Abstract

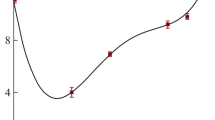

A method for obtaining nonwoven precursors of carbon materials based on natural and viscose fibers was developed. Bast (flax and hemp) fibers were used as sources of natural fibers which were previously processed in order to remove impurities and enrich with the alpha fraction of cellulose. The structure, morphology, and chemical composition of natural and viscose fibers were studied by X-ray, SEM, and IR spectroscopy. The mechanical characteristics of the fibers were determined. The results of studies of the thermal behavior of mixed materials based on viscose, flax, and hemp fibers at temperatures up to 1000 °C were presented. The introduction of a small fraction of natural fibers into viscose (up to 30%) leads to a sharp decrease in the carbon yield. But the further increasing of the proportion of the natural fibers increases the carbon yield that means that depending on proportion of artificial and natural fibers the later could play a role of either promoter or inhibitor of pyrolysis process. The obtained dependence of the carbon residue on the composition of the neat fibers was used to identify optimal formulations for nonwovens.

Graphical abstract

Similar content being viewed by others

Availability of data and materials

All of the materials and data are owned by the authors and/or no permissions are required.

References

Abdullin ISh, Ibragimov RG, Muzafarova GS, Samatova EM (2014) Modern technologies for the production of nonwovens. Kazan State Technological University, Kazan, pp 114–119

Ainullov RK, Kostochko AV, Valishina ZT, Popov DV, Aleksandrov AA (2020) Method of producing bleached hempen cellulose. RF Patent 2735263 C1

Albrecht W, Fuchs H, Kittelmann W (2003) Nonwoven fabrics: raw materials, manufacture, applications, characteristics, testing processes. Wiley, Weinheim

ASTM D1795 (2021) Standard test method for intrinsic viscosity of cellulose. https://www.astm.org/d1795-13r21.html. Accessed 15 Aug 2023

ASTM D4243 (2023) Standard test method for measurement of average viscometric degree of polymerization of new and aged electrical papers and boards. https://www.astm.org/d4243-16.html. Accessed 15 Aug 2023

Bolton J (1995) The potential of plant fibres as crops for industrial use. Outlook AGR 24:85–89. https://doi.org/10.1177/003072709502400204

Budaeva VV, Gismatulina YA, Zolotukhin VN, Rogovoy MS, Melnikov AV (2015) A method for producing cellulose from flax is a paper bag for the paper industry. RF Patent 2566275C1

Carrillo F, Colom X, Sunol JJ, Saurina J (2004) Structural FTIR analysis and thermal characterization of lyocell and viscose-type fibres. Eur Polym J 40:2229–2234

Charlet K, Jernot J-P, Gomina M (2010) Mechanical properties of flax fibers and of the derived unidirectional composites. J Compos Mater 44(24):2887–2896. https://doi.org/10.1177/0021998310369579

Day A, Ruel K, Neutelings G, Cronier D, David H, Hawkins S, Chabbert B (2005) Lignification in the flax stem: evidence for an unusual lignin in bast fibers. Planta 222(2):234–245. https://doi.org/10.1007/s00425-005-1537-1

Egorov DA, Lukanin EA (2019) A cellulose product with an alpha-cellulose content of 98.5% or higher and an industrial method for its production. RF Patent 2017141513

Fink HP, Hofmann D, Philipp B (1995) Some aspects of lateral chain order in cellulosics from X-ray scattering. Cellulose 2:51–70. https://doi.org/10.1007/BF00812772

French AD (2020) Increment in evolution of cellulose crystallinity analysis. Cellulose 27:5445–5448. https://doi.org/10.1007/s10570-020-03172-z

French AD, Santiago Cintrón M (2013) Cellulose polymorphy, crystallite size, and the segal crystallinity index. Cellulose 20:583–588. https://doi.org/10.1007/s10570-012-9833-y

Gindl W, Keckes J (2005) All-cellulose nanocomposite. Polymer 46(23):10221–10225. https://doi.org/10.1016/j.polymer.2005.08.040

Gismatulina YA (2014) Obtaining cellulose by nitric acid method directly from flax straw-mezheumka. Polzunovsky Bull 3:160–163

Golova LK (2002) New cellulose fiber lyocell. Ross Khim Zh 46(1):49

Golova LK, Makarov IS, Matukhina EV, Kuptsov SA, Shambilova GK, Kulichikhin VG (2008) Crystal solvates of thermotropic alkylenearomatic copolyesters and poly(m-phenyleneisophthalamide) with N-methylmorpholine-N-oxide. Polym Sci Ser A 50(6):665–678

GOSТ 25438–82 (2022) Methods for determining the characteristic viscosity. https://docs.cntd.ru/document/1200018032?ysclid=l7eseeftxe93206373. Accessed 29 Jul 2022

GОSТ 6841-77 (2022) Cellulose. Method of determination of resins and fats. https://internet-law.ru/gosts/gost/15538/?ysclid=l7es91127p824648793. Accessed 29 Jul 2022

GОSТ 6840-78 (2022) Method for determining the content of alpha-cellulose. https://internet-law.ru/gosts/gost/15298/?ysclid=l7eii29x9r492322969. Accessed 29 Jul 2022

