Abstract

Xylan is the main contaminant of hardwood sulphite dissolving pulp used for the production of regenerated cellulose. The amount of xylan in pulp should not exceed the minimum allowable values and which is not easy to achieve. To control the pulping process, a basic knowledge of xylan removal is essential. In this study, Eucalyptus globulus glucuronoxylan (GX) conversion during acidic Mg-base acid sulphite pulping of dissolving pulp was assessed for the first time in pilot experiments simulating the industrial process. The kinetics of GX degradation and changes in its structure and molecular weight along all pulping steps were evaluated. According to pentosans analysis, more than 60% of wood xylan was removed already in the heating-up step. A pseudo-first-order reaction for xylan degradation at the final pulping temperature of 140–148 °C was obtained with an activation energy of 133.4 kJ/mol. Removal of residual GX from pulp was hampered by its entrapment in cellulose fibril aggregates. The dynamics of xylan deacetylation and depolymerization during pulping in isolated samples was revealed by 2D NMR and SEC techniques, respectively. Overall, the residual xylan structure in pulp is predetermined by its structural heterogeneity in the cell wall, rather than by structural changes occurring during pulping.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Glucuronoxylan (GX) is the most abundant non-cellulosic structural polysaccharide in most vascular plants providing a supporting function in the cell wall, among others (Ebringerová et al. 2005; Scheller and Ulvskov 2010). In the woody plant domain, angiosperm GX is the second most abundant polysaccharide consisting of linear chains of β-(1,4)-D-xylopyranose (Xylp) linked to terminal 4-O-methyl-α-D-glucuronic acid (MeGlcpA) units on the O-2 of xylosyl residues (5–15 mol.%) having degrees of acetylation (DS) ranging between 0.4 and 0.6. Unlike angiosperm GX, gymnosperm GX are generally non-acetylated and, in addition to the terminal MeGlcpA units at the O-2 position (20–30 mol.%), have small amounts of α-L-arabinofuranosyl (Araf) residues linked mainly to O-3 of the xylan backbone (5–8 mol.%). GX plays a significant role in the chemical processing of wood, contributing decisively to the properties of cellulosic pulps (Sixta 2006), being the target for the production of biofuels, diverse composite materials, and supplements for food or biomedical applications (Deutschmann and Dekker 2012; Petzold-Welcke et al. 2014; Nechita et al. 2021).

Regarding acid sulphite pulping of dissolving hardwood pulps, GX is the main non-cellulosic contaminant that deteriorates the production of target rayon fibres, whose control is essential (Sixta 2006; Mendes et al. 2021; Ngene et al. 2022). In the acid sulphite pulping of wood, the lignin removal occurs due to its sulphonation by hydrosulphite ions derived from SO2 in the presence of a suitable base (Ca2+, Mg2+, Na+ or NH4+) at ca. 130–145 °C (Sixta 2006; Evtuguin 2016). The sulphonated lignin (lignosulphonate) is dissolved in the spent pulping liquor (SSL) together with sugars and oligosaccharides from degraded cellulose and hemicelluloses, mainly GX, under acidic conditions (pH < 2). It is noteworthy that the GX degradation products such as xylooligosaccharides (XOS), xylose, furfural, and acetic acid, released in spent liquor during pulping, represent a promising source of profits for the pulp mill (Pereira et al. 2013; Evtuguin 2016; Magina et al. 2022). On the other hand, the hitherto unclear resistance to the removal of xylan from wood causes problems with the control of the pulping process. In this context, deep basic knowledge about the behaviour of GX during acid sulphite pulping is vital for elaborating the dissolving pulp quality and biorefinery profits.

It is generally assumed that GX is readily hydrolysed during the acid sulphite pulping, giving rise to the depolymerised (XOS and xylose) and more profound degradation products (furfural, xylonic and acetic acids) dissolved in SSL (Sjöström 1993; Sixta 2006). However, there is only scarce knowledge of the GX degradation kinetics during acid sulphite pulping. Thus, formal kinetics of spruce hemicelluloses (mainly glucomannan and a small proportion of GX) dissolution were reported under simulated laboratory conditions of Na-base acid sulphite pulping being quite different from industrial practice (Hagberg and Schöön 1973). A similar approach was expanded to evaluate hemicelluloses dissolution from eucalyptus wood in the Ca-base acid sulphite dissolving pulp pulping (Kilian and de Vaal 2000). In another study, the GX dissolution of Eucalyptus grandis and Eucalyptus saligna wood in Ca-base acid sulphite dissolving pulp pulping was evaluated in pilot experiments under conditions close to industrial practice (Watson 1992). It was concluded that the removal of GX did not follow kinetics nor pseudo-zero, pseudo-first or pseudo-second-order. Although the best correlation (r2 ≈ 0.62) was found with the first-order kinetic model, giving rise to a rather suspicious activation energy (69.3 kJ/mol). This is explained, at least partially, by inaccuracies in the determination of the residual GX in pulps in a previous study (Watson 1992). Hence, the proper chemical kinetics of GX hydrolysis concerning structural changes in GX was never previously studied.

The main objective of this study was to evaluate the chemical kinetics of GX hydrolysis and the structural changes accompanying it in the Mg-base acid sulphite pulping of Eucalyptus globulus for dissolving pulp production. The pulping experiments were carried out in pilot-scale equipment following the sequence of operations and reagent loading, in accordance with industrial practice. First, the wood residue or pulp was analysed for yield and pentosans content along the pulping operations to assess the dynamics of GX removal. The GX structure was evaluated after isolation from wood or pulp samples by extraction with dimethyl sulphoxide (DMSO) of the respective peracetic holocellulose samples. Then, the composition of isolated GX was analysed by wet chemistry methods, the structure by 1D and 2D NMR techniques, and the molecular weight was determined by size-exclusion chromatography (SEC). Finally, the changes in cellulose's physical structure during the pulping were assessed by solid-state 13C NMR of the purified pulp samples.

