Abstract

The grafting of stimuli-responsive polymers into medical devices to create functional materials has attracted the attention of scientific community. The capacity of these polymers to change its conformation reversibly as function of variables of the environment in which it is applied, is well taken into account to create drug delivery systems. Because cotton gauzes are materials of priority use in biomedical area, and they are susceptible to develop biofilm on its surface contaminating skin wounds. This work proposes the modification of cotton gauze with a dual stimuli-responsive copolymer, composed of two monomers such as methacrylic acid and N-isopropylacrylamide, through a grafting copolymerization induced by chemical initiator and gamma radiation. Experimental conditions were evaluated for each method. Grafting was verified by infrared spectroscopy (FTIR-ATR) and scanning electron microscopy as well as its thermal behavior was determined through thermogravimetric analysis. Critical pH was confirmed by potentiometric titrations finding a value of 4.7 for grafted cotton gauzes and their critical temperature ranging between 31 and 34 °C, which was determined by water uptake as function of temperature. The loading and release of norfloxacin were tested, finding that grafted gauzes exhibited affinity for this drug and it is released under simulated physiological conditions of temperature and pH. Norfloxacin-loaded gauzes show their efficiency inhibiting Escherichia coli and Staphylococcus aureus growth in a contaminated environment, at different pH values. This improvement of cotton gauzes can serve as barrier to avoid the formation of biofilm in surgical conditions and for wound healing.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cellulose is a polymer of natural origin that plays structural roles in plants, and it is the main constituent of cotton, representing approximately 90% of its composition. The remaining 10% belongs to hydrophobic impurities such as waxes, pectin, and some proteins (Keshipour and Maleki 2019). Cotton cellulose is the purest form of cellulose (Rongpipi et al. 2019). Its chemical structure consists of β-1,4-D (+)-glucopyranose rings covalently linked by 1,4-glycosidic bonds, generating a large cellulose chain. Each ring has three hydroxyl groups (–OH), one primary at C6 and two secondary at C2 and C3. This abundance of hydroxyl groups and the chain conformation allows a complex network of hydrogen bond interactions between and inside the cellulose chains as well as with other molecules. This particularity confers mechanical properties of cellulose including high stability, as well as its high hydrophilicity. Other important properties derived from its chemical structure include a high surface energy, biodegradability, biocompatibility, thermal stability, and chemical reactivity. About this last point, it is governed by its supramolecular structure as well as the hydroxyl groups at C2, C3, and C6 positions. The hydroxyl group at C6 (primary carbon) is ten times more reactive than those on secondary carbons following this trend C6 > > C2 ≈ C3 (Bezerra et al. 2015). Among other factors that determines this reactive behavior and accessibility including cellulose morphology, degree of polymerization, degree of crystallinity, purity, and, even, particle size.

Due to the high biocompatibility that this polymer exhibits, cellulose-based materials tend to be incorporated in biological systems and to be used in the evaluation, treatment, increase or replacement of any tissue, organ or body function (Vázquez et al. 2021; Hasanin 2022). Among these materials of cellulosic origin, cotton gauze stands out because this material is primarily used in the biomedical field especially as wound dressing derived from skin cuts, burns, ulcers or diabetes, amongst any others. Although the biocompatibility of this material represents an advantage, it also has problems and limitations. One of them is derived precisely from this property, which is the facility with which pathogen microorganisms are hosted in their structure causing damage in the wound and inducing the healing process and tissue regeneration. Over the years, some studies have been carried out to modify this polymer structure with functional groups or antimicrobial agents that avoids the microbial adhesion or serves as a delivery system of such agents to fight against frequent wound infections (Keshipour and Maleki 2019). The progressive advances in the investigations in this field, have showed that the modification of medical devices, including cotton gauzes, allows to overcome mentioned adversities and, even, convert them into sophisticated materials with relevant and useful properties (Li et al. 2015; Sun et al. 2015; Velazco-Medel et al. 2020).

One of the more promising approximations is the inclusion of polymers with characteristics and properties different from medical material, through a procedure known as graft copolymerization. This approach has the main objective to take advantage of the properties of original materials and the functional groups grafted to them (Priya James et al. 2014; Pino-Ramos et al. 2017; Velazco-Medel et al. 2020). Grafting copolymerization can be achieved by two approaches that are “grafting to” and “grafting from”, which are based on the criteria of how the polymer chain growth. On the one hand, “grafting to” method, a previously formed polymer chain is grafted into the matrix. Although it is a useful method, it presents a great disadvantage which is the very low graft density due to the great volume of the rolled chains that generates steric hindrance between them (Pino-Ramos et al. 2018). Alternatively, the “grafting from” approach involves the participation of a previously activated polymeric matrix and a reactive monomer, starting the polymerization in the matrix with surrounding monomer molecules. This method produces copolymers with a greater graft density because of monomer, by their small size, can access to more reactive sites of the matrix.

The basic principle behind graft copolymerization is the creation of active sites in the polymeric matrix backbone in the form of free radicals. In this way, the reaction of a monomer or polymer with an activated polymeric matrix will allow the formation of a graft copolymer. The creation of those active sites can be achieved by using physical or chemical methods, that is, by chemical initiators or by an ionizing radiation source. In the first case, one of the most used initiators is azobisisobutyronitrile (AIBN) which acts by thermal decomposition generating two radicals in their structure which reach polymeric matrix and activates it (Androvič et al. 2016; Kulkarni et al. 2019). In the latter case, graft copolymerization includes the use of ionizing radiation to create active sites along the polymeric matrix, taking advantage of penetrating power of this type of sources (Gürdag and Sarmad 2013; Ramos-Ballesteros et al. 2019). Both methods present their advantages and limitations, providing materials with different properties and characteristics, and have successfully proven in the development of graft copolymers specially on the synthesis of functional materials based on stimuli-responsive polymers.

Stimuli-responsive polymers, also known as smart polymers, are a relatively novel type of macromolecules and their highlight is that they present remarkable physical or chemical changes in their structure in response to little variations in the variables or stimuli of their environment (Li et al. 2015; Wei et al. 2017; Peponi et al. 2017). Those changes are reflected into conformational changes passing from a compressed or dehydrated state to a collapsed or hydrated state, depending on the type and direction of the stimulus. Besides this, it is remarkable that this behavior is reversible, which means that, in the absence of such stimulus, the smart polymer returns to its original conformation. This type of polymers is obtained by synthetic methods and included in polymeric matrices to obtain versatile materials with response to a variety of stimuli such as pH, temperature, mechanical force, ionic force, the presence of small molecules, biomolecules, and, even, electric and magnetic fields (Wang et al. 2016; Chakraborty et al. 2018). Due to this peculiarity, they have found diverse applications in some fields including biology and medicine, to the design and development of sensors and biosensors, in systems for environmental remediation and, especially in drug delivery systems (Liechty et al. 2010; Neamtu et al. 2017; Chatterjee and Chi-leung Hui 2019). In this field, drugs, or active agents including metallic nanoparticles and biomolecules, are loaded into the grafted material, which means there is an electrostatic interaction between functional groups of smart polymer and those of active agent, allowing its retention into the graft copolymer. Once that conformational change occurs, retained agent is released to the medium, without losing its structure and activity. Using this method, researchers have designed some drug delivery systems based on these polymers with potential application in biomedical field (Camacho-Cruz et al. 2021; Bustamante-Torres et al. 2021; López-Saucedo et al. 2022).

On the most studied stimuli-responsive polymers for biomedical purposes with response to temperature is poly(N-isopropylacrylamide) (PNIPAAm). PNIPAAm is mainly synthesized by a free radical polymerization from its monomer N-isopropylacrylamide (NIPAAm). PNIPAAm is a peculiar polymer because it exhibits reversible changes in the limit of its hydrated and dehydrated forms during a temperature variation belonging to their lower critical solution temperature (LCST). In the case of this polymer, LCST is around 32 °C in aqueous solution, which is inside the physiological range (20–35 °C) (Crespy and Rossi 2007). Under its LCST, the polymer is on a swollen state, with molecules of water retained in its hydrophilic component (C=O), while above this value, polymer is dehydrated passing to a collapsed state by repulsion of hydrophobic component (CH(CH3)2), breaking the hydrophilic/hydrophobic balance in the structure of the polymer network (Zhang and Peppas 2000). This behavior is remarkable for drug delivery applications given that a drug molecule could be retained in the PNIPAAm structure and it could be released when this variation occurs. Several reports and review articles of the inclusion of this polymer alone or with other component into cellulose backbone for drug delivery approaches have been reported, finding promising results (Metaxa et al. 2014; Amalin Kavitha et al. 2020; Liang et al. 2020).

