Abstract

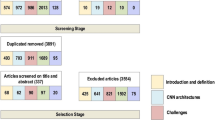

The technology of big data analysis and artificial intelligence deep learning has been actively cross-combined with various fields to increase the effect of its original low single field. Precision components commonly used in electronic products use changes in the conductivity of semiconductors to process information. This study aims to review key milestones and recent developments in the semiconductor industry using artificial intelligence methods. For this systematic review, we searched academic networks between 2015 and 2022, including Nature, Elsevier, Springer, Taylor & Francis Online, Multidisciplinary Digital Publishing Institute, and the Institute of Electrical and Electronics Engineers. The literature reviewed is based on conference proceedings and journal articles, specifically covering the key achievements of the discussion paper, the key technologies used, experimental results, opportunities, and future research pathways. After searching on an academic website, we selected six major studies. In five of these studies, visual object detection, surface defect detection, machine production scheduling application, fault diagnosis and prediction, and monitoring of the manufacturing process were made using artificial neural networks, machine learning methods, and hybrid models. In addition, the studies covered independent, single methods or used more than two types of technologies for performance comparison. Finally, we reviewed the strengths and weaknesses of the literature. We also analysed various datasets, acquisition systems, and experimental scenarios. The review shows that as the number of studies conducted in manufacturing continues to increase, more research is needed to unearth key information that is often overlooked, all of which are challenges in refining science and overcoming real-world scenarios.

Similar content being viewed by others

Data availability

Enquiries about data availability should be directed to the authors.

References

Kotsiopoulos, T., Sarigiannidis, P., Ioannidis, D., Tzovaras, D.: Machine learning and deep learning in smart manufacturing: the smart grid paradigm. Comput. Sci. Rev. 1(40), 100341 (2021)

Cheng, Q., Kwon, J., Glick, M., Bahadori, M., Carloni, L.P., Bergman, K.: Silicon photonics codesign for deep learning. Proc. IEEE. 108(8), 1261–1282 (2020)

Theis, T.N., Wong, H.S.: The end of Moore’s law: a new beginning for information technology. Comput. Sci. Eng. 19(2), 41–50 (2017)

Semiconductor industry association, state of the U.S. semiconductor industry. https://www.semiconductors.org/state-of-the-u-s-semiconductor-industry/ (2021)

Takiguchi, T., Takarada, Y., Fukada, T., Sugiyama, S., Yoshimura, K.: Lithography tool improvement at productivity and performance with data analysis and machine learning. InPhotomask Technology, vol. 11855, pp. 98–106. SPIE (2021)

Hamilton, J.A., Pugh, T., Johnson, A.L., Kingsley, A.J., Richards, S.P.: Cobalt(I) olefin complexes: precursors for metal-organic chemical vapor deposition of high purity cobalt metal thin films. Inorg. Chem. 55(14), 7141–7151 (2016)

Speransky, S.K., Rodionov, I.V., Speransky, K.S.: Modeling the process of physical vapor deposition. In: 2018 International Conference on Actual Problems of Electron Devices Engineering (APEDE), Sep 27 pp. 276–279. IEEE (2018)

Vishnu, T.V., Gupta, P., Malhotra, P., Vig, L., Shroff, G.: Recurrent neural networks for online remaining useful life estimation in ion mill etching system. In: Proceedings of the Annual Conference of the PHM Society, Philadelphia, Sep 22 vol. 22 (2018)

Chang, Y.F., Lee, H.J., Chou, F.H., Lee, S.C., Chung, Y.A., Lian, N.T., Han, T.T., Yang, T., Chen, K.C., Lu, C.Y.: Machine learning assists on high aspect ratio slit trench etching in 3D NAND. In: 2022 33rd annual SEMI Advanced Semiconductor Manufacturing Conference (ASMC), May 2 pp. 1–4. IEEE (2022)

Jia, X., Di, Y., Feng, J., Yang, Q., Dai, H., Lee, J.: Adaptive virtual metrology for semiconductor chemical mechanical planarization process using GMDH-type polynomial neural networks. J. Process Control. 62, 44–54 (2018)

Feng, C., Lan, X.: Material removal model of chemical mechanical polishing based on genetic algorithm and neural network optimization. In: 2022 IEEE 2nd International Conference on Mobile Networks and Wireless Communications (ICMNWC), Dec 2 pp. 1–5. IEEE (2022)

American congress government 116th Congress, Creating Helpful Incentives to Produce Semiconductors for America Act or the CHIPS for America Act. https://www.congress.gov/bill/116th-congress/senate-bill/3933 (2020)

Congress US. United States Innovation and Competition Act of 2021. In: S. 1260. 117th Congress, Passed Senate June vol. 8, p. 2021 (2021)

Zheng, X., Zheng, S., Kong, Y., Chen, J.: Recent advances in surface defect inspection of industrial products using deep learning techniques. Int. J. Adv. Manuf. Technol. 113(1), 35–58 (2021)

Wuest, T., Weimer, D., Irgens, C., Thoben, K.D.: Machine learning in manufacturing: advantages, challenges, and applications. Product. Manuf. Res. 4(1), 23–45 (2016)

Espadinha-Cruz, P., Godina, R., Rodrigues, E.M.: A review of data mining applications in semiconductor manufacturing. Processes. 9(2), 305 (2021)

Weichert, D., Link, P., Stoll, A., Rüping, S., Ihlenfeldt, S., Wrobel, S.: A review of machine learning for the optimization of production processes. Int. J. Adv. Manuf. Technol. 104(5), 1889–1902 (2019)

de la López, R., Sánchez-Reolid, R., Gómez-Sirvent, J.L., Morales, R.: A review on machine and deep learning for semiconductor defect classification in scanning electron microscope images. Appl. Sci. 11(20), 9508 (2021)

Batool, U., Shapiai, M.I., Tahir, M., Ismail, Z.H., Zakaria, N.J., Elfakharany, A.: A systematic review of deep learning for silicon wafer defect recognition. IEEE Access. 18(9), 116572–116593 (2021)

Sunny, F.P., Taheri, E., Nikdast, M., Pasricha, S.: A survey on silicon photonics for deep learning. ACM J. Emerging Technol. Comput. Syst. 17(4), 1–57 (2021)

Chen, P.C., Miao, W.C., Ahmed, T., Pan, Y.Y., Lin, C.L., Chen, S.C., Kuo, H.C., Tsui, B.Y., Lien, D.H.: Defect inspection techniques in SiC. Nanoscale Res. Lett. 17(1), 1–7 (2022)

Lingitz, L., Gallina, V., Ansari, F., Gyulai, D., Pfeiffer, A., Sihn, W., Monostori, L.: Lead time prediction using machine learning algorithms: a case study by a semiconductor manufacturer. Procedia Cirp. 1(72), 1051–1056 (2018)

Ademujimi, T.T., Brundage, M.P., Prabhu, V.V.: A review of current machine learning techniques used in manufacturing diagnosis. In: IFIP International Conference on Advances in Production Management Systems pp. 407–415. Springer, Cham Sep 3 (2017)

