Abstract

In this contribution, we report on the TEMPO-mediated oxidation of pulp fibers used in the general context of papermaking and for the future design of tailor-made paper in advanced applications. We focus in our studies on properties of TEMPO-oxidized pulp fibers to explain the characteristics of the paper made thereof. 13C solid-state NMR analysis reveals that in particular amorphous regions of the fibers are being chemically oxidized, while at the same time the crystalline regions of the fibers are not significantly affected. Investigation of the fiber morphology before and after oxidation shows that the fiber length is not changed, yet the fibers do exhibit an increase in width if in contact with water, which is attributed to an increase in fiber swelling. In addition, fibrillation decreases due to the oxidative removal of loosely bound fines and fibrils, rendering the surface of the resulting oxidized fibers much smoother in comparison to the original fibers. Finally, we observe that both, dry and wet tensile strengths are also higher for paper made of oxidized fibers, most likely due to cross linkable aldehyde groups formed during oxidation (i.e. hemiacetal bond formation in the sheet during thermal drying). Our results of the oxidation of paper fibers thus offer a systematic study helpful for the design of tailor-made paper useful in several applications where a fiber-modification with fiber-immobilized functional motifs is crucial, such as for example in paper-based microfluidic sensors (µPADs) or lab-on a chip-devices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Functional paper in advanced applications, such as lab-on-a-chip devices or µPADs, have attracted considerable attention and extensive research efforts in the recent past (Hillscher et al. 2021; Hristov et al. 2019; Liebich et al. 2021; Martinez et al. 2007; Schwenke et al. 2019). Cellulose-based materials and research on their derivatives have been known for a very long time and since then gained increasing interest, resulting in a variety of prominent materials such as cellulose ethers and acetates. These cellulose derivatization and functionalization strategies almost exclusively use cellulosic hydroxyl groups as reaction partners (Klemm et al. 2005). Although these are present in large numbers in the cellulose structure, they are generally of low reactivity due to their involvement in the cellulosic hydrogen bond network. One prominent reaction, that allows the regioselective cellulosic hydroxyl group conversion with high yield, is the 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO)-mediated oxidation of cellulosic materials. This reaction can be conducted in aqueous environment at slightly alkaline pH of 10–11 and preferentially oxidizes primary hydroxyl groups. As these primary hydroxyl groups are solely present on C6 in the cellulose structure, this enables a regioselective cellulose derivatization (Nooy et al. 1994).

TEMPO is a nitroxyl radical that catalyzes the oxidation of primary hydroxyl groups in the presence of sodium hypochlorite as primary oxidant and sodium bromide as co-catalyst (ESI, Fig. S1) in aqueous environment at pH 10–11, resulting in carboxylate groups on the C6 position of the cellulose polymer backbone. The primary cellulosic hydroxyl group at the C6 position is initially oxidized to an aldehyde group and in a further oxidation step, converted into a carboxylic group if sufficient amount of NaClO is present (Isogai et al. 2018; Nooy et al. 1994, 1996a, b; Ono et al. 2021).

Historically, oxidation reactions with TEMPO were first described in 1965, with the TEMPO radical being used solely as oxidant (Golubev et al. 1965). In the following years, research was mainly concerned with reducing the amount of TEMPO to catalytic amounts under usage of NaClO as oxidant and NaBr as co-oxidant (Lucio Anelli et al. 1987), as well as applying the reaction to soluble polysaccharides such as glucans, pullulans and starch (Nooy et al. 1994, 1995, 1996a, b) and insoluble ones such as cellulose, amylose and chitin (Chang and Robyt 1996). Since then, a variety of publications on the kinetics of TEMPO oxidation on cellulose and its influencing factors as well as effects on physico chemical properties of cellulose have been published. One of the pioneers in this field is the group of Isogai and co-workers, which has published a large number of research papers (Isogai et al. 2018; Isogai 2022). In the following, some of the most relevant publications for our work on TEMPO oxidation of cellulose fibers used in paper making are briefly summarized.

Saito and Isogai (2004) adapted the TEMPO-mediated oxidation reaction to native cellulose fibers and extensively investigated the reaction kinetics (Saito and Isogai 2004). For their studies they applied the TEMPO-mediated oxidation to native cellulose linters fibers. Thereby, they assessed various reaction conditions and analyzed the amount of emerging carboxylate and aldehyde groups on the fibers, as well as the amount of water-soluble and insoluble fractions, the molecular weights and crystal structures. They showed that the content of carboxylates and aldehydes can be controlled by a proper adjustment of the reaction parameters such as NaClO concentration and reaction time, respectively. Furthermore, the same group proposed that the use of about 5 mmol/g NaClO and a reaction time of 4 h provide the best compromise between achieving a high carboxylate content of around 0.8 mmol/g and at the same time a high yield of insoluble cellulose of about 90%. Finally, they showed by X-ray analysis that the overall crystallinity of cotton linters remains almost unchanged during oxidation. The latter indirectly suggests that the oxidation occurs mainly in the amorphous regions of the fibers, however, XRD does not give final prove for this.

The same groups further investigated the aldehyde/carboxylate group distribution on the fibers (Saito et al. 2005a; Saito and Isogai 2006), the formation of cellulose microfibrils (Okita et al. 2010; Saito et al. 2006) and nanofibrils/-fibers (Hiraoki et al. 2015; Isogai et al. 2011; Okita et al. 2011; Saito et al. 2007; Shinoda et al. 2012), the molecular weight of water soluble and –insoluble fractions (Hiraoki et al. 2014, 2015; Isogai et al. 2009; Saito et al. 2005b) and finally wet-strength improvement of papers made from oxidized fibers (Saito and Isogai 2006, 2007). Next to the detailed chemical analysis, Isogai and co-workers Kitaoka et al. (1999) investigated the influence of TEMPO oxidation on the degree of polymerization and morphology of hardwood kraft pulp fibers, as well as the physical properties of handsheets made of these fibers. They obtained that the degree of polymerization of cellulose drops significantly upon applying NaClO amounts of 5% on dry pulp and above during TEMPO oxidation. Furthermore, the group reported that handsheets made from oxidized fibers exhibit higher elasticity but less plasticity. Finally, they demonstrated that the degree of swelling and water retention value surprisingly remains constant for oxidized fibers compared to native fibers, although their carboxylate content is higher (Kitaoka et al. 1999). Later, in 2016, the group of Isogai an co-workers (Kobayashi et al. 2016) evaluated the properties of TEMPO-oxidized hardwood bleached kraft pulp and handsheets made thereof and mixed with different ratios of the same but TEMPO-oxidized pulp. Importantly, they observed that the TEMPO-oxidized fibers significantly increase the wet and dry tensile strength of the handsheets by forming hemiacetal bonds. Furthermore, by microscopic examination the group reported that the fibers are less fibrillated after TEMPO oxidation. Very recent research has focused on mechanistic aspects of TEMPO oxidation that uses ClO2 as a co-oxidant for fiber oxidation (Giraldo Isaza et al. 2023). Furthermore, oxidation of cellulose nanofibers for high tech applications such as enzyme carriers (Zhang et al. 2022) or antimicrobial packaging materials (Dechojarassri et al. 2023; Otenda et al. 2022) has been investigated.

