Abstract

Colloidal gels are soft solids composed of particles dispersed in a fluid phase. Their rheological behavior highly depends on the particle concentration, but establishing a relationship can be challenging. This article showcases the potential of fractional rheology to model and predict linear viscoelastic responses of colloidal hydrogels containing TEMPO-oxidized cellulose nanofibers. Cellulose nanofiber hydrogels are soft solids whose rheology is directly related to the particle concentration. Therefore, this work defined the rheological behavior of the hydrogels using a fractional order derivative analytically solved to determine rheological responses in frequency, stress relaxation, and creep. Using two parameters, it evaluated the rheology of cellulose nanofiber hydrogels and established tests that predict rheological behaviors for given particle concentrations. The findings suggested that the fractional approach could become a standard method for characterizing cellulose nanofiber hydrogels in the reported concentration regime. The two parameters of the fractional model build a comparison framework to assess the rheology of different viscoelastic materials.

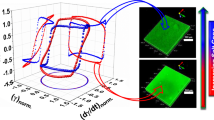

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Colloidal gels are viscoelastic materials with a soft solid texture commonly used in the food, cosmetics, and pharmaceutical industries. Colloidal gels are crucial for dispersing solid components that may otherwise settle quickly. As metastable solids, colloidal gels have a low particle density, forming a rigid structure with an interconnected fractal-like network (Jiang and Seto 2023; Angelini et al. 2023; Rouwhorst et al. 2020). Describing the rheology of colloidal gels is challenging because their stress–strain response is greatly influenced by their complex microstructures (Bantawa et al. 2023; Faber et al. 2017a, b). In real-world situations, not fully grasping the rheology of colloidal gels creates obstacles in material processing and product design. Simply put, there is no arbitrary way to connect rheological behavior with material composition.

Typically, the rheology of viscoelastic materials can be described phenomenologically. Existing rheological models consider the viscoelastic behavior as a mixture of elasticity and viscosity using two rheological elements: springs and dashpots. A spring represents an elastic solid with a stress–strain relationship given by Hooke’s law. In contrast, a dashpot stands for a fluid with a Newtonian stress–strain relationship. Although the spring-dashpot approach yields rational representations of rheological phenomena, for complex materials such as colloidal gels, it requires many parameters (Bonfanti et al. 2020). Assigning physical meaning to the resulting parameters constrains the potential universality of the spring-dashpot approach.

Cellulose nanofiber (CNF) hydrogels are an example of colloidal gels with complex rheological behavior. These gels are made from cellulose nanofibers, nanocelluloses with a slender shape that can extend to several microns (Isogai et al. 2011). Despite their small size and semicrystalline structure, CNF particles exhibit remarkable elasticity, making them helpful in, for example, designing hydrogels for biomedical applications, where they serve as a dispersion medium for drugs and other nanoparticles (Fneich et al. 2019; Hubbe et al. 2017; De France et al. 2017; Kontturi et al. 2018; Zeng et al. 2021; Reichler et al. 2021). Characteristically, CNFs are obtained as aqueous colloidal systems that tend to percolate into hydrogels even at low concentrations (Hill 2008; Pääkkö et al. 2007). Their rheology is known for displaying power-law signatures over a wide range of conditions and concentrations (\(\phi )\), which can be challenging to describe mathematically without using recursive constitutive equations and numerous spring-dashpot arrangements (Pääkkö et al. 2007; Hill 2008; Koponen 2020; Naderi and Lindström 2014; Šebenik et al. 2019).

Particularly, describing the rheology of CNF hydrogels is constrained to empirical equations (Pääkkö et al. 2007; Naderi and Lindström 2014). Therefore, characterizing the rheology of CNF hydrogels requires a different mathematical framework than the common spring-dashpot approach. Scott Blair, a pioneer in establishing the foundations of rheology, suggested that certain viscoelastic materials show a rheological response intermediate between elasticity and viscosity (Scott Blair et al. 1947; Scott Blair 1969). For those materials, Scott Blair proposed using fractional calculus and introduced the concept of “principle of intermediacy”. Using fractional calculus has allowed the creation of models that better align with experimental rheological data. This, in turn, has improved the understanding of viscoelastic phenomena on a physical level (Ciancio et al. 2023; Tarasov and Tarasova 2020).

The principle of intermediacy defines the viscoelastic behavior with a fractional order derivative that generalizes Hooke’s and Newton’s laws. Nowadays, the principle of intermediacy translates to fractional rheology, the application of fractional calculus to the viscoelasticity of materials (West et al. 2003). Fractional rheology has great potential for describing viscoelastic systems with complex microstructures (Bantawa et al. 2023; Bonfanti et al. 2020; Faber et al. 2017b; Owens et al. 2022). Yet, to our knowledge, no work has used fractional rheology to comprehend the viscoelasticity of CNF hydrogels. Describing the rheology of CNF hydrogels with constitutive equations rather than with empirical relationships would shed light on understanding the hierarchical nature of colloidal systems.

This article proposes using fractional rheology to characterize the rheological properties of colloidal hydrogels with TEMPO-oxidized CNFs. For that, the principle of intermediacy introduces a rheological element called springpot. The springpot constitutive equation describes the degree of viscoelasticity (\(\alpha\)) of a material by varying the fractional order of the derivative between 0 and 1 (Koeller 1984). In particular, the springpot can accurately describe timescales for materials exhibiting power-law signatures. For instance, casein food gels were characterized by Faber et al. (2017b) and Keshavarz et al. (2017); the authors demonstrated that the power-law rheological behavior of such protein gels could be described using the principle of intermediacy. Similar to the former example, the literature showcases multiple materials whose rheology was successfully characterized by including a springpot in the mathematical framework (Alcoutlabi and Martinez-Vega 1998; Bantawa et al. 2023; Bonfanti et al. 2020; Faber et al. 2017a, b; Reyes-Melo et al. 2008).

This article hypothesizes that one springpot can describe and predict the viscoelastic behavior of CNF hydrogels within the linear viscoelastic regime (LVR). In its simplest form, the springpot constitutive equation is called the Scott-Blair (SB) model. This paper uses the SB model to fit the material functions storage [\(G^{\prime }(\omega )\)] and loss [\(G^{\prime \prime }(\omega )\)] modulus measured from dynamic mechanical analysis (DMA) with only two parameters: \(\mathbb {G}\) and \(\alpha\). \(\mathbb {G}\) is a quasi-property with Pa s\(^{\alpha }\) units related to the gel firmness, while \(\alpha\) defines the degree of viscoelasticity. To show the potential of the principle of intermediacy, we computed the stress relaxation and creep response of the CNF hydrogels from the frequency spectrum, indicating that the data obtained with the SB model approximated the experimental results. We demonstrated that the SB model allowed for building a framework to predict rheological responses given a CNF concentration. Our findings showed us at a glance that the SB model could be used as a standard model to characterize the rheology of CNF hydrogels in the reported concentration regime and therefore ease material design and processing operations.