Fernandes, M., Corchado, J.M., Marreiros, G.: Machine learning techniques applied to mechanical fault diagnosis and fault prognosis in the context of real industrial manufacturing use-cases: a systematic literature review. Appl. Intell. 4, 1–35 (2022)

Wu, M.J., Jang, J.S., Chen, J.L.: Wafer map failure pattern recognition and similarity ranking for large-scale data sets. IEEE Trans. Semicond. Manuf. 28(1), 1–12 (2015)

Tabernik, D., Šela, S., Skvarč, J., Skočaj, D.: Segmentation-based deep-learning approach for surface-defect detection. J. Intell. Manuf. 31(3), 759–776 (2020)

Torres, J.A.: ICCAD-2012 CAD contest in fuzzy pattern matching for physicalverification and benchmark suite. In: Proceeding of the ICCAD, pp. 349–350 (2012)

Topaloglu, R.O.: ICCAD-2016 CAD contest in pattern classification for integrated circuit design space analysis and benchmark suite. In: Proceeding of the ICCAD, pp. 1–4 (2016)

Nakazawa, T., Kulkarni, D.V.: Wafer map defect pattern classification and image retrieval using convolutional neural network. IEEE Trans. Semicond. Manuf. 31(2), 309–314 (2018)

Lin, T.Y., Maire, M., Belongie, S., Hays, J., Perona, P., Ramanan, D., Dollár, P., Zitnick, C.L.: Microsoft COCO: common objects in context. In: Fleet, D., Pajdla, T., Schiele, B., Tuytelaars, T. (eds.) ECCV 2014. LNCS, vol. 8693, pp. 740–755. Springer, Cham. https://doi.org/10.1007/978-3-319-10602-1_48 (2014)

Nagwanshi, K., Sharma, V.: Dataset: defective photonic bandgap crystals using Finite Difference Time Domain (FDTD). IEEE DataPort. Available from: https://ieee-dataport.org/open-access/defective-photonic-bandgap-crystals-using-finite-difference-time-domain-fdtd (2020)

Ferguson, M., Ak, R., Lee, Y.T., Law, K.H.: Detection and segmentation of manufacturing defects with convolutional neural networks and transfer learning. arXiv preprint arXiv:1808.02518. Aug 7 (2018)

Dua, D.: UCI Machine Learning Repository. University of Califo, Irvine (2019)

Deng, L.: The MNIST database of handwritten digit images for machine learning research. IEEE Signal Process. Mag. 29(6), 141–142 (2012)

Deng, J., Dong, W., Socher, R., Li, L.J., Li, K., Fei-Fei, L.: Imagenet: a large-scale hierarchical image database. In: 2009 IEEE conference on computer vision and pattern recognition. Jun 20 pp. 248–255. IEEE (2009)

Godwin, L.W., Brown, D., Livingston, R., Webb, T., Karriem, L., et al.: Open-source automated chemical vapor deposition system for the production of two-dimensional nanomaterials. PLoS ONE (2019). https://doi.org/10.1371/journal.pone.0210817

PHM Data Challenges.: The Prognostics and Health Management Society PHM Society, https://drive.google.com/file/d/15Jx9Scq9FqpIGn8jbAQB_lcHSXvIoPzb/view/ (2018)

Yuting, S., Hongxing, L.: A deep learning based dislocation detection method for cylindrical silicon growth process. Appl. Intell. 5, 1–6 (2022)

Houben, T., Huisman, T., Pisarenco, M., van der Sommen, F.: Depth estimation from a single SEM image using pixel-wise fine-tuning with multimodal data. Mach. Vis. Appl. 33(4), 1–6 (2022)

Pan, Y., Liao, H., Li, J., Liu, X., Zhu, W.: Improved image processing algorithms for microprobe final test. IEEE Trans. Compon. Pack. Manuf. Technol. 8(3), 499–505 (2018)

Qin, M., Shi, Z., Chen, W., Gao, S., Shi, L.: Wafer defect inspection optimization with partial coverage: a numerical approach. IEEE Trans. Autom. Sci. Eng. 18(4), 1916–1927 (2020)

Xu, J., Hu, H., Lei, Y., Liu, H.: A wafer prealignment algorithm based on Fourier transform and least square regression. IEEE Trans. Autom. Sci. Eng. 14(4), 1771–1777 (2017)

Meng, Y., Kim, Y.C., Guo, S., Shu, Z., Zhang, Y., Liu, Q.: Machine learning models for edge placement error based etch bias. IEEE Trans. Semicond. Manuf. 34(1), 42–48 (2020)

Hsu, P.N., Shie, K.C., Chen, K.P., Tu, J.C., Wu, C.C., Tsou, N.T., Lo, Y.C., Chen, N.Y., Hsieh, Y.F., Wu, M., Chen, C.: Artificial intelligence deep learning for 3D IC reliability prediction. Sci. Rep. 12(1), 1–7 (2022)

Shao, H.C., Peng, C.Y., Wu, J.R., Lin, C.W., Fang, S.Y., Tsai, P.Y., Liu, Y.H.: From IC layout to die photograph: a CNN-based data-driven approach. IEEE Trans. Comput.-Aided Des. Integr. Circuits Syst. 40(5), 957–970 (2020)

Geng, H., Yang, H., Zhang, L., Miao, J., Yang, F., Zeng, X., Yu, B.: Hotspot detection via attention-based deep layout metric learning. In: Proceedings of the 39th International Conference on Computer-Aided Design pp. 1–8 Nov 2 (2020)

Yang, H., Su, J., Zou, Y., Yu, B., Young, E.F.: Layout hotspot detection with feature tensor generation and deep biased learning. IEEE TCAD 38(6), 1175–1187 (2019)

Jiang, Y., Yang, F., Zhu, H., Yu, B., Zhou, D., Zeng, X.: Efficient layout hotspot detection via binarized residual neural network. In: Proceeding of the DAC, pp. 1–6 (2019)

Chen, Y., Lin, Y., Gai, T., Su, Y., Wei, Y., Pan, D.Z.: Semi-supervised hotspot detection with self-paced multi-task learning. In: Proceeding of the ASPDAC, pp. 420–425 (2019)

Chen, J., Lin, Y., Guo, Y., Zhang, M., Alawieh, M.B., Pan, D.Z.: Lithography hotspot detection using a double inception module architecture. JM3 18(1), 013507 (2019)

Ji, B., Ameri, F., Choi, J., Cho, H.: Hybrid approach using ontology-supported case-based reasoning and machine learning for defect rate prediction. In: IFIP International Conference on Advances in Production Management Systems pp. 291–298. Springer, Cham (2019) Sep 1

Cheng, K.C., Li, K.S., Huang, A.Y., Li, J.W., Chen, L.L., Tsai, N.C., Wang, S.J., Lee, C.S., Chou, L., Liao, P.Y., Liang, H.C.: Wafer-level test path pattern recognition and test characteristics for test-induced defect diagnosis. In 2020 Design, Automation and Test in Europe Conference and Exhibition (DATE) pp. 1710–1711. IEEE Mar 9 (2020)

López de la Rosa, F., Gómez-Sirvent, J.L., Kofler, C., Morales, R., Fernández-Caballero, A.: Detection of Unknown defects in semiconductor materials from a hybrid deep and machine learning approach. In: International Work-Conference on the Interplay Between Natural and Artificial Computation pp. 356–365. Springer, Cham (2022)