Although, the kinetics (Mazega et al. 2023; Dai et al. 2011; Sun et al. 2005) and parameters that influence the kinetics (Ono et al. 2021; Saito and Isogai 2004, 2006) of the TEMPO oxidation on cellulose seems to be well-studied, a closer look reveals that questions that in particular concern the fiber swelling and WRV as well as the geometric and morphological characteristics of the fibers upon TEMPO oxidation have not been addressed in detail or are controversially discussed to date. Still, for any kind of paper application it is of utmost importance to know the details of the beforementioned parameters and thus a systematic analysis of the influence of TEMPO-oxidation on paper fiber characteristics still needs scientific attention.

In the following, according to the outline shown in Scheme 1, we present a systematic analysis of individual fiber parameters (kinks, curls, etc.) in combination with the accompanying paper properties (tensile index, etc.) of lab-made hand sheets made from TEMPO-oxidized cotton linters as model. In addition to the analysis of geometric and morphologic properties of fibers and paper sheets, we also performed a detailed analysis of the crystalline and amorphous fiber domains employing 13C solid state NMR, a powerful spectroscopic technique to investigate structural order of fibers (Foston 2014; Maunu et al. 2000; Montanari et al. 2005; Saito et al. 2005a; Svenningsson et al. 2019) as well as to investigate chemical modifications of lignocellulosic fiber-based materials (Gutmann et al. 2017; Höfler et al. 2023). This systematic study was additionally inspired, since highly reactive fibers prepared by TEMPO mediated oxidation have recently been used for functionalization of paper for applications as lab-on-a-chip or µPad devices. Nadar et al. (2021) Due to their enhanced reactivity, TEMPO-oxidized cellulose fibers can further serve as potential platform for binding of a variety of molecules including proteins bio-medical applications since it offers reactive carboxylate groups suitable for a wider range of chemical reaction strategies Credou and Berthelot (2014). In this content, some of the authors have recently demonstrated the immobilization of the model protein tGFP on TEMPO-oxidized cellulose linters fibers using an oxime ligation, respectively a reductive amination of cadaverine reaction approach (Liebich et al. 2021).

Materials and methods

Materials

Cotton linters (Grade 225 HSR-M, Buckeye Technologies) were used as a cellulose fiber source. TEMPO, NaBr and ethanol (EtOH) of laboratory grade from Sigma-Aldrich, NaClO (12 wt% Cl) of technical grade from Carl Roth, NaOH 1 M and 0.01 M and hydrochloric acid (HCl) 1 M and 0.1 M of laboratory grade from VWR were used without further purification.

TEMPO-mediated oxidation of cellulose

Cotton linters (10 g) were suspended in 1 L water (MilliQ quality). NaBr (300 mg) and TEMPO (30 mg) were added, and the cellulose slurry stirred until NaBr and TEMPO reagents were fully dissolved (approx. 1 h). To start the oxidation, a NaClO solution (0–15 mmol/g cellulose) was added to the suspension and the pH adjusted to pH 10–11 by addition of respective amounts of a 1 M HCl solution. The reaction mixture was continuously stirred throughout the whole reaction time (15 min–24 h) and the pH was constantly monitored and kept between 10–11 by repeated dosing of appropriate amounts of a 0.1 M NaOH solution. The reaction progress was observed by a discoloration of the reaction mixture from light yellow to colorless through NaClO consumption and a slower pH drop. To stop the reaction, the pH was adjusted to 7 by adding 1 M HCl and remaining NaClO was deactivated by adding 15 mL EtOH. The obtained TEMPO-oxidized linters fibers were repeatedly thoroughly washed with 1 L water and collected by centrifugation (minimum 3 extraction cycles). TEMPO-oxidized fibers were stored in suspension at 4 °C without drying for subsequent morphological fiber analysis and paper-making. TEMPO-oxidized fibers were dried at 40 °C in a vacuum oven prior to carboxylate content titrations.

Determination of carboxylate contents

Dry TEMPO-oxidized fibers (50–100 mg) were suspended in MilliQ water (55 mL). 0.01 M NaCl (5 mL) and 0.1 M HCl (1 mL) were added and a conductivity titration with the Methrom Titrando 905 and the Metrohm Conductivity module 856 was performed using 0.01 M NaOH. To correct for carbon dioxide impurities in NaOH, a blank value of the water/NaCl/HCl mixture without addition of TEMPO-oxidized fibers was acquired before every titration.

Preparation of laboratory paper sheets from TEMPO-oxidized fibers

Laboratory paper sheets were prepared using the Rapid-Koethen method according to DIN EN ISO 5269-2 (DIN 54358) from TEMPO-oxidized fibers, as well as untreated cotton linters without the addition of any additives or fillers. The resulting paper sheets made from the respective fiber source consist of isotropically aligned horizontally layered cotton linters. The sheet grammage was adjusted to 80 g/m2 with an experimental error of 2 wt%.

Physical paper testing

Laboratory paper sheets made from untreated and TEMPO-oxidized cotton linters were analyzed according to DIN EN ISO 534:2012-02 for average raw density, DIN ISO 8791-4:2023-08 for Roughness Parker Print Surf, DIN 53108:2018-12 for Roughness Bendtsen, DIN 53107:2016-05 for Bekk Smoothness, ZM IV/33/57 for water retention value, DIN EN ISO 1924-2:2009-05 for average width-related breaking strength and elongation in dry state and DIN ISO 3781:2012-07 for average width-related breaking strength and elongation in wet state.