Poly (methacrylic acid) (PMAAc) belongs to the group of methacrylates, which shows a high hydrophilicity and a relevant ionization capacity. PMAAc is commonly formed by a free radical polymerization from its monomer, methacrylic acid (MAAc), which is a viscous and colorless liquid, with a pungent odor and miscible in organic solvents, including water (Swift 2002). MAAc has two reactive sites, the double bonds from C=C of vinyl component and C=O carbonyl group, being the first one the most reactive and which allows polymerization process. In its structure, PMAAc contains carboxylic groups (–COOH), which are responsible of its pH-response behavior. That is, at a pH surrounding their pKa value (4.8), PMAAc will release the acid hydrogen to the medium. This fact will induce the conformational variation at a macromolecular level, given that, PMAAc will change its compressed conformation to an extended due to the repulsion of negatives charges (–COO−) generated by deprotonation of the polymer. As in the case of PNIPAAm, some research articles report the grafting of PMAAc onto cellulose backbone for drug loading and release, including one of our research group (Zahran 2006; Lumbreras-Aguayo et al. 2019; Romero-Fierro et al. 2022).

In this work, we propose the one-step grafting copolymerization of NIPAAm and MAAc onto cellulose backbone, induced by gamma radiation and chemical initiator AIBN, to achieve a thermo- and pH-responsive cotton gauze which serves as a drug delivery system. Experimental parameters such as solvent, concentration of monomers, irradiation dose or AIBN quantity, temperature and reaction time, were evaluated to determine the optimal conditions that guarantees innate properties of cotton gauze and included properties. Grafting of both monomers will be verified through FTIR-ATR and SEM as well as their thermal performance was determined by TGA. The pH-response of grafted material was evaluated by potentiometric titrations and their thermo-response by water uptake tests as function of temperature. Loading and release of antimicrobial drug norfloxacin was controlled by UV-Vis spectrophotometer. Finally, antimicrobial turbidity assays were performed at different pH values (5,7, and 9) showing the effectiveness of grafted materials as drug delivery system.

Materials and methodology

Materials

Sterile cotton gauzes (unfolded gauze: 20 × 20 cm) were purchased from Miyako, Galia Textil, S.A de C.V. Tlaxcala, Mexico. Pyrex glass test tubes (diameter: 16 mm; height: 170 mm) and glass tubes (diameter: 4 mm; height: 120 mm) were used to make glass ampoules. Solvents such as distilled water, methanol (99.94%), anhydrous ethanol, propanol (99.94%), anhydrous isopropanol, toluene (99.5%), and n-hexane (95%) were purchased from REPROQUIFIN Reactivos y Productos Químicos Finos, S.A. de C.V. Distilled water was used in all experiments. Monomers such as methacrylic acid (99%) and N-isopropylacrylamide (97%) were obtained from Sigma-Aldrich (St. Louis, United States). Norfloxacin (≥ 98% TLC), analytical standard, MW: 319.33 g/mol from Sigma-Aldrich® (St. Louis, United States). A gamma radiation source which was a 60Co Gammabeam 651-PT (Nordion Ottawa, Ontario Canada Inc., Toronto, ON, Canada) provided by Nuclear Science Institute of the National Autonomous University of Mexico (ICN-UNAM). CG-g-NIPAAm and CG-g-MAAc, used as reference in some experiments, were synthesized following methodologies reported previously (Jun et al. 2001; Romero-Fierro et al. 2022).

Dissection forceps, sterile glass beads, automatic micropipette (ThermoScientific™), vortex, incubator of 35 ± 2 °C, laminar flow hood, autoclave. Tubes with brain heart infusion broth (BD Bioxon™). Tubes with Luria Bertani LB (BD Bioxon™). Tubes with 5 mL of Müeller Hinton broth (BD Bioxon™) adjusted to a different pH value (5, 7, and 9). Tubes with 9 mL of isotonic saline solution (0.9% NaCl). Strains of Escherichia coli ATCC™ 25,922 and Staphylococcus aureus ATCC™ 25,923.

Preparation of cotton gauzes

Cotton gauzes were cut into pieces of 10 × 10 cm and washed in absolute ethanol under constant stirring. Then washed cotton gauzes were dried under vacuum at 50 °C for 12 h. After that, dried gauzes were weighed, registering initial weigh of pristine material and placed into a glass ampoule until their use.

Preparation of monomers and chemical initiator

Methacrylic acid were distilled under reduced pressure to eliminate impurities and inhibitor, and it was stored until its use. N-isopropylacrylamide was purified by recrystallization using toluene and hexane in a ratio 2:3.55 g of monomers were dissolved into 180 mL of toluene under constant agitation. When the monomer was completely dissolved, 270 mL of hexane, previously cooled at 4 °C, were added and it was placed into a cold water bath to promote recrystallization. The recovered solid was filtered and dried in a vacuum oven at 30 °C during 12 h and stored under refrigeration until their use.

Azobisisobutyronitrile (AIBN) initiator was purified through recrystallization. 10 g of AIBN were dissolved into 200 mL of ethanol at 50 °C, until its complete dissolution. To induce recrystallization, this dissolution was placed in a water bath. The recrystallized initiator was filtered and dried in a vacuum oven at 30 °C during 12 h and stored until their use.

Grafting of NIPAAm and MAAc in cotton gauzes using AIBN as initiator

To graft NIPAAm and MAAc in cotton gauzes using AIBN as a free radical polymerization initiator, several parameters such as solvent, monomers concentration, AIBN quantity, reaction temperature and reaction time, were studied. After evaluate all of these parameters, it was obtained the following procedure and ideal graft conditions. It was prepared an aqueous solution of monomers in a molar relationship (1:1) and with concentrations of 1 M, adding 10 mg of AIBN initiator. Approximately 10 mL of the monomeric solution was added to the glass ampoule containing cotton gauzes previously dried and weighed. To displace oxygen present in the medium and to create inert conditions, ampoule was bubbled with argon for 15 min. Glass ampoule was sealed with a blowtorch and placed in a water bath at 70 °C for 2 h. After that, ampoule was opened and the cotton gauze was washed with ethanol under constant stirring to remove residues and copolymer PNIPAAm-co-PMAAc, which was isolated to be used as a reference in potentiometric titrations. Finally, the sample was dried in a vacuum oven at 50 °C for 8 h. The final weight was reported, and the grafting percentage (GP) was obtained according to the following equation (Eq. 1):

where \({W}_{g}\) is the final weight of the grafted material and \({W}_{0}\)is the initial weight of the pristine cotton gauze.

Grafting of NIPAAm and MAAc in cotton gauzes using gamma radiation as initiator

To graft NIPAAm and MAAc monomers in cotton gauzes using gamma radiation as free radical polymerization initiator, several parameters such as solvent, monomers concentration, irradiation dose, reaction temperature and reaction time were studied. After evaluate all of these parameters, it was designed the following procedure based on ideal graft conditions. It was prepared an aqueous solution of monomers in a molar relationship (1:1) with concentrations of 0.5 M. Approximately 10 mL of this solution was added to the glass ampoule containing previously dried and weighed cotton pristine gauze. To create inert reaction conditions, oxygen present in the ampoule is displaced by means of argon bubbling for 15 min. After that, glass ampoule was sealed with a blowtorch and placed in a water bath at 70 °C for 3 h. Then, ampoule was opened and the cotton gauze was washed with a mixture of ethanol and water (50/50) under constant stirring to remove residues and copolymer PNIPAAm-co-PMAAc, which was isolated to be used as a reference in potentiometric titrations. Finally, grafted sample was dried in a vacuum oven at 50 °C for 8 h. The final weight of the grafted was measured and reported, and the GP was obtained by weight difference following Eq. 1.

Fourier transform infrared spectroscopy with attenuated total reflectance (FTIR-ATR)

Samples of pristine cotton gauze, copolymer PNIPAAM-co-PMAAc, CG-g-(NIPAAm/MAAc) (AIBN), and CG-g-(NIPAAm/MAAc) (γ) were dried during 12 h at 60 °C. Completely dried samples were analyzed in a Perkin-Elmer Spectrum 100 Spectrophotometer with diamond tip from Perkin Elmer Cetus Instruments, Norwal, CT, performing 16 scans for each one using the ATR modulus.

Scanning electron microscopy (SEM)

Samples of pristine cotton gauze, CG-g-(NIPAAm/MAAc) (AIBN), and CG-g-(NIPAAm/MAAc) (γ), with a dimension of 1 cm2 were dried for 12 h at 60 °C. These samples were placed into a sample holder to the scanning electron microscope SEM TM3030Plus Tabletop Microscope from Hitachi, Ltd., Japan. Some micrographs with magnitude of 25× and 50× were taken, with the purpose of seeing variations in the morphology of grafted samples.

Thermogravimetric analysis (TGA)

5–10 mg of each sample of pristine cotton gauze, PNIPAAm-co-PMAAc, CG-g-(NIPAAm/MAAc) (AIBN), and CG-g-(NIPAAm/MAAc) (γ) were dried for 12 h at 60 °C. Those samples were placed on the platinum tray of the thermogravimetric analysis equipment TGA Q50 from TA Instruments, United States. Experiments were carried out in the temperature range from 38 to 800 °C under nitrogen atmosphere.