Taha, K.: An effective approach for associating the sources of defect signatures to process zones. IEEE Trans. Semicond. Manuf. 30(2), 176–184 (2017)

Wang, J., Yu, Z., Duan, Z., Lu, G.: A sub-region one-to-one mapping (SOM) detection algorithm for glass passivation parts wafer surface low-contrast texture defects. Multimedia Tools Appl. 80(19), 28879–28896 (2021)

Fan, S.K., Hsu, C.Y., Jen, C.H., Chen, K.L., Juan, L.T.: Defective wafer detection using a denoising autoencoder for semiconductor manufacturing processes. Adv. Eng. Inform. 1(46), 101166 (2020)

Yu, W., Zhang, Y., Shi, H.: Surface Defect inspection under a small training set condition. In: International Conference on Intelligent Robotics and Applications pp. 517–528. Springer, Cham Aug 8 (2019)

Park, Y., Kang, K., Kim, S.: A visual inspection method based on periodic feature for wheel mark defect on wafer backside. In: International Conference on Computer Analysis of Images and Patterns pp. 219–D227. Springer, Cham Aug 22 (2017)

Zhang, W., Qiao, T., Pang, Y., Yang, Y., Chen, H., Hao, G.: A novel defect diagnosis method for Kyropoulos process-based sapphire growth. IEEE Sens. J. 20(10), 5435–5441 (2020)

Mannodi-Kanakkithodi, A., Xiang, X., Jacoby, L., Biegaj, R., Dunham, S.T., Gamelin, D.R., Chan, M.K.: Universal machine learning framework for defect predictions in zinc blende semiconductors. Patterns 3(3), 100450 (2022)

Nagamura, Y., Ide, T., Arai, M., Fukumoto, S.: CNN-based layout segment classification for analysis of layout-induced failures. IEEE Trans. Semicond. Manuf. 33(4), 597–605 (2020)

Kang, D., Han, Y., Zhu, J., Lai, J.: An axially decomposed self-attention network for the precise segmentation of surface defects on printed circuit boards. Neural Comput. Appl. 5, 1–6 (2022)

Lu, H.P., Su, C.T.: CNNs combined with a conditional GAN for mura defect classification in TFT-LCDs. IEEE Trans. Semicond. Manuf. 34(1), 25–33 (2021)

Lu, H.P., Su, C.T., Yang, S.Y., Lin, Y.P.: Combination of convolutional and generative adversarial networks for defect image demoiréing of thin-film transistor liquid-crystal display image. IEEE Trans. Semicond. Manuf. 33(3), 413–423 (2020)

Arena, S., Bodrov, Y., Carletti, M., Gentner, N., Maggipinto, M., Yang, Y., Beghi, A., Kyek, A., Susto, G.A.: Exploiting 2D coordinates as Bayesian priors for deep learning defect classification of SEM images. IEEE Trans. Semicond. Manuf. 34(3), 436–439 (2021)

O’Leary, J., Sawlani, K., Mesbah, A.: Deep learning for classification of the chemical composition of particle defects on semiconductor wafers. IEEE Trans. Semicond. Manuf. 33(1), 72–85 (2020)

Imoto, K., Nakai, T., Ike, T., Haruki, K., Sato, Y.: A CNN-based transfer learning method for defect classification in semiconductor manufacturing. In: 2018 international symposium on semiconductor manufacturing (ISSM) pp. 1–3. IEEE Dec 10 (2018)

Wen, G., Gao, Z., Cai, Q., Wang, Y., Mei, S.: A novel method based on deep convolutional neural networks for wafer semiconductor surface defect inspection. IEEE Trans. Instrum. Measure. 69(12), 9668–9680 (2020)

Kim, E.S., Choi, S.H., Lee, D.H., Kim, K.J., Bae, Y.M., Oh, Y.C.: An oversampling method for wafer map defect pattern classification considering small and imbalanced data. Comput. Ind. Eng. 1(162), 107767 (2021)

Cheon, S., Lee, H., Kim, C.O., Lee, S.H.: Convolutional neural network for wafer surface defect classification and the detection of unknown defect class. IEEE Trans. Semicond. Manuf. 32(2), 163–170 (2019)

Jang, C., Yun, S., Hwang, H., Shin, H., Kim, S., Park, Y.: A defect inspection method for machine vision using defect probability image with deep convolutional neural network. In: Asian Conference on Computer Vision pp. 142–154. Springer, Cham Dec 2 (2018)

Kim, J., Nam, Y., Kang, M.C., Kim, K., Hong, J., Lee, S., Kim, D.N.: Adversarial defect detection in semiconductor manufacturing process. IEEE Trans. Semicond. Manuf. 34(3), 365–371 (2021)

Kang, H., Kang, S.: A stacking ensemble classifier with handcrafted and convolutional features for wafer map pattern classification. Comput. Ind. 1(129), 103450 (2021)

Shim, J., Kang, S., Cho, S.: Active cluster annotation for wafer map pattern classification in semiconductor manufacturing. Expert Syst. Appl. 30(183), 115429 (2021)

Saqlain, M., Jargalsaikhan, B., Lee, J.Y.: A voting ensemble classifier for wafer map defect patterns identification in semiconductor manufacturing. IEEE Trans. Semicond. Manuf. 32(2), 171–182 (2019)

Wang, S., Zhong, Z., Zhao, Y., Zuo, L.: A variational autoencoder enhanced deep learning model for wafer defect imbalanced classification. IEEE Trans. Compon. Pack. Manuf. Technol. 11(12), 2055–2060 (2021)

Yu, J., Liu, J.: Two-dimensional principal component analysis-based convolutional autoencoder for wafer map defect detection. IEEE Trans. Ind. Electron. 68(9), 8789–8797 (2020)

Kyeong, K., Kim, H.: Classification of mixed-type defect patterns in wafer bin maps using convolutional neural networks. IEEE Trans. Semicond. Manuf. 31(3), 395–402 (2018)

Yoon, S., Kang, S.: Semi-automatic wafer map pattern classification with convolutional neural networks. Comput. Ind. Eng.. 1(166), 107977 (2022)

Kong, Y., Ni, D.: Recognition and location of mixed-type patterns in wafer bin maps. In: 2019 IEEE International Conference on Smart Manufacturing, Industrial & Logistics Engineering (SMILE) pp. 4–8. IEEE, Apr 20 (2019)

Tao, X., Gong, X., Zhang, X., Yan, S., Adak, C.: deep learning for unsupervised anomaly localization in industrial images: a survey. In: IEEE Transactions on Instrumentation and Measurement. Aug 4 (2022)

Shawon, A., Faruk, M.O., Habib, M.B., Khan, A.M.: Silicon wafer map defect classification using deep convolutional neural network with data augmentation. In: 2019 IEEE 5th International Conference on Computer and Communications (ICCC) pp. 1995–1999. IEEE Dec 6 (2019)

Jang, J., Seo, M., Kim, C.O.: Support weighted ensemble model for open set recognition of wafer map defects. IEEE Trans. Semicond. Manuf. 33(4), 635–643 (2020)