Materials and methods

Pilot scale experiments

Pulping experiments were conducted in a pilot scale digester (MK Systems Inc.), where about 1 kg of oven-dry (o.d.) wood chips was used for each pulping trial (Fig. 1). The composition of the filling acid varied to have in side-relief the concentrations of total SO2 and MgO of 6.0–7.0% and 0.70–0.9%, respectively. After filling the digester with wood chips and pulping acid at room temperature, the temperature was allowed to increase to 70 °C in the digester, whereas the pressure was increased with nitrogen to 9.0 bar (impregnation pressure). The temperature continues to rise according to the set point for the heating rate, and at 115 °C the extraction of the pulping acid occurs (side-relief) to set the hydromodulus in the set point (3.5), with a decreasing in the pressure. The temperature increases until the set-point (e.g., 142 °C, time 0 in data), and the pressure stabilizes at 7.7 bar. The depressurisation starts after the cooking following the established procedure when the pulping time reaches the set-point value (high-pressure depressurisation from 7.7 bar to 3.0 bar and the low-pressure depressurisation from 3.0 to 0.1 bar). The pulping residues were disintegrated, washed exhaustively with water and air-dried. The yields were determined as an o.d. residue per weight of initial o.d. wood used for the pulping.

Chemical characterisation

The pentosans content (w/w %) in wood and pulp (Fig. 1) was analysed in the reaction with 3.85N hydrochloric acid under steam distillation during boiling giving rise to furfural, which was collected in the distillate and determined colorimetrically with orcinol-ferric chloride reagent, according to the Tappi standard T 223 cm-10. The lignin content in the pulps was analysed as kappa number according to the Tappi T 236 cm-10 standard.

The isolated glucuronoxylans were treated with 72% H2SO4 at 20 °C for 3 h, followed by 1.5 h hydrolysis with dilute 1 M H2SO4 at 100 °C according to Saeman hydrolysis (Selvendran et al. 1979). Neutral monosaccharides were determined as alditol acetate derivatives by gas chromatography with flame-ionisation detection (GC-FID). Standard solutions were prepared for the identification and quantification of each sample sugar. Alditol acetates were quantified using a Focus GC-FID (Thermo Scientific, Waltham, MA, USA) using Chrom-Card software to control the instrument operation and to data acquisition under the following conditions: inlet temperature at 225 °C with a split flow of 30 mL/min; oven temperature at 220 °C with a run time of 28 min and carrier flow of 3 mL/min; detector temperature at 250 °C.

The uronic acids content in the glucuronoxylans (Fig. 1) was determined colorimetrically with m-phenylphenol from an aliquot separated from the hydrolysis of neutral sugars (0.5 mL) and diluted four times according to the modified method of Blumenkrantz and Asboe-Hansen (Blumenkrantz and Asboe-Hansen 1973; Coimbra et al. 1996). The quantification was made using galacturonic acid standards.

Isolation of holocellulose and xylans

Holocellulose was isolated from extractives-free Eucalyptus globulus wood (Fig. 1) using peracetic acid (concentration ca. 10%), according to a previously described method with some modifications (Evtuguin et al. 2003). About 5 g of extractives-free wood was treated with 200 mL of peracetic acid at 80 °C for 20 min under constant stirring and reflux. After the reaction, the flask content was quickly filtered off and washed with hot water and acetone to neutral pH. For pulp residues obtained throughout the acid sulphite pulping, the procedure is the same, except the time of reaction that varied between 5 and 15 min, depending on the sampling point (pulps with lower residual lignin content need less reaction time). Xylans were isolated from peracetic holocelluloses by extraction with DMSO (HPLC grade) followed by precipitation in a methanol/ethanol mixture according to a previously described procedure (Evtuguin et al. 2003).

Structural characterisation

Quantitative 1H NMR spectra were recorded using a Bruker AVANCE 300 spectrometer operating at 300.13 MHz, registered in D2O at 298 K using sodium 3-(trimethylsilyl)propionate-d4 as internal standard (δ = 0.00). The quantitative spectra were acquired using a 90° pulse, 12 s relaxation delay and collecting 300 scans. 2D 1H–1H (TOCSY) spectroscopy was recorded using a Bruker AVANCE 300 spectrometer operating at 300.13 MHz, registered at 298 K. The spectrum was acquired at a spectral width of 2185 Hz in both dimensions (τmix = 0.050 s) with a relaxation delay of 2.0 s. For each FID, 128 transients were acquired; the data size was 1024 in t1 × 512 in t2. The phase-sensitive 1H–13C (HSQC) spectrum was recorded using a Bruker AVANCE 300 spectrometer operating at 300.13 MHz at 298 K over an F1 spectral weight of 12,000 Hz and an F2 width of 2000 Hz with 2048 × 1024 matrix and 128 transients per increment. The delay between scans was 2 s, and the delay for polarization transfer was optimised for 1JCH = 148 Hz.