Acid-base titrations

20 mg of CG-g-NIPAAm, CG-g-MAAc, CG-g-(NIPAAm/MAAc) (AIBN), and CG-g-(NIPAAm/MAAc) (γ) were taken to perform acid-base titrations using an aqueous solution of potassium hydroxide ([KOH] ≈ 0.15 M) as titrant. Titrant was normalized using a potassium hydrogen phthalate solution with a concentration of 0.04 M, adding two drops of phenolpthalein indicator and the titrant solution was titrated until it reached a pale pink coloration in the solution. This standardization process was performed by triplicate obtaining the titrant concentration.

Cotton gauzes samples were placed into a 250 mL beaker and covered with 100 mL of distilled water. To acidify media, 3 drops of a hydrochloric solution ([HCl] = 1 M) were added, adjusting a pH of 2. This was performed because the pKa of acid component of the graft is approximately 4.8. Titrant solution was added to a 5 mL glass burette and this solution is added slowly, drop-by-drop, to the system in the beaker which includes the sample, water, and hydrochloric acid under constant stirring. pH values were recorded using a pH/conductivity meter Orion Star A215 from ThermoScientific™, United States coupled with a ROSS Ultra pH/ATC Triode Orion 8157NUMD electrode from ThermoScientific™, United States. Titration profiles were plotted using OriginPro 2017 software and the end points of each profile were determined using first derivative.

Water uptake and determination of LCST

For water uptake, 80 mg of pristine cotton gauze, CG-g-(NIPAAm/MAAc) (AIBN), and CG-g-(NIPAAm/MAAc) (γ) were weighed and reported their initial weight. Samples were deposited into a glass beaker with 10 mL of distilled water and placed in a water bath at a controlled temperature of 25 °C. At some intervals of time (15, 30, 60, 120, 180, 300, 480, and 1440 min), samples are extracted from the beaker, excess water was removed and weight controls were performed by quadruplicate, using Eq. (2), obtaining a profile for water retention as function of time.

where \({W}_{i}\) is the final weight of the sample at a determined time and \({W}_{0}\) is the initial weight of the sample before being immersed in water.

For LCST determination, a similar methodology was employed. 80 mg of pristine cotton gauze, CG-g-(NIPAAm/MAAc) (AIBN), and CG-g-(NIPAAm/MAAc) (γ) were weighed reporting their initial weight. Samples are deposited into a beaker with 10 mL of distilled water and are placed in a water bath during 6 h (maximum water retention value) at temperatures in the range of 24–50 °C, with an interval of 2 °C between each weight control, using Eq. (2) at 6 h after immersed the sample in water. LCST determination was performed by quadruplicate.

Loading and release of norfloxacin

Loading of antimicrobial drug such as norfloxacin into cotton gauzes was performed taking approximately 50 mg of previously dried pristine cotton gauze, CG-g-(NIPAAm/MAAc) (AIBN), and CG-g-(NIPAAm/MAAc) (γ). Each sample was weighted and placed into glass vessels with a capacity of 7 mL, and 5 mL of norfloxacin aqueous solution with a concentration of 10 µg/mL (A ≈ 1). Glass vessels containing samples and solution are placed in a water bath at 25 °C. To evaluate the progressive load and to obtain a loading profile, absorbance controls at some intervals of time (1, 3, 5, 7, 24, 30, and 48 h) was performed. Absorbance measurements were carried out using quartz cuvettes with a capacity of 3.5 mL at 268 nm using water as reference in a UV-Vis SPECORD® 200 Plus spectrophotometer from Analytik Jena AG, Germany.

To achieve a precise determination of concentration in each absorbance measurement, a calibration curve was performed. From norfloxacin stock solution (10 µg/mL), some dissolutions were carried out (2, 4, 5, 6, 8 µg/mL), placed into the quartz cuvettes and the absorbance of each solution is measured at 268 nm. A calibration curve is obtained relating absorbance and drug concentration. Drug dissolution from stock solution and measurements were performed by quadruplicate to reduce the error margin and to obtain a linear equation with a r2 value of 0,99914; (A = 0.09559 + 0.01912 [norfloxacin loaded]).

Release of norfloxacin from loaded cotton gauzes was carried out taking previously loaded samples. The loaded samples were dried in a vacuum oven at 30 °C during 18 h. Dried samples were deposited into glass vessels with a capacity of 7 mL and 5 mL of a phosphate buffer saline (PBS) solution with a pH of 7.4 were added and placed in a water bath at 37 °C. To evaluate the progressive release of norfloxacin from loaded gauzes, absorbance measurements were performed at some intervals of time (0.5, 1, 1.5, 2, 3, 4, 6, 8, 24, 30, 48, 72, and 96 h) taking the PBS solution as reference and using quartz cuvettes with a capacity of 3.5 mL at 268 nm. A UV-Vis SPECORD® 200 Plus spectrophotometer from Analytik Jena AG, Germany was used to absorbance measurements.

To achieve a precise determination of drug released concentration at each time interval, a calibration curve was plotted. From a norfloxacin stock solution in PBS (2.5 µg/mL; A ≈ 1), some dissolutions were carried out (2, 1.5, 1, 0.5, 0.25, and 0.1 µg/mL) and their absorbance were measured at 268 nm. Then a calibration curve that relates absorbance and drug released to the PBS solution was achieved. Dissolutions and measurements were performed by quadruplicate to minimize the error margin and to obtain a r2 value of 0.99949; (A = 0.34531 − 0.01566 [norfloxacin released])

Turbidity tests against pathogens

Media Preparation: The required amount of BD Bioxon® brand Hinton Müeller broth was weighed to prepare 150 mL of broth according to the manufacturer’s instructions. The pH of the medium (5, 7 or 9) was determined and adjusted with 1.0 M HCl or 1.0 M NaOH as appropriate. The medium was placed in test tubes in 5.0 mL aliquots in each tube, autoclaved at 121 °C, 15 lb for 15 min. Finally, all tubes were maintained in 35 °C incubator for 48 h before use.

Strain Preparation: S. aureus ATCC 25,923 and E. coli ATCC 25,922 strains that were preserved in ultrafreeze (-70 °C) were activated with brain heart broth (BD Bioxon™) and Luria broth (BD Bioxon™) respectively, for 24 h. Subsequently, 100 µL of each microorganism was taken and placed in the respective media for 6 h, after which time an aliquot was taken with a Pasteur pipette and added dropwise into the respective fresh culture medium until the cultures were adjusted to Mac Farland’s (MF) 0.5 standard.

Bacterial Concentration: In order to know the amount of bacteria in each suspension, their concentration was determined by the surface extension technique as follows: from the bacterial suspension adjusted to 0.5 MF, 6 serial decimal dilutions were made in tubes with isotonic saline solution and from the last 3 dilutions (10−4, 10−5 and 10−6) 100 µl were taken and placed in duplicate on the surface of Hinton Müeller agar contained in Petri dishes, the inoculum was spread with sterile glass beads and allowed to absorb. The boxes were incubated at 35 °C for 24 h. At the end of the incubation period, the number of colonies was determined, and calculations were made to determine the concentration, which was 6.5 × 107 CFU/mL for E. coli and 2.0 × 107 CFU/mL for S. aureus.

Assay: The gauze samples with different treatments were placed with dissection forceps in Hilton Müeller broth tubes with different pH in triplicate (see diagram), then 200 µL of the bacterial suspensions adjusted to the 0.5 standard of MF were added.

Results and discussion

Synthesis of CG-g-(NIPAAm/MAAc) by free radical copolymerization using AIBN as initiator

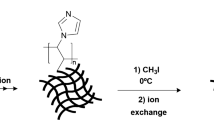

AIBN is an azo-type chemical agent which act as initiator of free radical polymerization at the moment to be thermally decomposed and generate two 2-cyano-2-propyl radicals. The temperature range at which this occurs is 60–80 °C (Clayden et al. 2012). For this reason, it is necessary to apply a certain temperature to start the copolymerization process. Once generated radicals, these will act over the cellulose backbone, taking the most available proton, which is in the hydroxil at C6 from pyranose ring, generating a radical in the oxygen atom (Halasa et al. 2013; Kang et al. 2015). In the propagation step, this radical will reacts with double bond from monomeric units, either MAAc and NIPAAm, which will generate a random graft copolymer along the cellulose matrix. Termination stage could be induced by coupling of two growing chains or by disproportion, taking a proton from the other growing chain, obtaining the final graft copolymer CG-g-(NIPAAm/MAAc) (AIBN). The proposed mechanism for this process is presented in Fig. 1.