Solid state NMR of TEMPO-oxidized cellulose fibers

Solid state NMR experiments on all TEMPO-oxidized and untreated linters fibers were performed under magic angle spinning (MAS). It has to be noted that the oxidized fibers were analyzed in their dry state, after preparation employing different reaction parameters (concentration of NaClO, oxidation time) and drying them at 40 °C under vacuum. Measurements were carried out on a Bruker Avance III 300 MHz spectrometer equipped with a H/X broadband probe. Spectra were recorded at 7.05 T, which leads to frequencies of 300.11 MHz for 1H and 75.47 MHz for 13C. Samples were packed into 4 mm ZrO2 rotors and spun at a frequency of 8 kHz. Measurements were performed with cross polarization (CP MAS) employing a linear ramp on 1H during contact. The contact time in these 1H → 13C CP MAS experiments was set to 2 ms. During data acquisition of 49 ms the TPPM15 sequence was applied for heteronuclear proton decoupling (Bennett et al. 1995). A repetition delay of 2 s and 2048 scans were used to record the spectra. Adamantane (signal at 38.5 ppm) was utilized as an external standard to reference the spectra to TMS (0 ppm).

To analyze the spectra (ESI Figs. S2–S4), the areas of the different peaks were determined by integrating the signals in the region from 181.4 to 170 ppm (C=O), 114.1 to 97.3 ppm (C1), 93.6 to 86 ppm (cr. C4), 86 to 80.1 ppm (am. C4), 67.9 to 64 ppm (cr. C6) and 64 to 58.3 ppm (am. C6). This procedure was applied for three batches for each sample. The mean value was then plotted and the error was calculated according to the standard deviation of the mean value.

Fiber morphology analysis

The morphological analysis was performed using a Valmet FS5 Fiber Image Analyzer, that uses a high-resolution camera and image analysis techniques for the investigation of fibers and particles. TEMPO-oxidized and untreated cotton linters (10 mg) were suspended in 15 mL water by a laboratory stirrer. The suspended fiber sample was poured in the analysis cup of the FS5 device and filled up with water to around 300 mL. During analysis, the FS5 device dilutes the sample automatically to the measurement concentration range of 18–22 mg/L and starts the analysis once the appropriate concentration range is reached. Note, since we have experienced decomposition of the fibers at high NaClO concentrations, we kept the latter during fiber modification in this set of experiments below 7.5 mmol/g relative to the fiber weight.

Scanning electron microscopy (SEM)

Scanning electron microscopy was carried out for laboratory paper sheets made from untreated and TEMPO-oxidized cotton linters. The dry paper samples were immobilized on a SEM plate and for contrast sputtered with a thin layer of platinum/palladium (< 10 nm layer). The micrographs were acquired on a Philips XL30 FEG high-resolution electron microscope using an acceleration voltage of 20 kV.

Results and discussion

Physical paper testing

To study the influence of TEMPO oxidation on paper properties, we oxidized native cotton linters with varying NaClO concentrations (0.5–15 mmol/g) and reaction times (15 min–24 h). The respective carboxylate content for each tested reaction condition and a detailed analysis of each batch is presented in the ESI (Figs. S5, S6). We found a maximum carboxylate content of about 1.0 mmol/g for 5 mmol/g NaClO and 4 h oxidation time, which is in good agreement with the results (Saito and Isogai 2004) reported earlier. A comprehensive kinetic study of TEMPO oxidation on linters fibers was conducted by Dai et al. (2011). This group proposed that this reaction follows a pseudo-first-order reaction kinetic whose rate constant is based on the cellulose microstructure.

Next, handsheets from TEMPO-oxidized and native cotton linters, respectively, were prepared by the Rapid-Koethen technique. The physical and mechanical properties of lab-engineered papers made from TEMPO-oxidized (5 mmol/g NaClO, 4 h oxidation time) and untreated cotton linters are summarized in Table 1.

Paper made of TEMPO-oxidized cotton linters show a higher average raw density of 0.54 g/m3, than those made of untreated cotton linters with an average raw density of 0.42 g/cm. This is in line with the results Kobayashi et al., (2016) observed for paper made from untreated and TEMPO-oxidized hardwood bleached kraft pulp in different ratios (Kobayashi et al. 2016). However, the roughness of the surface of the paper sheets made from TEMPO-oxidized fibers does not significantly differ from those made of untreated cotton linters. This is in excellent agreement with the results obtained by Kitaoka et al. (1999) for bleached hardwood kraft pulp.

The same observation is true for the water retention value, which measures the ability of a sample of wood fiber or pulp to retain water under centrifugal forces. It provides valuable information about the swellability of fibers and their suitability for the paper-making process and is mainly influenced by the carboxylate content, fiber fibrillation, as well as fines content, where both fibrils and fines consist of amorphous cellulose. The WRV for paper made from untreated cotton linters is in the range of 62.5% verses 63.5% for paper made from TEMPO-oxidized fibers and thus remains almost constant. Our observation is in line with the results earlier reported by Kitaoka et al. (1999) for bleached hardwood kraft pulp. They interpreted this observation as unexpected, as the increase in carboxylate content is assumed to increase WRV (Dang et al. 2006; Saito et al. 2007). In contrast, Saito and Isogai (2004) reported a steep increase in WRV for TEMPO-oxidized cotton linters and Kobayashi et al. (2016) for bleached hardwood kraft pulp. The swelling ability of fibers and thus also the WRV depends strongly on the amorphous fraction and the carboxylate content. Since fines consist primarily of amorphous cellulose, Saito and Isogai (2004) explained the observed increase in WRV of cotton linters upon TEMPO oxidation with an increase in the fines content. Kobayashi et al. (2016) related the increase in WRV for TEMPO-oxidized hardwood kraft pulp to the emerging carboxyl groups. However, this does not explain our findings and those from Kitaoka et al. (1999). Saito and co-workers further attributed the differences between TEMPO-oxidized cotton linters and hardwood kraft pulp to a different content of hydrophilic hemicelluloses, which is significantly increased in kraft pulp compared to cotton linters, so that the changes caused by TEMPO-oxidation are suppressed (Saito and Isogai 2004).

The average dry and wet tensile strengths (Table 1), as calculated by the force per unit width (expressed in N/m), is significantly higher for paper made of TEMPO-oxidized fibers in our studies here. This observation is in agreement with Kitaoka et al. (1999), Kobayashi et al. (2016), Saito and Isogai (2006, 2007). An explanation for this is given by Saito and Isogai, who proposed that emerging aldehyde groups on the fiber surface lead to intra- and inter-fiber connection through hemiacetal bonds, which significantly increases the dry and wet tensile strength of paper made from TEMPO-oxidized fibers (Saito and Isogai 2005a, b, 2006, 2007). In addition, Kobayashi and co-workers hypothesized that the higher paper density of the TEMPO-oxidized hardwood kraft pulp fibers could also have an influence on the higher dry breaking strength compared to non-oxidized pulp (Kobayashi et al. 2016).