Experimental section

The CNF hydrogels are made from TEMPO-oxidized cellulose nanofibers obtained from Kraft softwood pulp according to the methods described in the literature (Leppiniemi et al. 2017; Pöhler et al. 2020; Skogberg et al. 2017). Figure S1 shows the structure of a CNF hydrogel under polarized optical microscopy; the image highlights the broad particle size distribution of the fibers. VTT Technical Research Centre of Finland kindly provided the CNFs as a hydrogel with 1.16 wt% fiber concentration (Koochi et al. 2023). To assess the effect of CNF concentration (\(\phi\)) in the hydrogel, a dilution series of 0.90, 0.70, 0.50, and 0.30 wt% \(\phi\) was prepared by adding deionized water to the 1.16 wt% CNF hydrogel. All the hydrogels were homogenized mechanically and then rested at 4 \(^{\circ }\)C for three days to coarsen any bubble formed during the homogenization. After this time, we evaluated the rheology of the samples.

Small strain shear rheology

Rheological characterization of the CNF hydrogels consisted of three time-dependent experiments: dynamic mechanical analysis (DMA), stress relaxation, and creep. These three experiments were conducted on hydrogels with 0.30, 0.50, 0.70, 0.90, and 1.16 wt% CNF concentration. The experiments took place on an Anton Paar (Austria) modular compact rheometer (MCR) 302 equipped with a Couette geometry. The geometry comprises a lower cup and upper bob tool with serrated walls (Viitanen et al. 2023). For the experiments, the tested CNF hydrogel was slowly poured into the cup, avoiding bubble formation. Then, the bob tool was lowered to the measuring position. Before starting an experiment, the sample was allowed to rest for 15–20 min at 10 \(^{\circ }\)C to ensure its thermal equilibrium and structure recovery. All the tests were carried out at a constant temperature since modifying the temperature showed a neglectable influence on the viscoelastic properties of the CNF hydrogels, see Fig. 1a. Accordingly, to avoid drying out the CNF hydrogels, all experiments were at a temperature of 10 \(^{\circ }\)C.

Pre-characterization of the cellulose nanofiber (CNF) hydrogels for determining measuring conditions. a Dynamic mechanical thermal analysis on a CNF hydrogel with concentration (\(\phi\)) of 0.90 wt%. The results show that the material functions \(G^{\prime } (T)\), \(G^{\prime \prime } (T)\) show a neglectable dependence on the temperature (T). No clear effects of hysteresis are observed from heating and cooling cycles at 1 \(^{\circ }\)C min\(^{-1}\) at a constant angular frequency (\(\omega\)) of 10 rad s\(^{-1}\) and strain amplitude (\(\gamma _{0}\)) of 0.2 %. b Strain tests on samples with \(\phi =0.30\) wt% (empty and solid circles of lower magnitudes) and \(\phi =1.16\) wt% (empty and solid circles of higher magnitudes), \(\omega = 10\) rad s\(^{-1}\). The plot also shows the chosen \(\gamma _{0}\) (0.2 %) value for dynamic mechanical analysis (DMA) and stress relaxation. c DMA measured from high to low frequencies on a CNF hydrogel with \(\phi =1.16\) wt% (\(\gamma _{0} = 0.2~\%\))

Dynamic Mechanical Analysis (DMA): The rheometer measured the material functions storage and loss modulus (\(G^{\prime }\) and \(G^{\prime \prime }\)) in response to angular frequency (\(\omega\)) in a range from 0.1 to 100 rad s\(^{-1}\). The tests were performed at a constant temperature \(T=10~^{\circ }\)C and constant strain amplitude \(\gamma _{0}=0.2~\%\). The parameter \(\gamma _{0}\) was within the linear viscoelastic regime (LVR), and its magnitude was chosen from strain amplitude tests on the CNF hydrogels with the lowest and highest concentrations, see Fig. 1b. During DMA, the angular frequency was increased logarithmically from \(\omega =0.1\) rad s\(^{-1}\) to \(\omega =100\) rad s\(^{-1}\), and the rheometer set the data acquisition rate. We discarded the experimental points that the rheometer tagged as unsteady. For some authors, a common practice is to measure from high to low frequencies rather than from low to high. Figure 1c shows a DMA result from high to low frequencies. We use Fig. 1c to demonstrate that the material functions were independent of the measuring protocol.

Stress relaxation: On the rheometer, the sample was submitted to a step strain of \(\gamma _{0}=0.2~\%\) for a time of \(t=100\) s. The device measured the relaxation modulus [G(t)], a property that represents the ability of a material to relieve stress. G(t) is defined as \(\sigma (t) / \gamma _{0}\), where \(\sigma (t)\) is the stress signal as a function of time. The tests were carried out at a constant temperature \(T=10~^{\circ }\)C. Data acquisition was logarithmic from \(t=0.1\) s to \(t=100\) s. The lower time limit corresponds to the timescale that the rheometer can accurately record.

Creep: Similar to the stress relaxation protocol, creep tests were carried out on the rheometer to measure the creep compliance [J(t)] of the CNF hydrogels. A step stress (\(\sigma _{0}\)) of 5 Pa or 20 Pa (depending on the sample concentration: 5 Pa for the lowest concentration and 20 Pa for the highest) was generated for \(t=100\) s, followed by a recovery phase of \(t=100\) s, where the stress was relieved. Since the magnitude of \(\sigma _{0}\) highly affects the creep response, we chose a small \(\sigma _{0}\) to deform the sample elastically (Owens et al. 2022). J(t) is defined as \(\gamma (t) / \sigma _{0}\), and the test was carried out at a constant temperature \(T=10~^{\circ }\)C. Data acquisition was logarithmic from \(t=0.1\) s to \(t=100\) s, following the same protocol used during stress relaxation.