Wang, J., Xu, C., Yang, Z., Zhang, J., Li, X.: Deformable convolutional networks for efficient mixed-type wafer defect pattern recognition. IEEE Trans. Semicond. Manuf. 33(4), 587–596 (2020)

Zhang, Q., Zhang, Y., Li, J., Li, Y.: WDP-BNN: efficient wafer defect pattern classification via binarized neural network. Integration 1(85), 76–86 (2022)

Yu, N., Xu, Q., Wang, H.: Wafer defect pattern recognition and analysis based on convolutional neural network. IEEE Trans. Semicond. Manuf. 32(4), 566–573 (2019)

Yu, J., Liu, J.: Multiple granularities generative adversarial network for recognition of wafer map defects. IEEE Trans. Ind. Inform. 18(3), 1674–1683 (2021)

Yu, J., Shen, Z., Wang, S.: Wafer map defect recognition based on deep transfer learning-based densely connected convolutional network and deep forest. Eng. Appl. Artif. Intell. 1(105), 104387 (2021)

Wang, J., Yang, Z., Zhang, J., Zhang, Q., Chien, W.T.: AdaBalGAN: an improved generative adversarial network with imbalanced learning for wafer defective pattern recognition. IEEE Trans. Semicond. Manuf. 32(3), 310–319 (2019)

Yu, J., Li, S., Shen, Z., Wang, S., Liu, C., Li, Q.: Deep transfer Wasserstein adversarial network for wafer map defect recognition. Comput. Ind. Eng.. 1(161), 107679 (2021)

Kim, J.S., Jang, S.J., Kim, T.W., Lee, H.J., Lee, J.B.: A productivity-oriented wafer map optimization using yield model based on machine learning. IEEE Trans. Semicond. Manuf. 32(1), 39–47 (2018)

Park, I.B., Huh, J., Kim, J., Park, J.: A reinforcement learning approach to robust scheduling of semiconductor manufacturing facilities. IEEE Trans. Autom. Sci. Eng. 17(3), 1420–1431 (2019)

Nalbach, O., Linn, C., Derouet, M., Werth, D.: Predictive quality: towards a new understanding of quality assurance using machine learning tools. In: International Conference on Business Information Systems pp. 30–42. Springer, Cham, Jul 18 (2018)

Fang, X., Chang, C., Liu, G.: Using Bayesian network technology to predict the semiconductor manufacturing yield rate in IoT. J. Supercomput. 77(8), 9020–9045 (2021)

Chiu, C.C., Lai, C.M., Chen, C.M.: An evolutionary simulation-optimization approach for the problem of order allocation with flexible splitting rule in semiconductor assembly. Appl. Intell. 11, 1–23 (2022)

Wang, J., Zhang, J., Wang, X.: A data driven cycle time prediction with feature selection in a semiconductor wafer fabrication system. IEEE Trans. Semicond. Manuf. 31(1), 173–182 (2018)

Ren, J.C., Liu, D., Wan, Y.: Model-free adaptive iterative learning control method for the Czochralski silicon monocrystalline batch process. IEEE Trans. Semicond. Manuf. 34(3), 398–407 (2021)

Sakr, A.H., Aboelhassan, A., Yacout, S., Bassetto, S.: Simulation and deep reinforcement learning for adaptive dispatching in semiconductor manufacturing systems. J. Intell. Manuf. 8, 1–4 (2021)

Tsai, Y.C., Pang, J., Chou, F.D.: Modeling and scheduling for the clean operation of semiconductor manufacturing. In: International Symposium on Intelligence Computation and Applications pp. 488–496. Springer, Singapore. Nov 16 (2019)

Qiao, Y., Lu, Y., Li, J., Zhang, S., Wu, N., Liu, B.: An efficient binary integer programming model for residency time-constrained cluster tools with chamber cleaning requirements. In: IEEE Transactions on Automation Science and Engineering. Dec 8 (2021)

Yu, T.S., Kim, H.J., Lee, T.E.: Scheduling single-armed cluster tools with chamber cleaning operations. IEEE Trans. Autom. Sci. Eng. 15(2), 705–716 (2017)

Lee, T.G., Yu, T.S., Lee, T.E.: Cleaning plan optimization for dual-armed cluster tools with general chamber cleaning periods. In: IEEE Transactions on Automation Science and Engineering. Jul 13 (2022)

Kokyay, S., Kilinc, E., Uysal, F., Kurt, H., Celik, E., Dugenci, M.: A prediction model of artificial neural networks in development of thermoelectric materials with innovative approaches. Eng. Sci. Technol. Int. J. 23(6), 1476–1485 (2020)

Pugalenthi, K., Park, H., Raghavan, N.: Prognosis of power MOSFET resistance degradation trend using artificial neural network approach. Microelectron. Reliab. 1(100), 113467 (2019)

Chen, Y.J., Lee, Y.H., Chiu, M.C.: Construct an intelligent yield alert and diagnostic analysis system via data analysis: Empirical study of a semiconductor foundry. In: IFIP International Conference on Advances in Production Management Systems pp. 394-401. Springer, Cham, Aug 26 (2018)

Nuhu, A.A., Zeeshan, Q., Safaei, B., Shahzad, M.A.: Machine learning-based techniques for fault diagnosis in the semiconductor manufacturing process: a comparative study. J. Supercomput. 6, 1–51 (2022)

Hsieh, T.J.: A micro-view-based data mining approach to diagnose the aging status of heating coils. Knowl.-Based Syst. 1(143), 10–18 (2018)

Fan, S.K., Cheng, C.W., Tsai, D.M.: Fault diagnosis of wafer acceptance test and chip probing between front-end-of-line and back-end-of-line processes. In: IEEE Transactions on Automation Science and Engineering. Aug 31 (2021)

Fan, S.K., Hsu, C.Y., Tsai, D.M., He, F., Cheng, C.C.: Data-driven approach for fault detection and diagnostic in semiconductor manufacturing. IEEE Trans. Autom. Sci. Eng. 17(4), 1925–1936 (2020)

Zhakov, A., Zhu, H., Siegel, A., Rank, S., Schmidt, T., Fienhold, L., Hummel, S.: Application of ANN for fault detection in overhead transport systems for semiconductor fab. IEEE Trans. Semicond. Manuf. 33(3), 337–345 (2020)

Liu, C., Zhang, L., Li, J., Zheng, J., Wu, C.: Two-stage transfer learning for fault prognosis of ion mill etching process. IEEE Trans. Semicond. Manuf. 34(2), 185–193 (2021)

Ma, B., Cai, W., Han, Y., Yu, G.: A novel probability confidence CNN model and its application in mechanical fault diagnosis. IEEE Trans. Instrum. Measure. 6(70), 1–11 (2021)

Hu, B., Hu, Z., Ran, L., Ng, C., Jia, C., McKeever, P., Tavner, P.J., Zhang, C., Jiang, H., Mawby, P.A.: Heat-flux-based condition monitoring of multichip power modules using a two-stage neural network. IEEE Trans. Power Electron. 36(7), 7489–7500 (2020)

Zhou, H., Zhang, H., Yang, C., Sun, Y.: Deep learning based silicon content estimation in ironmaking process. IFAC-PapersOnLine 53(2), 10737–10742 (2020)