Another essential parameter for paper performance is the elongation at break (measured as percentage relative to the undisturbed state). Here, we observe that in the dry state, reference paper made of untreated cotton linters have a significantly higher elongation at break when compared to paper sheets made from oxidized fibers (2.3 vs. 0.9%). Considering that the aldehyde groups formed during TEMPO-oxidation tend to hemiacetal formation, it is not surprising that the elongation in the dry state thus decreases for paper made from TEMPO-oxidized fibers. Chemically linked fibers cannot slide off each other under mechanical stress and thus exhibit less elongation. This is in good agreement with the observations of Kobayashi et al. (2016) for TEMPO-oxidized hardwood kraft pulp. For the elongation in the wet state, however, we obtained a different behavior in contrast to reports by Kobayashi et al. (2016). Paper-made from oxidized cotton linters exhibit similar elongation at break in the wet state (2.2 ± 0.1%) compared to paper from untreated cotton linters (1.8 ± 0.5%) in our studies. Here, another morphological or chemical effect may be superimposed to the hemiacetal bonding. Saito and Isogai et. al. have observed earlier, that TEMPO-oxidized fibers having the same aldehyde content, but oxidized with different NaClO concentrations exhibit different tensile indices (Saito and Isogai 2005a, b). This is a further indication that the mechanical properties in the wet state are not controlled purely by the aldehyde content and hemiacetal bonding. They explained this effect by different aldehyde distributions at the inner-fiber vs. fiber-surface obtained at different NaClO concentrations. Kobayashi et al. (2016) reported that the wet strengths of paper made of purely TEMPO-oxidized hardwood kraft pulp being the same or slightly lower than those of paper made from the same but untreated pulp. The group suggested that the formation of a hydrophilic carboxyl group, which leads to increased fiber swelling in the presence of water, can cause lower wet strength. We believe that this effect can play a major role in elongation at break in the wet state and hence can cause earlier slide-off of the individual fibers in wet state. We hypothesized at this point that changes in the fiber morphology thus play a crucial role here, which will be further discussed below.

To shed more light on the discrepancies between different reports, it became evident that a systematic study of the different properties of the fibers including crystallinity, morphology and their chemical behavior is necessary, to understand the influence of the TEMPO-oxidation on resulting paper sheet properties. Especially for WRV, different observations have been reported, which have not yet been substantiated by a comprehensive fiber analysis. The following chapters will discuss the outcome of our systematic fiber analysis and help to finally understand the effects of TEMPO-oxidation on the properties of paper sheets derived from oxidized lignocellulosic fibers.

Fiber crystallinity

First, we investigated the chemical constitution of native vs. TEMPO-oxidized fibers by 13C solid state NMR. A typical spectrum of native fibers (reference), in comparison to TEMPO-oxidized fibers (superimposed) obtained by 1H → 13C CP MAS is shown in ESI Fig. S3. The peak at 175 ppm containing two superimposed signals can be clearly assigned to the carboxylic groups formed by TEMPO-oxidation, whereas all other peaks in the spectrum are attributed to the cellulose carbons C1–C6 according to the literature. (Atalla and Vanderhart 1984; Ono et al. 2021) By dividing the peak area Iox of the C=O peak by the peak area IC1 of the C1 peak in a similar matter compared to Ono et al. (2021), the oxidation kinetics using various NaClO concentrations or oxidation times, respectively, have been investigated. The corresponding graphs are shown in Fig. 1A, B, respectively. The peak ratio increases up to a NaClO concentration of 5 mmol/g or an oxidation time of 4 h, respectively and subsequently flattens down and reaches a plateau with the tendency to decrease. These observations match well with the trend found by conductometry titrations (ESI Fig. S5).

Fraction of oxidized parts in the investigated fiber samples obtained by 1H → 13C CP MAS NMR. Fractions are plotted as function of the NaClO concentration (A; full squares) and as function of the oxidation time (B; empty squares), respectively. Note: For the oxidized samples, cotton linters were oxidized with various NaClO amounts (A), resp. different oxidation times (B) at pH 10.5. For the reference samples, cotton linters were treated with NaOH for 4 h (A) and various times (B) at pH 10.5 without the addition of TEMPO and NaClO (full triangles). The blank samples refer to untreated cotton linters (full circles). The ratio Iox/IC1 was calculated by dividing the area of the C= O peak by the area of the C1 peak for the different spectra shown in ESI Fig. S2–S4. The C1 peak was thereby used as the cellulose reference peak, as no significant changes of C1 were visible in the solid-state NMR spectra during the TEMPO-oxidation

Next, changes of the structural order during the TEMPO-oxidation are analyzed using the C4 or C6 signals, respectively, as the signals C4,am. and C6,am. attributed to disordered (amorphous) parts exhibit a shift of 4 ppm high-field compared to the signals C4,cr. and C6,cr. assigned to more ordered (crystalline) parts. By calculating Iam./Icr. of the respective signals (C4 or C6) (obtained spectra are shown in ESI Figs. S2–S4) the ratio between disordered and ordered parts is estimated. It has to be noticed that although 1H → 13C CP MAS is not quantitative at first approximation it can be used to estimate ratios of ordered (crystalline) and disordered (amorphous) parts in cellulose as well as cellulose fiber samples and to follow the progress of carboxylate group formation in TEMPO-oxidation (Daicho et al. 2020; Leguy et al. 2018; Liu et al. 2018; Saito et al. 2005a; Sang et al. 2017).

To examine the influence of TEMPO-oxidation on this ratio, it is plotted as function of the carboxylate content. Figure 2A, B clearly show that the ratio obtained for the C4 signals stays constant for increasing carboxylate contents. In contrast, the ratio obtained for the C6 signal decreases significantly by around 34% for the TEMPO-oxidized fibers with increasing carboxylate content. This intensity change obtained for C6 clearly demonstrates the oxidation at the more reactive C6 position because the oxidized carbons no longer contribute to the C6 signal. By adding the area of the C6,am. signal (Iam. C6) to the area of the C=O (Iox.) signal and divide this sum by the area of the C6,cr. signal (Icr. C6) (ESI, Fig. S7), it becomes obvious that the oxidized carbons contribute to the C=O signal, because this value stays constant with varying NaClO in the margin of error. The decrease of Iam./Icr. obtained for C6 further indicates that mainly the more disordered parts get oxidized during TEMPO-oxidation which is in agreement with the results obtained by Montanari et al. (2005).