Principle of intermediacy: Scott-Blair model

To describe the rheology of the CNF hydrogels, we used the Scott-Blair (SB) model based on the principle of intermediacy. As Fig. 2a illustrates, the SB model defines the shear stress (\(\sigma\)) signal of a viscoelastic material as an intermediate behavior between a spring (Hooke’s law for elastic solids) and dashpot (Newton’s law for viscous liquids). Such intermediate behavior is represented by a rheological element called springpot, and Eq. 1 presents its constitutive equation as a fractional order derivative (Koeller 1984),

Equation 1 generalizes Hooke’s and Newton’s laws. The fractional order (\(\alpha\)), which ranges between 0 and 1, specifies whether the rheology of a sample approximates a solid-like (\(\alpha \approx 0\)) or liquid-like (\(\alpha \approx 1\)) behavior. Furthermore, \(\alpha\) indicates the time-dependence response of the viscoelastic sample (Faber et al. 2017a). In Eq. 1, t is the time, and \(\gamma\) is the shear strain. The factor \(\mathbb {G}\) is a quasi-property, namely quasi-modulus, with units of Pa s\(^{\alpha }\). When \(\alpha =0\), \(\mathbb {G}\) has units of elasticity; \(\mathbb {G}\) has units of viscosity when \(\alpha =1\). \(\mathbb {G}\) is correlated with the material firmness. It is important to remark that others have defined the springpot as a three-parameter element, introducing the concept of relaxation time (Friedrich et al. 1999; Schiessel et al. 1995). However, it is not possible to design an experiment to measure the relaxation time, which constrains the practical use of the three-parameter springpot (Bonfanti et al. 2020; Jaishankar and Mckinley 2013). Accordingly, the two-parameter version of the springpot is preferred as it eases fitting the springpot parameters to experimental data. Next, we present a succinct description of how Eq. 1 can be solved to describe the material properties of viscoelastic materials. The reader may refer to textbooks by Mainardi (2010) and West et al. (2003) to obtain more details about the springpot fractional derivative.

Equation 1 has analytical solutions for describing \(G^{\prime }(\omega )\) and \(G^{\prime \prime }(\omega )\) in DMA, G(t) in stress relaxation, and J(t) in creep (Mainardi 2010). To find the analytical solutions, Eq. 1 can be redefined using the Caputo derivative as:

where \(\Gamma\) is the Gamma function (Surguladze 2002). Equation 2 represents a response given by a Boltzmann memory integral with a power-law relaxation (Faber et al. 2017a; Koeller 1984; Torvik and Bagley 1984). The Caputo derivative states the assumption that the system is at rest before time 0, which reflects the reality of the test.

In DMA, \(G^{\prime }(\omega )\) and \(G^{\prime \prime }(\omega )\) result from shear oscillations; the material functions are frequency-dependent. The condition can be defined by applying the Fourier transform to the Caputo derivative of \(\gamma (t)\), as Eq. 3 (Schiessel et al. 1995),

The Fourier transform results in the complex modulus function \(G^{*}(\omega )\) given by Eq. 4,

Then, the same equation can be separated, providing a mathematical framework to characterize \(G^{\prime }(\omega )\) with Eq. 5,

and \(G^{\prime \prime }(\omega )\) with Eq. 6 (Friedrich et al. 1999),

On the other hand, the Laplace transform in Eq. 7,

allows for establishing the G(t) and J(t) functions as given in Eq. 8,

and Eq. 9,

respectively (Bird et al. 1987; Faber et al. 2017a, b). The Laplace transform is a mathematical tool that eases obtaining time-dependent analytical solutions.

Modeling and prediction of materials functions

The DMA results of the CNF hydrogels, except the one with \(\phi = 0.90\) wt%, were fitted using Eq. 5 and Eq. 6. It is possible to fit only the material function \(G^{*}(\omega )\); however, fitting \(G^{\prime }(\omega )\) and \(G^{\prime \prime }(\omega )\) reduces the bias (Faber et al. 2017b). Fitting the DMA results yields two parameters, \(\mathbb {G}\) and \(\alpha\), for each \(\phi\) of CNF hydrogel. Then to show the potential of the Scott-Blair model, both parameters were replaced in Eq. 8 and 9 to compute the materials functions G(t) and J(t). These computations were compared to the experimental results measured during stress relaxation and creep. Finally, we use the classic scaling law approach to describe the dependence between the Scott-Blair model parameters and \(\phi\). From describing how \(\mathbb {G}\) and \(\alpha\) vary as a function of \(\phi\), we attempt to predict all the rheological responses for a given CNF concentration of \(\phi = 0.90\) wt%.

Results and discussion

Rheological models: a comparison

We first present in Fig. 2b–d the material functions \(G^{\prime }(\omega )\) and \(G^{\prime \prime }(\omega )\) for the Maxwell, Voigt-Kelvin, and Scott-Blair (SB) models. In brief, Maxwell and Voigt-Kelvin are two of the simplest linear viscoelastic traditional models; the first assembles a spring and dashpot in series, and the second in parallel. While the Maxwell model can characterize rheological behaviors in frequency for cross-linking materials, Voigt-Kelvin fails to represent typical rheological responses in viscoelastic materials (Zelenkova et al. 2017; Webber and Tibbitt 2022). In comparison, the SB model depicts in frequency a power-law behavior whose viscoelastic nature can be assessed using the parameter \(\alpha\). In the case of Fig. 2d, it shows a more elastic response given by \(\alpha = 0.30\).

a Scheme of the principle of intermediacy depicted by a spring, springpot, and dashpot (from top to bottom order). The springpot represents the stress (\(\sigma\)) response of viscoelastic materials as an intermediate behavior between Hooke’s (spring) and Newton’s (dashpot) laws. The constitutive equation of the springpot generalizes both laws with a fractional order derivative. \(\alpha\) is the fractional order of the derivative (between 0 and 1) of strain (\(\gamma\)) respective to time (t). \(\alpha\) represents the degree of viscoelasticity, and \(\mathbb {G}\) is a quasi-property with Pa s\(^{\alpha }\) units. Signature rheological response of b Maxwell, c Voigt-Kelvin, and d Scott-Blair (\(\alpha = 0.30\)) models in a frequency sweep test or dynamic mechanical analysis (DMA). The figure highlights the potential of the Scott-Blair model to characterize power-law behaviors typically observed in cellulose hydrogels. e Dynamic mechanical analysis (DMA) at constant temperature \(T=10\) \(^{\circ }\)C. The measured sample is a cellulose nanofiber (CNF) hydrogel with a concentration (\(\phi\)) of 0.50 wt%. Note: G stands for shear modulus and \(\eta\) for dynamic viscosity, shown in b and c

The response depicted in Fig. 2d is common in soft solids, such as cheese, bitumen, and some natural gums (Bonfanti et al. 2020; Faber et al. 2017b; Fagioli et al. 2018). Mainly, cellulose-based materials, which tend to percolate, also exhibit DMA responses that can be characterized using a springpot (Miranda-Valdez et al. 2023). Accordingly, we present in Fig. 2e one of the DMA results measured for a CNF hydrogel with \(\phi = 0.50\) wt%. One can see that the rheological response of the CNF hydrogel resembles the SB model curves in Fig. 2d. Recently, Bantawa et al. (2023) correlated the rheological behavior characterized using a springpot with the fractal and hierarchical microstructure in soft particulate gels. CNF hydrogels meet both features; they are soft particulate gels and display microstructures with fractal dimensions (Serra-Parareda et al. 2021). Intuitively, such structural characteristics of CNF hydrogels may reveal why the SB model approaches the experimental rheological response (Fig. 2d,e).

