Abstract

Mining is one of the principal economic activities in Mexico, which in addition to bringing benefits to the population, causes health and environmental problems. This activity produces a lot of wastes, but the main one is tailings. In Mexico, these wastes are disposed of in the open air, and there is no control over them, so the particles of these wastes are dispersed by wind currents to the surrounding population. In this research, tailings were characterized, finding in them particles smaller than 100 microns; in this way, tailings can enter into the respiratory system and hence can cause diseases. Furthermore, it is important to identify the toxic components. The present work does not have previous research in Mexico, and it shows a qualitative characterization of the tailings from an active mine using different analytical techniques. In addition to the data obtained from the characterization of the tailings, as well as the concentration of the toxic elements found, which were Pb and As, a dispersal model was generated and used to estimate the concentration of particles in the wind generated at the studied area. The air quality model used in this research is AERMOD, where it uses emission factors and available databases provided by Environmental Protection Agency (USEPA); Moreover, the model was coupled with meteorological information from the latest generation WRF model. The modeling results estimated that the dispersion of particles from the tailings dam can contribute up to 10.15 µg/m3 of PM10 to the air quality of the site, which, according to the characterization of the samples obtained, could be dangerous for human health and can be estimated up to a concentration of 0.04 µg/m3 of Pb and 10.90 ng/m3 of As. It is very important to make this kind of research to know the risk which people around this disposal sites are exposed to.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nowadays, the necessity to manufacture products to satisfy human needs, whose essential elements are metals, has increased (Armienta et al., 2016; Xiaolong et al., 2021). In Mexico, mining has belonged to the main economic activities since colonial times and has currently contributed significantly to economic development. Mainly extracting: silver, gold, copper, zinc, and lead. However, this activity affects the environment and generates considerable amounts of waste. Mine tailings (or “jales”, as they are known in Mexico), refer to the materials that are left over after the valuable substances have been removed at the end of mining or mineral processing. They are the primary residues produced in the metal extraction process, they contain significant concentrations of potentially toxic metals and metalloids (Corrales-Pérez & Romero, 2013; Dótor-Almazán et al., 2017; Zúñiga-Vázquez et al., 2018). Tailings may contain Ni, Cu, Fe, Zn, and Pb, in relatively high concentrations (0.5 to 3%) and sometimes Ag and Au. However, these residues can also contain potentially toxic elements, such as arsenic, in concentrations of up to 100 mg/kg. (Ceniceros-Gómez et al., 2018; Falagán et al., 2017).

Historically, tailings were frequently placed in convenient areas, occasionally even in rivers or drainage systems (Ritcey, 2005; Vick, 1990). Currently, a range of approaches has been devised to handle mining waste. These approaches encompass the placement of dehydrated or thickened tailings in self-supporting deposits or stockpiles, their application as fill material in underground and open-pit mines, subaqueous disposal, and the prevailing method, which entails depositing tailings in open air dams (Carrillo López et al., 2016). In Mexico, mine tailings deposits principally are carried out in piles, depending on the type of mineral and the applicable environmental regulation. However, it is important to note that the construction of new tailings dams is currently regulated and restricted due to the environmental risks they pose (SEMARNAT, 2003). Managing mine tailings is not easy and represents trouble because the piles that contain them can have problems from the dispersion of material, have structural failures, cause spills and generate acid drainage the disposal is done in open-air conditions (Hudson-Edwards, 2016; Kossoff et al., 2014; Loredo-Portales et al., 2020). Sometimes these mining piles are abandoned and the dispersion of tailings is favored, either by hydraulic or wind processes (Loredo-Portales et al., 2020; Sánchez-Donoso et al., 2019).

One of the leading environmental problems in Mexico is the lousy management of tailings due to mining being one of the principal economic activities since colonial time (García et al., 2017; Meza-Figueroa et al., 2009; Suter, 2016). During the windy season, the dispersion of the particles in the environment can be seen with the naked eye. According to literature, it is known that mining tailings are very fine-grained. The consist of particles ranging from sizes of 1–600 μm; so they can be classified according to aerodynamic diameter: PM2.5 and PM10 (less than 2.5 µm and less than 10 µm respectively), based on their respective health impacts (Ceniceros-Gómez et al., 2018; World Health Organization, 2013).

Carrying out an impact assessment on the surrounding areas of a mining site, as well as the surrounding ecosystems and human settlements, it is complicated since assessing of risks to human health is needed. (Corrales-Pérez & Romero, 2013; Kossoff et al., 2014; Solà et al., 2004). However, a first approximation of the site’s dangerousness could be made based on the characterization of the particulate matter from tailings using different analytical techniques and determining the total concentrations of potentially toxic elements and comparing them with the maximum permissible limits established by governmental or international organizations (Gavilán-García et al., 2020; Loredo-Portales et al., 2020; Salas Urviola et al., 2020a, 2020b). Dispersion modeling of tailings’ particles into the air can be done by having the availability of data and representative inventories of particle emissions that are essential for an environmental risk assessment and provide the basis for the analysis of the environmental fate of these tailings’ emissions (Richardson et al., 2019a, 2019b). For this reason, to estimate the emission factors, the following equation can be used (“Emission Factors for Air Pollutants Related to Mining and Mineral Processing,” 2016).

where

- \({\mathrm{PME}}_{\mathrm{process}} =\):

-

particulate matter emissions for a given process, lbs or kg.

