Abstract

The transition towards a sustainable cellulose industry needs more environmentally friendly technologies, including the use of lignocellulosic waste as alternative raw materials. This work shows the potential of dead biomass from the Andalusian Mediterranean coastline to obtain cellulosic pulp. With this purpose, predominant species in onshore residues (mainly Posidonia oceanica) were prepared, characterized, and subjected to a soda-anthraquinone pulping process. A central composite design was defined in order to relate the process conditions to the composition and characteristics of the cellulose pulp. It was concluded that polynomial models encompassing linear, quadratic, and binary effect parameters reproduce the experimental results satisfactorily. Results allowed to choose high anthraquinone dosage, alkali charge and temperature, low liquid/solid ratio and short time as a compromise solution, by which the brightness, ethanol–benzene extractives content, kappa number, lignin content and viscosity were near their optimal. Low values of liquid/solid ratio reduce water consumption, which is of utmost importance in cellulose industries likewise short time treatments to save energy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Despite the improvements in environmental performance of modern kraft pulp mills (Marson et al. 2023), soda pulping (without sulphur salts) is still generally preferred for non-wood materials (Bhardwaj et al. 2019). In 1977, Holton proposed the addition of a small amount of anthraquinone in the cooking liquor, which accelerated alkaline delignification, stabilized carbohydrates and increased cellulose pulp yield with respect to soda addition alone (Holton 1977). This is understood to be due to anthraquinone acting as a redox catalyst for the reactions that take place in the digester. Its reduced form, anthrahydroquinone, attacks the transient and reactive structures of lignin (Jahan et al. 2021). In addition, the soda-anthraquinone pulping process has the following advantages: a) it could be adapted to small industrial productions (Sharma et al. 2015); b) it has high throughput with a short cooking time (Saad et al. 1988); c) the cooking liquors can be recovered and reused (Zhang and Chen 2017).

The overuse of wood raw materials in the cellulose industry has increased the need to find new sources (Gabriel et al. 2020). Alternative raw materials that are commonly studied are non-woody and/or annual plants such as Hesperaloe funifera, with 76.50% of cellulose (Sánchez et al. 2010) or Chamaecytisus proliferus, with a 79.73% of cellulose (Jiménez et al. 2007). Other examples are agricultural residues including palm oil residues, with 66.00% of cellulose (Alriols et al. 2009), or sesame residues, with 66.40% of cellulose (Saeed et al. 2017). The use of agricultural residues also can solve the environmental problems associated with the accumulation of residual materials in woods and cropping fields (e.g. fires, the appearance of pests on the plant cover, etc.) (Vadrevu and Lasko 2018).

Although cellulose from marine species have similar structure and properties to those of terrestrial species (Percival 1979), there are few studies from marine plants or algae, and even less about the beach wrack as a cellulose source. Seaweed and seagrass constitute an irreplaceable element of the coastal environment because marine plants and algae are involved in the correct oxygenation of seawaters, and they act in the prevention of erosion (Himes-Cornell et al. 2018). However, important quantities of marine plants and algae fragments are rejected by the sea especially following storms or high tides in many coastal regions. These onshore residues are accumulated in the beaches resulting in several problems related to hygiene and public health when these beach wracks can provide adequate conditions for bacterial growth (de Araújo and Costa 2006; den Hartog 1994). Moreover, the smell of putrefaction and its consequences on the economy and local tourism makes it necessary to regularly remove and dispose of this residue (Pal et al. 2020; Trégarot et al. 2021). The coast of Andalusia houses marine phanerogams such as Cymodocea nodosa, Posidonia oceanica, which 61.80% of cellulose (Khiari et al. 2010), Zostera marina, which 57.00% of cellulose (Davies et al. 2007), Zostera noltii, and an extensive variety of green, red, and brown algae which originates the waste on the coasts.