Some parameters will influence the grafting yield in weight in the copolymerization process of MAAc and NIPAAm in cotton gauzes, such as solvent, amount of AIBN, concentration of monomers, reaction time, and reaction temperature. Figure 2 indicates the results for the variation of all of these parameters. From these kinetic profiles, we stablished the optimal conditions such that there is no affectation in the apparent mechanical properties of the cotton gauze and to obtain stimuli-responsive characteristics, which is achieved with grafting percentages of around 40%. First, despite AIBN is an oil-soluble initiator, with poor solubility in water (Li et al. 2018), this is precisely the solvent which is adequate to graft both monomers into cotton cellulose (Fig. 2a). Also, water is the better solvent to swell the polymeric matrix and allow to monomer molecules to reach active sites generated by AIBN initiator into the cellulose backbone (Cuissinat and Navard 2006; Fidale et al. 2008). From this, it can be inferred that there is a better coupling between initiator, matrix, and solvent in aqueous media, favoring the grafting process, and with only a little fraction of AIBN dissolved in water is enough to induce copolymerization. This second observation is corroborated with the tendency relating amount of AIBN and grafting yield, given that with all experimented quantities, there is the same grafting yield (~ 50%) (Fig. 2b). For the ideal temperature (Fig. 2c), it can be noted that at 70 °C there is a maximum value of grafting yield, observing an abrupt decrease after this temperature. This behavior is attributed to a decrease in the AIBN effectivity mainly related with the reduction in the stability of the radicals generated in the initiator (Bhattacharya 2004; Li et al. 2008). For the evaluation of reaction time, there is a decrease after 2 h, taking this value as the suitable with higher grafting yields. In the case of concentration of monomers, an equimolar relationship is preferred in order to graft both monomers in the same proportion.

Evaluation of parameters that influence the grafting copolymerization of MAAc and NIPAAm in cotton gauzes by using AIBN as initiator. a Effect of solvents (AIBN: 10 mg, Temperature: 70 °C, Time: 2 h, [NIPAAm: MAAc]: 1 M); b AIBN amount (Solvent: water, Temperature: 70 °C, Time: 2 h, [NIPAAm:MAAc]: 1 M); c Effect of temperature (Solvent: water, AIBN: 10 mg, Time: 2 h, [NIPAAm:MAAc]: 1 M); d Effect of time (Solvent: water, AIBN: 10 mg, Temperature: 70 °C, [NIPAAm:MAAc]: 1 M), e Effect of NIPAAm concentration (Solvent: water, AIBN: 10 mg, Temperature: 70 °C, Time: 2 h)

Synthesis of CG-g-(NIPAAm/MAAc) by free radical copolymerization using gamma radiation as initiator

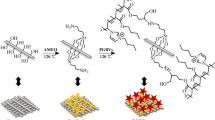

Gamma radiation induces degradative process in the matter exposed to it. In the case of α-cellulose, main component of cotton gauze, there are some rupture of chemical bonds due to the presence of a great amounts of carbon-oxygen and carbon-hydrogen covalent bonds. Ionizing gamma radiation produces degradation of polysaccharides followed by decomposition of pyranose ring, by breaking C2–C3 bonds and the formation of carboxyl and carbonyl groups as well as the formation of hydrogen, carbon dioxide, and carbon monoxide. According to Tissot et al., at the end of the entire degradative process, there is the formation of a radical at carbon 2 (C2) from cellulose (Tissot et al. 2013). Taking into account the degradation of cellulose, to the grafting of MAAc and NIPAAm a free radical copolymerization mechanism is proposed. The irradiation of cellulose matrix was in presence of oxygen from the air, which reacts with radicals formed in the polymeric backbone by action of radiation. This reaction generates peroxides and hydroperoxides, which are highly reactive species that thermallydecomposes, producing highly reactive radicals. These radicals react with vinyl part from MAAc and/or NIPAAm monomer, beginning the propagation step. Due to the presence of both monomer in the media, this process will random and the next monomer could met to another unit of the same type or with other different. So, the graft over the cellulose backbone will be a random copolymer. The termination stage could be done by the meeting of two growing chains or by disproportion of one of these chains, obtaining the final random graft copolymer CG-g-(NIPAAm/MAAc) (γ). The proposed mechanism of this grafting process is showed in the Fig. 3.

In the case of the grafting of MAAc and NIPAAm into cotton cellulose induced by ionizing gamma radiation, some parameters where evaluated including solvent, irradiation dose, reaction temperature, reaction time, and concentration of monomers. As in the case of AIBN-induced grafting, optimal parameters where chose to obtain grafting percentages of around 40% which ensure good apparent mechanical properties and stimuli-responsive properties. Figure 4 displays the results in the variations of those parameters. According to Jun et al., a mixture of an alcohol and water (1:4) is suitable to graft NIPAAm into cellulose (Jun et al. 2001). But, when this experiments were performed it can be noted that despite grafting yield is highest for the mixture of methanol and water, only NIPAAm component were grafted successfully into the matrix, which was verified by FTIR-ATR. This pattern is observed in the other mixtures, which does not happen with only water. For this reason water is chosen as the ideal solvent to graft both monomer.

For the evaluation of ideal irradiation dose, it can be demonstrated by observating Fig. 4b that an increase in this parameter induces the formation of higher grafting yields, due to the formation of more actives sites in the cellulose backbone. This indicates that this range of dose is good, because above this values, irradiated matrix suffers degradation instead of grafting. 25 kGy is an ideal dose to graft vinylic monomers without damaging properties of cellulose. Temperature and reaction times are important parameters the appropiate kinetic movement that generates greater probabilities of effective collision between molecules of monomers and active sites generated by gamma radiation depend on them (Takács et al. 2005; Ramos-Ballesteros et al. 2019). As can be seen in Fig. 4c, there is an increment in the grafting as temperature increases until 70 °C, that is related with an excellent thermal decomposition of peroxides and hydroperoxides formed on the matrix which will reach active sites and forming the graft. This value is defined as suitable for grafting purposes. On the other hand, Fig. 4d shows the variation of grafting yield as function of time (1–5 h). At low reaction times, grafting copolymerization is not favored, while as this time is increases there is a greater probability that monomer molecules achieve active sites, inducing grafting (Chapiro 1977; Bucio and Burillo 2009). It is determined that the ideal reaction time is 3 h due to, at this time, it is possible to obtain grafting yields that do not affect cotton gauze properties. Finally, at the same case of grafting by chemical initiator, an equimolar concentration is suitable to guarantee the successful grafting of both monomer, but concentration is lesser than first method because higher concentrations affects flexibility properties of cotton gauze.

Evaluation of parameters that influences the grafting copolymerization of MAAc and NIPAAm in cotton gauzes by using gamma radiation as initiator. a Effect of solvents (Dose: 25 kGy, Temperature: 70 °C, Time: 3 h, [NIPAAm: MAAc]: 0.5 M); b Effect of dose (Solvent: water, Temperature: 70 °C, Time: 3 h, [NIPAAm:MAAc]: 0.5 M); c Effect of temperature (Solvent: water, Dose: 25 kGy, Time: 3 h, [NIPAAm:MAAc]: 0.5 M); d Effect of time (Solvent: water, Dose: 25 kGy, Temperature: 70 °C, [NIPAAm:MAAc]: 0.5 M), (e Effect of NIPAAm concentration (Solvent: water, Dose: 25 kGy, Temperature: 70 °C, Time: 3 h)

FTIR-ATR

The analysis of FTIR-ATR vibrational spectra of pristine cotton gauze, PNIPAAm-co-PMAAc copolymer, CG-g-(NIPAAm/MAAc) (AIBN), and CG-g-(NIPAAm/MAAc) (γ) allow to verify the correct grafting of MAAc and NIPAAm monomers into cotton gauze. In the Fig. 5a, it is showed the IR spectrum of pristine cotton gauze, observing bands associated with the –OH stretching of each glucose unit at ~ 3334 cm−1 and the –CH stretching from glucopyranose ring at ~ 2899 cm−1. Also, at 1053 cm−1 it can be seen a band related with the stretching of C–O bond inside the ring and at 1029 cm−1 the stretching of the C1–O–C4 bridge that binds glucose monomeric units (Gürdag and Sarmad 2013). The IR spectrum of PNIPAAm-co-PMAAc copolymer (Fig. 5b) it can be observed characteristics bands related with each grafted unit. For NIPAAm component, the spectrum exhibited two bands at 1631 and 1540 cm−1 associated with vibrations of C=O stretching and the bending vibration of –NH bond from amide, respectively. Furthermore, bands at 2974, 1387, and 1367 cm−1 were observed, which are related with the presence of isopropyl group (–CH(CH3)2), due to –CH stretching, and symmetric and asymmetric stretchings from this group, respectively (Işıklan and Küçükbalcı 2016). For PMAAc component, bands at 3282 cm−1 were seen referring to the –OH bond stretching, at 1702 cm−1 appears a band belonging to the C=O stretching and the band showed at 1458 cm−1 is involved with the bending vibration of methyl group –CH3 (Romero-Fierro et al. 2022).

In the case of CG-g-(NIPAAm/MAAc) (AIBN) and CG-g-(NIPAAm/MAAc) (γ) spectra (Fig. 5c and d), a combination of bands corresponding to cotton cellulose and graft copolymer PNIPAAm-co-PMAAc were noted. Among the most important bands to highlight are those belonging to carbonyl group stretchings from both monomers, isopropyl group stretching from NIPAAm, carboxylic acid group stretchings, and the stretching of glucopyranose bridge, verifying the grafting of both monomers and the conservation of original vibrational bands from cotton gauze.

