assessment, 24(9), 1729–1742. https://doi.org/10.1007/s11367-019-01593-y

Rajak, D. K., Pagar, D. D., Kumar, R., & Pruncu, C. I. (2019). Recent progress of reinforcement materials: A comprehensive overview of composite materials. Journal of Materials Research and Technology, 8(6), 6354–6374. https://doi.org/10.1016/j.jmrt.2019.09.068

Ramos Huarachi, D. A., Piekarski, C. M., Puglieri, F. N., & de Francisco, A. C. (2020). Past and future of Social Life Cycle Assessment: Historical evolution and research trends. Journal of Cleaner Production, 264, 121506. https://doi.org/10.1016/j.jclepro.2020.121506

Roh, S., Tae, S., Kim, R., & Martínez, D. M. (2018). Analysis of worker category social impacts in different types of concrete plant operations: A case study in South Korea. Sustainability Switzerland, 10(10), 9–17. https://doi.org/10.3390/su10103661

Russo Garrido, S., Parent, J., Beaulieu, L., & Revéret, J. P. (2018). A literature review of type I SLCA—making the logic underlying methodological choices explicit. International Journal of Life Cycle Assessment, 23(3), 432–444. https://doi.org/10.1007/s11367-016-1067-z

Sala, S., Vasta, A., Mancini, L., Dewulf, J., & Rosenbaum, E. (2015). Social life cycle assessment : state of the art and challenges for product policy support. Retrieved from http://bookshop.europa.eu/uri?target=EUB:NOTICE:LBNA27624:EN:HTML

Sánchez, S., Cancio, Y., Sánchez, I. R., Martirena, J. F., Rosa, E. R., & Habert, G. (2019). Sustainability assessment in Cuban cement sector- a methodological approach. IOP Conference Series: Earth and Environmental Science, 323(1). https://doi.org/10.1088/1755-1315/323/1/012128

Scope, C., Vogel, M., & Guenther, E. (2021). Greener, cheaper, or more sustainable: Reviewing sustainability assessments of maintenance strategies of concrete structures. Sustainable Production and Consumption, 26, 838–858. https://doi.org/10.1016/j.spc.2020.12.022

SHDB. (2019). Social hotspot database. Retrieved September 9, 2020, from http://www.socialhotspot.org/

Stahr, M. (2015). Bausanierung (6th ed.; M. Stahr, Ed.). https://doi.org/10.1007/978-3-658-07456-2

statista. (2021). Leading countries based on carbon fiber production capacity in 2018. Retrieved from https://www.statista.com/statistics/380549/leading-countries-by-carbon-fiber-production-capacity/

Sureau, S., Neugebauer, S., & Achten, W. M. J. (2020). Different paths in social life cycle impact assessment (S-LCIA)—a classification of type II impact pathway approaches. International Journal of Life Cycle Assessment, 25(2), 382–393. https://doi.org/10.1007/s11367-019-01693-9

Textilbetontage, C. (2017). 9. Carbon- und Textilbetontage. (September). Dresden.

UNEP Setac life cycle initiative. (2009). Guidelines for Social Life Cycle Assessment of Products. Management, 15(2), 104. Retrieved from http://www.unep.fr/shared/publications/pdf/DTIx1164xPA-guidelines_sLCA.pdf

UNEP. (2009). Guidelines for social life cycle assessment of products.

UNEP. (2013). The methodological sheets for sub-categories in social life cycle assessment (S-LCA). https://doi.org/10.1007/978-1-4419-8825-6

UNEP. (2020). Guidelines for social life cycle assessment of products. Management, 15(2), 104. Retrieved from http://www.unep.fr/shared/publications/pdf/DTIx1164xPA-guidelines_sLCA.pdf

UNEP. (2021). Methodological Sheets for Subcategories in Social Life Cycle Assessment ( S-LCA ) 2021. Retrieved from https://www.lifecycleinitiative.org/wp-content/uploads/2021/12/Methodological-Sheets_2021_final.pdf

UNEP. (2022). Pilot projects on Guidelines for Social Life Cycle Assessment of Products and Organizations 2022. Retrieved from https://www.lifecycleinitiative.org/wp-content/uploads/2022/05/Pilot-projects-on-UNEP-SLCA-Guidelines-12.5.pdf

Wang, J., Wang, Y., Sun, Y., Tingley, D. D., & Zhang, Y. (2017). Life cycle sustainability assessment of fly ash concrete structures. Renewable and Sustainable Energy Reviews., 80, 1162–1174. https://doi.org/10.1016/j.rser.2017.05.232

Wietek, B. (2019). Beton–Stahlbeton–Faserbeton. https://doi.org/10.1007/978-3-658-27707-9

Witten, E., Mathes, V., Sauer, M., & Kühnel, M. (2018). Composites-Marktbericht 2018.

Witten, E. (2013). Handbuch Faserverbundkunststoffe/Composites. Grundlagen Verarbeitung Anwendungen (4th ed.). Springer Fachmedien Wiesbaden.

WongDin, K., & Fan, Q. (2013). Building information modelling (BIM) for sustainable building design. Facilities, 31(3), 138–157. https://doi.org/10.1108/02632771311299412

Zheng, X., Easa, S. M., Yang, Z., Ji, T., & Jiang, Z. (2019). Life-cycle sustainability assessment of pavement maintenance alternatives: Methodology and case study. Journal of Cleaner Production, 213, 659–672. https://doi.org/10.1016/j.jclepro.2018.12.227

Zuo, J., & Zhao, Z. Y. (2014). Green building research-current status and future agenda: A review. Renewable and Sustainable Energy Reviews, 30, 271–281. https://doi.org/10.1016/j.rser.2013.10.021

Acknowledgements

This research was funded by the German Research Foundation (DFG), as part of the Sonderforschungsbereich/Transregio 280 (SFB/TRR 280) ‘Konstruktionsstrategien für materialminimierte Carbonbetonstrukturen’/’Design Strategies for Material-Minimized CRC Structures’ (Subproject E01, project number 417002380). The financial support by the German Research Foundation (DFG) is gratefully acknowledged.

Funding

Open Access funding enabled and organized by Projekt DEAL. This study was funded by the German Research Foundation (DFG), as part of the Sonderforschungsbereich/Transregio 280 (SFB/TRR 280) ‘Konstruktionsstrategien für materialminimierte Carbonbetonstrukturen’/’Design Strategies for Material-Minimized CRC Structures’ (Subproject E01, project number 417002380). The financial support by the German Research Foundation (DFG) is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

Conceptualization was done by JGB; Methodology was done by JGB; Formal analysis and investigation were done by JGB; Writing—original draft preparation were done by JGB; Writing—review and editing were done by JGB and MT; Funding acquisition was done by MT and JGB; and Supervision was done by MT. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflicts of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Backes, J.G., Traverso, M. Social Life Cycle Assessment in the Construction Industry: Systematic Literature Review and Identification of Relevant Social Indicators for Carbon Reinforced Concrete. Environ Dev Sustain 26, 7199–7233 (2024). https://doi.org/10.1007/s10668-023-03005-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-023-03005-6