Huang, X., Zhou, Q., Zeng, L., Li, X.: Monitoring spatial uniformity of particle distributions in manufacturing processes using the K function. IEEE Trans. Autom. Sci. Eng. 14(2), 1031–1041 (2015)

Lee, H., Kim, Y., Kim, C.O.: A deep learning model for robust wafer fault monitoring with sensor measurement noise. IEEE Trans. Semicond. Manuf. 30(1), 23–31 (2016)

Hung, S.Y., Lee, C.Y., Lin, Y.L.: Data science for delamination prognosis and online batch learning in semiconductor assembly process. IEEE Trans. Compon. Pack. Manuf. Technol. 10(2), 314–324 (2019)

Zhang, J., Tang, Q., Liu, D.: Research into the LSTM neural network-based crystal growth process model identification. IEEE Trans. Semicond. Manuf. 32(2), 220–225 (2019)

Nakata, K., Orihara, R., Mizuoka, Y., Takagi, K.: A comprehensive big-data-based monitoring system for yield enhancement in semiconductor manufacturing. IEEE Trans. Semicond. Manuf. 30(4), 339–344 (2017)

Frittoli, L., Carrera, D., Rossi, B., Fragneto, P., Boracchi, G.: Deep open-set recognition for silicon wafer production monitoring. Pattern Recognit. 1(124), 108488 (2022)

Wu, H., Zhang, X., Xie, H., Kuang, Y., Ouyang, G.: Classification of solder joint using feature selection based on Bayes and support vector machine. IEEE Trans. Compon. Pack. Manuf. Technol. 3(3), 516–522 (2013)

Hong, S.J., Lim, W.Y., Cheong, T., May, G.S.: Fault detection and classification in plasma etch equipment for semiconductor manufacturing \({e}\) diagnostics. IEEE Trans. Semicond. Manuf. 25(1), 83–93 (2011)

Chung, B.S., Lim, J., Park, I.B., Park, J., Seo, M., Seo, J.: Setup change scheduling for semiconductor packaging facilities using a genetic algorithm with an operator recommender. IEEE Trans. Semicond. Manuf. 27(3), 377–387 (2014)

Wang, Z., Wu, Q., Qiao, F.: A lot dispatching strategy integrating WIP management and wafer start control. IEEE Trans. Autom. Sci. Eng. 4(4), 579–583 (2007)

Zhang, H., Jiang, Z., Guo, C.: Simulation-based optimization of dispatching rules for semiconductor wafer fabrication system scheduling by the response surface methodology. Int. J. Adv. Manuf. Technol. 41(1), 110–121 (2009)

Sha, D.Y., Storch, R.L., Liu, C.H.: Development of a regression-based method with case-based tuning to solve the due date assignment problem. Int. J. Product. Res. 45(1), 65–82 (2007)

Chen, T., Wang, Y.C.: Incorporating the FCM-BPN approach with nonlinear programming for internal due date assignment in a wafer fabrication plant. Robot. Comput.-Integr. Manuf. 26(1), 83–91 (2010)

Tobon-Mejia, D.A., Medjaher, K., Zerhouni, N., Tripot, G.: A data-driven failure prognostics method based on mixture of Gaussians hidden Markov models. IEEE Trans. Reliab. 61(2), 491–503 (2012)

He, H., Bai, Y., Garcia, E.A., Li, S.: ADASYN: Adaptive synthetic sampling approach for imbalanced learning. In: 2008 IEEE international joint conference on neural networks (IEEE world congress on computational intelligence) Jun 1 pp. 1322–1328. IEEE (2008)

Pan, S.J., Tsang, I.W., Kwok, J.T., Yang, Q.: Domain adaptation via transfer component analysis. IEEE Trans. Neural Netw. 22(2), 199–210 (2010)

Li, X., Yang, Y., Cheng, X.: Ultrasonic-assisted fabrication of metal matrix nanocomposites. J. Mater. Sci. 39(9), 3211–3212 (2004)

Nguyen, H.M., Cooper, E.W., Kamei, K.: Borderline over-sampling for imbalanced data classification. Int. J. Knowl. Eng. Soft Data Paradig. 3(1), 4–21 (2011)

Long, J., Shelhamer, E., Darrell, T.: Fully convolutional networks for semantic segmentation. In: Proceedings of the IEEE conference on computer vision and pattern recognition pp. 3431–3440 (2015)

Jiang, Y., Zhu, X., Wang, X., Yang, S., Li, W., Wang, H., Fu, P., Luo, Z.: R2CNN: rotational region CNN for orientation robust scene text detection. arXiv preprint arXiv:1706.09579. Jun 29 (2017)

Isola, P., Zhu, J.Y., Zhou, T., Efros, A.A.: Image-to-image translation with conditional adversarial networks. In: Proceedings of the IEEE conference on computer vision and pattern recognition pp. 1125–1134 (2017)

Goodfellow, I., Pouget-Abadie, J., Mirza, M., Xu, B., Warde-Farley, D., Ozair, S., Courville, A., Bengio, Y.: Generative adversarial networks. Commun. ACM 63(11), 139–144 (2020)

Yan, Y., Shi, X., Zhou, T., Xu, B., Li, C., Yuan, W., Gao, Y., Pan, B., Diao, X., Chen, S., Zhao, Y.: Machine learning virtual SEM metrology and SEM-based OPC model methodology. J. Micro/Nanopattern. Mater. Metrol. 20(4), 041204 (2021)

He, K., Zhang, X., Ren, S., Sun, J.: Deep residual learning for image recognition. In: Proceedings of the IEEE conference on computer vision and pattern recognition pp. 770–778 (2016)

Mao, X., Li, Q., Xie, H., Lau, R.Y., Wang, Z., Paul Smolley, S.: Least squares generative adversarial networks. In: Proceedings of the IEEE international conference on computer vision (2017) pp. 2794–2802

Rasmussen, C.: The infinite Gaussian mixture model. Adv. Neural Inform. Process. Syst. 89, 12 (1999)

Breiman, L.: Bagging predictors. Mach. Learn. 24(2), 123–140 (1996)

Breiman, L.: Random forests. Mach. Learn. 45(1), 5–32 (2001)

Slavik, P.: Improved performance of the greedy algorithm for partial cover. Inform. Process. Lett. 64(5), 251–254 (1997)

Gandhi, R., Khuller, S., Srinivasan, A.: Approximation algorithms for partial covering problems. In: International Colloquium on Automata, Languages, and Programming Jul 8 pp. 225–236. Springer, Berlin (2001)

Wu, H.: Solder joint defect classification based on ensemble learning. Soldering & Surface Mount Technology. Jun 5 (2017)

Woo, M., Kim, S., Kang, S.: GRASP based metaheuristics for layout pattern classification. In: 2017 IEEE/ACM International Conference on Computer-Aided Design (ICCAD) pp. 512–518. IEEE Nov 13 (2017)

Wu, H., Gao, W., Xu, X.: Solder joint recognition using mask R-CNN method. IEEE Trans. Compon. Pack. Manuf. Technol. 10(3), 525–530 (2019)