- \({\mathrm{PMEF}}_{\mathrm{process}} =\):

-

particulate matter emission factor for a given process; lbs unit−1 or kg unit.−1

- \({\mathrm{Unit}}_{\mathrm{process}} =\):

-

tons (processed, produced, charged, transferred), miles traveled, kg solvent used, etc.

- \(\mathrm{EC}\):

-

= emission control factor, %

This work aims to evaluate the danger of tailings belonging to an active mine in Mexico through its tailings characterization and dispersion modelling of particles present in them, so that in subsequent studies, a treatment of these residues can be proposed to mitigate environmental and health damage. With the information obtained from this research, it is intended to be beneficial to the environmental regulatory entity of Mexico, the academy and the environment.

Materials and methods

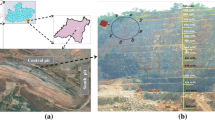

Samples

Ten samples of mining wastes were obtained following the NMX-AA-132-SCFI-2006 procedure (Secretaría de Economía, 2006). The sampling was superficial in an area of approximately 15 ha. Samples were taken at a depth of 10 cm, and approximately 5 kg of wastes were collected and stored in plastic bags (Figure S1, Supplementary Materials).

Characterization of samples

pH and humidity

The pH was determined at each point using the Corning pH-30 Sensor equipment, and deionized water was used throughout. The collected samples were then transferred in polyethylene bags and stored at 4 °C in a cold room of the laboratory of Sanitary and Environment Engineering of Engineering Faculty of the UNAM. The humidity was later determined following the European standard UNE-EN ISO 17892–1 (BS EN ISO 17892–1:2014, 2004).

Size of the particles and chemical characterization

Afterward, physical properties of the samples were determined: granulometry using the UNE-EN 933–1 standard (BS EN 933–1:2012, 2012) and particle size using the Philips XL20 scanning electron microscope to 20 kV of power with a 4-mm spot and BSE detectors (electro scattered electrons) located in the materials laboratory of the Mechanical and Electrical Engineering Division (DIMEI) of the Faculty of Engineering, UNAM. For the chemical and structural properties, a punctual elemental analysis was carried out using an Oxford microprobe with 10 mm glass and Inca SL-20 software which is in the aforementioned laboratory. The composition of samples was determined employing the Infrared technique (FTIR), the analysis was carried out in Laboratory of Environmental Molecular Geochemistry of Institute of Geology, UNAM with a Thermo Scientific Nicolet iS10 brand FTIR spectrometer using a GladiATR accessory with a diamond crystal under the entire mid-infrared range (400–4000 cm−1). The reading of the samples consisted of 64 scans with a resolution of 4 cm−1, applying a background at the beginning of each analysis. All the samples were analyzed in nitrogen (NUAP type) to ensure the absence of moisture and CO2.

Elemental characterization

To determine the total lead and arsenic concentration, digestion of the samples was carried out using a CEM microwave unit, model Mars 6.0. Ten milliliters of aqua regia (25% HNO3, Baker, 70% and 75% HCl, Baker, 36.5–38%) were added along with 0.5 g of sample in each tube of the microwave. Then, for 20 min the temperature was increased until it reached 200 °C and was held for another 15 min. Samples were then left to cool for 10 min and filtered with a nylon membrane with a pore size of 45 microns.

As and Pb were determined in digests using a GBC AVANTA atomic absorption spectrophotometer equipped with a GBC HG 3000 peristaltic pump. The concentrations in digests and extracts were determined using Hydride Generation-Atomic Absorption Spectroscopy for As and Flame Atomic Absorption Spectroscopy for Pb, following the methodology described in literature (Environmental Protection Agency, 1994, 2007; García et al., 2017). For all the solutions de-ionized water 18 MΩ cm, Millipore Milli-Q system were used. Moreover, two calibration curves were prepared, one for As and one for Pb with a concentration range of 5 to 50 ng/L and 5 to 30 mg/L respectively. All samples were analyzed by triplicate.

Air dispersion model

A dispersion air quality model was used to evaluate the impact of the mining tailings in the zone. The primary data in air quality systems are information of topography, meteorology, and pollutant emissions (González-Rocha et al., 2015). In the following section, these variables are described. To predict and model airborne concentrations of suspended particulate matter, AERMOD has been the dispersion model with promising results (Tartakovsky et al., 2013).

Wind direction

Due to the scarce meteorological information in the study area, it was decided to obtain the data through a meteorological model. The data obtained was input for the Weather Research and Forecasting (WRF) model. The results identified in the direction and speed of the wind (Figure S2, Supplementary Materials), showing the wind rose representative of the study area. The dominant wind direction comes from the northeast, with 31.5% of the frequency with maximum speeds of 11 m/s. According to the modeled database, the average wind speed is 3.69 m/s, and the calms are below 1.91% of the data.