Solid-state Cross Polarization–Magic Angle Spinning 13C Nuclear Magnetic Resonance (CP-MAS 13C NMR) spectra of holocelluloses (Fig. 1) were registered on a Bruker Advance 400 spectrometer. The CP-MAS 13C NMR spectroscopy was used to study a cellulose crystallinity index (CrI), which describes the relative amounts of crystalline and amorphous cellulose phases. Samples were packed into a zirconia rotor sealed with Kel-FTM caps. The rotor's spinning speed was 12 kHz, contact time 1 ms, and ca. 7000 scans with a 90° proton pulse were collected with a recovery delay of 2.5 s. Glycine was used for the Hartman-Hahn matching procedure and as an external standard for calibrating the chemical shift scale relative to tetramethyl silane ((CH3)4Si). CP-MAS 13C NMR spectra were registered using holocelluloses samples (ca. 14% humidity). The crystallinity index was determined from the relationship between the integration areas of the ordered (A86–92ppm) and amorphous (A79–86ppm) C-4 signals in cellulose (Liitiä et al. 2000):

The lateral fibril dimensions and fibril aggregates were determined by methodology proposed by (Wickholm et al. 1998), according to the model of a fibril with a square cross-section:

where q is the fraction of intensity of the signal of accessible and inaccessible surfaces to assess fibril dimensions or the fraction of intensity of the signal of accessible surfaces only to assess the dimensions of fibril aggregates; n is the number of cellulose polymers perpendicular to the cross-section along one side of the square fibril cross-section. The assumed square fibril aggregate cross-section n can be converted to a lateral dimension expressed in nm using a factor of 0.55 nm per chain (Krässig 1993).

Acetic acid quantification

The acetic acid present in the spent liquor samples (Fig. 1) was quantified by High-Performance Liquid Chromatography (HPLC). Standard solutions were prepared for the identification and elaboration of the calibration curves. Before the HPLC analysis, the solutions were filtered through syringe filters with polyether sulfone membrane (0.45 μm porosity and 25 mm diameter). The HPLC analysis was conducted using a Thermo Scientific Accela HPLC system equipped with an Accela 600 pump, Accela PDA and RI detectors, and an 8 μm Thermo Scientific HyperRez XP Organic Acids column 100 × 7.7 mm. ChromQuest software was used to ensure complete control of the instrument operation and data acquisition. The isocratic method consisted of using 0.001 M H2SO4 as the eluent at a 300 μL/min flow rate, with a run duration of 90 min, keeping the column at 40 °C.

Molecular weight determination

The molecular weight of the isolated glucuronoxylan samples (Fig. 1) was determined by size exclusion chromatography (SEC). About 4–5 mg of the sample was dissolved in 50 μm of 10% LiCl in dimethylacetamide (DMA, HPLC grade) and then diluted to 500 μm with the same solvent. The analysis was carried out using Agilent PL-GPC 220 system equipped with two columns Agilent PL gel MIXED-D, 7.5 × 300 mm, 5 µm (in series) protected by a PL gel MIXED pre-column, 7.5 × 50 mm, 5 µm. The columns, injector system, and detector (RI) were maintained at 70 °C during the analysis. The eluent (0.1 M LiCl in DMA) was pumped at a flow rate of 0.9 mL/min. The columns were calibrated using pullulans (Polymer Laboratories, UK) (Mp = 0.8–100.0 kDa).

Results and discussion

Hemicellulose removal kinetics

The main steps of acid sulphite pulping of Eucalyptus globulus wood, mimicking the industrial process, include filling the pilot digester with warm (ca. 70 °C) pulping acid containing a mixture of predetermined amounts of H2SO3·SO2 and Mg(HSO3)2 at pH 1.5–1.6 to cover the wood chips and fill the free headspace of the digester. The digester is then pressurised to 9 bar to impregnate the wood, and the temperature rises to 115 °C for 2h10min. The excess pulping acid is then withdrawn (side-relief), and the content of the digester is heated up to the final pulping temperature for ca. 50–55 min with inside liquor circulation. The pulping time to produce the dissolving grade pulp was 196 min. The pulping is accomplished by programmed digester depressurising to atmospheric pressure and pulp discharge. More than 30% of the lignin is removed in the heating-up period, and the pseudo-first-order delignification kinetics were registered (Mendes et al. 2022b). The final pulp had a low residual lignin content with a Kappa number of 5–6.

The amount of GX in wood, wood residue after side-relief and in the pulps (0, 15, 30, 60, 120 and 196 min) was evaluated as pentosans content. As in many hardwoods, Eucalyptus globulus GX contributes to almost 90% of the hemicelluloses (Evtuguin et al. 2003; Pinto et al. 2005a), this approach is justified being a common industrial practice (Sixta 2006). Knowing the yields of wood residues after side-relief and pulps after pulping at different times and the pentosans content, an overall GX retention profile was established throughout the process (Fig. 2). About 40% of GX was removed from the wood until side-relief and more than 60% during the whole heating-up period (until 0 min pulping time). Intensive GX removal continued until 15 min of pulping (about 80%), after which it was more moderate at higher pulping times (Fig. 2). Therefore, the major release of GX was detected at a pulping H-factor below 20. Similar features were previously reviewed for the GX removal in acid sulphite pulping from other hardwoods (Sixta 2006).

The intensity of hydrolysis reactions cannot explain the disclosed GX behaviour that occurred in the impregnation and heating-up step. During this period, the pH of the pulping liquor is the highest (Mendes et al. 2022a,b), and the severity of the pulping conditions is the lowest (H factor < 20). Furthermore, the molecular weight of residual GX dropped from 36.4 kDa in wood to only 18.6 kDa in wood residue after side-relief and to 13.6 kDa at the end of the heating-up period. The concentration of acetic acid in SSL released from GX (Alén 2015; Evtuguin 2016), which may be an indication of the severity of its hydrolysis, was three times higher at the end of pulping than at the beginning (Fig. 3). All these facts indicate that GX was removed from the wood during the heating period mainly due to its dissolution and not to hydrolysis.