GОSТ 16932-93 (2023) Cellulose. Determination of the dry matter content. https://www.iso.org/standard/4764.html. Accessed 14 Aug 2023

Goudenhooft C, Bourmaud A, Baley C (2019) Flax (Linum usitatissimum L.) fibers for composite reinforcement: exploring the link between plant growth, cell walls development, and fiber properties. Front Plant Sci 10:411. https://doi.org/10.3389/fpls.2019.00411

Höppner F, Menge-Hartmann U (2007) Yield and quality of fibre and oil of fourteen hemp cultivars in Northern Germany at two harvest dates. Landbauforsch Volk 3(57):219–232

Hubbe MA, Mclean DS, Stack KR, Lu X, Strand A, Sundberg A (2020) Self-assembly of alkyl chains of fatty acids in papermaking systems: a review of related pitch issues, hydrophobic sizing, and pH effects. BioResources 15:4591–4635

Hummel M (2018) High-performance lignocellulosic multicomponent fibers spun from superbase-based ionic liquids. Lenzinger Berichte 94:67–76

Ivanova NV, Korolenko EA, Korolik EV, Zhbankov RG (1989) Mathematical processing of the IR spectrum of cellulose. J Appl Spectrosc 51(2):301–306

Jiang G, Yuan Y, Wang B, Yin X, Mukuze KS, Huang W, Zhang Y, Wang H (2012) Analysis of regenerated cellulose fibers with ionic liquids as a solvent as spinning speed is increased. Cellulose 19(4):1075–1083. https://doi.org/10.1007/s10570-012-9716-2

Kabashova AN (2020) The relevance of nonwovens and innovations in their production. Symbol Sci 5:38–39

Kaplan DL (1998) Biopolymers from renewable resources. Springer, Berlin

Kashcheyeva EI, Gismatulina YA, Budaeva VV (2019) Pretreatments of non-woody cellulosic feedstocks for bacterial cellulose synthesis. Polymers 11(10):1645. https://doi.org/10.3390/polym11101645

Kukin GN, Soloviev LN, Koblyakov LI (1989) Textile materials science (fibers and threads): textbook for universities, 2nd edn, reprint. and additional. M.: Legprombytizdat

Levdansky VA, Levdansky AV, Kuznetsov BN (2014) A method for producing a cellulose product from flax with a high content of alpha-cellulose. J Sib Fed Univ Chem 1:63–70

Makarov IS, Bondarenko GN, Kuznetsova LK (2016) Hemicellulose in the process of obtaining cellulose fibers and membranes. Phys Fibrous Mater Struct Prop High Technol Mater Smartex 1(1):142–149

Makarov IS, Golova LK, Bondarenko GN, Skvortsov IYu, Berkovich AK, Bermeshev MV, Mironova MV (2017) Carbon–silicon-carbide fibers prepared from solid solutions of cellulose in N-methylmorpholine-N-oxide with added tetraethoxysilane. Fibre Chem 49(4):231–236. https://doi.org/10.1007/s10692-018-9874-6

Makarov IS, Golova LK, Vinogradov MI, Levin IS, Shandryuk GA, Arkharova NA, Golubev YV, Berkovich AK, Eremin TV, Obraztsova ED (2020) The effect of alcohol precipitants on structural and morphological features and thermal properties of lyocell fibers. Fibers 8(6):43. https://doi.org/10.3390/fib8060043

Makarov IS, Golova LK, Vinogradov MI, Egorov YE, Kulichikhin VG, Mikhailov YM (2021) New hydrated cellulose fiber based on flax cellulose. Russ J Gen Chem 91:1807–1815. https://doi.org/10.1134/S1070363221090280

Makarov IS, Golova LK, Smyslov AG, Vinogradov MI, Palchikova EE, Legkov SA (2022a) Flax noils as a source of cellulose for the production of lyocell fibers. Fibers 10(5):45. https://doi.org/10.3390/fib10050045

Makarov IS, Golova LK, Bondarenko GN, Anokhina TS, Dmitrieva ES, Levin IS, Makhatova VE, Galimova NZ, Shambilova GK (2022b) Structure, morphology, and permeability of cellulose films. Membranes 12(3):297. https://doi.org/10.3390/membranes12030297

Marchessault RH, Liang CY (1960) Infrared spectra of crystalline polysaccharides. III. Mercerized cellulose. J Polym Sci 43(141):71–84. https://doi.org/10.1002/pol.1960.1204314107

Mezentseva E, Rukhlova E, Ivanov V (2020) Trends in the nonwovens market. https://plastinfo.ru/information/articles/710/

Moryganov AP, Zakharov AG, Zhivetin VV (2002) Promising polymer materials for chemical and textile production. Ros Chem Zh 46(1):58–65

Nag S, Mitra J, Karmakar PG (2015) An overview on Flax (Linum usitatissimum L.) and its genetic. IJAEB 8(4):805–817. https://doi.org/10.5958/2230-732X.2015.00089.3