In this work, the predominant species in Andalusian tidal waste (P. oceanica) was selected and characterized in terms of its contents in α-cellulose, ash, ethanol–benzene extractable compounds, holocellulose, lignin, hot water-soluble compounds and 1% NaOH soluble material. Moreover, we used an experimental factorial design to examine the influence of operational variables (dosage of anthraquinone, alkali charge, liquid/solid ratio, temperature, and time) on the cellulosic pulp’s content in ethanol–benzene extractables, holocellulose and lignin, and key properties like the dependant response (brightness, beating degree, kappa number, viscosity, and yield).

Materials and methods

Collection and identification

All collection processes involved in this work have been carried out according to the Spanish Catalogue of Threatened Species (Ministry of Environment, Rural and Marine 2011) and the state regulations of article 57 of the Law on Natural Heritage and Biodiversity (Head of State 2007). Onshore residues were collected on San Roque (Cádiz, Andalusia, Mediterranean Sea) in October 2021. Visual inspection showed the presence of phanerogams (many leaves and a small number of rhizomes) and traces of algae. After collection, the waste was rinsed with fresh water, dry at room temperature and the species of marine plants and algae were identified. The predominant species was selected, separated from the rest of the waste, and exhaustively washed with cold freshwater in order to remove sand and other impurities and dried at 40 °C for 3 days. Next, sampling and sample preparation followed the standard method TAPPI T257 cm-02 (TAPPI T257 2012).

Chemical characterization of the species

After sample conditioning, the species selected was characterized chemically according to TAPPI Standards shown next: α-cellulose content following the T203 (TAPPI T203 2009), ash content the T211 (TAPPI T211 2022), ethanol–benzene extractable content the T204 (TAPPI T204 2017), lignin content the T222 (TAPPI T222 2015), hot water-soluble compounds content the T207 (TAPPI T207 2008) and 1% NaOH soluble compounds content the T212 (TAPPI T212 2018). Holocellulose content was determined according to the method of Wise et al. (1946) (Hubbel and Ragauskas 2010).

Cellulose extraction

The lignocellulosic material collected and selected was cooked in a 15 L cylindrical batch reactor wrapped in a heating wire jacket. The reactor was connected via a rotary axis to the control unit, which included a motor actuating the reactor stirring (by turnover), and temperature and pressure measurement and control instruments. The species selected were placed in the reactor and amounts of soda, anthraquinone and water required were added in order to obtain the desired liquid/solid ratio. Then, the system was heated until reaching the cooking temperature, which was maintained for a specific time. After cooking, the reactor contents were filtered and the resulting solid was washed with water, fibres being separated from uncooked material by screening through a sieve of 1 mm mesh, to determine the cellulose pulp yield (by weight). The intervals of operation of the five operational variables used during soda-anthraquinone cooking were: anthraquinone dosage (0, 0.5 and 1% on the basis of oven-dried biomass weight), charge of caustic soda (10, 20 and 30%, also on the basis of oven-dried weight of waste), liquid/solid ratio (4, 7 and 10), temperature (100, 135 and 150 °C) and time (30, 60 and 90 min).

Characterization of cellulose pulps

In order to determine holocellulose and lignin content, the cellulose pulps were subjected to reflux in a Soxhlet extractor for 7–8 h to eliminate resins, waxes, sterols, fats, and fatty acids that might interfere in the measurements, and ethanol benzene extractables content was determined (TAPPI T204 2017). Holocellulose content was obtained from extractive-free biomass according to the method of Wise et al. (Hubbel and Ragauskas 2010) and lignin content with the TAPPI method T222 (TAPPI T222 2015). Brightness was determined according to T452 (TAPPI T452 2018), beating degree (using a Shopper-Riegler apparatus) according to UNE5267 (UNE 5267 2001); kappa number and viscosity according to T236 (TAPPI T236 2013) and T254 (TAPPI T254 2010), respectively. Yield was calculated gravimetrically, by weighting the solid fraction, measuring its moisture content, and comparing it to the initial biomass weight on a dry basis.