AERMOD

AERMOD View (paid software) version 10 with the model code for AERMOD Version 22,112 (US EPA). The supplier company is Lakes Software. AERMOD is an air quality modeling system developed in the USA by the AMS and the EPA (American Meteorological Society and the Environmental Protection Agency EPA, respectively) (Kumar et al., 2016). The Gaussian dispersion model (Tran et al., 2019) contains building downwash algorithms and advanced meteorological calculations(Kalhor & Bajoghli, 2017). One of the most important characteristics of the model is that it can execute with real or estimated meteorological information (USEPA, 2018).

Additionally, the model can estimate the concentration of air pollutants: (1) the outputs of the model are 1-h average concentrations (Pandey & Sharan, 2019), (2) and the recommendation that it applies to study areas less than 50 km from the source (Mokhtar et al., 2014). The software requires meteorological and terrain inputs through two preprocessors, AERMET and AERMAP.

Regarding meteorology, the modeling system considers variables such as temperature, dew point, pressure, solar radiation (O’Shaughnessy & Altmaier, 2011), wind speed, wind direction, total and low cloud cover, convective velocity scale, temperature scale, mixing height, and surface heat flux (Ma et al., 2013). The preprocessor results are directly introduced to AERMOD (Huang & Guo, 2019). AERMOD is compatible with many weather models which can ease predicting the particle dispersion (Seangkiatiyuth et al., 2011).

Given that the terrain is complex in the area of study, AERMOD calculates the concentrations and simulates a plume as a sum horizontally and vertically, taking into account the different elevations in the area (Zou et al., 2010). The database with the best resolution was obtained from the U.S. Geological Survey (USGS), while the digital model used was the Shuttle Radar Topography Mission (SRTM) with a resolution of 30 m.

In the case of the receptors used for calculating concentrations, a 50 × 50-km grid with 0.5 km of spacing (de Ferreyro Monticelli et al., 2020) generating a total of 10,201 receptors is considered to estimate the airborne pollutants in the area. Having as a reference point the following UTM coordinate (Zone 14): 459,922.05 m N, 2,292,568.0 m E.

Surface and vertical weather data can be obtained from meteorological stations near the study area. However, in Mexico and other countries, there are regions where it takes more work to install and operate weather stations to obtain surface and vertical weather information. Therefore, it is essential to generate databases, protocols, guides, standards, and indexes to improve the accuracy of models and the diagnosis that would enhance air quality management (Mendoza-Lara et al., 2021).

In the present work, weather stations are distant, and their data may not be representative. Therefore, WRF was used, a state-of-the-art mesoscale numerical weather prediction model designed for both atmospheric research and operational forecasting applications. This model helps attach weather parameters required for air quality models (Kesarkar et al., 2007).

WRF modeling results were coupled using Mesoscale Model Interface (MMIF) developed by USEPA. Table 1 shows the parameters used in weather modeling.

Results and discussions

Mining tailings characterization

pH and humidity

The pH and humidity are shown in Figure S3 and S4, Supplementary Materials. The samples have a slightly neutral-alkaline pH, this may be due to the fact that there are minerals with neutralization capacity such as carbonates and a low concentration of acid-forming components such as pyrites (Armienta et al., 2004; Corona Sánchez et al., 2021; Espinosa et al., 2009). Due to these values, it can be said that there is also a low mobility towards aquifers of dangerous toxic elements because it is necessary to have acid conditions in the environment for this to happen (Salas-Luevano et al., 2021; Salas Urviola et al., 2020a, 2020b). It should be noted that the survey was carried out from the top to the base of the dam (Figure S1), beginning with point z-1 and as the numbering increases, it is closer to the base with point z-10. The average humidity of the site is 8% and there is greater humidity at point z-3 because it is the point of deposit of new tailings, and they come out in the form of sludge. However, over time the tailings dry up due to the environmental conditions of the site and become a loose, dry, and sandy form that is very easy to disperse in the air as it is the case at points of z-6 to z-8 with the lowest humidity, where at first sight the tailings were found in that way (Figure S5, Supplementary Materials).

Size of the particles and chemical characterization

The minimum opening in sieving by the mechanical method was 37 microns, finding that the largest particle size was 0.92 mm (Fig. 1). As shown in Fig. 1, between 0.5 and 1% of the samples have a size smaller than 37 microns. Given the very small measurement of the particles, size was determined using the scanning electron microscope (SEM) (Fig. 2). Due to the above, it is very likely that the particles enter into the body. Those that are smaller than 100 microns form aerosols when they are suspended in the air and can be inhaled. Given the particle size, all the samples can form aerosols. The sample z-3 which has the highest probability of forming it because 69% of its composition has a smaller size than 100 microns (Gavilán-García et al., 2020). In addition, when they measure less than 10 microns, they can be accumulated in the respiratory system and cause physical damage if they are insoluble and toxicity if they are solubilized, especially breathable particles (< 4 microns) which can pass into the bloodstream (Gavilán-García et al., 2020; Puga et al., 2006).