Nelson ML, O’Connor RT (1964) Relation of certain infrared bands to cellulose crystallinity and crystal lattice type. Part II. A new infrared ratio for estimation of crystallinity in Celluloses I and II. J Appl Polym Sci 8:1325–1341

Nelson ML, O’Connor RT (1964) Relation of certain infrared bands to cellulose crystallinity and crystal lattice type. Part I. Spectra of lattice types I, II, III and amorphous cellulose. J Appl Polym Sci 8:1311–1324

Nomura S, Kugo Y, Erata T (2020) 13 C NMR and XRD studies on the enhancement of cellulose II crystallinity with low concentration NaOH post-treatments. Cellulose 27:3553–3563. https://doi.org/10.1007/s10570-020-03036-6

Nugmanov OK, Grigorieva NP, Gidiyatullin MM, Kuramshina EA, Karimova AM, Khlebnikov VN, Lebedev NA, Akulinin VA (2007) Method for producing cellulose. RF Patent 2304647C2

PatentWO2009006207A1 (2007) Lyocell fibers

Peng Y, Gardner DJ, Han Y, Kiziltas A, Cai Z, Tshabalala MA (2013) Influence of drying method on the material properties of nanocellulose I: thermostability and crystallinity. Cellulose 20(5):2379–2392. https://doi.org/10.1007/s10570-013-0019-z

Perepelkin KE (2008) Ways of developing chemical fibres based on cellulose: viscose fibres and their prospects. Part 1. Development of viscose fibre technology. Alternative hydrated cellulose fibre technology. Fibre Chem 40(1):10–23

Röder T, Moosbauer J, Wöss K, Schlader S, Kraft G (2013) Man-made cellulose fibres – a comparisonbased on morphology and mechanical properties. Lenzinger Berichte 91:07–12

Ryzhov AI, Grigorov SI, Torgun IN, Usherovich EM, Kocharov SA, Ilyin AA, Golubev AE, Nikishov VP (2014) Method for obtaining bleached baster pulp. RF Patent 2578586C1

Sedelnik N (2004) Properties of hemp fibre cottonised by biological modification of hemp hackling noils. Fibres Text East Eur 12(145):58–60

Sidorova NR, Vinogradova AV (2021) The Russian market of nonwovens. In: Yemelyanov NV (ed) Materials of the VII International scientific and practical conference new impulses of development: issues of scientific research. Moscow, Publishing House, KDU, Dobrosvet., pp 160–164

Sjostrom E (2013) Wood chemistry: fundamentals and applications. Elsevier, Amsterdam, p 293

Smyslov AG (2022) Method for producing cellulose. RF Patent 2779000:C1

Strunk P, Lindgren A, Eliasson B, Agnemo R (2012) Chemical changes of cellulose pulps in the processing to viscose dope. Cell Chem Technol 46(9–10):559–569

TAPPI T 204 cm-97 (2007) Solvent extractives of wood and pulp. https://www.tappi.org/content/sarg/t204.pdf. Accessed 14 Aug 2023

Veselov VM, Abramov YaK, Zalevsky VM, Tamurka VG (2016) Method for obtaining cellulose. RF Patent 2574958 C1

Wiener J, Kovacic V, Dejlova P (2003) Differences between flax and hemp. Autex Res J 3(2):58–63

Yao W, Weng Y, Catchmark JM (2020) Improved cellulose X-ray diffraction analysis using Fourier series modeling. Cellulose 27:5563–5579. https://doi.org/10.1007/s10570-020-03177-8

Zhang J, Kitayama H, Gotoh Y, Potthast A, Rosenau T (2019) Non-woven fabrics of fine regenerated cellulose fibers prepared from ionic-liquid solution via wet type solution blow spinning. Carbohyd Polym 226:115258. https://doi.org/10.1016/j.carbpol.2019.115258

Zhivetin VV, Kocharov SA, Yarullin RN (2003) Modified bast fiber for pulp production. RF Patent 2196850 C1

Zommere G, Viļumsone A, Kalniņa D, Solizenko R, Stramkale V (2013) Comparative analysis of fiber structure and cellulose contents in flax and hemp fibres. Mater Sci Text Cloth Technol 8:96–104

Funding

The work was carried out with the financial support of LINUM LLC within the framework of the Grant Agreement 4409GS1/72609 dated 12/28/2021, within the State Program of A.V. Topchiev Institute of Petrochemical Synthesis (TIPS RAS) and with the support of the Ministry of Science and Higher Education within the framework of the State Program of the Federal Research Institute of Crystallography and Photonics of the Russian Academy of Sciences.

Author information

Authors and Affiliations

Contributions

Provided the idea for this study, proposed the experiments and wrote the paper, ISM and VGK; analyzed the data and reviewed the paper, ISM, VGK, EEP, AGS and MIV; produced the samples, EEP, NAA and AGS; investigation, ISM, MIV, EEP, NAA and AGS; analyzed the data, ISM and VGK; edited the final paper, ISM, VGK and AGS. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interest.

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Makarov, I.S., Smyslov, A.G., Palchikova, E.E. et al. Nonwoven materials based on natural and artificial fibers. Cellulose 31, 1927–1940 (2024). https://doi.org/10.1007/s10570-023-05719-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05719-2