Experimental design

The proposed model used a series of experiments based around a central test plus several additional tests to estimate the terms of a second-order polynomial equation. This design meets the general requirement that every parameter in the mathematical model can be estimated in a small number of tests (Montgomery 2004). The total number of tests required for the five independent variables studied (anthraquinone dosage, alkali charge, liquid/solid ratio, temperature, and time) was 27. The independent variables were normalized to values from –1 to + 1 using Eq. (1) in order to facilitate direct comparison of the coefficients of the resulting polynomial equation and an understanding of the effects of the individual independent variables on the dependent variables of cellulosic pulp ones considered (brightness, beating degree, ethanol–benzene extractables content, holocellulose content, kappa number, lignin content, viscosity and yield).

where Xn was the normalized value of anthraquinone dosage, alkali charge, liquid/solid ratio, temperature, and time; X was the absolute experimental value of the variable concerned; Xme was the mean of the extreme values of X; and Xmax and Xmin were their maximum and minimum values, respectively. Experimental data were fitted to the second-order polynomial equation showed in Eq. (2):

where Y was the response or dependent variable [viz. brightness, beating degree, ethanol–benzene extractables content, holocellulose content, kappa number, lignin content, viscosity, and yield]; Xn was the normalized value of the independent variable concerned; and a0, bi, ci and dij were unknown characteristic constants estimated from the experimental data. Table 1 shows the absolute and normalized values obtained for the independent variables in the 27 tests required to construct the model.

Results and discussion

Identification and selection

More than half of the onshore waste collected corresponded to Posidonia oceanica. This agrees with the classification of marine phanerogams in Andalusia carried out by the project Life Blue Natura. It cites the majority meadows for Posidonia oceanica with 7097 ha (60.40%), followed by Cymodocea nodosa with 4179 ha (35.36%), by Zostera noltii with 474 ha (4.03%) and by Zostera marina with 0.09 ha (0.0008%) (Mendoza 2021). Marine phanerogams are composed by leaves, rhizomes, roots, flowers, and fruits. The parts of less weight and volume (roots, flowers, and fruits) with a part of the dead leaves are dragged by the waves to deeper areas while the parts of more weight and volume (leaves and rhizomes) are transported and accumulated on the coast generating residues (Moral et al. 2019). For species identification, a bibliographic search to know the differences between the species constituting these residues was carried out (Table 2).

The leaves found in the tidal waste were cintyform and measured between 20 and 100 cm in length and 4 to 10 mm in width. Those that remained on the rhizomes were of 70–90 cm in length, 8–10 mm in with and in bundles of 7–8. The loosest leaves were similar to those that remained on the rhizomes (70–100 cm in length, 8–10 mm in width). Narrower and shorter loose leaves (27–35 cm in length, 2–3 mm in with) were found in small quantities. At numerous apexes, the shape could not be distinguished due to fractures or being bitten by herbivores; this factor was mentioned by other authors in literature (Tomas et al. 2005). The apexes that could be classified were rounded.

The residues of phanerogam leaves were deposited on the coasts throughout the year due to natural detachment, storms, or other causes. However, there were periods of greater generation. The collection was done in October, autumn, when the phanerogams generate more waste. Plagiotropic and orthotropic rhizomes with a length between 5 and 13 cm and a thickness between 8 mm and 1 cm were also found.

P. oceanica was identified as the only phanerogam that exports a large quantity of rhizomes to this coast. Leaf bundles (7–8) and the size of the plants (leaves of 50–100 cm in length and 8–10 mm in with, rhizomes of 5–13 cm in length and 8 mm–1 cm in thickness) were within the intervals indicating high growth in accordance with the maximum growth in September and the collection in October. The narrower and shorter loose leaves (27–35 cm in length, 2–3 mm in width) corresponded to C. nodosa; both have rounded apex. Although the replacement of leaves is faster in C. nodosa than in P. oceanica, the remains of C. nodosa reach the coast in small quantities (Piñeiro-Juncal 2021). C. nodosa is common in places where there are meadows of P. oceanica where it is found in a discontinuous distribution (Olesen et al. 2002). Due to the small number of leaves of C. nodosa, a single predominant species, P. oceanica, was selected.