All in all, a qualitative comparison between the theoretical and experimental material functions, \(G^{\prime }(\omega )\) and \(G^{\prime \prime }(\omega )\) in Fig. 2d,e, showed at a glance that the linear rheology of CNF hydrogel can be described using the SB model. The efficacy of the SB model is based on the fact that the springpot parameterizes the relaxation spectrum, which in turn determines the distribution of characteristic timescales, unlike the spring-dashpot models that define specific timescales (Bonfanti et al. 2020; Suzuki et al. 2021). In other words, the springpot can be seen as an infinite fractal representation of spring-dashpot elements which can be correlated to the fractal scaling properties of gel clusters (Schiessel and Blumen 1993; Suzuki et al. 2021; Larson 1999). Furthermore, the concept aligns with the fractal structure of CNF hydrogels, as it suggests a broad range of lengths and timescales. In the following sections, we confirmed the relevance of using the principle of intermediacy to characterize other rheological responses, focusing on the relaxation modulus [G(t)] and creep compliance [J(t)].

Scott-Blair model: fitting and computation of material functions

All the results from DMA, stress relaxation, and creep are presented in Fig. S2 and Fig S3. The manuscript hereby collects representative figures to complement the discussion. The material functions of the CNF hydrogels agreed with the physical dispersion stability precondition since \(G^{\prime }(\omega )\) > \(G^{\prime \prime }(\omega )\). In other words, the CNF systems met some of the characteristics of a viscoelastic solid (Winter and Mours 1996). Furthermore, we observed that \(G^{\prime }(\omega )\) > \(G^{\prime \prime }(\omega )\) by one decade, which is a characteristic behavior in CNF hydrogels (Dimic-Misic et al. 2013; Nechyporchuk et al. 2014). This precondition can be seen in the DMA results exemplified in Fig. 2e and Fig. 3a,b. What complicates understanding the rheology of CNF hydrogels is the slight dependency of \(G^{\prime }\) and \(G^{\prime \prime }\) on \(\omega\), meaning that the CNF hydrogels deviate from the ideal behavior of true gels (Winter and Mours 1996). Generally, when the material functions are frequency-dependent, they indicate an imperfect gel network (Rubinstein and Colby 2003). This is expected since CNF hydrogels, as colloidal gels, form a metastable solid structure rather than a chemically crosslinked one.

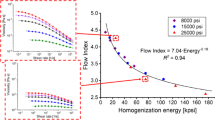

Rheological responses of cellulose nanofiber (CNF) hydrogels with a concentration (\(\phi\)) of 0.70 wt% and b \(\phi\) of 1.16 wt% in dynamic mechanical analysis (DMA). c Parameters of the Scott-Blair (SB) model as a function of the cellulose nanofiber concentration (\(\phi\)) in the hydrogels; the dashed lines represent the fittings of the parameters as a function of \(\phi\)

Regarding the results obtained using the SB model, we present a subset of DMA experiments on CNF hydrogels. Figure 3a,b show the SB model fittings of the DMA results on hydrogels with \(\phi = 0.70\) wt% and \(\phi = 1.16\) wt%. In addition to these DMA results, the SB model also fitted the experimental data for systems with \(\phi = 0.50\) wt% and \(\phi = 0.30\) wt%. All the experimental data were well described using the SB model since the mean absolute error (MAE) was small; see Table 1. In previous work, we showcased how the MAE using a springpot can be four times smaller than the analysis with a generalized Maxwell model with 200 parameters (Miranda-Valdez et al. 2023). Furthermore, Fig. 3c shows how the fitting parameters \(\alpha\) and \(\mathbb {G}\) changed as a function of \(\phi\). One must remark that at high frequencies, \(G^{\prime \prime }(\omega )\) deviated from the SB model; \(G^{\prime \prime }(\omega )\) slightly increased, indicating a gradual change of the dangling gel structure as a function of frequency. Despite this deviation, the SB model offered an analytical description of \(G^{\prime }(\omega )\) and \(G^{\prime \prime }(\omega )\) for the CNF hydrogels. This allowed for computing other material functions in the CNF hydrogels and built a systematic approach to capturing their rheology. For example, the SB model could replace empirical equations that have been suggested in the literature to describe \(G^{\prime }(\omega )\) in CNF hydrogels and systems with similar rheological responses (Jampala et al. 2005; Kim and Yoo 2006; Naderi and Lindström 2014). What is remarkable from the results in Fig. 3a,b is that, to the best of our knowledge, this is the first time that the SB model has been used successfully to fit the material functions \(G^{\prime }(\omega )\) and \(G^{\prime \prime }(\omega )\) of CNF hydrogels. This demonstrates that the SB model can capture the behavior of colloidal systems containing high aspect ratio particles, as CNFs are.

Knowing that the hydrogel concentration directly affects the rheological properties, we analyzed how the parameters changed as a function of \(\phi\). Table 1 summarizes the fitted values for the SB model parameters. We observed two characteristic behaviors in Fig. 3c. On the one hand, \(\mathbb {G}\) scaled as a function of \(\phi\) following a power-law behavior. Alternatively, \(\alpha\) decreased exponentially as a function of \(\phi\), then reached a plateau. We should mention that this work only evaluates the effect of \(\phi\) on the rheological properties of CNF hydrogels. However, there are more experimental conditions that may influence the rheology. For example, the pH of the liquid phase, the \(\zeta\)-potential, and particle size distribution are other parameters that can be controlled and change the rheological behavior of a colloidal system. The effect of these different experimental conditions on the rheology could be interconnected with the SB model parameters by using experimental design approaches that allow predictions in high-dimensional spaces (response surface methodology or Bayesian optimization) (Miranda-Valdez et al. 2022).

As the parameter \(\mathbb {G}\) is closely related to the hydrogel stiffness, the observed power-law increment in \(\mathbb {G}\) means that the CNF hydrogels became stiffer when \(\phi\) increased. Such power-law behavior of \(\mathbb {G}\) is analogous to the common approach used in the literature which characterizes the rheology of CNF hydrogels given an empirical power-law \(G^{\prime } \propto \phi ^{n}\) (Pääkkö et al. 2007; Hill 2008; Koponen 2020; Naderi and Lindström 2014; Avallone et al. 2023). For example, here, the CNF hydrogels showed a scaling exponent (n) of \(\sim\)2.45, when \(G^{\prime }\) was taken at \(\omega =1\) rad s\(^{-1}\). n typically varies between 2 and 3 (Pääkkö et al. 2007; Hill 2008; Koponen 2020; Naderi and Lindström 2014). The drawback of the latter approach is its bias raised from neglecting the effect of frequency on the material functions \(G^{\prime }(\omega )\) and \(G^{\prime \prime }(\omega )\). A more systematic solution can be obtained from determining the scaling law of the quasi-modulus \(\mathbb {G} \propto \phi ^{n}\). From fitting the data in Fig. 3c to a power-law function, we found that \(\mathbb {G} \approx 578\phi ^{2.45}\) (\(R^{2}=0.999\)).