Ratio between disordered and ordered parts of C4 (A) and C6 (B) obtained by 1H → 13C CP MAS NMR of the investigated cotton linters. The ratios are plotted as a function of carboxylate content for TEMPO-oxidized fibers, prepared with different NaClO concentrations between 0.5–7.5 mmol/g (full squares) and varying reaction times between 15 min to 24 h (empty squares). The reference sample refers to cotton linters treated with NaOH at pH 10.5 for 4 h (full circles) and the blank sample to untreated cotton linters (full circles). Iam./Icr. was calculated by dividing the areas in the spectra shown in ESI Fig. S2–S4 referring to the disordered (amorphous) part by that of the ordered (crystalline) part of the C4 and C6 signals, respectively

Morphological fiber analysis

The morphological properties of TEMPO-oxidized fibers obtained by reaction of native fibers with various NaClO concentrations between 0.5 and 7.5 mmol/g, as well as obtained for various reaction times between 15 min and 24 h, were studied by an optical fiber analyzer device. The results on length, diameter of the fibers, curl and kinks as well as fibrillation and fines content are summarized in Figs. 3, 4 and 5, respectively.

Length-weighted fiber length distribution (A) and fiberwidth (B) as a function of the carboxylate content for TEMPO-oxidized fibers prepared with different NaClO concentrations between 0.5 and 7.5 mmol/g (full squares) and varying reaction times between 15 min and 24 h (half squares). Blank, untreated linters fibers are included in full circles and the reference linters fibers treated with NaOH and without the addition of catalysts and oxidants at pH 10.5 for 24 h are included as full triangles

Fiber kinks/1000 fibers (A), fiber curl (B) and kinkangle (C) as a function of the carboxylate content for TEMPO-oxidized fibers prepared with different NaClO concentrations between 0.5 and 7.5 mmol/g (full squares) and varying reaction times between 15 min and 24 h (half squares). Blank, untreated linters fibers are included in full circles and the reference linters fibers treated with NaOH and without the addition of catalysts and oxidants at pH 10.5 for 24 h are included as full triangles. Kinkangle definition (D)

Fibrillation (A) and fines content (B) as a function of the carboxylate content for TEMPO oxidized fibers prepared with different NaClO concentrations between 0.5 and 7.5 mmol/g (full squares) and varying reaction times between 15 min and 24 h (half squares). Blank, untreated linters fibers are included in full circles and the reference linters fibers treated with NaOH and without the addition of catalysts and oxidants at pH 10.5 for 24 h are included as full triangles

Figure 3A shows that the average fiber length does not significantly change with increasing carboxylate content, which suggests that the fiber stays morphologically intact under the chosen oxidation conditions. This is in line with the results reported by Kobayashi et al. (2016) for TEMPO-oxidized hardwood bleached kraft pulp. Since the mechanical paper strength in the dry state is strongly influenced by the fiber length, no significant change of this mechanical property is expected after TEMPO oxidation of the fiber.

For the fiber-width, however, we observed a slight increase for higher carboxylate contents (Fig. 3B) in agreement with Kobayashi et al. (2016) who reported a similar observation for TEMPO oxidized hardwood bleached kraft pulp. This increase in fiber width is most likely caused by an increase in water uptake, i.e. fiber swelling. During oxidation, the number of charges being introduced into the fiber enhances electrostatic repulsion between cellulose polymer chains which in turn opens new spaces/pores that can be filled with further incoming, capillary driven water molecules. The increase in the number of negative charges on/in the fibers is proven by an increasing negative Zeta potential (ESI, Fig. S8). Moreover, one may assume also changes in the relative amount of less swellable crystalline regions versus highly swellable amorphous regions. Such an effect of increased fiber swelling in alkaline conditions is known e.g. from cellulose mercerization using harsh alkaline conditions, where the crystal structure of cellulose changes (Rippon and Evans 2012). As shown by our solid-state NMR studies above, the chosen oxidation protocols did not affect the crystalline parts of the fiber but the amorphous ones in a significant way. Such a decrease of the amorphous fiber fraction would cause a decrease of fiber swelling and thus a decrease of the WRV would be expected. At first glance, this seems to be in strong contradiction to the obtained increase in fiber swelling and the constant WRV before and after TEMPO oxidation, respectively. The TEMPO oxidation, however, yield an increase of electrostatic charges in the fibers, which in turn can overcompensate the loss of the amorphous regions by stronger repulsions and thus increase in capillary driven imbibition of water in such regions. The latter thus explains the increase in fiber swelling, still the constant WRV at this point was unexpected.

Figure 4A, B show the number of kinks and curls, respectively, being present in the fiber as function of the carboxylate content. For both, kinks and curls the number decreases with increasing carboxylate content. This observation is explained by an increased flexibility of the fibers due to a strong increase in swelling (Saito and Isogai 2004). Besides the discussed covalent hemiacetal bonds, the higher flexibility of the fibers can explain the lower elongation at break in the dry state of the paper made from oxidized fibers, since oxidized fibers have fewer possibilities for elongation due to the lower number of kinks and curls. Furthermore, the kink-angle as defined in Fig. 4D decreases with increasing carboxylate content as shown in Fig. 4C which underlines the hypothesis that elongation becomes more restricted with increasing number of oxidized fibers.

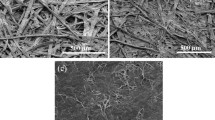

Another important parameter that influences the paper properties is fiber fibrillation which has been studied with the fiber analyzer. Fibrillation upon TEMPO-oxidation decreases with increasing carboxylate content of the fibers, as shown in Fig. 5A. This observation is in line with Kobayashi et al. (2016), who reported a decreased fibrillation for paper made from TEMPO-oxidized hardwood bleached kraft pulp compared to those made from the same but untreated pulp. When we further investigated the fibrillation via electron microscopy, we observed that our findings differ from those reported by Saito et. al. earlier, where they observed an increase in fibrillation (Saito and Isogai 2004). We explain this with the strong swelling of the fibers in alkaline environment, which leads to a dissolution and delamination of smaller fragments of cellulosic particles/microfibrils from the outer surface of the fiber. This argumentation is supported by the observation that the content of fines (cellulosic fractions, much smaller than the fiber) decreases in the fiber slurry with increasing NaClO concentration, as shown in Fig. 5B. The latter suggests that at higher degree of carboxylation such fines are dissolved, similar to the findings by Saito and Isogai (2004). In contrast, Kobayashi et al. (2016) reported an increase in fines for TEMPO-oxidized hardwood bleached kraft pulp, which are most probably caused by a different depolymerization behavior of hardwood vs. cellulose linters pulp. Another explanation is the formation of acetaldehyde by quenching of sodium hypochlorite with ethanol, as is common practice in the literature (Saito et al. 2005a, b; Saito and Isogai 2004; Sang et al. 2017; Praskalo et al. 2009). This can cause inter-fiber linkages. However, this is considered rather unlikely, since the reaction mixture was decanted directly after quenching and the fibers were thoroughly washed.