The GX solubility in water is favoured by its partial acetylation and branching with MeGlcpA residues (Evtuguin et al. 2003). Breaking of lignin-carbohydrate bonds and partial depolymerization of GX during the heating period must be two obvious factors that can promote its solubility in SSL. Furthermore, the most accessible cells for the cooking acid of the hardwood xylem, the vessels and ray parenchyma, contain even higher levels of GX than the fibres (Yoshinaga et al. 1993; Vaz et al. 2022). This accessibility factor also contributes to removing a significant amount of xylan in the impregnation and heating-up pulping periods. In eucalyptus wood, vessels and ray parenchyma contribute to 30–40% (v/v) of xylem being second only to fibre content (libriform cells) (Dadswell and Wardrop 1960). Accordingly, the kinetics of xylan removal, at least in the impregnation and heating-up period, cannot be explained as simply the results of hydrolysis reactions of the main backbone chains. This explains the abnormally high order (n) on hemicellulose degradation reaction (2.5 < n < 2.9) found in previous formal kinetic studies (Hagberg and Schöön 1973; Kilian and de Vaal 2000) and the inability to describe the GX removal by pseudo-first or pseudo-second-order reaction models (Watson 1992).

The rate of the GX hydrolysis can be expressed in general form by Eq. (3):

where [HC] and [H+] are the concentration of GX expressed as the pentosan content and hydrogen ions concentration, respectively, and kHC(T) is a temperature-dependent reaction constant.

Since the liquor acidity was almost constant for the 0–150 min of the pulping at final temperature (Mendes et al. 2022a,b), the observed rate constant of GX hydrolysis can be combined with the concentration of hydrogen ions (Eq. (4)). Therefore, Eq. (3) can be rewritten as the first-order kinetics—Eq. (5).

The integration of Eq. (5) for the pulping time and the pentosans conversion \({\left[{\text{HC}}\right]}/{{\left[{\text{HC}}\right]}_{0}}\) gives the known equation to determine the hydrolysis constant \({\text{K}}_{\text{HC}}^{\text{Obs}} \, \left({\text{T}}\right)\) at a specific temperature T, Eq. (6):

The plot of \(-{\text{Ln}}\left(\frac{\left[{\text{HC}}\right]}{{\left[{\text{HC}}\right]}_{0}}\right)\) vs t at 142 °C for a pulping period of 0–196 min showed a relatively moderate correlation (r2 = 0.901) with the first-order model kinetics, which is certainly due to the zero point (t = 0 min) dropping out of the general trendline (Fig. 4A)). However, this dependency has been improved (r2 = 0.989) by eliminating the zero point and showing the observed hydrolysis constant of 1.03.10–4 s−1 (Fig. 4B)). The explanation is the aforementioned abnormal drop in pentosans content during the first 15 min of pulping, which is predetermined by GX dissolution in SSL rather than by its hydrolysis (Fig. 2).

The effective activation energy (Ea), determined from the Arrhenius equation in the pulping interval of 15–196 min (Fig. 5), within the temperature range commonly practised in the industry (140–148 °C), was 133.4 kJ/mol. However, it is noteworthy that when Ea was determined over the entire range of 0–196 min, its value was only 78.3 kJ/mol, indicating the importance of the substrate diffusion during the first 15 min of pulping.

The order in hydrogen ions for the GX hydrolysis kinetics was estimated using different pulping acid compositions (i.e., varying the pulping base concentration and, thus, the concentration of HSO3− and H+ ions). The experiments were performed at 142 °C applying the levels of combined SO2 between 1.14 and 1.66% while the total SO2 charge varied between 6.0% and 7.0%. The concentration of hydrogen ions was determined immediately at the end of the pulping at 25 °C.

The reaction order n of the GX hydrolysis was determined from the logarithmic plot Ln(\({\text{K}}_{\text{HC}}^{\text{Obs}}\)) vs Ln([H+]) (Fig. 6), considering Eq. (7). Consequently, the final kinetic equation of GX removal during acid sulphite pulping at the final temperature can be expressed as in Eq. (8).

A non-integer reaction order in [H+] less than 1 indicates that the removal of GX from the pulp is a much more complex phenomenon than the simple hydrolytic degradation of the xylan backbone and may involve, for example, specific interactions of GX with cellulose fibrils or permeation problems through the cellulose fibrils network.

Changes in the chemical composition of xylan throughout the acid sulphite pulping

To better understand the structural changes of GX during acid sulphite pulping, GX samples from wood before pulping (XylEG), at the end of the side-relief (Xylside), at the beginning (t = 0 min; Xyl0min) and after 15 (Xyl15min), 30 (Xyl30min), 60 (Xyl60min), 120 (Xyl120min) and 196 min (Xyl196min) of pulping at final temperature were isolated by extraction with DMSO from peracetic holocellulose of respective pulps. This approach allowed the isolation of chemically intact GX (Evtuguin et al. 2003; Prozil et al. 2012) in relatively high yields (50–60% of the total GX in the residue). At the same time, the efforts to isolate a suitable sample from the pulping liquor at the heating-up period for the characterisation of released GX were unsuccessful due to the problems of GX purification from other SSL components, mainly from water-soluble sulphonated lignin.

The analysis of monosaccharide compositions revealed the predominance of xylose and uronic acids in the hydrolysates of isolated GX samples (Table 1), which is common for hardwood O-acetyl-(4-O-methylglucurono)-β-D-xylan (Ebringerová et al. 2005; Pinto et al. 2005b). Small amounts of detected galactose, arabinose and rhamnose are due to rhamnoarabinogalactan (RAG) fragments attached to O-2 of the terminal MeGlcpA residues linked to the main xylan backbone (Shatalov et al. 1999; Evtuguin et al. 2003; Reis et al. 2004). The structural association of GX with other polysaccharides favours its retention in the cellulosic pulp during kraft pulping, thus positively contributing to the kraft pulp yield (Pinto et al. 2005a). However, this linkage between RAG and MeGlcpA residues is labile under alkaline and, especially, under acidic conditions. This is why it is not surprising that structurally association with the GX RAG almost disappeared in the heating-up pulping period (Table 1). Contaminations with gluco-oligosaccharides formed from partially hydrolysed accessible cellulose can explain the increase in glucan content in the isolated GX along the pulping.