Regarding the behavior of \(\alpha\) as a function of \(\phi\), from Fig. 3c, we observed that the CNF hydrogels took a viscoelastic solid conformation since \(\alpha\) readily approached a minimum value close \(\alpha = 0.053\), a number in the order of magnitude reported for other polymer gels with similar \(G^{\prime }(\omega )\) and \(G^{\prime \prime }(\omega )\) (Keshavarz et al. 2017). To characterize the behavior of \(\alpha\) as a function of \(\phi\), we fitted the results in Fig. 3c using an exponential function. This is, \(\alpha \approx 0.053 + 0.322 \cdot 0.0045 ^{\phi }\). However, one should remark that the function for describing \(\alpha\) as a function of \(\phi\) depends on case-by-case. Here we chose the function that best fitted the \(\alpha\)-\(\phi\) relationship. Moreover, \(\alpha\) and \(\mathbb {G}\) were determined only as a function of \(\phi\), but they are sensitive to varying conditions (e.g., pH) that may lead the colloidal cluster to form a different network. The next section shows the relevance of the defined functions of \(\mathbb {G}\) and \(\alpha\) as a function of \(\phi\). Given a \(\phi\) value, one can predict the rheological response of the CNF hydrogel in frequency, stress relaxation, and creep. Further, as shown in Fig. S4, predicting flow curves is possible for a given \(\phi\).

To show how the scaling law \(\mathbb {G} \propto \phi ^{n}\) can be used, we estimated the fractal dimension \(d_{f}\) of the CNF hydrogels following the approach reported by Shih et al. (1990). The authors reported that \(d_{f}\) of a strong-gel network, as the CNF hydrogels studied here, can be extracted from the storage modulus scaling law, \(G^{\prime } \propto \phi ^{n}\) (Shih et al. 1990). We have demonstrated that \(G^{\prime } \propto \phi ^{n}\) and \(\mathbb {G} \propto \phi ^{n}\) are analogous; furthermore, they share the same exponent n. Accordingly, one can estimate \(d_{f}\) from \(n = (d + x) / (d - d_{f})\). There, \(d = 3\) represents a three-dimensional network, and x is the backbone fractal dimension of flocs for strong-linked CNF hydrogels (Fneich et al. 2019), usually ranging from 1 to 1.4. Recalling that \(n = 2.45\), the fractal dimension can be approximated to a constant value ranging from \(d_f = 1.37\) to \(d_f =1.20\), depending on the value of x. This value is slightly lower than the one reported in the literature for CNF hydrogels (Fneich et al. 2019), implying weaker aggregation. In the weak link regime, where \(n=(d-2)/(d-d_f)\), the Shih model would give a much higher fractal exponent (\(d_f=2.59\)), but one can explore intermediate link strengths by employing the Wu–Morbidelli model (Wu and Morbidelli 2001). This model is given by \(n = \beta /(d-d_f)\) where the exponent \(\beta = d-2 + (2+x)(1-z)\) includes a parameter z which interpolates between the strong (\(z =0\)) and weak link (\(z=1\)) regimes. Then, with a quite small deviation from the strong link regime (\(z=0.2\)) one can achieve \(d_f \approx 1.5\), which was previously found for CNF hydrogels (Fneich et al. 2019) in the dilute regime. As this is only an estimation, we suggest that future research attempts to correlate the fractional parameters with the structure of CNF hydrogels. The latter is out of the scope of this article, but it could be achieved by combining rheological characterization with confocal microscopy.

The SB model can be analytically solved for stress relaxation and creep experiments. Similar to the analytical equations of \(G^{\prime }(\omega )\) and \(G^{\prime \prime }(\omega )\), the model could describe the material functions of the relaxation modulus [G(t)] and creep compliance [J(t)] using the same two parameters: \(\alpha\) and \(\mathbb {G}\). Stress relaxation and creep tests are critical to assessing the durability and shape stability of CNF hydrogels. For example, creep behavior is desired when a material needs to flow through a pipe. In particular, for CNF hydrogels, creep is favorable for injectability or pipe flow. Therefore, characterizing G(t) and creep compliance J(t) allows a thorough comprehension of the rheological behavior.

Rheological responses of cellulose nanofiber (CNF) hydrogels with a concentration (\(\phi\)) of 1.16 wt% and \(\phi\) of 0.70 wt% in a stress relaxation and b creep experimental. The dashed lines are the results of replacing the Scott-Blair (SB) model parameters obtained from dynamic mechanical analysis (DMA) in the c constitutive equations of the SB model for the relaxation modulus G(t) and creep compliance J(t)

For all the concentrations, we replaced the previously obtained values of \(\alpha\) and \(\mathbb {G}\) in Eq. 8 and Eq. 9. Then, we compared the computed responses of G(t) and J(t) with the experimental results obtained for each CNF hydrogel. Figure 4a,b demonstrate that the SB computation approximates the experimental results, confirming that the SB model could reduce the experimental burden during the rheological characterization of CNF hydrogels. One must highlight that the SB model can only describe the power-law regime during stress relaxation and creep. The latter was less noticeable for stress relaxation since the rheometer cannot record the G(t) response at short timescales. On the other hand, during creep, one can see that only the second stage of creep can be accurately described. Since the CNF hydrogels were highly elastic, it took longer to induce creep than relaxation. In general, with the SB model, as shown in Fig. 4c, and its analytical equations, one can obtain a holistic framework that characterizes the rheology of CNF hydrogels in the reported concentration regime and could be expanded to characterize a broader range of concentrations.