Chemical characterization of Posidonia oceanica

The results of chemical characterization, along with values from other authors and terrestrial raw materials (conventional, non-wood and agricultural residues), are shown in Table 3.

Reportedly, a proportion of cellulose above 34% is an indicator of suitability for paper and cellulose industries (Agu et al. 2014). Photosynthetic aquatic species such as phanerogams also contain other fibrous materials that are potentially beneficial for paper production (Kuo and den Hartog 2001). Comparing the results of P. oceanica with the chemical characterization from other authors, the values were similar to those found in literature except for lignin content, which was lower. This was probably due to the high number of leaves, accounting for less lignin content than rhizomes, and the variation of the plant depending on the geographic area (Kaal et al. 2016).

Comparing the results obtained for P. oceanica with values of wood raw materials, α-cellulose content (35.80%), ethanol–benzene extractable content (10.10%), holocellulose content (59.00%), lignin content (21.30%) and NaOH-soluble compounds (19.90%) were into the corresponding ranges: (24.52–55.40%), (1.50–15.90%), (46.30–64.30%), (21.80–39.29%) and (10.58–29.70%). However, ashes content for P. oceanica (9.90%) and hot water-soluble content (9.60%) were higher.

Regarding non-wood raw materials, results for P. oceanica were found within their ranges of α-cellulose content (31.40–45.37%), holocellulose content (57.00–79.73%), lignin content (2.46–28.30%), hot water-soluble compounds content (2.79–20.00%,) and NaOH-soluble compounds content (16.67–68.90%). Ash and ethanol–benzene extractable content were found in higher proportion.

The content of α-cellulose, ashes, holocellulose, lignin, hot water-soluble compounds and NaOH-soluble compounds in P. oceanica waste was found to lie within the general ranges of agricultural residues, except for the content in ethanol–benzene extractables, which was higher.

The higher proportion of ashes in P. oceanica could be due to the abundant presence of minerals in marine phanerogams. Likewise, the contribution of the remaining sand and carbonated deposits, despite being largely washed away after waste collection, should not be neglected. The higher content in ethanol–benzene extractives was probably due to the presence of lipids, organic salts and polyphenols. Finally, the water-soluble fraction can be mostly attributed to starch.

Characterization of cellulose pulps

All tests were conducted in triplicate, the average results obtained for the dependent variables are shown in Table 4. The time needed to reach the working temperature (4–8 min) was excluded.

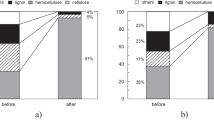

As shown, the brightness and the beating degree indicated cellulose pulp with promising potential. The content in ethanol–benzene extractables found in P.oceanica residue (10.10%) decreased by half with the soda-anthraquinone process, probably due to the alkaline hydrolysis of organic salts and esters. The holocellulose content, as expected, increased after the process by eliminating the rest of the components. The lignin content changed from 21.30% in the residue to 3.47–4.54%’ in the pulp, improving hardness, bleachability and colour. Soda-anthraquinone process was quite efficiently delignified judging by the kappa number of the pulp; this, together with its good viscosity (in the order of 1000 mL/g), facilitates bleaching without degradation of cellulose fibres. Yield was acceptable for cellulosic pulps.

The BMDP software package (Dixon 1988) was used to conduct a multiple linear regression analysis involving all terms in Eq. (2); those with Snedecor´s F-values smaller than unity were eliminated using the stepwise method (Draper and Smith 1998). The equations thus obtained for the different dependent variables, their multiple-r, r2 and fitted-r2 values, the highest p-values and the smallest Student´s t values for the terms in such equations (at a confidence level of 95%) were as follows (statistics showed in brackets):

(multiple-R = 0.99; R2 = 0.97; fitted-R2 = 0.96; p < 0.001; t > 2.12)