As we can see in Fig. 2, the different shades of gray can be observed, which indicates different densities between the particles for which, a qualitative chemical analysis was carried out. Making a spot in different areas of the samples (Table 2) and finding that the dark parts are made up of silicates (SiO4) and carbonates (CO3) which are the least dense. The white parts are made up mainly of pyrites with higher density. The existence of these phases was confirmed using the FTIR-ATR technique.

According to the Tables 2 and 3, there are potential toxic elements such as arsenic and lead present in the samples. Furthermore, in some samples where sulfur was detected, however, analyzing the contrast of the images, it is noted that the surrounding particles that contain this element are mostly carbonates (calcite, magnesite, smithsonite, principally), so in the presence of water, they can neutralize to sulfuric acid generated by sulfur and thus avoiding the formation of acid drainage and the leaching of toxic metals, which is also justified with the pH values obtained (García et al., 2017; Salas Urviola et al., 2020a, 2020b).

According to various standards (World Health Organization, WHO; Environment Protection Agency, EPA and Mexican legislation (NOM-147-SEMARNAT/SSA1-2004))(Semarnat, 2007; US EPA, 2022; Guidelines for drinking-water quality, 2022), considered for residential land use, the concentration of As and Pb in all samples is higher than the allowable maximum limit (AML) (Fig. 3). For industrial land use, the AML of WHO and EPA legislation for As is exceeded, while for Mexican legislation with a value of 260 ppm, some samples exceeded the limit, except for z-1, z-2, z-5, z-8, and z-10. All samples considered for industrial land use exceed the AML established by the three different legislations for Pb, except for sample z-8, which meets the limits established by EPA and Mexican legislation. The literature suggests that due to the measured particle size, both As and Pb can cause harm to the population and the environment through direct inhalation of the tailings. However, the measured pH values and sample characterization suggest that the abundance of carbonates and the basic pH of the samples will result in low dilution of both As and Pb in bodies of water, forming insoluble species and not generating acid drainage (Armienta et al., 2016; Gavilán-García et al., 2020; Gavilán García et al., 2017 et al., 2017; Kossoff et al., 2014; Salas Urviola et al., 2020a, 2020b).

AERMOD modeling

WRF and MMIF coupled data generated a single grid cell (12 km) representative of the entire domain. Modeling took into account each hour and variable in a whole year (2018). The generated surface and vertical meteorology files were input into AERMOD to estimate the dispersion of air pollutant emissions from mining tailings. With the application of the AERMOD model, the distribution of PM10 (plume forecast) over the urban area was obtained (Jayadipraja et al., 2020).

The digital elevation model is represented in Figure S6, Supplementary Materials, and the mesh was used to calculate the number of receptors considering a spacing of 0.5 km. The final number of receptors in the study area was 10,201. With the help of the AERMAP module, the images were generated.

According to the emission factors, the WRF meteorology, and the 365-day modeling for the year 2018; the estimated impact on air quality by PM10, Pb, and As was generated for the study area. These values are shown in Table 4. Pb and As concentrations were estimated based on the highest concentrations measured in samples from mining tailings. Regarding the maximum permissible limits allowed for Pb and As concentrations in PM10 particles, AML was searched both in the Mexican regulations, as well as in the USEPA and in the World Health Organization (WHO), and no limits for As were found. For this reason, it was decided to use the values established in the European Union. The calculated values are compared with the thresholds recommended by Europe Union Air Quality Standards (EU AQS). Figure 4 shows the concentrations for the worst modeled scenario, the maximum average concentration (24-h) of PM10 is close to the study area.

Considering the direction and speed of the wind as well as the concentrations of the particles, the dispersion cloud travels to the opposite side of the highest concentration of human settlements. However, there is an impact on the population. According to the estimation of the concentration of the particles from the dispersion model, it was calculated that this site could contribute up to 10.15 μg/m3 of particles to the air quality of the zone.

Other emission sources are not considered; however, in the study area, other companies are engaged in mining, generating tailings exposed to dispersion.

Since the study area is characterized by its mining activity and the wind direction coming from the northeast, the particles generated by the different activities and mining processes can be dispersed and deposited in human settlements.

The study area does not have an air quality monitoring system; however, monitoring and measurements of TSP, PM2.5, and PM10 concentrations in the air have been carried out. For PM10, 70 samples were measured and collected at five sites during February–March 2017. The range of measurements for PM10 was 23.6 to 80.1 µg/m3 (Corona Sánchez et al., 2021). This data suggests that if we take the 99th percentile (5.36 µg/m3) concentration of the study area and compare it with the maximum value monitored (80.1 µg/m3), it contributes 6.69% to the air quality levels at the site.

According to the results of the meteorological modeling with WRF, the AERMOD air quality modeling system (365 days of the year 2018), and the emission factors of particles (wind erosion), it is estimated that the study area (mining activity) generates an impact on air quality due to the dispersion of PM10 with airborne concentrations of 0.28 µg/m3 annual average (24 h), 5.36 µg/m3 for the 99th percentile (24 h) and 10.15 µg/m3 the maximum concentration (24 h). Compared to the Mexican Standard Levels, it represents 0.70, 7.15, and 10.15% of the threshold, respectively.