Scaling law of quasi-modulus and degree of viscoelasticity: prediction of material functions

In practice, the relevance of rheological models relies on their potential to predict rheological responses given a material composition (Bonfanti et al. 2020). In that context, for CNF hydrogels, this translates to tailoring a hydrogel with the desired rheological properties based on the CNF concentration. Hence, to validate the relevance of the SB model, we used the functions defined for \(\mathbb {G}\) and \(\alpha\) (i.e., the dashed lines in Fig. 3c) to predict the magnitude of both parameters given \(\phi = 0.90\) wt%. Then, we replaced the predicted values of \(\alpha\) and \(\mathbb {G}\) at \(\phi = 0.90\) wt% in Eqs. 5 and 6. Figure 5a shows that the predicted material functions, \(G^{\prime }(\omega )\) and \(G^{\prime \prime }(\omega )\), corresponded to the experimental results. Additionally, knowing that the prediction in Fig. 5a was in agreement with the experimental results, one could further predict the material functions G(t) and J(t) by replacing \(\mathbb {G}\) and \(\alpha\) in Eqs. 8 and 9. The predicted responses, G(t) and J(t), for a hydrogel with \(\phi = 0.90\) wt% are shown in Fig. 5b,c. The experimental results agreed again with the predicted responses. In addition, the constitutive equation of the springpot can be extended to describe other experiments. For example, the springpot can be analytically solved to predict the engineering stress–strain curve of the CNF hydrogels (Meng et al. 2019; Meng 2021). Furthermore, when the Cox-Merz rule is valid, the SB parameters can be used to predict the non-linear response \(\eta ^{*}(\omega )\), i.e., complex viscosity (Jaishankar and Mckinley 2014). Figure S4 compares the experimental data of \(\eta ^{*}(\omega )\) with the predicted values from scaling the SB parameters to \(\phi = 0.90\) wt%. The results in Fig. S4 confirmed that it is possible to compute non-linear responses from the linear behavior using the SB model. Also, it demonstrated that the SB model could describe the dynamic viscosity of materials with yield point such as CNF hydrogels.

Comparison between the experimental and predicted rheological responses of a cellulose nanofiber hydrogel with concentration (\(\phi\)) of 0.90 wt%. The predicted results are obtained by replacing the theoretical quasi-modulus (\(\mathbb {G}\)) and degree of viscoelasticity (\(\alpha\)) calculated at the given \(\phi\) value. Then, \(\mathbb {G}\) and \(\alpha\) were replaced in the analytical equations of the Scott-Blair model for the material functions in a dynamic mechanical analysis (DMA), b stress relaxation, and c creep. \(\mathbb {G} = 447\) Pa s\(^{\alpha }\) and \(\alpha = 0.056\)

Conclusions

Fractional rheology successfully described the viscoelastic phenomena in colloidal hydrogels containing TEMPO-oxidized cellulose nanofibers, proving our hypothesis that the Scott-Blair (SB) model could characterize the power-law behavior depicted by the material functions. The model accurately describes the stress relaxation, creep, and even complex viscosity response from the information obtained from the frequency spectrum of CNF hydrogels. The Scott-Blair model uses only two parameters: the quasi-modulus (\(\mathbb {G}\)) and the degree of viscoelasticity (\(\alpha\)). Assessing the effect of particle concentration (\(\phi\)) on the magnitude of \(\mathbb {G}\) and \(\alpha\) showed that the quasi-modulus followed the same scaling law that has been suggested empirically for the storage modulus (\(G^{\prime }\)) of CNF hydrogels. Regarding the magnitude of \(\alpha\), the degree of viscoelasticity dropped exponentially as a function of \(\phi\). The latter was evidence of the highly elastic character of the hydrogels. The SB model provided constitutive equations for material functions previously described empirically for CNF hydrogels. The results demonstrated that fractional rheology can be used to describe materials with complex viscoelastic responses. Accordingly, our findings suggest that the SB model could be used as a standard method to characterize CNF hydrogels in the studied regime. For example, the \(\mathbb {G}\) and \(\alpha\) parameters characterized for a CNF hydrogel could be compared with those characterized for another material. Offering a comparison framework is crucial for easing material selection and design. In particular, since CNF hydrogels can be produced with high particle concentrations (e.g., \(\phi =7\) wt%), such colloidal systems could be easily diluted to achieve a rheological behavior suiting the target application. We showcased an example of how after scaling the \(\mathbb {G}\) and \(\alpha\) as a function of \(\phi\), the material functions [\(G^{\prime } (\omega )\), \(G^{\prime \prime } (\omega )\), G(t), J(t) and \(\eta ^{*}(\omega )\)] can be predicted for a given \(\phi\). We found that the predictions matched the experimental results. The results highlight the SB model robustness since all the experimental observations were consistently accurate with the predictions.

References

Alcoutlabi M, Martinez-Vega J (1998) Application of fractional calculus to viscoelastic behaviour modelling and to the physical ageing phenomenon in glassy amorphous polymers. Polymer 39(25):6269–6277. https://doi.org/10.1016/S0032-3861(98)00168-2

Angelini R, Larobina D, Ruzicka B, Greco F, Pastore R (2023) Rheological signatures of a glass-glass transition in an aging colloidal clay. J Rheol 67(4):811. https://doi.org/10.1122/8.0000592

Avallone PR, Russo Spena S, Acierno S, Esposito MG, Sarrica A, Delmonte M, Pasquino R, Grizzuti N (2023) Thermorheological behavior of k-carrageenan hydrogels modified with xanthan gum. Fluids 8(4):119. https://doi.org/10.3390/fluids8040119

Bantawa M, Keshavarz B, Geri M, Bouzid M, Divoux T, Mckinley GH, Del Gado E (2023) The hidden hierarchical nature of soft particulate gels. Nat Phys. https://doi.org/10.1038/s41567-023-01988-7

Bird R, Armstrong R, Hassager O (1987) Dynamics of polymer liquids. Wiley, Hoboken

Bonfanti A, Kaplan JL, Charras G, Kabla A (2020) Fractional viscoelastic models for power-law materials. Soft Matter 16(26):6002–6020. https://doi.org/10.1039/d0sm00354a

Ciancio A, Ciancio V, Flora BFF (2023) A fractional rheological model of viscoanelastic media. Axioms 12(3):243. https://doi.org/10.3390/axioms12030243

Dimic-Misic K, Puisto A, Gane P, Nieminen K, Alava M, Paltakari J, Maloney T (2013) The role of MFC/NFC swelling in the rheological behavior and dewatering of high consistency furnishes. Cellulose 20(6):2847–2861. https://doi.org/10.1007/s10570-013-0076-3

Faber T, Jaishankar A, Mckinley G (2017) Describing the firmness, springiness and rubberiness of food gels using fractional calculus. Part II: measurements on semi-hard cheese. Food Hydrocoll 62:325–339. https://doi.org/10.1016/j.foodhyd.2016.06.038

Faber T, Jaishankar A, Mckinley G (2017) Describing the firmness, springiness and rubberiness of food gels using fractional calculus. Part I: Theoretical framework. Food Hydrocoll 62:311–324. https://doi.org/10.1016/j.foodhyd.2016.05.041

Fagioli L, Pavoni L, Logrippo S, Pelucchini C, Rampoldi L, Cespi M, Bonacucina G, Casettari L (2018) Linear viscoelastic properties of selected polysaccharide gums as function of concentration, pH, and temperature. J Food Sci. https://doi.org/10.1111/1750-3841.14407