Wu, H., Xu, X.: Solder joint inspection using eigensolder features. Soldering & Surface Mount Technology. Jul 11 (2018)

Krizhevsky, A., Sutskever, I., Hinton, G.E.: Imagenet classification with deep convolutional neural networks. Commun. ACM 60(6), 84–90 (2017)

Huang, Z., Wang, X., Huang, L., Huang, C., Wei, Y., Liu, W.: Ccnet: Criss-cross attention for semantic segmentation. In: Proceedings of the IEEE/CVF international conference on computer vision (2019) pp. 603–612

Long, M., Cao, Y., Wang, J., Jordan, M.: Learning transferable features with deep adaptation networks. In: International conference on machine learning, Jun 1 pp. 97–105. PMLR (2015)

Ghifary, M., Kleijn, W.B., Zhang, M., Domain adaptive neural networks for object recognition. In: Pacific Rim international conference on artificial intelligence, Dec 1 pp. 898–904. Springer, Cham (2014)

Sun, Y., Yu, Y., Wang, W.: Moiré photo restoration using multiresolution convolutional neural networks. IEEE Trans. Image Process. 27(8), 4160–4172 (2018)

Guo, L., Lei, Y., Xing, S., Yan, T., Li, N.: Deep convolutional transfer learning network: a new method for intelligent fault diagnosis of machines with unlabeled data. IEEE Trans. Ind. Electron. 66(9), 7316–7325 (2018)

He, J., Deng, Z., Qiao, Y.: Dynamic multi-scale filters for semantic segmentation. In: Proceedings of the IEEE/CVF International Conference on Computer Vision (2019) pp. 3562–3572

Yin, M., Yao, Z., Cao, Y., Li, X., Zhang, Z., Lin, S., Hu, H.: Disentangled non-local neural networks. In: European Conference on Computer Vision, Aug 23 pp. 191-207. Springer, Cham (2020)

Li, X., Zhong, Z., Wu, J., Yang, Y., Lin, Z., Liu, H.: Expectation-maximization attention networks for semantic segmentation. In: Proceedings of the IEEE/CVF International Conference on Computer Vision (2019) pp. 9167–9176

Zhang, H., Dana, K., Shi, J., Zhang, Z., Wang, X., Tyagi, A., Agrawal, A.: Context encoding for semantic segmentation. In: Proceedings of the IEEE conference on Computer Vision and Pattern Recognition (2018) pp. 7151–7160

Cao, Y., Xu, J., Lin, S., Wei, F., Hu, H.: Gcnet: Non-local networks meet squeeze-excitation networks and beyond. In: Proceedings of the IEEE/CVF international conference on computer vision workshops (2019)

Szegedy, C., Liu, W., Jia, Y., Sermanet, P., Reed, S., Anguelov, D., Erhan, D., Vanhoucke, V., Rabinovich, A.: Going deeper with convolutions. In: Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, pp. 1–9 (2015)

Chan, T.H., Jia, K., Gao, S., Lu, J., Zeng, Z., Ma, Y.: PCANet: a simple deep learning baseline for image classification? IEEE Trans. Image Process. 24(12), 5017–5032 (2015)

Zhao, H., Zhang, Y., Liu, S., Shi, J., Loy, C.C., Lin, D., Jia, J.: Psanet: point-wise spatial attention network for scene parsing. In: Proceedings of the European Conference on Computer Vision (ECCV), pp. 267–283 (2018)

Graham, B., Engelcke, M., Van Der Maaten, L.: 3D semantic segmentation with submanifold sparse convolutional networks. In: Proceedings of the IEEE conference on computer vision and pattern recognition, pp. 9224–9232 (2018)

Ronneberger, O., Fischer, P., Brox, T.: U-net: Convolutional networks for biomedical image segmentation. In: International Conference on Medical image computing and computer-assisted intervention, Oct 5 pp. 234–241. Springer, Cham (2015)

Simonyan, K., Zisserman, A.: Very deep convolutional networks for large-scale image recognition. arXiv preprint arXiv:1409.1556. Sep 4 (2014)

Williams, C.K., Rasmussen, C.E.: Gaussian Processes for Machine Learning, vol. 2. MIT Press, Cambridge (2006)

Bengio, Y., Lamblin, P., Popovici, D., Larochelle, H.: Greedy layer-wise training of deep networks. Adv. Neural Inform. Process. Syst. 78, 19 (2006)

Cover, T., Hart, P.: Nearest neighbor pattern classification. IEEE Trans. Inform Theory 13(1), 21–27 (1967)

Manevitz, L.M., Yousef, M.: One-class SVMs for document classification. J. Mach. Learn. Res. 2(Dec), 139–154 (2001)

Vincent, P., Larochelle, H., Lajoie, I., Bengio, Y., Manzagol, P.A., Bottou, L.: Stacked denoising autoencoders: Learning useful representations in a deep network with a local denoising criterion. J. Mach. Learn. Res. 12, 11 (2010)

Saqlain, M., Abbas, Q., Lee, J.Y.: A deep convolutional neural network for wafer defect identification on an imbalanced dataset in semiconductor manufacturing processes. IEEE Tran. Semicond. Manuf. 33(3), 436–444 (2020)

Tello, G., Al-Jarrah, O.Y., Yoo, P.D., Al-Hammadi, Y., Muhaidat, S., Lee, U.: Deep-structured machine learning model for the recognition of mixed-defect patterns in semiconductor fabrication processes. IEEE Tran. Semicond. Manuf. 31(2), 315–322 (2018)

Chiu, M.C., Chen, T.M.: Applying data augmentation and mask R-CNN-based instance segmentation method for mixed-type wafer maps defect patterns classification. IEEE Tran. Semicond. Manuf. 34(4), 455–463 (2021)

Yu, J., Zheng, X., Liu, J.: Stacked convolutional sparse denoising auto-encoder for identification of defect patterns in semiconductor wafer map. Comput. Ind. 1(109), 121–133 (2019)

Piao, M., Jin, C.H., Lee, J.Y., Byun, J.Y.: Decision tree ensemble-based wafer map failure pattern recognition based on radon transform-based features. IEEE Tran. Semicond. Manuf. 31(2), 250–257 (2018)

Tsai, T.H., Lee, Y.C.: A light-weight neural network for wafer map classification based on data augmentation. IEEE Trans. Semicond. Manuf. 33(4), 663–672 (2020)

Ishida, T., Nitta, I., Fukuda, D., Kanazawa, Y.: Deep learning-based wafer-map failure pattern recognition framework. In: 20th International Symposium on Quality Electronic Design (ISQED) Mar 6 pp. 291–297. IEEE (2019)

Shim, J., Kang, S., Cho, S.: Active learning of convolutional neural network for cost-effective wafer map pattern classification. IEEE Tran. Semicond. Manuf. 33(2), 258–266 (2020)

Lee, H., Kim, H.: Semi-supervised multi-label learning for classification of wafer bin maps with mixed-type defect patterns. IEEE Tran. Semicond. Manuf. 33(4), 653–662 (2020)

Wang, T., Chen, Y., Qiao, M., Snoussi, H.: A fast and robust convolutional neural network-based defect detection model in product quality control. Int. J. Adv. Manuf. Technol. 94(9), 3465–3471 (2018)