The most intriguing is the drastic drop in GX branching with MeGlcpA residues at the heating-up period (Table 1), which cannot be assigned to the cleavage of quite stable under acidic conditions aldobiuronic acid structures (→ 4)[4-O-Me-α-D-GlcpA-(1 → 2)][3-O-Ac]-β-D-Xylp-(1 →) (Bishop 1953). The plausible explication is a previously suggested structural heterogeneity of eucalyptus GX (Gomes et al. 2020). Thus, about one-third of the GX in the cell wall is closely aligned to cellulose fibrils and is much less branched and accessible than the other two-thirds of the GX allocated in the interfibrillar space. In alkaline pulp extraction, the latter counterpart of the GX is easily removable, which depends on the permeation capacity of the fibre cell wall (Gomes et al. 2020). By analogy, the release of partially depolymerised and highly branched GX from the interfibrillar space during the heating-up period of acid sulphite pulping led to residual GX with a less branched structure tightly bound to cellulose fibrils. This explains a significant drop in MeGlcpA residues content in isolated GX even before reaching the final pulping temperature (Table 1). It is noteworthy that during pulping at the final temperature, the content of MeGlcpA in the residual GX does not change significantly.

Structural analysis of glucuronoxylan throughout the acid sulphite pulping

The main assumptions concerning the GX behaviour during the acid sulphite pulping were confirmed by the structural analysis of GX samples isolated from wood and pulps, characterised in detail by 1D and 2D NMR. In addition, the presence of partially acetylated structures was unambiguously confirmed by HSQC spectra (Fig. 7). The proton and carbon signal assignments were done using a previously published database (Evtuguin et al. 2003; Pinto et al. 2005a; Prozil et al. 2012) and are depicted in Table 2.

HSQC spectrum of Xyl0min (D2O, 25 °C). The non-acetylated units are in blue, the acetylated ones in red and the MeGlcA residues in green. All the designations are the same as in Table 2

The HSQC spectrum of GX isolated from the wood residue at the final pulping temperature showed typical partially acetylated structures in GX commonly reported in GX from wood (Evtuguin et al. 2003; Prozil et al. 2012). This fact confirms that no extensive deacetylation reaction occurred in the GX retained in the residue after the impregnation and heating-up cooking periods. However, the H/C cross signal at 5.39/98.2 ppm from corresponding anomeric atoms in MeGlcpA residues linked at O-2 with galactose residue of the attached RAG galactan backbone was too weak to be clearly seen (Fig. 7). This means these bonds were mostly cleaved in the impregnation pulping step, or the GX molecular fragments with these structural elements were readily dissolved in the SSL.

The detailed analysis of different acetylated and non-acetylated GX structures was carried out while acquiring the quantitative 1H NMR spectra. The proton resonances were assigned using HSQC (Fig. 7) and TOCSY spectra and the literature database (Evtuguin et al. 2003; Prozil et al. 2012). 1H NMR spectra of extreme Xylside and Xyl196min samples clearly demonstrated their differences with regard to the patterns of acetylated residues in GX (Fig. 8). The integrals of specific signals shown in the expanded anomeric proton region (Fig. 8) allowed the quantification of each particular structure based on 100 Xylp units of the GX backbone according to a previously published approach (Evtuguin et al. 2003).

1H NMR spectra of O-acetyl-(4-O-methylglucurono)-β-D-xylan isolated from woody residue after side-relief of Eucalyptus globulus magnesium-base sulphite pulping, Xylside (A) and from pulp at the end of pulping, Xyl196min (B). The expanded region of anomeric protons in the 1H NMR spectrum of Xylside (C); the designations are the same as presented in Table 3

The amount of deacetylated Xylp units in the residual GX decreased noticeably in the impregnation and heating-up pulping period being then almost constant until the last hour of the pulping (Table 3). This feature is in tune with the almost constant profile of hydrosulphite ions in SSL and coincides with the SSL acidity profile within the cooking period of 0–150 min (Mendes et al. 2022a,b). Hence, the sharp increase in the acetic acid concentration in the SSL during the first 120 min at the final temperature (Fig. 3) is mainly due to the deacetylation of the GX dissolved in the SSL, and not to the residual GX in the pulp. Furthermore, the amount of terminal and branched at O-2 MeGlcpA residues in the residual GX also dropped during the heating-up period, keeping almost constant throughout the pulping at the final temperature (Table 3). These findings on the GX structure are consistent with previous suggestions about the predominant dissolution of highly branched GX from the vessels, ray parenchyma and fibres in the heating-up pulping period.

It is noteworthy that all Xylp residues branched at O-2 with terminal MeGlcpA units were O-3 acetylated, thus confirming the particular stability of these substructures in the pulping (Table 3). The content of O-2,3 diacetylated Xylp units in the residual GX decreased substantially in the heating-up period and maintained almost constant until the end of the pulping. The major decrease of DS with acetyl groups in GX over the time-at-temperature period was due to hydrolysis at the O-2 or O-3 positions of the Xylp units. Moreover, the ratio of O-2 (Xyl-2Ac) and O-3 (Xyl-3Ac) acetylated Xylp units in the residual GX was inconsistent throughout the pulping. The plausible explication of such behaviour can be the migration of the acetyl groups between O-2 and O-3 positions under acidic conditions, as already reported for acetylated xylan (Reicher et al. 1984) and glucomannan (Lassfolk et al. 2019, 2021). The most accentuated deacetylation of the GX occurred right at the end of pulping, probably due to the increased pulping liquor acidity (Table 3). Thus, the deacetylation of GX retained in the pulp also contributed substantially to the increased amount of acetic acid detected in SSL at the end of pulping (Fig. 3). The molecular weight of GX in the pulp also dropped substantially after 196 min of cooking at final temperature (Table 3).