Another key factor to determine is the composition in percentage of each component (MAAc or NIPAAm) in the final graft copolymer. This was achieved developing FTIR quantification following a previously reported method (Othman et al. 2020). For that, some FTIR-ATR spectra were collected variating the concentration of NIPAAm in the grafting process. A linear regression plot relating peak area versus concentration of NIPAAm (%) was obtained from the characteristic NIPAAm band of around 1631 cm−1, corresponding to carbonyl stretching of this monomer for the calibration purposes. Calibration curves of both methods are exposed in the Supplementary Section (S1 and S2). From these figures and following a variation of Beer Lambert Law described in the reference, it was determined that NIPAAm content in the final graft is of 10.15% for AIBN-induced grafting and 26.51% for gamma radiation-induced grafting, taking suitable conditions previously described.

SEM

SEM micrographs with magnifications of 25x and 50x belonging to pristine cotton gauze and grafted cotton gauzes, CG-g-(NIPAAm/MAAc) (AIBN) and CG-g-(NIPAAm/MAAc) (γ), are shown in Fig. 6. Both magnifications allowed us to observe the morphological change that the cotton gauzes experiment showed by the presence of graft. Comparing pristine cotton gauze and CG-g-(NIPAAm/MAAc) (AIBN) it is possible to observe the occurrence of polymer chains on the surface of grafted cotton gauze, clearly differentiated as white pots over the surface. Free radicals generated by action of thermal scission of chemical initiator AIBN acts over monomers and the surface of gauze threads, allowing the grafting between them in this zone. Also, a great difference in the thread thickness cannot be observed, which indicates that grafting by using chemical initiator gives a clear surface graft. On the other hand, the higher penetrating power of ionizing gamma radiation let it to reach deeper sites and generate random active sites along the cellulose backbone of cotton gauze. This is reflected in the micrograph corresponding to CG-g-(NIPAAm/MAAc) (γ) observing an increase on the thickness of the gauze thread, in comparison with pristine gauze, being more evident in 25x magnification. This fact indicates that grafting process was produced inside the thread, which is attributed to bulk grafting.

TGA

Thermal behavior and stability of CG-g-(NIPAAm/MAAc) (AIBN) and CG-g-(NIPAAm/MAAc) (γ) where evaluated by their weight loss profile in comparison with those of pristine cotton gauze and PNIPAAm-co-PMAAc copolymer. Also, these profiles allow us to verify the satisfactory graft of both monomers into the cellulose backbone by comparison between them. Figure 7 shows weight loss profiles of analyzed samples and Table 1 describes the values of degradation temperatures at each stage. Pristine cotton gauze, mainly composed of α-cellulose, exhibits a high thermal stability showing a weight loss at 10% at 337 °C and a single degradation stage at 374 °C, reflected on an abrupt weight loss. This last value is related with the glucopyranose ring scission and the liberation of some degradation products (Shen and Gu 2009). On the other hand, PNIPAAm-co-PMAAc copolymer exhibits lesser thermal stability in comparison with the gauze, showing a weight loss at 10% at 263 °C. Their thermogravimetric profile shows a bi-stage thermal decomposition occurring at 251 and 417 °C. First stage concerns to the conversion of poly(methacrylic acid) into poly(methacrylic anhydride) due to the elimination of CO2 (Schild 1993; Cervantes-Uc et al. 2006; Tang et al. 2021). The second stage is related to decomposition of the pendant group of isopropylacrylamide from PNIPAAm (Sousa et al. 1998; Kotsuchibashi 2020). Grafted gauzes display tri-stage decomposition profiles including those corresponding to degradation of PMAAc, cellulose, and PNIPAAm, previously described. Also, observing temperatures of weight loss at 10%, it is possible to note that grafting process reduces thermal stability of the cotton gauze, being more evident this reduction in that gauze grafted with AIBN as initiator. Despite this fact, the application of grafted gauzes would not be affected because it is difficult to achieve those temperatures in the storage stage of the material and its biomedical application, where a physiological temperature is required.

Determination of critical pH by acid-base titrations

One of the main properties of stimuli-sensitive polymers is their response to changes in the variables of their environment. In this case, one of the components of graft into cotton gauze is a pH-responsive polymer, the poly (methacrylic acid), at determined value of pH, it will liberate acid proton from its pendant group. To evaluate this behavior, potentiometric titrations were performed, which profiles are showed in Fig. 8 and the equivalence points in Table 2. The titration of CG-g-NIPAAm, which was used as a reference, it can be seen a single equivalence point at 6.95 referred to the titration of the strong base used as titrant ([KOH] = 0.12 M) and the strong acid used to acidify the media ([HCl] = 1 M). PNIPAAm does not present available acid protons to be liberated and does not contribute to the pH-response in the graft copolymer. On the other hand, CG-g-MAAc exhibited three equivalence points. The first one occurs near to the pKa value of methacrylic acid monomer and their polymer which is ~ 4.7 (Rojas-Hernández et al. 2015). At this value, the polymer will liberate their acids protons and it will produce a charge repulsion between all deprotonated pendant groups, inducing the conformational change by expansion of the polymer chains (Swift 2002, 2020; Dai et al. 2008). This equivalence point is observed both in CG-g-(NIPAAm/MAAc) (AIBN) and CG-g-(NIPAAm/MAAc) (γ), which is stablished as the critical pH of the graft copolymer. As explained early, the second equivalence point of grafted cotton gauzes is attributed to the conventional titration between strong base and strong acid. While third equivalence point confirms the grafting of acid groups in the cellulose backbone which is related with the titration of free protons present in the media (Bassaid et al. 2008; Bensacia et al. 2015; Wang et al. 2015). Another important fact that can be observed from titration profiles is that reaching the first equivalence point is more difficult for cotton gauze grafted with both monomers in comparison with CG-g-MAAc, that is, more quantity of titrant is necessary to achieve this equivalence. This is principally attributed to the presence of other functionality such as isopropylacrylamide which counteract the repulsion from negative electrostatic charges generated by the deprotonation of acid component of the graft.

The obtained critical pH (~ 4.7) of grafted cotton gauzes obtained by chemical initiator and gamma radiation is suitable for biomedical applications given that, from this value to more basic values, grafted materials will exhibit a pH-response to that variable, obtaining a wide spectrum of application.

Water uptake and determination of LCST

One of the ways to determine how much the grafting has modified the properties of cotton gauzes is evaluating their water uptake capacity. Cotton gauzes are highly hydrophilic materials due to the great quantity of O and H atoms present in their chemical structure, that is why cotton gauze can absorb and retain until 27 times its weight in water. Also, cellulose is composed by crystalline and amorphous regions, because the amorphous region is more predominant and which is responsible of the greater water uptake (Djafari Petroudy 2017; Sahu and Gupta 2022). As be seen in the Fig. 9, the water uptake profiles show that this property is affected by the graft of both monomers, which despite to show a greater hydrophilicity, they graft preferably in the amorphous zone of cellulose matrix (Bhattacharya 2004). Grafted material still absorbs greater quantities of water, but pristine cotton gauze is much more cognate to water than graft.

Comparing both methods to obtain grafted cotton gauzes, it can be observed that CG-g-(NIPAAm/MAAc) (AIBN) uptakes lesser quantities of water than CG-g-(NIPAAm/MAAc) (γ). This fact can be explained taking into account the type of graft that each method produces, that is surface grafting, for chemical method, and bulk grafting for physical method, which was determined and corroborated by SEM micrographs. In CG-g-(NIPAAm/MAAc) (AIBN), the water molecules are retained mainly in the surface of the graft and this avoids to those molecules to penetrate the cellulose matrix. Also, to remove water excess, those particles could have been removed. While CG-g-(NIPAAm/MAAc) (γ), graft was produced inside the thread and, for this reason, there is a combination of the action of matrix and graft that retains water particles, which were more difficult to remove.

In both cases, despite the fact that grafted cotton gauzes have lost a little fraction of their water uptake capacity, these materials still retain greater quantities of water. Furthermore, through these experiments it can observed that maximum water uptake occurs at 6 h, where the tendency lines no longer varies.

Considering the time of the maximum water uptake (6 h), experiments of this type were made as function of temperature to determine the LCST of grafted cotton gauzes, taking into account the swelling-deswelling behavior of thermo-responsive component (Kaneko et al. 1999; Fu and Soboyejo 2010; Li et al. 2023). Figure 10 exhibits the profiles obtained by performing such experiments. At a determined temperature, PNIPAAm suffers a volume phase transition going from a hydrate state with expanded structure to a dehydrated state with compressed structure. Pristine cotton gauze is not able to suffer such conformational, observing that there is no change along the experiment. However, CG-g-(NIPAAm/MAAc) (AIBN) and CG-g-(NIPAAm/MAAc) (γ) show a loss in the water molecules uptake capacity as function of temperature, observing an abrupt change near to theoretical range reported to LCST of PNIPAAm, which is 32–35 °C (Lanzalaco and Armelin 2017; Ansari et al. 2022). In this way, by deriving water uptakes profiles, it can be deduced that LCST for CG-g-(NIPAAm/MAAc) (AIBN) is 31 °C and 34 ° C for CG-g-(NIPAAm/MAAc) (γ).