Because the WRV is strongly correlated with the amount of swellable fiber fractions, any changes in fiber fibrillation and fines content will likewise affect this parameter. In our studies, we observed that fibrillation as well as fines-content in the fiber (suspension) is decreasing. The highly swellable fines and fibrils contribute significantly to the WRV. Therefore, the reduction of fines content and lower degree of fibrillation thus counterbalances the increase in WRV by swelling of the remaining amorphous regions. Hence, we can now explain the obtained constant WRV value by this combination of effects that increase and decrease WRV at the same time for a given state of oxidation. The latter also explains the difference to the findings by Kobayashi et al. (2016) and Saito and Isogai (2004) who reported a steep increase in WRV for paper made of TEMPO-oxidized fibers. However, in their case, pulp fibers were used including fines particles for their WRV measurement and the impact of fines was not investigated in detail. In our case, lab-made paper sheets were used for the WRV measurement, and during paper-making process, fines are being washed out of the pulp. As such fines are taking-up a significant amount of water, it is not trivial to compare the WRV values for oxidized and non-oxidized sheets in a quantitative manner. Note, adding fines into readily formed sheets is feasible, however, the experimental error is assumed to be large since the control of the retention of the fines is challenging. As such we did not consider this here but rather accept the observed WRV values in a more qualitative way.

Depolymerization of cellulose is common and has been reported for TEMPO-oxidized lignocellulosic fibers (Kitaoka et al. 1999; Kekäläinen et al.2014; Saito and Isogai 2004). Similar to our findings, other studies have shown that bond breaks (i.e. depolymerization) mainly occur in the amorphous regions of the fibers (Ono et al. 2021; Kekäläinen et al.2014; Okita et al. 2010; Saito and Isogai 2004). The latter may also explain our findings of a smoothening of the outer surface of the fibers as well as of a decrease in WRV due to the change in relative composition of crystalline versus amorphous cellulosic parts.

In addition to our investigations using the fiber analyzer, scanning electron microscopy images of TEMPO-oxidized (5 mmol/g NaClO, 4 h and 24 h oxidation time) and untreated fibers were acquired. The observation of decreased fibrillation on the fiber surface compared to the untreated reference fibers as discussed above, is supported by the SEM images shown in Fig. 6. Untreated cotton linters appear more fibrillated (Fig. 6A, B), with structures like webbed skin consisting of fines and fibrils between the individual fibers. In contrast, the TEMPO-oxidized fibers appear quite smooth (Fig. 6C–F) without the typical fibrillary and webbed skin structures. Besides, oxidation of linters fibers does not only result in reactive carboxylate groups on the fiber surface, but also yields more defined pore-structures with smooth interfaces in paper sheets. The latter, although not in focus here, can control the transport of fluids by capillary forces as shown by some of the authors earlier (Böhm and Biesalski 2017; Dubois et al. 2017).

Additionally, the higher average raw density for the paper made of oxidized fibers is caused by the less fibrillated and more flexible fibers after TEMPO-oxidation; hence, fibers can arrange more densely during the paper-making process. However, the roughness of the surface of the paper sheets made from TEMPO-oxidized fibers does not significantly differ from those made of untreated cotton linters. This observation is understandable since all SEM measurements were performed under dry conditions and smaller fibrils may fall back into larger macro pores, which causes similar roughness values for both kind of paper sheets.

Conclusion

The control of the chemical composition of lignocellulosic fibers is crucial for several paper sheet properties, mainly mechanical properties, as well as for further use in applications where additional functional groups may be grafted onto the paper fibers, such as in paper-based sensing applications. In our report here, we follow-up on a number of studies of TEMPO-oxidation of cellulose and lignocellulosic fibers and systematically analyze the influence of this chemical fiber treatment on the morphological and chemical structure–property relation of paper fibers. Using 13C solid-state NMR analysis, we conclude that the ordered (crystalline) parts of C4 and C6 remain almost constant, while the disordered (amorphous) parts of the C6 are strongly affected by TEMPO-oxidation, and carboxylates are formed predominantly in these regions. From a morphological point of view, the fiber length is preserved after oxidation. Significant changes were observed for the fiber width, which increased due to enhanced fiber swelling of TEMPO-oxidized cotton linters. At the same time the fiber fibrillation is decreased for oxidized fibers, which explains the higher average raw density and the constant WRV of paper made from TEMPO-oxidized fibers in contrast to non-modified fibers. Finally, a decrease in kinks and curls is observed for the TEMPO-oxidized fibers which yields a lower elongation at break for paper sheets made from TEMPO-oxidized fibers. An increase in dry and wet tensile strengths for the paper sheets made from oxidized fibers is explained by aldehyde groups that are formed during oxidation, and that can form hemiacetal bonds during the drying process of papermaking. Thus, our studies do not only complement existing reports on TEMPO-mediated oxidation of pulp, but answer a number of open questions regarding the influence of this oxidation on resulting structure–property relationships of pulp fibers and paper sheets made thereof. The latter is of high importance as a base for applying further chemical modifications on such TEMPO-oxidized paper sheets carrying controlled amounts of reactive carboxyl-groups. These are especially required for high-tech paper-based sensor applications where defined amounts of immobilized signal/capturing molecules are essential.

Availability of data and materials

Additional material is available in the supplementary information.