The GX released into the pulping solution is mainly hydrolysed to monosaccharides, although the xylooligosaccharides (XOS) were also detected in SSL (Marques et al., 2009). It was concluded that about 75% of the GX is reduced to sugars (mainly xylose) and 25% is present in the form of XOS in the SSL at the end of the acid sulphite pulping of E. globulus wood (Xavier et al. 2010). According to common mass balance, about 10% of the xylose in SSL is converted to furfural and xylonic acid (Magina et al. 2022).

To summarize the results obtained from the composition and structural changes of GX during pulping, it can be proposed that the GX removal in the heating-up pulping period occurs predominantly from the interfibrillar space of the fibre cell wall together with sulphonated lignin. This leads to increased fibril aggregation due to its newly formed free surfaces. Furthermore, fibril aggregates entrap the residual tightly bound GX, thus hindering the dissolution of partially hydrolysed macromolecules. These features are schematically represented in Fig. 9. Thus, the kinetics of GX removal during the impregnation and heating-up cooking periods is more affected by the dissolution of its degraded molecular fragments in SSL than by the kinetics of hydrolysis. In contrast, at the final pulping temperature, the release of large fragments of GX is hampered, and the removal of GX is mainly determined by the hydrolysis kinetics.

Schematic representation of the glucuronoxylan (GX) removal from fibre secondary cell wall during acid sulphite pulping. The accessible partially hydrolysed GX is dissolved jointly with lignin from interfibrillar space, causing the elementary cellulose fibril (EF) rearrangement. As a result, the release of the residual GX is hampered by formed EF aggregates

Relationship between glucuronoxylan removal and physical structure of cellulose.

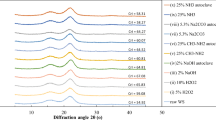

The previously proposed relationship between the dissolution of GX in SSL and changes in the physical structure of cellulose was studied by solid-state 13C NMR on isolated wood holocellulose (HEG), wood residue after side-relief (Hside) and pulps obtained at the beginning (H0min) and after 196 min (H196min) of pulping at final temperature. CP-MAS 13C NMR spectra of holocelluloses (Fig. 10) showed a progressive decrease in the residual GX content, as follows from the gradual decrease in the integral intensity of the characteristic resonance at 62.0 ppm (C-5 in GX). Simultaneously, the resonance at 88.8 ppm (C-4 in mostly crystalline cellulose) was increased over resonance at 84.0 ppm (C-4 mostly in amorphous cellulose) throughout the pulping process, thus indicating the increased degree of cellulose crystallinity. As a result, the cellulose crystallinity index (CrI) in the final pulp increased by 25% concerning the wood (Table 4). The latter feature is quite common for cellulosic pulps when part of amorphous cellulose is degraded during the pulping, and the aggregation of cellulose fibrils causes some increase in their crystallinity due to the cocrystallization phenomenon (Hult et al. 2001; Rebuzzi and Evtuguin 2006; Rebola et al. 2021).

CP-MAS 13C NMR spectra of holocelluloses isolated at various stages of the magnesium-base acid sulphite pulping of Eucalyptus globulus (from wood (HEG), wood residue after side-relief (Hside) and pulps obtained at the beginning (H0min) and after 196 min (HEnd) of pulping). The expanded spectrum region of H0min at 80.0–92.0 ppm depicts the deconvolution peaks assigned to hemicelluloses (HC) and inaccessible (IN) and accessible (AC) cellulose surfaces used to calculate the lateral fibril aggregates

Aggregation of cellulose fibrils becomes possible when their surface is free of cell wall concomitants, mainly hemicelluloses and lignin. In other words, this process is enhanced as non-cellulosic substances are removed. Therefore, it is unsurprising that even partial delignification and GX removal until side-relief led to more than twice the increase in lateral fibril aggregate dimension (DA), from 3.5 to 8.5 nm (Table 4). At the end of the heating-up period, DA was increased to 15.1 nm, which is not very far from the maximum aggregate dimension found for the pulp after 196 min of pulping (20.0 nm). These results on cellulose fibre aggregation corroborate with GX removal from the fibre cell wall (Fig. 2) being inversely proportional (Fig. 11). This fact corroborates with the initial assumption about the importance of GX diffusion from fibre cell wall on the kinetics of its removal. In other words, the cellulose fibril network in the cell wall controls the release of GX caused by hydrolysis.

Conclusions

The results of this study showed that the removal of glucuronoxylan (GX) from wood during the impregnation and heating-up period of the acid sulphite pulping of Eucalyptus globulus is predetermined mainly by the dissolution of its macromolecular structural fragments rather than by the rate of hydrolysis reactions. More than 60% of the GX was removed from the wood by the end of the impregnation and heating-up period. The kinetics of GX removal at the final pulping temperature follows a first-order kinetics and non-integer (0.64) order in hydrogen ions, showing that not only the hydrolysis reactions affected the GX removal. These features of the GX removal kinetics were explained by its accessibility in the fibre cell wall and changes in the physical structure of cellulose occurring during the pulping. The partial hydrolysis of GX and its bonds with lignin, which is easily sulphonated and becomes soluble, favours the dissolution of GX in the initial phase of sulphite pulping. Those most accessible to pulping acid and rich in GX vessels and ray parenchyma are considered to be the most susceptible to GX removal in the early stages of cooking. Much less accessible xylem fibres must be responsible for retaining GX at the final pulping temperature. As most of the GX in the eucalyptus fibres allocated in the interfibrillar space is more branched than the other counterpart of the GX lined with cellulosic fibers, the former becomes more accessible and soluble in the spent sulphite liquor (SSL). Accordingly, the residual GX possesses a less ramified structure more closely related to cellulose fibrils. In addition, the deacetylation favours GX hydrogen bonding to cellulose, which contributes to their tighter interaction. As wood delignification proceeds, cellulose fibres become more available for aggregation and entrap the concomitant aligned GX molecules, thus hampering their removal in the sulphite spent liquor. It can also be assumed that the degree of branching of residual GX embedded into cellulose fibre aggregates is mainly the result of the GX heterogeneity in the cell wall rather than the result of structural changes that occurred during acid sulphite pulping. It was also concluded that most of the acetic acid released in SSL (about 70%) was formed from GX at the final cooking temperature (bulk and residual delignification).