Kingma, D.P., Welling, M.: Auto-encoding variational bayes, Available: arXiv:1312.6114 (2013)

Kingma, D.P., Mohamed, S., Jimenez Rezende, D., Welling, M.: Semi-supervised learning with deep generative models. In: Proceeding Advances in Neural Information Processing Systems pp. 3581–3589 (2014)

Kahng, H., Kim, S.B.: Self-supervised representation learning for wafer bin map defect pattern classification. IEEE Trans. Semicond. Manuf. 34(1), 74–86 (2020)

Sha, Y., He, Z., Du, J., Zhu, Z., Lu, X.: Intelligent detection technology of flip chip based on H-SVM algorithm. Eng. Fail. Anal. 1(134), 106032 (2022)

Lim, M.Y., Sharma, A., Chin, C.S., Yip, T.C., Ong, J.Y.: Prediction of wafer map categories using wafer acceptance test parameters in semiconductor manufacturing. In: IFIP International Conference on Artificial Intelligence Applications and Innovations pp. 136–144. Springer, Cham (2022)

Chen, T., He, T., Benesty, M., Khotilovich, V., Tang, Y., Cho, H., Chen, K.: Xgboost: extreme gradient boosting. R Package Version 0.4-2 1(4), 1–4 (2015)

Weimer, D., Scholz-Reiter, B., Shpitalni, M.: Design of deep convolutional neural network architectures for automated feature extraction in industrial inspection. CIRP Ann. 65(1), 417–420 (2016)

Siebel, N.T., Sommer, G.: Learning defect classifiers for visual inspection images by neuro-evolution using weakly labelled training data. In: 2008 IEEE Congress on Evolutionary Computation (IEEE World Congress on Computational Intelligence) Jun 1 pp. 3925–3931. IEEE (2008)

Timm, F., Barth, E.: Non-parametric texture defect detection using Weibull features. In: Image Processing: Machine Vision Applications IV Feb 7 Vol. 7877, pp. 150–161. SPIE (2011)

Wang, X., Girshick, R., Gupta, A., He, K.: Non-local neural networks. In: Proceedings of the IEEE conference on computer vision and pattern recognition, pp. 7794–7803 (2018)

Sharma, V.S., Nagwanshi, K.K., Sinha, G.R.: Classification of defects in photonic bandgap crystal using machine learning under microsoft AzureML environment. Multimedia Tools Appl. 17, 1–6 (2022)

Tsan, T.C., Shih, T.F., Fuh, C.S.: TsanKit: artificial intelligence for solder ball head-in-pillow defect inspection. Mach. Vis. Appl. 32(3), 1–7 (2021)

Bella, R.D., Carrera, D., Rossi, B., Fragneto, P., Boracchi, G.: Wafer defect map classification using sparse convolutional networks. In: International Conference on Image Analysis and Processing pp. 125–136. Springer, Cham, Sep 9 (2019)

Yu, J., Shen, Z., Zheng, X.: Joint feature and label adversarial network for wafer map defect recognition. IEEE Trans. Autom. Sci. Eng. 18(3), 1341–1353 (2020)

Ganin, Y., Lempitsky, V.: Unsupervised domain adaptation by backpropagation. In: International conference on machine learning, Jun 1 pp. 1180–1189. PMLR (2015)

Huang, C.J.: Clustered defect detection of high quality chips using self-supervised multilayer perceptron. Expert Syst. Appl. 33(4), 996–1003 (2007)

Demant, M., Virtue, P., Kovvali, A., Stella, X.Y., Rein, S.: Learning quality rating of as-cut mc-si wafers via convolutional regression networks. IEEE J. Photovolt. 9(4), 1064–1072 (2019)

Yu, J., Lu, X.: Wafer map defect detection and recognition using joint local and nonlocal linear discriminant analysis. IEEE Trans. Semicond. Manuf. 29(1), 33–43 (2015)

Yu, J.: Enhanced stacked denoising autoencoder-based feature learning for recognition of wafer map defects. IEEE Trans. Semicond. Manuf. 32(4), 613–624 (2019)

Yang, H., Mei, S., Song, K., Tao, B., Yin, Z.: Transfer-learning-based online Mura defect classification. IEEE Trans. Semicond. Manuf. 31(1), 116–123 (2017)

Hyun, Y., Kim, H.: Memory-augmented convolutional neural networks with triplet loss for imbalanced wafer defect pattern classification. IEEE Trans. Semicond. Manuf. 33(4), 622–634 (2020)

Hearst, M.A., Dumais, S.T., Osuna, E., Platt, J., Scholkopf, B.: Support vector machines. IEEE Intell. Syst. Appl. 13(4), 18–28 (1998)

Batool, U., Shapiai, M.I., Fauzi, H., Fong, J.X.: Convolutional neural network for imbalanced data classification of silicon wafer defects. In: 2020 16th IEEE International Colloquium on Signal Processing & Its Applications (CSPA) Feb 28 pp. 230–235. IEEE (2020)

Han, H., Gao, C., Zhao, Y., Liao, S., Tang, L., Li, X.: Polycrystalline silicon wafer defect segmentation based on deep convolutional neural networks. Pattern Recognit. Lett. 1(130), 234–241 (2020)

Sun, B., Saenko, K., Deep coral: Correlation alignment for deep domain adaptation. In: European conference on computer vision Oct 8 pp. 443–450. Springer, Cham (2016)

Kim, Y., Cho, D., Lee, J.H.: Wafer defect pattern classification with detecting out-of-distribution. Microelectron. Reliab. 1(122), 114157 (2021)

Chen, S., Zhang, Y., Yi, M., Shang, Y., Yang, P.: AI classification of wafer map defect patterns by using dual-channel convolutional neural network. Eng. Fail. Anal. 1(130), 105756 (2021)

Jin, C.H., Kim, H.J., Piao, Y., Li, M., Piao, M.: Wafer map defect pattern classification based on convolutional neural network features and error-correcting output codes. J. Intell. Manuf. 31(8), 1861–1875 (2020)

Syntetos, A.A., Boylan, J.E.: The accuracy of intermittent demand estimates. Int. J. Forecast. 21(2), 303–314 (2005)

Jia, S., Morrice, D.J., Bard, J.F.: A performance analysis of dispatch rules for semiconductor assembly & test operations. J. Simul. 14, 29 (2018)

Liu, Z.: Using neural network to establish manufacture production performance forecasting in IoT environment. J. Supercomput. 78(7), 9595–9618 (2022)

Alawieh, M.B., Ye, W., Pan, D.Z.: Re-examining vlsi manufacturing and yield through the lens of deep learning:(invited talk). In: 2020 IEEE/ACM International Conference on Computer Aided Design (ICCAD) pp. 1–8. IEEE Nov 2 (2020)

Chen, H., Boning, D.: Online and incremental machine learning approaches for IC yield improvement. In: 2017 IEEE/ACM International Conference on Computer-Aided Design (ICCAD) pp. 786–793. IEEE, Nov 13 (2017)