The obtained values in this experiment, firstly demonstrate that the thermosensitive component was successfully grafted in the cotton gauze. A second observation indicates that the presence of pH-sensitive component did not induce a relevant displacement in the LCST value reported in the literature. Also, those values are useful for biomedical applications, because from this value, there will be the conformational change which is a property of stimuli-sensitive polymers.

Loading and release of norfloxacin

One of the main factors to be taking into account at the moment to load norfloxacin in CG-g-(NIPAAm/MAAc) (AIBN) and CG-g-(NIPAAm/MAAc) (γ) is the temperature at which this process is performed. Figure 11 exhibits the results for the evaluation of the loading of norfloxacin at two temperatures, 5 and 25 °C. From this figure, it can be noted a better drug loading efficiency at 25 °C, which could be attributed to a better diffusion of drug molecules in the system, allowing to reach and interact with functional groups of graft with relative ease. At 5 °C, drug molecules are more restricted in their kinetic movement, hindering its diffusion (Li and Yang 2015). For this reason, it is determined that 25 °C is the suitable temperature of norfloxacin loading into the grafted cotton gauzes, being suitable because it is room temperature.

Figure 12 shows the loading profile for norfloxacin loading in grafted cotton gauzes and pristine gauze. As it could be expected, pristine cotton gauze is not a suitable drug carrier, loading only a very little fraction of norfloxacin molecules due to that probably there are some weak interactions between matrix and drug, which are not relevant or significant. However, in the case of grafted cotton gauzes, a bounded exponential loading tendency can be observed, that begin to be constant since 24 h of exposition of material with norfloxacin solution, achieving a maximum loading tendency at 48 h. A bounded exponential fitting indicates a fast capture of norfloxacin molecules and a rapid interaction of these with the graft, achieving a bound where there is no more capture of molecules. This loading capacity is attributed to the electrostatic interactions between drug and graft (Li and Yang 2015; Wells et al. 2019). Furthermore, this grafted materials can retain until approximately 800 micrograms per gram of material, which is highly attributed to the diffusion capacity of norfloxacin. Another important observation is that it is indifferent the grafting method to obtain modified materials, that is, both materials are suitable drug carriers under this reported conditions. Complementing this observation with the information provided by SEM, CG-g-(NIPAAm/MAAc) (AIBN) can retain drug molecules on its surface while CG-g-(NIPAAm/MAAc) (γ) on the bulk.

Releasing of norfloxacin loaded on cotton gauzes was performed during 48 h trying to emulate physiological conditions, that is, at 37 °C and in a phosphate buffer saline (PBS) solution with a pH of 7.4, and under constant agitation. Figure 13 displays norfloxacin releasing profiles for loaded cotton gauzes, under afore mentioned conditions. Moreover, Table 3 shows the values of drug loading, releasing, and percentage of drug released from grafted gauzes. Analyzing Fig. 13; Table 3, a comparison between both grafting methods can be performed. On one side, pristine cotton gauze, due to its hydrophilic nature, can carry and release rapidly, and almost entirely (90%), the drug molecules that interacted with its structure. Now, CG-g-(NIPAAm/MAAc) (AIBN), release the largest amount of norfloxacin, which makes sense since AIBN-induced method developed a surface grafting and drug molecules are retained at the surface of the copolymer being more available for their release to the media. In comparison with this copolymer, CG-g-(NIPAAm/MAAc) (γ) release lesser quantities of norfloxacin. This is because, radiation-induced grafting induces a bulk grafting and drug molecules are inside the thread, in the cellulose matrix, making difficult their release by the greater interactions, related with matrix, graft, and drug, that they must overcome.

Releasing profiles where treated with the complement of Excel, DDSolver complement, which is a tool to adjust data coming from those experiments (Zhang et al. 2010). According to fitting statistical parameters, norfloxacin releasing profiles follow a Korsmeyer-Peppas mode drug release mechanism according to Eq. 3:

where \({f}_{i}\) is fraction of released drug at each time interval, \({M}_{t}\) is the maximum quantity of drug released at determined time t, \({M}_{\infty }\) is the maximum quantity of drug released at the equilibrium, \(\alpha\) (known as release rate) is a constant that incorporates geometric and structural characteristics of drug form, and n is the release exponent that indicates the drug release mechanism (Costa and Sousa Lobo 2001; Bruschi 2015).

Korsmeyer-Peppas mechanism with an n value < 0.5 indicates that drug releasing is governed by a Fickian diffusion, that is, there is a predominant role of drug diffusion in the media over the relaxation of polymer chains (Liechty et al. 2010; Peppas and Narasimhan 2014). Drug and the medium where it is present will penetrate in a significant way in the polymeric matrix. Also, to evaluate the rate at which drug is diffused, the values of α are examined, observing that CG-g-(NIPAAm/MAAc) (AIBN) (α = 1.899 ± 0.042) released drug faster than CG-g-(NIPAAm/MAAc) (γ) (α = 1.609 ± 0.071), which is evident due to the type of grafting that originates modified cotton gauzes. Fitting parameters of this model to the release profiles are detailed in Table 4.

Antimicrobial activity

Norfloxacin is an antimicrobial drug of the family of fluoroquinolone of a broad spectrum, mainly used in the treatment of urinary infections, but that has demonstrated a potential application in the healing of skin burn wounds (Goldstein 1987; Dua et al. 2016). Its main mode of action is governed by the inhibition of the A subunit of the enzyme DNA gyrase, that is essential for DNA replication (Goldstein 1987). Grafted cotton gauzes loaded with this antimicrobial drug has been tested against S. aureus and E. coli pathogen microorganisms, which are prevalently present in this type of burn wound infections and in the biofilm formation into cotton gauzes (Lim et al. 2017; Yin et al. 2017; Xiang et al. 2021). This assays were developed at different pH values to demonstrate the broad range of application of the material due to the grafting of pH-responsive polymer. The results of this antimicrobial turbidity assays are showed in Fig. 14. As can be noted, test tube labeled as (a) in Fig. 14, corresponding to pristine cotton gauze, shows growing of both microorganisms in that medium, which indicates that this material is a potential candidate to develop biofilm on its surface. Tubes labeled as (b) and (c), belonging to CG-g-(NIPAAm/MAAc) (γ) and CG-g-(NIPAAm/MAAc) (AIBN), respectively, also exhibits the development of pathogens at different pH values, which makes sense since both grafted monomers are highly hydrophilic and biocompatible, being able to host microorganisms in their surfaces. Also this indicates that the only grafting of these stimuli-responsive polymers is not enough to achieve a barrier against pathogens. However, in the case of tubes labeled as (d) and (e) containing CG-g-(NIPAAm/MAAc) (γ) and CG-g-(NIPAAm/MAAc) (AIBN) both loaded with norfloxacin, can eradicate the presence of E. coli and S. aureus present in the media, which indicates that the quantities of norfloxacin released to the media (2.11 µg/mL for CG-g-(NIPAAm/MAAc) (AIBN) and 1.98 µg/mL CG-g-(NIPAAm/MAAc) (γ) are enough to avoid biofilm formation in grafted cotton gauzes. Comparing the results of assays at different pH values, all of them show the successful inhibition of E. coli and S. aureus. From this results, it is possible to determine that grafted cotton gauzes are a suitable intermediate to release the necessary amount of antimicrobial drug to successfully prevent S. aureus and E. coli growth in a highly contaminated environment.

Conclusions

Binary graft copolymerization of MAAc and NIPAAm onto cotton gauzes is possible using chemical initiator, such as AIBN, and gamma radiation to induce this process. Both methods allow to synthesize CG-g-(NIPAAm/MAAc). All experiments have a degree of reproducibility obtaining graft of, approximately, 40% in weight. Grafting process is performed by a free radical polymerization process, being AIBN and gamma radiation which induces the generation of active sites along the cellulose backbone by which both monomers are grafted. By comparing infrared spectra of pristine cotton gauze and grafted cotton gauzes, the modification was verified by seeing the inclusion of functional groups. Thermogravimetric analysis indicates a reduction in the thermal stability in comparison with pristine cotton gauze, which is not relevant to their package or biomedical application. Also, SEM micrographs allow to determine that using AIBN as initiator produces a surface grafting while using gamma radiation generates bulk grafting. Regarding to the physicochemical properties, acid-base potentiometric titrations determinate that grafted materials exhibit a pH response, obtaining a critical pH of approximately 4.7, value that opens a broad range of application. The graft alters the water uptake capacity of pristine cotton gauze, being those gauzes modified using gamma radiation which results more affected. However, modified materials still retain great quantities of water. Water uptake assays as function of temperature proved that grafted cotton gauzes exhibit a response to temperature embodied into a LCST in the range of 31–34 °C, which is near to the physiological temperature (37 °C).