It is essential to mention the practical implications and difficulties of air quality modeling (Huertas et al., 2012), for example, when there is no air quality monitoring system.

Conclusions

This research evaluated the exposure to the population and the danger of tailings belonging to an active mine in Mexico through the characterization of its tailings and using a dispersion model. The modeling results estimated that the dispersion of particles from the tailings dam can contribute up to 10.15 µg/m3 of PM10 to the air quality of the site, which, according to the characterization of the samples obtained, it could be dangerous for human health and due to estimated concentration superior of 0.04 µg/m3 of Pb and 10.90 ng/m3 of As. In this way it is recommended that different treatments be applied to the tailings in order to mitigate potential emissions.

It is suggested that in the urban area, the installation of an air quality monitoring station be promoted, specifically for particles (PM10 and PM2.5). In addition, it is recommended to carry out particle monitoring for at least 1 year in the study area to analyze the concentrations of these atmospheric pollutants and take biological samples to analyze the concentrations of Pb and As.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Armienta, M. A., Talavera Mendoza, O., Villasenor, G., Espinosa, E., Pérez-Martínez, I., Cruz, O., Ceniceros, N., & Aguayo, A. (2004). Environmental behaviour of metals from tailings in shallow rivers: Taxco, central Mexico. Transactions of the Institution of Mining and Metallurgy, Section B: Applied Earth Science, 113(1). https://doi.org/10.1179/037174504225004510.

Armienta, M. A., Mugica, V., Reséndiz, I., & Arzaluz, M. G. (2016). Arsenic and metals mobility in soils impacted by tailings at Zimapán, México. Journal of Soils and Sediments. https://doi.org/10.1007/s11368-015-1244-x.

BS EN 933–1:2012. (2012). Tests for geometrical properties of aggregates Part 1 : Determination of particle size distribution — sieving method BS EN 933–1:2012. In International standard (Vol. 3, Issue 1). https://bsol.bsigroup.com/en/Bsol-Item-Detail-Page/?pid=000000000030117183. Accessed 18 June 2023

CEN. (2004). ISO/TS 17892-1: Geotechnical investigation and testing - Laboratory testing of soil - Part 1: Determination of water content. Nederlands Normalisatie-Instituut, 1–6.

Carrillo López, A., Carrillo López, K. Y., & Laborín Moreno, J. A. (2016). Diseño y evaluación de presas de jales [Universidad de Sonora]. http://www.repositorioinstitucional.uson.mx/handle/20.500.12984/1773. Accessed 18 June 2023.

Ceniceros-Gómez, A. E., Macías-Macías, K. Y., de la Cruz-Moreno, J. E., Gutiérrez-Ruiz, M. E., & Martínez-Jardines, L. G. (2018). Characterization of mining tailings in México for the possible recovery of strategic elements. Journal of South American Earth Sciences, 88, 72–79. https://doi.org/10.1016/j.jsames.2018.08.013

Corona Sánchez, J. E., González Chávez, M. del C. A., Carrillo González, R., Scheckel, K., Tapia Maruri, D., & García Cue, J. L. (2021a). Metal(loid) bioaccessibility of atmospheric particulate matter from mine tailings at Zimapan, Mexico. Environmental Science and Pollution Research, 28(15), 19458–19472.https://doi.org/10.1007/s11356-020-11887-6.

Corrales-Pérez, D., & Romero, F. M. (2013). Evaluacion de la peligrosidad de jales de zonas mineras de nicaragua y mexico y alternativas de solucion. Boletin de La Sociedad Geologica Mexicana, 65(3), 427–446. https://doi.org/10.18268/BSGM2013v65n3a1.

de Ferreyro Monticelli, D., Santos, J. M., Dourado, H. O., Moreira, D. M., & Reis, N. C. (2020). Assessing particle dry deposition in an urban environment by using dispersion models. Atmospheric Pollution Research, 11(1), 1–10. https://doi.org/10.1016/j.apr.2019.07.010

Dótor-Almazán, A., Armienta-Hernández, M. A., Talavera-Mendoza, O., & Ruiz, J. (2017). Geochemical behavior of Cu and sulfur isotopes in the tropical mining region of Taxco, Guerrero (southern Mexico). Chemical Geology, 471, 1–12. https://doi.org/10.1016/j.chemgeo.2017.09.005

Emission Factors for Air Pollutants Related to Mining and Mineral Processing. (2016). In Environmental Impact of Mining and Mineral Processing (pp. 271–297). Elsevier. https://doi.org/10.1016/b978-0-12-804040-9.15001-6

Environmental Protection Agency. (1994). Method 7062. Antimony and arsenic (atomic absorption, borohydride reduction) (Issue 1990). https://www.epa.gov/sites/production/files/2015-12/documents/7062.pdf. Accessed 18 June 2023

Environmental Protection Agency. (2007). METHOD7000b.FLAME ATOMIC ABSORPTION SPECTROPHOTOMETRY. In Environmental Protection Agency (Vol. 3, Issue September). https://www.epa.gov/sites/production/files/2015-12/documents/7000b.pdf