Fu, W., Chien, C.F., Lin, Z.H.: A hybrid forecasting framework with neural network and time-series method for intermittent demand in semiconductor supply chain. In IFIP International Conference on Advances in Production Management Systems pp. 65–72. Springer, Cham, Aug 26 (2018)

Ganin, Y., Ustinova, E., Ajakan, H., Germain, P., Larochelle, H., Laviolette, F., Marchand, M., Lempitsky, V.: Domain-adversarial training of neural networks. J. Mach. Learn. Res. 17(1), 2096–2096 (2016)

Ye, J., Janardan, R., Li, Q.: Two-dimensional linear discriminant analysis. Adv. Neural Inform. Process. Syst. 9, 17 (2004)

Gong, B., Shi, Y., Sha, F., Grauman, K.: Geodesic flow kernel for unsupervised domain adaptation. In: 2012 IEEE conference on computer vision and pattern recognition, Jun 16 pp. 2066–2073. IEEE (2012)

Long, M., Wang, J., Ding, G., Sun, J., Yu, P.S.: Transfer feature learning with joint distribution adaptation. In: Proceedings of the IEEE international conference on computer vision, pp. 2200–2207 (2013)

Wang, J., Chen, Y., Hao, S., Feng, W., Shen, Z.: Balanced distribution adaptation for transfer learning. In: 2017 IEEE international conference on data mining (ICDM) (2017) Nov 18 pp. 1129–1134. IEEE

Lei, Y., Li, N., Guo, L., Li, N., Yan, T., Lin, J.: Machinery health prognostics: a systematic review from data acquisition to RUL prediction. Mech. Syst. Signal Process. 1(104), 799–834 (2018)

PCCNN.: GitHub, Available at: https://github.com/caiwd/PCCNN (2021)

Azamfar, M., Li, X., Lee, J.: Deep learning-based domain adaptation method for fault diagnosis in semiconductor manufacturing. IEEE Trans. Semicond. Manuf. 33(3), 445–453 (2020)

Lee, K.B., Cheon, S., Kim, C.O.: A convolutional neural network for fault classification and diagnosis in semiconductor manufacturing processes. IEEE Trans. Semicond. Manuf. 30(2), 135–142 (2017)

Gaber, L., Hussein, A.I., Moness, M.: Fault detection based on deep learning for digital VLSI circuits. Procedia Comput. Sci. 1(194), 122–131 (2021)

Shim, J., Kang, S.: Domain-adaptive active learning for cost-effective virtual metrology modeling. Comput. Ind. 1(135), 103572 (2022)

Hendrycks, D., Gimpel, K.: A baseline for detecting misclassified and out-of-distribution examples in neural networks. arXiv preprint arXiv:1610.02136. Oct 7 (2016)

Bendale, A., Boult, T.E.: Towards open set deep networks. In: Proceedings of the IEEE conference on computer vision and pattern recognition, pp. 1563–1572 (2016)

Geng, C., Tao, L., Chen, S.: Guided CNN for generalized zero-shot and open-set recognition using visual and semantic prototypes. Pattern Recognit. 1(102), 107263 (2020)

Zhu, Y., Ting, K.M., Zhou, Z.H.: Multi-label learning with emerging new labels. IEEE Trans. Knowl. Data Eng. 30(10), 1901–1914 (2018)

Zhang, Y., Wang, Y., Liu, X.Y., Mi, S., Zhang, M.L.: Large-scale multi-label classification using unknown streaming images. Pattern Recognit. 1(99), 107100 (2020)

Schuetz, M.J., Brubaker, J.K., Katzgraber, H.G.: Combinatorial optimization with physics-inspired graph neural networks. Nat. Mach. Intell. 4(4), 367–377 (2022)

Majdabadi, M.M., Shokouhi, S.B., Ko, S.B.: Efficient hybrid CMOS/memristor implementation of bidirectional associative memory using passive weight array. Microelectron. J. 1(98), 104725 (2020)

VerWey, J.: The other artificial intelligence hardware problem. Computer 55(1), 34–42 (2022)

Robbins, S., van Wynsberghe, A.: Our new artificial intelligence infrastructure: becoming locked into an unsustainable future. Sustainability 14(8), 4829 (2022)

Shetty, A., Raj, N.: A Study on Recent Advances in Artificial Intelligence and Future Prospects of Attaining Superintelligence. In: Proceedings of third international conference on communication, computing and electronics systems, pp. 879–892. Springer, Singapore (2022)

Tin, T.C., Tan, S.C., Lee, C.K.: Virtual metrology in semiconductor fabrication foundry using deep learning neural networks. IEEE Access. 25(10), 81960–81973 (2022)

Bordas B, Kurt K, Bamberg A, Engell S. Developing a digital twin of a polymerization reaction for process optimization. In: 2022 33rd Annual SEMI Advanced Semiconductor Manufacturing Conference (ASMC) May 2 pp. 1–6. IEEE (2022)

Li, D., Jia, Z., Tang, Y., Song, C., Liang, K., Ren, H., Li, F., Chen, Y., Wang, Y., Lu, X., Meng, L.: Inorganic-organic hybrid phototransistor array with enhanced photogating effect for dynamic near-infrared light sensing and image preprocessing. Nano Lett. 22(13), 5434–5442 (2022)

Wu, P., He, T., Zhu, H., Wang, Y., Li, Q., Wang, Z., Fu, X., Wang, F., Wang, P., Shan, C., Fan, Z.: Next-generation machine vision systems incorporating two-dimensional materials: progress and perspectives. InfoMat. 4(1), e12275 (2022)

Li, F., Cai, H., Moyne, J., Iskandar, J., Armacost, M., Lee, J.: Combining feature extraction-based and full trace analysiss capabilities in fault detection: methods and comparative analysis. In: 2021 32nd Annual SEMI Advanced Semiconductor Manufacturing Conference (ASMC), May 10 pp. 1–6. IEEE (2021)

Fan, S.K., Hsu, C.Y., Tsai, D.M., He, F., Cheng, C.C.: Data-driven approach for fault detection and diagnostic in semiconductor manufacturing. IEEE Trans. Autom, Sci. Eng. 17(4), 1925–1936 (2020)

Jeyaraj, P.R., Samuel Nadar, E.R.: Computer vision for automatic detection and classification of fabric defect employing deep learning algorithm. Int. J. Cloth. Sci. Technol. 31(4), 510–521 (2019)

Acknowledgements

The authors extend their gratitude for the support they received from the National Key R &D Program of China (2022YFB4701400/4701402), SZSTC Grant(JCYJ20190809172201639, WDZC20200820200655001), Shenzhen Key Laboratory (ZDSYS20210623092001004), Beijing Key Lab of Networked Multimedia, and the Information Engineering College, Yango University through the High-Level Talents Project under Grant CHN-F-IECY201871015.

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

The authors contributed to the article in order of their appearance. AC and TJ were involved in idea generation, design, and implementation of experiments, and drafting of the article, whereas SH was involved in idea generation, results, discussion, and feedback, and final revision and drafting of the article.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, A.C., Meng, S.H. & Huang, T.J. A survey on machine and deep learning in semiconductor industry: methods, opportunities, and challenges. Cluster Comput 26, 3437–3472 (2023). https://doi.org/10.1007/s10586-023-04115-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10586-023-04115-6