(multiple-R = 0.99; R2 = 0.97; fitted-R2 = 0.97; p < 0.001; t > 2.79)

(multiple-R = 0.95; R2 = 0.91; fitted-R2 = 0.89; p < 0.001; t > 2.86)

(multiple-R = 0.98; R2 = 0.96; fitted-R2 = 0.95; p < 0.001; t > 2.07)

(multiple-R = 0.99; R2 = 0.98; fitted-R2 = 0.97; p < 0.001; t > 2.10)

(multiple-R = 0.99; R2 = 0.99; fitted-R2 = 0.99; p < 0.001; t > 2.16)

(multiple-R = 0.97; R2 = 0.95; fitted-R2 = 0.93; p < 0.001; t > 2.00)

(multiple-R = 0.99; R2 = 0.99; fitted-R2 = 0.99; p < 0.001; t > 2.30).

where XA, XS, XR, XT and Xt are the normalized values of anthraquinone dosage, alkali charge, liquid/solid ratio, temperature, and time, respectively.

The values estimated using the previous equations reproduced the experimental values with standard errors of 1.06, 1.57, 0.21, 2.16, 0.59, 0.03, 29.96, and 0.22 for brightness, beating degree, ethanol–benzene extractables content, holocellulose content, kappa number, lignin content, viscosity, and yield, respectively. The experimental results fitted to the polynomial models satisfactorily, as reflected by the statistical parameters.

Response surface plots for six of the dependent variables are displayed in Fig. 1. The other two, beating degree and viscosity, were omitted due to being fitted to simpler models, i.e., multiple linear regression. In any case, there were no local minima or maxima around the central point, which means that, for each of the responses and under the range of conditions tested, their individual optimization lies in the star points (or, in this case, axial points) of the central composite design.

Identifying the independent variables most (or least) strongly influencing the dependent variables with the previous equations was not as simple as with linear equations, owing to the presence of quadratic terms and interactions between two independent variables. In order to identify the values of the independent variables that would provide the best values for the dependent variables, non-linear programming as implemented by More and Toraldo (1989) was used. Table 5 shows the optimum values of the dependent variables and the values of the independent ones required to obtain them.

From the data in Table 5 it was confirmed that to obtain optimal brightness, kappa number and lignin content values, the application of the operation variables at their highest levels were required. The optimal beating degree was obtained by operating at minima of anthraquinone dosage, alkali charge, liquid/solid ratio; and maxima of temperature and time. The optimal values for content in ethanol–benzene extractables and holocellulose were obtained under minimum conditions of anthraquinone dosage, liquid/solid ratio and maximum conditions of alkali charge, temperature, and time. To obtain the optimal viscosity, it was necessary to operate with minimum conditions, except for the anthraquinone dosage, which was maximum. The increased viscosity resulting from the use of higher values for the operational variables of the pulping process, because of the severity of the treatment, increases the number of short chains. However, prolonged heating damages fibres through the combined effects of a high alkali charge and temperature, decreasing viscosity (Seng 2001). Finally, maximizing the yield entails using a low value of operating conditions.

To achieve the optimal values, the following maximum values of independent variables were used: anthraquinone dosage in six dependent variables (BR, BD, KN, KLS, VI and YI), alkali charge in six (BR, BD, EB, HOL, KN and KLS), liquid/solid ratio in four (BR, BD, KN and KLS), and temperature and time in five dependent variables (BR, EB, HOL, KN and KLS). The minimum values were present through these conditions: anthraquinone dosage in two dependent variables (EB and HOL), alkali charge in two (VI and YI), liquid/solid ratio in four (EB, HOL, VI and YI) and temperature and time in three dependent variables (BD, VI and YI).

To save energy, water, and immobilized capital in industry it was necessary to reach a compromise about the conditions for the optimization of the product and the reduction of the resources required.

The independent variables which had a greater number of minimum values in the dependent variables to achieve the optimum ones were chosen (liquid/solid ratio, temperature, and time). The compromise sets of conditions to be evaluated were:

-

1.