The CG-g-(NIPAAm/MAAc) system is able to load the antimicrobial drug norfloxacin achieving a maximum load after 48 h of exposition of grafted material to drug solution at 25 °C. Release profiles reveals that these follow a Korsmeyer-Peppas kinetic model, releasing to the medium until approximately 25% of drug (2.11 µg/mL for CG-g-(NIPAAm/MAAc) (AIBN) and 1.98 µg/mL for CG-g-(NIPAAm/MAAc) (γ)). This model indicates that norfloxacin release is mainly governed by diffusion mechanisms, maintaining drug concentration for 8 h. Antimicrobial turbidity assays demonstrate that grafted and loaded cotton gauzes can inhibit the growth of pathogens such as S. aureus and E. coli in a highly contaminated environment which fits surgical conditions. This dual modification represents a comparison between synthetic methods and an improvement in the obtaining of drug delivery systems acting as barriers to the biofilm formation in cotton gauzes.

Data availability

All data generated or analyzed during this study are included in this article.

References

Amalin Kavitha A, Thomas Paul K, Anilkumar P (2020) Cellulose-derived materials for drug delivery applications. In F Mohammad, HA Al-Lohedan, M Jawaid (eds) Sustainable nanocellulose and nanohydrogels from natural sources. Elsevier, Amsterdam, pp 367–390

Androvič L, Bartáček J, Sedlák M (2016) Recent advances in the synthesis and applications of azo initiators. Res Chem Intermed 42:5133–5145

Ansari MJ, Rajendran RR, Mohanto S et al (2022) Poly(N-isopropylacrylamide)-based hydrogels for biomedical applications: a review of the state-of-the-art. Gels 8:454

Bassaid S, Chaib M, Bouguelia A, Trari M (2008) Elaboration and characterization of poly (acrylic acid-co-crotonic acid) copolymers: application to extraction of metal cations pb(II), cd(II) and hg(II) by complexation in aqueous media. React Funct Polym 68:483–491

Bensacia N, Moulay S, Garin F et al (2015) Effect of grafted hydroquinone on the acid-base properties of poly(acrylic acid) in the presence of copper (II). J Chem 2015:1–7

Bezerra RDS, Teixeira PRS, Teixeira ASNM et al (2015) Chemical functionalization of cellulosic materials—main reactions and applications in the contaminants removal of aqueous medium. In: Poletto M, Ornaghi H (eds) Cellulose—Fundamental Aspects and Current Trends. InTech

Bhattacharya A (2004) Grafting: a versatile means to modify polymers techniques, factors and applications. Prog Polym Sci 29:767–814

Bruschi ML (2015) Mathematical models of drug release. In: Bruschi ML (ed) Strategies to modify the drug release from Pharmaceutical systems. Elsevier, Cambridge, pp 63–86

Bucio E, Burillo G (2009) Radiation-induced grafting of sensitive polymers. J Radioanal Nucl Chem 280:239–243

Bustamante-Torres M, Pino-Ramos VH, Romero-Fierro D et al (2021) Synthesis and antimicrobial properties of highly cross-linked ph-sensitive hydrogels through gamma radiation. Polymers (Basel) 13:2223

Camacho-Cruz LA, Velazco-Medel MA, Parra-Delgado H, Bucio E (2021) Functionalization of cotton gauzes with poly(N-vinylimidazole) and quaternized poly(N-vinylimidazole) with gamma radiation to produce medical devices with pH-buffering and antimicrobial properties. Cellulose 28:3279–3294

Cervantes-Uc JM, Cauich-Rodríguez JV, Vázquez-Torres H, Licea-Claveríe A (2006) TGA/FTIR study on thermal degradation of polymethacrylates containing carboxylic groups. Polym Degrad Stab 91:3312–3321

Chakraborty DD, Nath LK, Chakraborty P (2018) Recent progress in smart polymers: behavior, mechanistic understanding and application. Polym Plast Technol Eng 57:945–957

Chapiro A (1977) Radiation induced grafting. Radiat Phys Chem 9:55–67

Chatterjee S, Chi-leung Hui P (2019) Review of stimuli-responsive polymers in drug delivery and textile application. Molecules 24:2547

Clayden J, Greeves N, Warren S (2012) Organic chemistry, 2nd edn. Oxford University Press, Oxford

Costa P, Sousa Lobo JM (2001) Modeling and comparison of dissolution profiles. Eur J Pharm Sci 13:123–133

Crespy D, Rossi RM (2007) Temperature-responsive polymers with LCST in the physiological range and their applications in textiles. Polym Int 56:1461–1468

Cuissinat C, Navard P (2006) Swelling and dissolution of cellulose part II: free floating cotton and wood fibres in NaOH–Water–additives systems. Macromol Symp 244:19–30

Dai S, Ravi P, Tam KC (2008) pH-Responsive polymers: synthesis, properties and applications. Soft Matter 4:435

Djafari Petroudy SR (2017) Physical and mechanical properties of natural fibers. In: Fan M, Fu F (eds) Advanced High Strength Natural Fibre composites in Construction. Elsevier, Cambridge, pp 59–83

Dua K, Malipeddi VR, Madan J et al (2016) Norfloxacin and metronidazole topical formulations for effective treatment of bacterial Infections and burn wounds. Interv Med Appl Sci 8:68–76

Fidale LC, Ruiz N, Heinze T, Seoud OAE (2008) Cellulose swelling by aprotic and protic solvents: what are the similarities and differences? Macromol Chem Phys 209:1240–1254

Fu G, Soboyejo WO (2010) Swelling and diffusion characteristics of modified poly (N-isopropylacrylamide) hydrogels. Mater Sci Eng C 30:8–13

Goldstein EJC (1987) Norfloxacin, a fluoroquinolone antibacterial agent. Am J Med 82:3–17

Gürdag G, Sarmad S (2013) Cellulose Graft Copolymers: Synthesis, Properties, and Applications. In: Kalia S, Sabaa M (eds) Polysaccharide Based Graft Copolymers. Springer, Berlin, pp 15–57

Halasa AF, Massie JM, Ceresa RJ (2013) The Chemical Modification of Polymers. In: Erman B, Mark J, Roland M (eds) The Science and Technology of Rubber, 4th edn. Elsevier, Oxford, pp 517–546

Hasanin MS (2022) Cellulose-based biomaterials: chemistry and biomedical applications. Starch Stärke 74:2200060

Işıklan N, Küçükbalcı G (2016) Synthesis and characterization of pH- and temperature-sensitive materials based on alginate and poly(N-isopropylacrylamide/acrylic acid) for drug delivery. Polym Bull 73:1321–1342

Jun L, Jun L, Min Y, Hongfei H (2001) Solvent effect on grafting polymerization of NIPAAm onto cotton cellulose via γ-preirradiation method. Radiat Phys Chem 60:625–628

Kaneko Y, Nakamura S, Sakai K et al (1999) Synthesis and swelling-deswelling kinetics of poly(N-isopropylacrylamide) hydrogels grafted with LCST modulated polymers. J Biomater Sci Polym Ed 10:1079–1091

Kang H, Liu R, Huang Y (2015) Graft modification of cellulose: methods, properties and applications. Polymer (Guildf) 70:A1–A16

Keshipour S, Maleki A (2019) Modification of cellulose. In: Mondal M (ed) Cellulose-based superabsorbent hydrogels. Springer, Cham, pp 435–486

Kotsuchibashi Y (2020) Recent advances in multi-temperature-responsive polymeric materials. Polym J 52:681–689

Kulkarni RV, Inamdar SZ, Das KK, Biradar MS (2019) Polysaccharide-based stimuli-sensitive graft copolymers for drug delivery. In: Maiti S, Jana S (eds) Polysaccharide Carriers for Drug Delivery. Elsevier, Cambridge, pp 155–177

Lanzalaco S, Armelin E (2017) Poly(N-isopropylacrylamide) and copolymers: a review on recent progresses in Biomedical Applications. Gels 3:36

Li Y, Yang L (2015) Driving forces for drug loading in drug carriers. J Microencapsul 32:255–272

Li X-R, Wang X-L, Koseki H (2008) Study on thermal decomposition characteristics of AIBN. J Hazard Mater 159:13–18

Li J, Stachowski M, Zhang Z (2015) Application of responsive polymers in implantable medical devices and biosensors. In: Woodhead Publishing, Series (eds) Switchable and responsive surfaces and materials for Biomedical Applications. Elsevier, Cambridge, pp 259–298

Li YJ, Wu K, Li Y et al (2018) Solubility in different solvents, crystal polymorph and morphology, and optimization of crystallization process of AIBN. J Chem Eng Data 63:27–38

Li L, Guo J, Kang C (2023) LCST-UCST transition property of a novel retarding swelling and thermosensitive particle gel. Mater (Basel) 16:2761