Espinosa, E., Armienta, M. A., Cruz, O., Aguayo, A., & Ceniceros, N. (2009). Geochemical distribution of arsenic, cadmium, lead and zinc in river sediments affected by tailings in Zimapán, a historical polymetalic mining zone of México. Environmental Geology, 58(7), 1467–1477. https://doi.org/10.1007/s00254-008-1649-6

Falagán, C., Grail, B. M., & Johnson, D. B. (2017). New approaches for extracting and recovering metals from mine tailings. Minerals Engineering, 106, 71–78. https://doi.org/10.1016/j.mineng.2016.10.008

García, I. C. G., Villagómez, G. F., Pérez, A. M., Torres, L. A. B., & García, A. G. (2017). Policy proposal for metals speciation in tailings contaminated soils: A case study in Chihuahua, Mexico. Journal of the Mexican Chemical Society, 61(1), 14–22.

Gavilán García, I. C., Fernández Villagómez, G., Menchaca Pérez, A., Barraza Torres, L. A., & Gavilán García, A. (2017). Policy proposal for metals speciation in tailings contaminated soils: a case study in Chihuahua, Mexico. Journal of the Mexican Chemical Society, 61(1). https://doi.org/10.29356/jmcs.v61i1.123

Gavilán-García, I. C., Ladino, L. A., Franco, E., & Juárez, J. (2020). Determination of factors involved in the assessment of potential risk of atmospheric dispersion and ingestion of mining tailings. Revista Internacional de Contaminacion Ambiental, 36(1), 127–138. https://doi.org/10.20937/RICA.2020.36.53384

González-Rocha, S. N., Mendoza-Lara, O. O., Fuentes-Gea, V., & Baldasano, J. M. (2015). Assessment of meteorological models for air pollution transport: Analysis between Mexico and Puebla Metropolitan Areas. A: 3rd BSC International Doctoral Symposium. Book of abstracts (pp. 46–48). Barcelona Supercomputing Center. Retrieved from: http://hdl.handle.net/2117/90391

Guidelines for drinking-water quality. (2022). Guidelines for drinking-water quality: Fourth edition incorporating the first and second addenda. https://www.ncbi.nlm.nih.gov/books/NBK579461/

Huang, D., & Guo, H. (2019). Dispersion modeling of odour, gases, and respirable dust using AERMOD for poultry and dairy barns in the Canadian Prairies. Science of the Total Environment, 690, 620–628. https://doi.org/10.1016/j.scitotenv.2019.07.010

Hudson-Edwards, K. (2016). Tackling mine wastes. In Science (Vol. 352, Issue 6283, pp. 288–290). American Association for the Advancement of Science. https://doi.org/10.1126/science.aaf3354

Huertas, J. I., Huertas, M. E., Izquierdo, S., & González, E. D. (2012). Air quality impact assessment of multiple open pit coal mines in northern Colombia. Journal of Environmental Management, 93(1), 121–129. https://doi.org/10.1016/j.jenvman.2011.08.007

Jayadipraja, E. A., Risky, S., Nofitasari, A., & Usman, A. N. (2020). The relationship between the cement emission stacks dispersion model using AERMOD and the lung capacity of the surrounding society. Enfermeria Clinica, 30, 494–498. https://doi.org/10.1016/j.enfcli.2019.07.146

Kalhor, M., & Bajoghli, M. (2017). Comparison of AERMOD, ADMS and ISC3 for incomplete upper air meteorological data (case study: Steel plant). Atmospheric Pollution Research, 8(6), 1203–1208. https://doi.org/10.1016/j.apr.2017.06.001

Kesarkar, A. P., Dalvi, M., Kaginalkar, A., & Ojha, A. (2007). Coupling of the weather research and forecasting model with AERMOD for pollutant dispersion modeling. A case study for PM10 dispersion over Pune, India. Atmospheric Environment, 41(9), 1976–1988. https://doi.org/10.1016/j.atmosenv.2006.10.042

Kossoff, D., Dubbin, W. E., Alfredsson, M., Edwards, S. J., Macklin, M. G., & Hudson-Edwards, K. A. (2014). Mine tailings dams: Characteristics, failure, environmental impacts, and remediation. In Applied Geochemistry (Vol. 51, pp. 229–245). Elsevier Ltd. https://doi.org/10.1016/j.apgeochem.2014.09.010

Kumar, A., Patil, R. S., Dikshit, A. K., Kumar, R., Brandt, J., & Hertel, O. (2016). Assessment of impact of unaccounted emission on ambient concentration using DEHM and AERMOD in combination with WRF. Atmospheric Environment, 142, 406–413. https://doi.org/10.1016/j.atmosenv.2016.08.024

Loredo-Portales, R., Bustamante-Arce, J., González-Villa, H. N., Moreno-Rodríguez, V., Del Rio-Salas, R., Molina-Freaner, F., González-Méndez, B., & Archundia-Peralta, D. (2020). Mobility and accessibility of Zn, Pb, and As in abandoned mine tailings of northwestern Mexico. Environmental Science and Pollution Research, 27(21), 26605–26620. https://doi.org/10.1007/s11356-020-09051-1