Low values for liquid/solid ratio and temperature (4, 100 °C) and high values for anthraquinone dosage (1%), alkali charge (30%) and time (60 min),

-

2.

Low values for temperature and time (100 °C, 30 min) and high values for anthraquinone dosage (1%), alkali charge (30%) and liquid/solid ratio (10)

-

3.

Low values for time and liquid/solid ratio (30 min, 4) and high values for anthraquinone dosage (1%), alkali charge (30%) and temperature (150 °C).

By simulating the alternatives indicated and applying Eqs. (3) to (10), the resulting values of the dependent variables were found (Table 6).

From the results of Table 6, to obtain bleachable cellulosic pulp of P. oceanica the compromise set C had to be used: high anthraquinone dosage, alkali charge and temperature (1%, 30% and 150 °C, respectively), besides low liquid/solid ratio (4) and time (30 min). With these conditions, the values of BR, EB, KN, KLS and VI were near their optimal. Low values of liquid/solid ratio reduce water consumption, which is of utmost importance in cellulose industries, and the decreasing time allows energy savings.

The operating conditions of set C were compared with those of soda-anthaquinone cellulose pulps from terrestrial raw materials found in bibliography (Table 7) and its corresponding characterization values (Table 8).

As it was shown in Table 7, the proportion of anthraquinone added to cook P. oceanica (1%) was in the range typically used in woody raw materials (0.1–1.5%) and in non-wood raw materials (0.1–1%); however, it was higher than the dosage values commonly chosen in agricultural residues. Alkali charge in set C (30%) was in the range of choice in woody raw materials (21–60%), and higher than the rest of NaOH dosages chosen. Liquid/solid ratio to cook P.oceanica was in the low range, along with the value of C. proliferus. The values of temperature and reaction time used for P. oceanica pulping were overall on the low side.

Comparing the results of cellulose pulp of P.oceanica with the characterizations of soda-anthraquinone pulps of lignocellulosic terrestrial materials, as can be observed in Table 8, results showed than the brightness (55.14%) was higher than the one obtained in cellulosic pulps of E. globulus (22.40%) and in cellulosic pulps of non-wood plants (23.10–31.10%). However, the results also showed that this brightness was lower than the observed in pulps of agricultural residues (66.30–77.64%). The beating degree (41.70 °SR) was similar in value to the obtained cellulosic pulp of P.halepensis (42.00 °SR). These results are in the ranges of cellulosic pulps of non-wood plants (19.00–61.50 °SR) and those of agricultural residues (38.00–55.50 °SR).

The content of ethanol–benzene extractables in the cellulosic pulp of P. oceanica was higher than that obtained from pulps of terrestrial non-woods plants. Also, the results of holocellulose obtained from cellulosic pulp of P. oceanica (65.26%) were higher than the shown in pulp of P. halepensis (43.80%); though, lower than values from pulps of non-wood materials (85.10–93.90%). Kappa number (4.17) in cellulosic pulp of P. oceanica was the lowest between of the studied raw material, lignin content (3.49%) was lower than values on pulp of P. halepensis (4.61%) and was in the range of pulps of non-wood materials (2.00–9.60%). Only pulps of P. halepensis had higher viscosity than those of P. oceanica, probably because the alkali charge in the cooking process was higher.

Comparing cellulose pulp of P.oceanica to all pulps of terrestrial raw materials, brightness, beating degree, holocellulose content, lignin content, viscosity and yield were in the respectives ranges (22.40–77.64%, 19.00–61.50 °SR, 43.80–93.90%, 2.00–9.60%, 635–1470 mL/g and 33.15–69.10%). Also, cellulose pulp from P. oceanica had the highest content in ethanol–benzene extractables and the lowest kappa number.