References

Atalla RH, Vanderhart DL (1984) Native cellulose: a composite of two distinct crystalline forms. Science 223:283–285

Bennett AE, Rienstra CM, Auger M, Lakshmi KV, Griffin RG (1995) Heteronuclear decoupling in rotating solids. J Chem Phys 103:6951–6958

Böhm A, Biesalski M (2017) based microfluidic devices: a complex low-cost material in high-tech applications. MRS Bull 42:356–364

Chang PS, Robyt JF (1996) Oxidation of primary alcohol groups of naturally occurring polysaccharides with 2,2,6,6-tetramethyl-1-piperidine oxoammonium ion. J Carbohydr Chem 15:819–830

Credou J, Berthelot T (2014) Cellulose: from biocompatible to bioactive material. J Mater Chem B 2(30):4767–4788

Dai L, Dai H, Yuan Y, Sun X, Zhu Z et al (2011) Kinetics of TEMPO oxidation. BioResources 6(3):2619–2631

Daicho K, Fujisawa S, Kobayashi K, Saito T, Ashida J (2020) Cross-polarization dynamics and conformational study of variously sized cellulose crystallites using solid-state 13C NMR. J Wood Sci 66:62

Dang Z, Elder T, Ragauskas AJ (2006) Influence of kraft pulping on carboxylate content of softwood kraft pulps. Ind Eng Chem Res 45:4509–4516

de Nooy AE, Besemer AC, van Bekkum H (1994) Highly selective TEMPO mediated oxidation of primary alcohol groups in polysaccharides. Recl Trav Chim Pays-Bas 113:165–166

de Nooy AEJ, Besemer AC, van Bekkum H (1995) Highly selective nitroxyl radical-mediated oxidation of primary alcohol groups in water-soluble glucans. Carbohydr Res 269:89–98

de Nooy AEJ, Besemer AC, van Bekkum H (1996a) On the use of stable organic nitroxyl radicals for the oxidation of primary and secondary alcohols. Synthesis 1996:1153–1176

de Nooy AE, Besemer AC, van Bekkum H, van Dijk J, Smit JA (1996b) TEMPO-mediated oxidation of pullulan and influence of ionic strength and linear charge density on the dimensions of the obtained polyelectrolyte chains. Macromolecules 29:6541–6547

Dechojarassri D, Komatsu K, Sawara A, Tamura H, Furuike T (2023) Antimicrobial properties of AgNP/TEMPO-oxidized cellulose nanofiber/chitosan composite fibers. Fibers 11(8):69

Dubois C, Herzog N, Rüttiger C, Geißler A, Grange E, Kunz U, Kleebe H-J, Biesalski M, Meckel T, Gutmann T (2017) Fluid flow programming in paper-derived silica-polymer hybrids. Langmuir 33:332–339

Foston M (2014) Advances in solid-state NMR of cellulose. Curr Opin Biotechnol 27:176–184

Giraldo Isaza L, Mortha G, Marlin N, Molton F, Duboc C (2023) ClO2-mediated oxidation of the TEMPO radical: fundamental considerations of the catalytic system for the oxidation of cellulose fibers. Molecules 28(18):6631

Golubev VA, Rozantsev ÉG, Neiman MB (1965) Some reactions of free iminoxyl radicals with the participation of the unpaired electron. Bull Acad Sci USSR Div Chem Sci 14:1898–1904

Gutmann T, Kumari B, Zhao L, Breitzke H, Schöttner S, Rüttiger C, Gallei M (2017) Dynamic nuclear polarization signal amplification as a sensitive probe for specific functionalization of complex paper substrates. J Phys Chem C 121:3896–3903

Hillscher LM, Liebich VJ, Avrutina O, Biesalski M, Kolmar H (2021) Functional paper-based materials for diagnostics. Chemtexts 7:1–22

Hiraoki R, Fukuzumi H, Ono Y, Saito T, Isogai A (2014) SEC-MALLS analysis of TEMPO-oxidized celluloses using methylation of carboxyl groups. Cellulose 21:167–176

Hiraoki R, Ono Y, Saito T, Isogai A (2015) Molecular mass and molecular-mass distribution of TEMPO-oxidized celluloses and TEMPO-oxidized cellulose nanofibrils. Biomacromoleclues 16:675–681

Höfler MV, Limprasart W, Rösler L, Fleckenstein M, Brodrecht M, Herr K, Schäfer J-L, Biesalski M, Breitzke H, Gutmann T et al (2023) Fluorine-labeled N-Boc-l-proline as a marker for solid-state NMR characterization of biofunctionalizations on paper substrates. J Phys Chem C 127(7):3570–3578

Hristov DR, Rodriguez-Quijada C, Gomez-Marquez J, Hamad-Schifferli K (2019) Designing paper-based immunoassays for biomedical applications. Sensors 19:554

Isogai A (2022) TEMPO-catalyzed oxidation of polysaccharides. Polym J 54(4):387–402

Isogai T, Yanagisawa M, Isogai A (2009) Degrees of polymerization (DP) and DP distribution of cellouronic acids prepared from alkali-treated celluloses and ball-milled native celluloses by TEMPO-mediated oxidation. Cellulose 16:117–127

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85

Isogai A, Hänninen T, Fujisawa S, Saito T (2018) Catalytic oxidation of cellulose with nitroxyl radicals under aqueous conditions. Prog Polym Sci 86:122–148

Kekäläinen K, Liimatainen H, Illikainen M, Maloney TC, Niinimäki J (2014) The role of hornification in the disintegration behaviour of TEMPO-oxidized bleached hardwood fibres in a high-shear homogenizer. Cellulose 21:1163–1174

Kitaoka T, Isogai A, Onabe F (1999) Chemical modification of pulp fibers by TEMPO-mediated oxidation. Nord Pulp Pap Res J 14:279–284

Klemm D, Heublein B, Fink H-P, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393

Kobayashi Y, Gondo T, Yamamoto M, Saito T, Isogai A (2016) Fundamental properties of handsheets containing TEMPO-oxidized pulp in various weight ratios. Nord Pulp Pap Res J 31:248–254

Leguy J, Nishiyama Y, Jean B, Heux L (2018) Ultrastructural characterization of the core–shell structure of a wide range of periodate-oxidized cellulose from different native sources by solid-state 13C CP-MAS NMR. ACS Sustain Chem Eng 7:412–420

Liebich VJ, Avrutina O, Habermann J, Hillscher LM, Langhans M, Meckel T, Biesalski M, Kolmar H (2021) Toward fabrication of bioactive papers: covalent immobilization of peptides and proteins. Biomacromol 22:2954–2962

Liu P, Pang B, Tian L, Schäfer T, Gutmann T, Liu H, Volkert CA, Buntkowsky G, Zhang K (2018) Efficient, self-terminating isolation of cellulose nanocrystals through periodate oxidation in pickering emulsions. Chemsuschem 11:3581–3585

Lucio Anelli P, Biffi C, Montanari F, Quici S (1987) Fast and selective oxidation of primary alcohols to aldehydes or to carboxylic acids and of secondary alcohols to ketones mediated by oxoammonium salts under two-phase conditions. J Org Chem 52:2559–2562

Martinez AW, Phillips ST, Butte MJ, Whitesides GM (2007) Patterned paper as a platform for inexpensive, low-volume, portable bioassays. Angew Chem 119:1340–1342