Fneich F, Ville J, Seantier B, Aubry T (2019) Structure and rheology of aqueous suspensions and hydrogels of cellulose nanofibrils: effect of volume fraction and ionic strength. Carbohydr Polym 211:315–321. https://doi.org/10.1016/j.carbpol.2019.01.099

De France KJ, Hoare T, Cranston ED (2017) Review of hydrogels and aerogels containing nanocellulose. Chem Mater 29(11):4609–4631. https://doi.org/10.1021/acs.chemmater.7b00531

Friedrich C, Schiessel H, Blumen A (1999) Constitutive behavior modeling and fractional derivatives. In: Siginer D, De Kee D, Chhabra R (eds) Advances in the flow and rheology of non-Newtonian fluids, rheology series, vol 8. Elsevier, Amsterdam, pp 429–466. https://doi.org/10.1016/S0169-3107(99)80038-0

Hill RJ (2008) Elastic modulus of microfibrillar cellulose gels. Biomacromol 9(10):2963–2966. https://doi.org/10.1021/bm800490x

Hubbe MA, Tayeb P, Joyce M, Tyagi P, Kehoe M, Dimic-Misic K, Pal L (2017) Rheology of nanocellulose-rich aqueous suspensions: a review. BioResources 12(4):9556–9661

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3(1):71–85. https://doi.org/10.1039/c0nr00583e

Jaishankar A, Mckinley GH (2013) Power-law rheology in the bulk and at the interface: quasi-properties and fractional constitutive equations. Proc R Soc A 469(2149):20120284. https://doi.org/10.1098/rspa.2012.0284

Jaishankar A, Mckinley GH (2014) A fractional k-BKZ constitutive formulation for describing the nonlinear rheology of multiscale complex fluids. J Rheol 58(6):1751–1788. https://doi.org/10.1122/1.4892114

Jampala SN, Manolache S, Gunasekaran S, Denes FS (2005) Plasma-enhanced modification of xanthan gum and its effect on rheological properties. J Agric Food Chem 53(9):3618–3625. https://doi.org/10.1021/jf0479113

Jiang Y, Seto R (2023) Colloidal gelation with non-sticky particles. Nat Commun 14(1):85. https://doi.org/10.1038/s41467-023-38461-1

Keshavarz B, Divoux T, Manneville S, Mckinley GH (2017) Nonlinear viscoelasticity and generalized failure criterion for polymer gels. ACS Macro Lett 6(7):663–667. https://doi.org/10.1021/acsmacrolett.7b00213

Kim C, Yoo B (2006) Rheological properties of rice starch-xanthan gum mixtures. J Food Eng 75(1):120–128. https://doi.org/10.1016/j.jfoodeng.2005.04.002

Koeller RC (1984) Applications of fractional calculus to the theory of viscoelasticity. J Appl Mech 51(2):299–307. https://doi.org/10.1115/1.3167616

Kontturi E, Laaksonen P, Linder MB, Nonappa Gröschel AH, Rojas OJ, Ikkala O (2018) Advanced materials through assembly of nanocelluloses. Adv Mater 30(24):1703779. https://doi.org/10.1002/adma.201703779

Koochi H, Mac Intyre J, Viitanen L, Puisto A, Maleki-Jirsaraei N, Alava M (2023) Local time-dependent microstructure of aging TEMPO nanofibrillated cellulose gel. Cellulose 30(1):61–74. https://doi.org/10.1007/s10570-022-04900-3

Koponen AI (2020) The effect of consistency on the shear rheology of aqueous suspensions of cellulose micro- and nanofibrils: a review. Cellulose 27(4):1879–1897. https://doi.org/10.1007/s10570-019-02908-w

Larson RG (1999) Structure and rheology of complex fluids. Oxford University Press, Oxford

Leppiniemi J, Lahtinen P, Paajanen A, Mahlberg R, Metsä-Kortelainen S, Pinomaa T, Pajari H, Vikholm-Lundin I, Pursula P, Hytönen VP (2017) 3D-Printable bioactivated nanocellulose-alginate hydrogels. ACS Appl Mater Interfaces 9(26):21959–21970. https://doi.org/10.1021/acsami.7b02756

Mainardi FF (2010) Fractional calculus and waves in linear viscoelasticity an introduction to mathematical models. Imperial College Press, London, pp 85–89. https://doi.org/10.1142/p926

Meng R (2021) Application of fractional calculus to modeling the non-linear behaviors of ferroelectric polymer composites: viscoelasticity and dielectricity. Membranes 11(6):409. https://doi.org/10.3390/membranes11060409

Meng R, Yin D, Drapaca CS (2019) Variable-order fractional description of compression deformation of amorphous glassy polymers. Comput Mech 64(1):163–171. https://doi.org/10.1007/s00466-018-1663-9

Miranda-Valdez IY, Puente-Córdova J, Rentería-Baltiérrez F, Fliri L, Hummel M, Puisto A, Koivisto J, Alava M (2023) Viscoelastic phenomena in methylcellulose aqueous systems: application of fractional calculus. Food Hydrocoll 147:109334

Miranda-Valdez IY, Viitanen L, Mac Intyre J, Puisto A, Koivisto J, Alava M (2022) Predicting effect of fibers on thermal gelation of methylcellulose using Bayesian optimization. Carbohydr Polym 298:119921. https://doi.org/10.1016/j.carbpol.2022.119921

Naderi A, Lindström T (2014) Carboxymethylated nanofibrillated cellulose: effect of monovalent electrolytes on the rheological properties. Cellulose 21(5):3507–3514. https://doi.org/10.1007/s10570-014-0394-0

Nechyporchuk O, Belgacem MN, Pignon F (2014) Rheological properties of micro-/nanofibrillated cellulose suspensions: wall-slip and shear banding phenomena. Carbohydr Polym 112:432–439. https://doi.org/10.1016/j.carbpol.2014.05.092

Owens CE, Fan MR, Hart AJ, Mckinley GH (2022) On oreology, the fracture and flow of “milk’s favorite cookie®’’. Phys Fluids 34(4):043107. https://doi.org/10.1063/5.0085362

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O et al (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromol 8(6):1934–1941. https://doi.org/10.1021/bm061215p

Pöhler T, Ketoja JA, Lappalainen T, Luukkainen VM, Nurminen I, Lahtinen P, Torvinen K (2020) On the strength improvement of lightweight fibre networks by polymers, fibrils and fines. Cellulose 27(12):6961–6976. https://doi.org/10.1007/s10570-020-03263-x

Reichler M, Rabensteiner S, Törnblom L, Coffeng S, Viitanen L, Jannuzzi L, Mäkinen T, Mac Intyre JR, Koivisto J, Puisto A et al (2021) Scalable method for bio-based solid foams that mimic wood. Sci Rep. https://doi.org/10.1038/s41598-021-03764-0