Economic and legal considerations

The feasibility of cellulose production from tidal waste along the Andalusian Mediterranean coastline (or Alboran Sea) is limited by both operational and transportation costs, and also by ecological issues. First of all, biomass harvesting should not be done indiscriminately, but when deemed beneficial to the ecosystems by independent assessors. The excuse of “removing waste” or “cleaning the beach” to attract tourism does not justify arbitrary and invasive recollection that may have a negative impact on biodiversity, and neither does the potential profit from the production of cellulosic pulp. Dry biomass to be valorized should be harvested when arranged and/or authorized by the public administration that is competent in each case, in a framework of transparent coordination between private and public agents.

In economic terms, a challenge to be overcome is the fact that pulp production is increasingly more centralized. The distance by road between San Roque and Almeria is 327 km, but all the provinces along this coastline account for only one pulp mill. The annual production of tidal waste by the 11.5·107 m2 of phanerogams found in this region (Mendoza 2021) could be roughly estimated as 10 kt/yr (Pal and Hogland 2022), far from meeting the typical production rates of modern pulp mills. Moreover, growth is not constant along the year (Moral et al. 2023). This is why this biomass would rather serve as an additional feedstock to an existing pulp mill, instead of justifying the construction of a new one.

The maximum load authorized for 4-axle road trains in Spain is 36 t (BOE 1998). Nonetheless, unless the harvested waste is washed and/or dried in situ, the actual content of lignocellulosic biomass on a dry basis will be roughly 12 t. Hence, approximately 850 one-way trips with an average distance of 160 km each would be necessary. Considering round trips, the total distance amounts to 272,000 km. The Spanish Ministry of Transport, Mobility and Urban Agenda estimates transportation costs by road train as 1.096 €/km, taking into account current fuel prices, salaries, insurance, maintenance, and other expenses (OTLE 2022).

The free-on-board price of NaOH in the European market was roughly 800 €/t by the end of 2022 (Procurement Resource 2023). Increasing it by 10% due to shipment costs and assuming that the NaOH recovery rate in the pulp mill, typically done with CaO, is 90%, the estimated cost of caustic soda to meet the conditions that have been optimized in this work is as high as 264,000 €/yr. Costs associated with the energy input to reach the desired temperature could be neglected on the basis that, as it is usual, the use of solubilized lignin, pectin and other hydrolyzates from pulping as fuel is expected to meet the heat duty of the boiler. Under these assumptions, the main costs are displayed in the inset graph of Fig. 2, which also highlights (in green) the portion of the Andalusian coastline considered.

Conclusions

Using a central composite factorial design in order to identify the optimum operating conditions (anthraquinone dosage, alkali charge, liquid/solid ratio, temperature and time) for P.oceanica soda-anthraquinone pulping provided equations which related the brightness, beating degree, ethanol–benzene extractives, holocellulose content, kappa number, lignin content, viscosity and yield with the operational variables. These models predicted the responses with errors lower than 2.50% for all except viscosity.

Pulp amenable to bleaching (i.e., with a low kappa number) was obtained using more drastic conditions of anthraquinone dosage, alkali charge and temperature, besides low liquid/solid ratio and time, reducing water consumption and decreasing time to save energy. In these conditions, the values of brightness, ethanol–benzene extractives, kappa number, lignin content and viscosity were near their optimal.

Comparing the values used in compromise set C (anthraquinone dosage: 1%, alkali charge: 30%, liquid/solid ratio: 4, temperature: 150°C, and time: 30 min) with the operating conditions reported for other lignocellulosic materials, cooking processes of P. oceanica required, in general term, similar dosages of anthraquinone and soda, but lower temperature, time, and liquid/solid ratio. When it comes to comparing the results of the pulp characterization with the responses for terrestrial raw materials, all P. oceanica values were within their ranges, except for the content of ethanol–benzene extractables, which was the higher, and the kappa number, which was the lower. Overall, it can be concluded that the valorization of onshore waste from P. oceanica towards cellulosic materials has promising potential, a potential that should be addressed more by future research in terms of specific cellulose-based products.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Agu CV, Njoku OU, Chilaka FC, Agbiogwu D, Iloabuchi KV, Ukazu B (2014) Physicochemical properties of lignocellulosic biofibres from South Eastern Nigeria: their suitability for biocomposite technology. Afr J Biotechnol 13:2050–2057. https://doi.org/10.5897/AJB2013.13443