Data availability

Data will be available upon reasonable request.

References

Alén R (2015) Pulp mills and wood-based biorefineries. In: Pandey A, Höfer R, Taherzadeh M et al (eds) Industrial biorefineries & white biotechnology. Elsevier, Amsterdam, pp 91–126

Bishop CT (1953) Isolation of the aldobiuronic acid, 3-(xylo-pyranosyl)-α-D-glucuronopyranoside, from wheat straw holocellulose and synthesis of its β-isomer. Can J Chem 31:134–144. https://doi.org/10.1139/v53-019

Blumenkrantz N, Asboe-Hansen G (1973) New method for quantitative determination of uronic acids. Anal Biochem 54:484–489. https://doi.org/10.1016/0003-2697(73)90377-1

Coimbra MA, Delgadillo I, Waldron KW, Selvendran RR (1996) Isolation and analysis of cell wall polymers from olive pulp. In: Linskens HF, Jackson JF (eds) Plant cell wall analysis. Modern methods of plant analysis. Springer, Berlin, pp 19–44

Dadswell HE, Wardrop AB (1960) Some aspects of wood anatomy in relation to pulping quality and to tree breeding. Appita J 13:161–173

Deutschmann R, Dekker RFH (2012) From plant biomass to bio-based chemicals: latest developments in xylan research. Biotechnol Adv 30:1627–1640. https://doi.org/10.1016/j.biotechadv.2012.07.001

Ebringerová A, Hromádková Z, Heinze T (2005) Hemicellulose. Polysaccharides I. Advances in polymer science. Springer, Berlin, pp 1–67

Evtuguin DV (2016) Sulphite pulping. In: Belgacem N, Pizzi A (eds) Lignocellulosic fibers and wood handbook renewable materials for today’s environment, 1st edn. Wiley, Hoboken, pp 225–244

Evtuguin DV, Tomás JL, Silva AMS, Neto CP (2003) Characterization of an acetylated heteroxylan from Eucalyptus globulus Labill. Carbohydr Res 338:597–604. https://doi.org/10.1016/S0008-6215(02)00529-3

Gomes TMP, Mendes De Sousa AP, Belenkiy YI, Evtuguin DV (2020) Xylan accessibility of bleached eucalypt pulp in alkaline solutions. Holzforschung 74:141–148. https://doi.org/10.1515/hf-2019-0023

Hagberg B, Schöön N-H (1973) Kinetic aspects of the acid sulfite cooking process. Part 1. Rates of dissolution of lignin and hemicellulose. Sven Papperstidning 76:561–568

Hult E-L, Larsson PT, Iversen T (2001) Cellulose fibril aggregation—an inherent property of kraft pulps. Polymer (guildf) 42:3309–3314. https://doi.org/10.1016/S0032-3861(00)00774-6

Kilian A, de Vaal PL (2000) Potential for improved control of an acid sulfite batch digester using a fundamental model. TAPPI J 83:1–13

Krässig HA (1993) Cellulose—structure accessibility and reactivity. In: Huglin MB (ed) Polymer monographs. Gordon and Breach Science Publishers, Amsterdam

Lassfolk R, Bertuzzi S, Ardá A et al (2021) Kinetic studies of acetyl group migration between the saccharide units in an oligomannoside trisaccharide model compound and a native galactoglucomannan polysaccharide. ChemBioChem 22:2986–2995. https://doi.org/10.1002/cbic.202100374

Lassfolk R, Rahkila J, Johansson MP et al (2019) Acetyl group migration across the saccharide units in oligomannoside model compound. J Am Chem Soc 141:1646–1654. https://doi.org/10.1021/jacs.8b11563

Liitiä T, Maunu SL, Hortling B (2000) Solid state NMR studies on cellulose crystallinity in fines and bulk fibres separated from refined kraft pulp. Holzforschung 54:618–624. https://doi.org/10.1515/HF.2000.104

Magina S, Mendes ISF, Prates A, Evtuguin DV (2022) Changes in sulfite liquor composition while re-profiling mill from paper-grade to dissolving pulp production. J Wood Chem Technol 42:193–203. https://doi.org/10.1080/02773813.2022.2068603

Mendes ISF, Caldeira T, Prates A, Evtuguin DV (2022a) Study of the anions profile throughout the sulphite pulp line. J Wood Chem Technol 42:244–252. https://doi.org/10.1080/02773813.2022.2077966

Mendes ISF, de Paula V, Prates A, Evtuguin DV (2022b) Lignin removal from eucalyptus wood during the magnesium-based acid sulphite pulping. 16th European Workshop on Lignocellulosics and Pulp. Gothenburg, Sweden, pp 72–75

Mendes ISF, Prates A, Evtuguin DV (2021) Production of rayon fibres from cellulosic pulps: state of the art and current developments. Carbohydr Polym 273(5):118466. https://doi.org/10.1016/j.carbpol.2021.118466

Nechita P, Mirela R, Ciolacu F (2021) Xylan hemicellulose: a renewable material with potential properties for food packaging applications. Sustainability 13:13504. https://doi.org/10.3390/su132413504