Reyes-Melo ME, González-González VA, Guerrero-Salazar CA, García-Cavazos F, Ortiz-Méndez U (2008) Application of fractional calculus to the modeling of the complex rheological behavior of polymers: from the glass transition to flow behavior. I. The theoretical model. J Appl Polym Sci 108(2):731–737. https://doi.org/10.1002/app.27435

Rouwhorst J, Ness C, Stoyanov S, Zaccone A, Schall P (2020) Nonequilibrium continuous phase transition in colloidal gelation with short-range attraction. Nat Commun. https://doi.org/10.1038/s41467-020-17353-8

Rubinstein M, Colby R (2003) Polymer Physics. Oxford University Press, Oxford

Šebenik U, Krajnc M, Alič B, Lapasin R (2019) Ageing of aqueous TEMPO-oxidized nanofibrillated cellulose dispersions: a rheological study. Cellulose 26(2):917–931. https://doi.org/10.1007/s10570-018-2128-1

Schiessel H, Blumen A (1993) Hierarchical analogues to fractional relaxation equations. J Phys A: Math Gen 26(19):5057. https://doi.org/10.1088/0305-4470/26/19/034

Schiessel H, Metzler R, Blumen A, Nonnenmacher T (1995) Generalized viscoelastic models: their fractional equations with solutions. J Phys A: Math Gen 28(23):6567. https://doi.org/10.1088/0305-4470/28/23/012

Scott Blair G (1969) Elementary rheology. Academic Press, London and New York

Scott Blair G, Veinoglou B, Caffyn J (1947) Limitations of the Newtonian time scale in relation to non-equilibrium rheological states and a theory of quasi-properties. Proc R Soc A 189(1016):69–87

Serra-Parareda F, Tarrés Q, Sanchez-Salvador JL, Campano C, Àngels Pèlach M, Mutjé P, Negro C, Delgado-Aguilar M (2021) Tuning morphology and structure of non-woody nanocellulose: ranging between nanofibers and nanocrystals. Ind Crops Prod 171:113877. https://doi.org/10.1016/j.indcrop.2021.113877

Shih WH, Shih WY, Kim SI, Liu J, Aksay IA (1990) Scaling behavior of the elastic properties of colloidal gels. Phys Rev A 42(8):4772–4779. https://doi.org/10.1103/PhysRevA.42.4772

Skogberg A, Mäki AJ, Mettänen M, Lahtinen P, Kallio P (2017) Cellulose nanofiber alignment using evaporation-induced droplet-casting, and cell alignment on aligned nanocellulose surfaces. Biomacromol 18(12):3936–3953. https://doi.org/10.1021/acs.biomac.7b00963

Surguladze TA (2002) On certain applications of fractional calculus to viscoelasticity. J Math Sci 112(5):4517–4557. https://doi.org/10.1023/a:1020574305792

Suzuki J, Zhou Y, D’Elia M, Zayernouri M (2021) A thermodynamically consistent fractional visco-elasto-plastic model with memory-dependent damage for anomalous materials. Comput Methods Appl Mech Eng 373:113494. https://doi.org/10.1016/j.cma.2020.113494

Tarasov VE, Tarasova SS (2020) Fractional derivatives and integrals: what are they needed for? Mathematics 8(2):164. https://doi.org/10.3390/math8020164

Torvik PJ, Bagley RL (1984) On the appearance of the fractional derivative in the behavior of real materials. J Appl Mech 51(2):294–298. https://doi.org/10.1115/1.3167615

Viitanen L, Miranda-Valdez IY, Koivisto J, Puisto A, Alava M (2023) Thermal gelation of cellulose based suspensions. Cellulose 30(7):4215–4223. https://doi.org/10.1007/s10570-023-05150-7

Webber MJ, Tibbitt MW (2022) Dynamic and reconfigurable materials from reversible network interactions. Nat Rev Mater 7(7):541–556. https://doi.org/10.1038/s41578-021-00412-x

West BJ, Bologna M, Grigolini P (2003) Fractional rheology. Springer, New York, pp 235–270. https://doi.org/10.1007/978-0-387-21746-8_7

Winter HH, Mours M (1996) Rheology of polymers near liquid-solid transitions. Springer, NewYok, pp 165–234. https://doi.org/10.1007/3-540-68449-2_3

Wu H, Morbidelli M (2001) A model relating structure of colloidal gels to their elastic properties. Langmuir 17(4):1030–1036. https://doi.org/10.1021/la001121f

Zelenkova J, Pivokonsky R, Filip P (2017) Two ways to examine differential constitutive equations: Initiated on steady or initiated on unsteady (LAOS) shear characteristics. Polymers 9(12):205. https://doi.org/10.3390/polym9060205

Zeng J, Zeng Z, Cheng Z, Wang Y, Wang X, Wang B, Gao W (2021) Cellulose nanofibrils manufactured by various methods with application as paper strength additives. Sci Rep. https://doi.org/10.1038/s41598-021-91420-y

Acknowledgments

The authors thank the Aalto University School of Science ”Science-IT” project for the computational resources provided, and the Department of Bioproducts and Biosystems at Aalto University for providing facilities. The authors thank VTT Technical Research Centre of Finland for kindly providing the cellulose nanofiber hydrogel. The authors acknowledge using the CircuiTikZ open library for drawing the spring, springpot, and dashpot schemes.

Funding

Open Access funding provided by Aalto University. I.M-V. thanks to the Finnish Ministry of Education and Culture for financial support via its Finland Fellowship scholarship program. M.J.A. and J.K. thank FinnCERES flagship (151830423), Business Finland (211835), and Future Makers programs. M.J.A., T.M. and I.M-V. thank Business Finland (211909).

Author information

Authors and Affiliations

Contributions

IYM-V: Conceptualization, Methodology, Software, Formal analysis, Visualization, Investigation, Writing–Original draft, Writing–Review & Editing. MS: Methodology, Investigation. TM: Validation, Writing–Review & Editing. JGP-C: Formal analysis, Validation, Writing–Review & Editing. AP: Formal analysis, Validation, Writing–Review & Editing. JK: Supervision, Validation, Writing–Review & Editing, Funding acquisition. MA: Supervision, Validation, Writing–Review & Editing, Funding acquisition, Project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors of this article declare no competing interests that may have influenced the work reported.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Miranda-Valdez, I.Y., Sourroubille, M., Mäkinen, T. et al. Fractional rheology of colloidal hydrogels with cellulose nanofibers. Cellulose 31, 1545–1558 (2024). https://doi.org/10.1007/s10570-023-05694-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05694-8