Ma, J., Yi, H., Tang, X., Zhang, Y., Xiang, Y., & Pu, L. (2013). Application of AERMOD on near future air quality simulation under the latest national emission control policy of China: A case study on an industrial city. Journal of Environmental Sciences (china), 25(8), 1608–1617. https://doi.org/10.1016/S1001-0742(12)60245-9

Mendoza-Lara, O. O., Arévalo-Mendoza, V., Villareal-Esquivel, C. G., Pérez-Castillo, A., & Morales-González, A. (2021). Evaluación del modelo meteorológico WRF para la validación del modelo AERMOD. Tecnología, Ciencia y Estudios Organizacionales, 3(5), 56–74. https://doi.org/10.56913/teceo.3.5.56-74

Meza-Figueroa, D., Maier, R. M., de la O-Villanueva, M., Gómez-Alvarez, A., Moreno-Zazueta, A., Rivera, J., Campillo, A., Grandlic, C. J., Anaya, R., & Palafox-Reyes, J. (2009). The impact of unconfined mine tailings in residential areas from a mining town in a semi-arid environment: Nacozari, Sonora, Mexico. Chemosphere, 77(1), 140–147.https://doi.org/10.1016/j.chemosphere.2009.04.068.

Mokhtar, M. M., Hassim, M. H., & Taib, R. M. (2014). Health risk assessment of emissions from a coal-fired power plant using AERMOD modelling. Process Safety and Environmental Protection, 92(5), 476–485. https://doi.org/10.1016/j.psep.2014.05.008

O’Shaughnessy, P. T., & Altmaier, R. (2011). Use of AERMOD to determine a hydrogen sulfide emission factor for swine operations by inverse modeling. Atmospheric Environment, 45(27), 4617–4625. https://doi.org/10.1016/j.atmosenv.2011.05.061

Pandey, G., & Sharan, M. (2019). Accountability of wind variability in AERMOD for computing concentrations in low wind conditions. Atmospheric Environment, 202, 105–116. https://doi.org/10.1016/j.atmosenv.2019.01.017

Puga, S., Sosa, M., Lebgue, T., Quintana, C., & Campos, A. (2006). Contaminación Por Metales Pesados En Suelo Provocada Por La Industria Minera. Ecología Aplicada, 5(1–2), 149. https://doi.org/10.21704/rea.v5i1-2.329.

Richardson, C., Rutherford, S., & Agranovski, I. (2019a). Particulate emission rates for open surfaces in Australian open cut black coal mines. Journal of Environmental Management, 232, 537–544. https://doi.org/10.1016/j.jenvman.2018.11.020

Richardson, C., Rutherford, S., & Agranovski, I. E. (2019b). Open cut black coal mining: Empirical verification of PM2.5 air emission estimation techniques. Atmospheric Research, 216, 151–159. https://doi.org/10.1016/j.atmosres.2018.10.008

Ritcey, G. M. (2005). Tailings management in gold plants. In Hydrometallurgy (Vol. 78, Issues 1–2 SPEC. ISS., pp. 3–20). https://doi.org/10.1016/j.hydromet.2005.01.001.

Salas Urviola, F. B., GuadarramaGuzmán, P., FernándezVillagómez, G., González Sánchez, J. F., & Barraza Torres, L. A. (2020). Predicción de drenaje ácido de mina, jales de la mina “la Prieta”, Chihuahua, México. Revista Internacional de Contaminación Ambiental, 36(4), 825–834. https://doi.org/10.20937/rica.53523

Salas Urviola, F. B., GuadarramaGuzmán, P., Gutiérrez Bazán, J. J., García Luna, N., FernándezVillagómez, G., & Alarcón Herrera, M. T. (2020). Determination of possible acid mine drainage and characterization of mine tailings from the cerro de mercado mine”, durango, Mexico. Revista Internacional de Contaminacion Ambiental, 36(3), 729–744. https://doi.org/10.20937/RICA.53461

Salas-Luevano, M. A., Puente-Cuevas, R., & Vega-Carrillo, H. R. (2021). Concentrations of heavy metals and measurement of 40K in mine tailings in Zacatecas, Mexico. Environmental Earth Sciences, 80(5). https://doi.org/10.1007/s12665-021-09460-6.

Sánchez-Donoso, R., Martín-Duque, J. F., Crespo, E., & Higueras, P. L. (2019). Tailing’s geomorphology of the San Quintín mining site (Spain): landform catalogue, aeolian erosion and environmental implications. Environmental Earth Sciences, 78(5). https://doi.org/10.1007/s12665-019-8148-9.

Seangkiatiyuth, K., Surapipith, V., Tantrakarnapa, K., & Lothongkum, A. W. (2011). Application of the AERMOD modeling system for environmental impact assessment of NO 2 emissions from a cement complex. Journal of Environmental Sciences, 23(6), 931–940. https://doi.org/10.1016/S1001-0742(10)60499-8

Secretaría de Economía. (2006). NMX-AA-132-SCFI-2016 Muestreo de suelos para la identificación y la cuantificación de metales y metaloides, y manejo de la muestra. Diario Oficial de la Federación.