Ngene GI, Roux J-C, Lachenal D (2022) Xylan extraction strategies and the performance of the resulting high purity cellulose fiber to swelling and dissolution. Carbohydr Polym Technol Appl 3:100196. https://doi.org/10.1016/j.carpta.2022.100196

Pereira SR, Portugal-Nunes DJ, Evtuguin DV et al (2013) Advances in ethanol production from hardwood spent sulphite liquors. Process Biochem 48:272–282. https://doi.org/10.1016/j.procbio.2012.12.004

Petzold-Welcke K, Schwikal K, Daus S, Heinze T (2014) Xylan derivatives and their application potential—mini-review of own results. Carbohydr Polym 100:80–88. https://doi.org/10.1016/j.carbpol.2012.11.052

Pinto PC, Evtuguin DV, Pascoal Neto C (2005a) Structure of hardwood glucuronoxylans: modifications and impact on pulp retention during wood kraft pulping. Carbohydr Polym 60:489–497. https://doi.org/10.1016/j.carbpol.2005.03.001

Pinto PC, Evtuguin DV, Pascoal Neto C (2005b) Effect of structural features of wood biopolymers on hardwood pulping and bleaching performance. Ind Eng Chem Res 44:9777–9784. https://doi.org/10.1021/ie050760o

Prozil SO, Costa EV, Evtuguin DV, Cruz Lopes LP, Domingues MRM (2012) Structural characterization of polysaccharides isolated from grape stalks of Vitis vinifera L. Carbohydr Res 356:252–259. https://doi.org/10.1016/j.carres.2012.02.001

Rebola SM, Azevedo CA, Evtuguin DV (2021) Effect of cooking and bleaching conditions on the properties of eucalyptus kraft fluff pulps. Cellulose 28:4411–4426. https://doi.org/10.1007/s10570-021-03789-8

Rebuzzi F, Evtuguin DV (2006) Effect of glucuronoxylan on the hornification of Eucalyptus globulus bleached pulps. Macromol Symp 232:121–128. https://doi.org/10.1002/masy.200551414

Reicher F, Corrêa JBC, Gorin PAJ (1984) Location of O-acetyl groups in the acidic D-xylan of Mimosa scabrella (bracatinga). A study of O-acetyl group migration. Carbohydr Res 135:129–140. https://doi.org/10.1016/0008-6215(84)85010-7

Reis A, Pinto P, Coimbra MA et al (2004) Structural differentiation of uronosyl substitution patterns in acidic heteroxylans by electrospray tandem mass spectrometry. J Am Soc Mass Spectrom 15:43–47. https://doi.org/10.1016/S1044-0305(03)00710-4

Scheller HV, Ulvskov P (2010) Hemicelluloses. Annu Rev Plant Biol 61:263–289. https://doi.org/10.1146/annurev-arplant-042809-112315

Selvendran RR, March JF, Ring SG (1979) Determination of aldoses and uronic acid content of vegetable fiber. Anal Biochem 96:282–292. https://doi.org/10.1016/0003-2697(79)90583-9

Shatalov AA, Evtuguin DV, Pascoal Neto C (1999) (2-O-α-D-Galactopyranosyl-4-O-methyl-α-D-glucurono)-D-xylan from Eucalyptus globulus Labill. Carbohydr Res 320:93–99. https://doi.org/10.1016/S0008-6215(99)00136-6

Sixta H (ed) (2006) Handbook of pulp, 1st edn. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Sjöström E (1993) Wood chemistry: fundamentals and applications, 2nd edn. Academic Press Inc, New York

Vaz Á, Coelho J, Costa V et al (2022) Eucalyptus globulus vessels enzymatic passivation: effect of pore structure on bulk and surface chemistry. Res Sq. https://doi.org/10.21203/rs.3.rs-2159866/v1

Watson E (1992) Mathematical modelling and experimental study of the kinetics of the acid sulphite pulping of eucalyptus wood. MSc. thesis, University of Natal, South Africa. http://hdl.handle.net/10413/7936

Wickholm K, Larsson PT, Iversen T (1998) Assignment of non-crystalline forms in cellulose I by CP/MAS 13C NMR spectroscopy. Carbohydr Res 312:123–129. https://doi.org/10.1016/S0008-6215(98)00236-5

Xavier AMRB, Correia MF, Pereira SR, Evtuguin DV (2010) Second generation bioethanol from eucalypt sulphite spent liquor. Bioresource Technol 101:2755–2761. https://doi.org/10.1016/j.biortech.2009.11.092

Yoshinaga A, Fujita M, Saiki H (1993) Compositions of lignin building units and neutral sugars in oak xylem tissue. Mokuzai Gakkaishi 39:621–627

Acknowledgments

This work was financially supported by Caima, S.A. within the scope of the PhD project of Inês S. F. Mendes and by CICECO-Aveiro Institute of Materials, UIDB/50011/2020, UIDP/50011/2020 & LA/P/0006/2020, financed by national funds through the FCT/MEC (PIDDAC).

Funding

Open access funding provided by FCT|FCCN (b-on). The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the presentation and design of the article. More specifically, ISFM: Methodology, Investigation, Writing—original draft. AP: Supervision, Writing—review & editing, Project administration. DVE: Conceptualisation, Methodology, Supervision, Writing—review & editing, Funding acquisition. All authors have read the final manuscript and provided feedback for intellectual and grammatical revisions.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the study reported in this manuscript.

Consent for publication

All authors agreed for publication. All of the material is owned by the authors and no additional permissions are required.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mendes, I.S.F., Prates, A. & Evtuguin, D.V. Transformations of glucuronoxylan during acid sulphite pulping of eucalyptus dissolving pulp. Cellulose 30, 10437–10452 (2023). https://doi.org/10.1007/s10570-023-05472-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05472-6