Maunu S, Liitiä T, Kauliomäki S, Hortling BO, Sundquist J (2000) 13C CPMAS NMR investigations of cellulose polymorphs in different pulps. Cellulose 7:147–159

Mazega A, Santos AF, Aguado R, Tarrés Q, Fiol N, Pèlach MÀ, Delgado-Aguilar M (2023) Kinetic study and real-time monitoring strategy for TEMPO-mediated oxidation of bleached eucalyptus fibers. Cellulose 30(3):1421–1436

Montanari S, Roumani M, Heux L, Vignon MR (2005) Topochemistry of carboxylated cellulose nanocrystals resulting from TEMPO-mediated oxidation. Macromolecules 38:1665–1671

Nadar SS, Patil PD, Tiwari MS, Ahirrao DJ (2021) Enzyme embedded microfluidic paper-based analytic device (μPAD): a comprehensive review. Crit Rev Biotechnol 41:1046–1080

Okita Y, Saito T, Isogai A (2010) Entire surface oxidation of various cellulose microfibrils by TEMPO-mediated oxidation. Biomacromoleclues 6:1696–1700

Okita Y, Fujisawa S, Saito T, Isogai A (2011) TEMPO-oxidized cellulose nanofibrils dispersed in organic solvents. Biomacromoleclues 12:518–522

Ono Y, Takeuchi M, Zhou Y, Isogai A (2021) TEMPO/NaBr/NaClO and NaBr/NaClO oxidations of cotton linters and ramie cellulose samples. Cellulose 28(10):6035–6049

Otenda BV, Kareru PG, Madivoli ES, Salim AM, Gichuki J, Wanakai SI (2022) Starch-Hibiscus-cellulose nanofibrils composite films as a model antimicrobial food packaging material. J Nat Fibers 19(15):12371–12384

Praskalo J, Kostic M, Potthast A, Popov G, Pejic B, Skundric P (2009) Sorption properties of TEMPO-oxidized natural and man-made cellulose fibers. Carbohydr Polym 77(4):791–798

Rippon JA, Evans DJ (2012) 3—Improving the properties of natural fibres by chemical treatments. In: Kozłowski RM (ed) Handbook of natural fibres: woodhead publishing series in textiles, vol 2. Woodhead Publishing, pp 63–140

Saito T, Isogai A (2004) TEMPO-mediated oxidation of native cellulose. The effect of oxidation conditions on chemical and crystal structures of the water-insoluble fractions. Biomacromol 5:1983–1989

Saito T, Isogai A (2006) Introduction of aldehyde groups on surfaces of native cellulose fibers by TEMPO-mediated oxidation. Colloids Surf A 289:219–225

Saito T, Isogai A (2007) Wet strength improvement of TEMPO-oxidized cellulose sheets prepared with cationic polymers. Ind Eng Chem Res 46:773–780

Saito T, Shibata I, Isogai A, Suguri N, Sumikawa N (2005a) Distribution of carboxylate groups introduced into cotton linters by the TEMPO-mediated oxidation. Carbohyd Polym 61:414–419

Saito T, Yanagisawa M, Isogai A (2005b) TEMPO-mediated oxidation of native cellulose: SEC–MALLS analysis of water-soluble and-insoluble fractions in the oxidized products. Cellulose 12:305–315

Saito T, Nishiyama Y, Putaux J-L, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromol 7:1687–1691

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolcules 8:2485–2491

Sang X, Qin C, Tong Z, Kong S, Jia Z, Wan G, Liu X (2017) Mechanism and kinetics studies of carboxyl group formation on the surface of cellulose fiber in a TEMPO-mediated system. Cellulose 24:2415–2425

Schwenke KU, Spiehl D, Krauße M, Riedler L, Ruppenthal A, Villforth K, Meckel T, Biesalski M, Rupprecht D, Schwall G (2019) Analysis of free chlorine in aqueous solution at very low concentration with lateral flow tests. Sci Rep 9:1–11

Shinoda R, Saito T, Okita Y, Isogai A (2012) Relationship between length and degree of polymerization of TEMPO-oxidized cellulose nanofibrils. Biomacromol 13:842–849

Sun B, Gu C, Ma J, Liang B (2005) Kinetic study on TEMPO-mediated selective oxidation of regenerated cellulose. Cellulose 12:59–66

Svenningsson L, Sparrman T, Bialik E, Bernin D, Nordstierna L (2019) Molecular orientation distribution of regenerated cellulose fibers investigated with rotor synchronized solid state NMR spectroscopy. Cellulose 26:4681–4692

Zhang H, Luan Q, Li Y, Wang J, Bao Y, Tang H, Huang F (2022) Fabrication of highly porous, functional cellulose-based microspheres for potential enzyme carriers. Int J Biol Macromol 199:61–68

Acknowledgments

We thank Nicole Panzer from the Chair of Paper Technology and Mechanical Process Engineering, TU Darmstadt, for performing the physical paper testing analyses. In addition, we thank Enis M. Saritas and Tristan Wagener for valuable technical support on fiber oxidation and Mathias Diefenbach for valuable technical support on electron microscopy. Financial support from the Merck Lab @ TUDarmstadt is gratefully acknowledged. TG and MVH gratefully acknowledge financial support by the DFG under contract GU-1650/3-1 project number 429632542. We thank Prof. Buntkowsky for generous allocation of measurement time at his Bruker Avance III HD 300 MHz NMR spectrometer in Darmstadt.

Funding

Open Access funding enabled and organized by Projekt DEAL. We kindly acknowledge the funding by Merck KGaA under the Merck Lab @ TU Darmstadt project, as well as financial support by the DFG under grant GU-1650/3–1 with project number 429632542.

Author information

Authors and Affiliations

Contributions

All fiber oxidation experiments, fiber analytics, data evaluation and manuscript writing: LMH, 13C-NMR analysis and manuscript writing: MVH, support with oxidations, titrations and electron microscopy: CL, method development of conductivity titration, valuable discussions and conceptualization of work: KUC, valuable discussions and conceptualization of work: GS, paper analytics: KV, SS, conceptualization of work, finalization and reviewing of manuscript: MB, TG. All authors have given approval to the final version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare that are relevant to the content of this article.

Ethics approval and consent to participate

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hillscher, L.M., Höfler, M.V., Gutmann, T. et al. Influence of TEMPO-oxidation on pulp fiber chemistry, morphology and mechanical paper sheet properties. Cellulose 31, 3067–3082 (2024). https://doi.org/10.1007/s10570-024-05748-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-024-05748-5