SEMARNAT. (2003). Nom-141-Semarnat-2003. In Secretaria de Medio Ambiente y Recursos Naturales (pp. 1–52). 2003. https://www.profepa.gob.mx/innovaportal/file/1317/1/nom-141-semarnat-2003.pdf. Accessed 18 June 2023

SEMARNAT (2007). NOM-147-SEMARNAT/SSA1-2004, Que establece criterios para determinar las concentraciones de remediación de suelos contaminados por arsénico, bario, berilio, cadmio, cromo hexavalente, mercurio, níquel, plata, plomo, selenio, talio y/o vanadio. Diario Oficial de La Federación.

Solà, C., Burgos, M., Plazuelo, Á., Toja, J., Plans, M., & Prat, N. (2004). Heavy metal bioaccumulation and macroinvertebrate community changes in a Mediterranean stream affected by acid mine drainage and an accidental spill (Guadiamar River, SW Spain). Science of the Total Environment, 333(1–3), 109–126. https://doi.org/10.1016/j.scitotenv.2004.05.011

Suter, M. (2016). Early 19th century geologic studies of the Zimapán Region, central Mexico. Boletin de La Sociedad Geologica Mexicana, 68(2), 215–230. https://doi.org/10.18268/BSGM2016v68n2a4

Tartakovsky, D., Broday, D. M., & Stern, E. (2013). Evaluation of AERMOD and CALPUFF for predicting ambient concentrations of total suspended particulate matter (TSP) emissions from a quarry in complex terrain. Environmental Pollution, 179, 138–145. https://doi.org/10.1016/j.envpol.2013.04.023

Tran, Q. B., Lohitnavy, M., & Phenrat, T. (2019). Assessing potential hydrogen cyanide exposure from cyanide-contaminated mine tailing management practices in Thailand’s gold mining. Journal of Environmental Management, 249. https://doi.org/10.1016/j.jenvman.2019.109357.

US EPA. (2022). Regional Screening Levels (RSLs) - Generic Tables Tables as of: November 2022. United States Environmental Protection Agency. https://www.epa.gov/risk/regional-screening-levels-rsls-generic-tables. Accessed 18 June 2023.

USEPA. (2018). Guidance on the Use of the Mesoscale Model Interface Program (MMIF) for AERMOD Applications. | National Technical Reports Library - NTIS. https://ntrl.ntis.gov/NTRL/dashboard/searchResults/titleDetail/PB2018101097.xhtml. Accessed 18 June 2023

Vick, S. G. (1990). Planning, Design, and Analysis of Tailings Dams.https://doi.org/10.14288/1.0394902.

World Health Organization. (2013). Health effects of particulate matter: policy implications for countries in eastern Europe, Caucasus and central Asia. Journal of the Korean Medical Association, 50(2), 20. http://synapse.koreamed.org/DOIx.php?id=10.5124/jkma.2007.50.2.175. Accessed 18 June 2023

Xiaolong, Z., Shiyu, Z., Hui, L., & Yingliang, Z. (2021). Disposal of mine tailings via geopolymerization. In Journal of Cleaner Production (Vol. 284). Elsevier Ltd. https://doi.org/10.1016/j.jclepro.2020.124756.

Zou, B., Benjamin Zhan, F., Gaines Wilson, J., & Zeng, Y. (2010). Performance of AERMOD at different time scales. Simulation Modelling Practice and Theory, 18(5), 612–623. https://doi.org/10.1016/j.simpat.2010.01.005

Zúñiga-Vázquez, D., Armienta, M. A., Deng, Y., Cruz, O., Aguayo, A., & Ceniceros, N. (2018). Evaluation of fe, zn, pb, cd and as mobility from tailings by sequential extraction and experiments under imposed physico-chemical conditions. Geochemistry: Exploration, Environment, Analysis, 19(2), 129–137. https://doi.org/10.1144/geochem2018-041.

Acknowledgements

The authors thank the technical support provided by Ana E. Silva, Armando Ortiz, Mario A. Minor, Deyanira Rodriguez, Juana Fernanda Contreras, and Ulises Loredo.

Funding

The first author thanks to Dirección General de Asuntos del Personal Academico (DGAPA), by Universidad Nacional Autónoma de México (UNAM) for a posdoctoral grant.

Author information

Authors and Affiliations

Contributions

Jesús Fidel González-Sánchez: investigation, methodology, data curation, conceptualization, formal analysis, writing—original draft, writing—review and editing and project administration. Osiel O. Mendoza-Lara: data curation, data curation, writing—review and editing. Jorge Luis Romero-Hernández: writing—review and editing. Fernández-Villagómez: methodology, supervision, writing—review and editing, visualization, validation and funding acquisition, and project administration.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

González-Sánchez, J.F., Mendoza-Lara, O.O., Romero-Hernández, J.L. et al. Evaluation of the danger of a tailings pile belonging to an active mine through its characterization and a dispersion model. Environ Monit Assess 195, 889 (2023). https://doi.org/10.1007/s10661-023-11475-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10661-023-11475-4