Liang Y, Zhu H, Wang L et al (2020) Biocompatible smart cellulose nanofibres for sustained drug release via pH and temperature dual-responsive mechanism. Carbohydr Polym 249:116876

Liechty WB, Kryscio DR, Slaughter BV, Peppas NA (2010) Polymers for drug delivery systems. Annu Rev Chem Biomol Eng 1:149–173

Lim K, Yoon C, Lee J (2017) Antimicrobial effect of skin for allograft and management in burn wound. Open J Organ Transpl Surg 07:1–11

López-Saucedo F, López-Barriguete JE, Flores-Rojas GG et al (2022) Polypropylene graft poly(methyl methacrylate) graft poly(N-vinylimidazole) as a smart material for pH-controlled drug delivery. Int J Mol Sci 23:304–317

Lumbreras-Aguayo A, Meléndez-Ortiz I, Puente-Urbina B et al (2019) Poly(methacrylic acid)-modified medical cotton gauzes with antimicrobial and drug delivery properties for their use as wound dressings. Carbohydr Polym 205:203–210

Metaxa A-F, Efthimiadou EK, Kordas G (2014) Cellulose-based drug carriers for cancer therapy: cytotoxic evaluation in cancer and healthy cells. Mater Lett 132:432–435

Neamtu I, Rusu AG, Diaconu A et al (2017) Basic concepts and recent advances in nanogels as carriers for medical applications. Drug Deliv 24:539–557

Othman NAF, Selambakkannu S, Tuan Abdullah TA (2020) Grafting yield determination of glycidyl methacrylate vapor on radiated kenaf fiber via FTIR spectroscopy. Mater Today Proc 29:207–211

Peponi L, Arrieta MP, Mujica-Garcia A, López D (2017) Smart polymers. In: Jasso-Gastinel C, Kenny J (eds) Modification of Polymer Properties. Elsevier, pp 131–154

Peppas NA, Narasimhan B (2014) Mathematical models in drug delivery: how modeling has shaped the way we design new drug delivery systems. J Control Release 190:75–81

Pino-Ramos VH, Ramos-Ballesteros A, López-Saucedo F et al (2017) Radiation grafting for the functionalization and development of smart polymeric materials. In: Venturi M, D’Angelantonio M et al (eds) Applications of Radiation Chemistry in the fields of Industry, Biotechnology and Environment. Springer International Publishing, Cham, pp 67–94

Pino-Ramos VH, Flores-Rojas GG, Alvarez-Lorenzo C et al (2018) Graft copolymerization by ionization radiation, characterization, and enzymatic activity of temperature-responsive SR-g-PNVCL loaded with lysozyme. React Funct Polym 126:74–82

Priya James H, John R, Alex A, Anoop KR (2014) Smart polymers for the controlled delivery of Drugs – a concise overview. Acta Pharm Sin B 4:120–127. https://doi.org/10.1016/j.apsb.2014.02.005

Ramos-Ballesteros A, Pino-Ramos VH, López-Saucedo F et al (2019) γ-Rays and ions Irradiation. Surface modification of polymers. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, pp 185–209

Rojas-Hernández A, Ibarra-Montaño EL, Rodríguez-Laguna N, Aníbal Sánchez-Hernández A (2015) Determination of pKa values for acrylic, methacrylic and itaconic acids by 1H and 13 C NMR in Deuterated Water. J Appl Solut Chem Model 4:7–18

Romero-Fierro DA, Camacho-Cruz LA, Bustamante-Torres MR et al (2022) Modification of cotton gauzes with poly(acrylic acid) and poly(methacrylic acid) using gamma radiation for drug loading studies. Radiat Phys Chem 190:109787

Rongpipi S, Ye D, Gomez ED, Gomez EW (2019) Progress and opportunities in the characterization of cellulose – an important regulator of cell wall growth and mechanics. Front Plant Sci 9:1–28

Sahu P, Gupta M (2022) Water absorption behavior of cellulosic fibres polymer composites: a review on its effects and remedies. J Ind Text 51:7480S-7512S

Schild HG (1993) Thermal degradation of poly(methacrylic acid): further studies applying TGA/FTIR. J Polym Sci Part A Polym Chem 31:2403–2405. https://doi.org/10.1002/pola.1993.080310925

Shen DK, Gu S (2009) The mechanism for thermal decomposition of cellulose and its main products. Bioresour Technol 100:6496–6504

Sousa RG, Magalhães WF, Freitas RFS (1998) Glass transition and thermal stability of poly(N-isopropylacrylamide) gels and some of their copolymers with acrylamide. Polym Degrad Stab 61:275–281

Sun D, Babar Shahzad M, Li M et al (2015) Antimicrobial materials with medical applications. Mater Technol 30:B90–B95

Swift G (2002) Acrylic (and methacrylic) acid polymers. In: Mark HF (ed) Encyclopedia of Polymer Science and Technology. John Wiley & Sons Inc., Hoboken, pp 79–86

Swift, T. (2020). pH dependence of acrylate-derivative polyelectrolyte properties. In S.-A. Ángel & S. Deb (Eds.), Acrylate polymers for advanced applications (p. 106). London: IntechOpen.

Takács E, Wojnárovits L, Borsa J et al (2005) Modification of cotton-cellulose by preirradiation grafting. Nucl Instrum Methods Phys Res Sect B Beam Interact with Mater Ats 236:259–265

Tang L, Wang L, Yang X et al (2021) Poly(N-isopropylacrylamide)-based smart hydrogels: design, properties and applications. Prog Mater Sci 115:100702

Tissot C, Grdanovska S, Barkatt A et al (2013) On the mechanisms of the radiation-induced degradation of cellulosic substances. Radiat Phys Chem 84:185–190. https://doi.org/10.1016/j.radphyschem.2012.06.020

Vázquez E, Duarte L, López-Saucedo F et al (2021) Cellulose-based antimicrobial materials. In: Inamuddin, Ahamed MI, Prasad R (ed) Advanced antimicrobial materials and applications Environmental and microbial biotechnology. Springer, Singapore, pp 61–85

Velazco-Medel MA, Camacho‐Cruz LA, Bucio E (2020) Modification of relevant polymeric materials for medical applications and devices. Med Devices Sens 3:1–17

Wang X, Ye X, Zhang G (2015) Investigation of pH-induced conformational change and hydration of poly(methacrylic acid) by analytical ultracentrifugation. Soft Matter 11:5381–5388

Wang D, Green MD, Chen K et al (2016) Stimuli-Responsive polymers: design, synthesis, characterization, and applications. Int J Polym Sci 2016:1–2

Wei M, Gao Y, Li X, Serpe MJ (2017) Stimuli-responsive polymers and their applications. Polym Chem 8:127–143

Wells CM, Harris M, Choi L et al (2019) Stimuli-responsive drug release from smart polymers. J Funct Biomater 10:34

Xiang J, Zhu R, Lang S et al (2021) Mussel-inspired immobilization of zwitterionic silver nanoparticles toward antibacterial cotton gauze for promoting wound healing. Chem Eng J 409:128291

Yin S, Jiang B, Huang G et al (2017) Burn serum increases Staphylococcus aureus Biofilm formation via oxidative stress. Front Microbiol 8:1–10

Zahran MK (2006) Grafting of methacrylic acid and other vinyl monomers onto cotton fabric using Ce (IV) ion–cellulose thiocarbonate redox system. J Polym Res 13:65–71

Zhang J, Peppas NA (2000) Synthesis and characterization of pH- and temperature-sensitive poly(methacrylic acid)/Poly(N-isopropylacrylamide) interpenetrating polymeric networks. Macromolecules 33:102–107

Zhang Y, Huo M, Zhou J et al (2010) DDSolver: an Add-In program for modeling and comparison of drug dissolution profiles. AAPS J 12:263–271

Acknowledgments

The authors thank to CONACyT for master scholarships provided to David Romero-Fierro (CVU: 1175725) and Y. Aylin Esquivel-Lozano (CVU: 952777). To Benjamín Leal-Acevedo for technical assistance.

Funding

This work was supported by the Dirección General de Asuntos del Personal Académico (DGAPA), Universidad Nacional Autónoma de México under Grant IN204223.

Author information

Authors and Affiliations

Contributions

DRF Conceptualization, Data Curation, Methodology, Formal analysis, Investigation, writing–Original draft, writing–Review & Editing YAEL Formal Analysis, Methodology, writing–Original draft, Review & Editing. ACC Methodology–antimicrobial assays, Review & Editing. EB Conceptualization, Visualization, Funding acquisition, Project administration, Resources, Review & Editing. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Consent to participate

Not applicable.

Consent for publication

All authors agree to the publication of this research article.

Ethical approval

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Romero-Fierro, D., Esquivel-Lozano, Y.A., Camacho-Cruz, A. et al. Thermo- and pH-responsive cotton gauzes as drug delivery system obtained by gamma radiation and chemical initiator. Cellulose 30, 11273–11294 (2023). https://doi.org/10.1007/s10570-023-05561-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05561-6