Ahmed T, Djalal D, Thomas M (2019) Microcrystalline cellulose from Posidonia oceanica brown algae: extraction and characterization. Int J Biol Macr 138:837–845. https://doi.org/10.1016/j.ijbiomac.2019.07.176

Alriols MG, Tejado A, Blanco M, Mondragon I, Labidi J (2009) Agricultural palm oil tree residues as raw material for cellulose, lignin and hemicelluloses production by ethylene glycol pulping process. Chem Eng J 148:106–114. https://doi.org/10.1016/j.cej.2008.08.008

Ankel M, Rubal M, Veiga P, Sampaio L, Guerrero-Meseguer L (2021) Reproductive cycle of the seagrass Zostera noltei in the Ria de Aveiro Lagoon. Plants 10:2286. https://doi.org/10.3390/plants10112286

Ashori A, Hamzeh Y, Amani F (2011) Lemon balm (Melissa officinalis) stalk: chemical composition and fiber morphology. J Polym Environ 19:297–300. https://doi.org/10.1007/s10924-010-0279-8

Barbera C, Tuya F, Boyra A, Sanchez-Jerez P, Blanch I, Haroun RJ (2005) Spatial variation in the structural parameters of Cymodocea nodosa seagrass meadows in the Canary Islands: a multiscaled approach. Bot Mar 48:122–126. https://doi.org/10.1515/BOT.2005.021

Bettaieb F, Khiari R, Hass ML, Belgacem N, Bras J, Dufresne A, Mhenni MF (2015) Preparation and characterization of new cellulose nanocrystals from marine biomass Posidonia oceanica. Ind Crop Prod 72:175–182. https://doi.org/10.1016/j.indcrop.2014.12.038

Bhardwaj NK, Kaur D, Chaudhry S, Sharma M, Arya S (2019) Approaches for converting sugarcane trash, a promising agro residue, into pulp and paper using soda pulping and elemental chlorine-free bleaching. J Clean Prod 217:225–233. https://doi.org/10.1016/j.jclepro.2019.01.223

BOE (1998) Royal Decree 2822/1998, 23rd of December, which approves the General Regulation of Vehicles. https://www.boe.es/eli/es/rd/1998/12/23/2822 Accessed on 09 Jun 2023

Boutahar L, Espinosa F, Richir J, Lepoint G, Gobert S, Maanan M, Bazairi H (2020) Deep-water Zostera marina meadows in the Mediterranean. Aquatic Bot 166:103269. https://doi.org/10.1016/j.aquabot.2020.103269

Brun FG, Perez-Pastor A, Hernandez I, Vergara JJ, Perez-Llorens JL (2006) Shoot organization in the seagrass Zostera noltii: implications for space occupation and plant architecture. Helgol Mar Res 60:59–69. https://doi.org/10.1007/s10152-005-0017-0

Caye G, Meinesz A (1985) Observations on the vegetative development, flowering and seeding of Cymodocea nodosa (Ucria) Ascherson on the Mediterranean coasts of France. Aquatic Bot 22:277–289. https://doi.org/10.1016/0304-3770(85)90005-1

Da-Ros Z, Corinaldesi C, Dell’Anno A, Gambi C, Torsani F, Danovaro R (2021) Restoration of Cymodocea nodosa seagrass meadows: Efficiency and ecological implications. Restor Ecol 29:e13313. https://doi.org/10.1111/rec.13313

Davies P, Morvan C, Sire O, Baley C (2007) Structure and properties of fibres from seagrass (Zostera marina). J Mater Sci 42:4850–4857. https://doi.org/10.1007/s10853-006-0546-1

De Araújo MCB, Costa MF (2006) Municipal services on tourist beaches: costs and benefits of solid waste collection. J Coast Res 22:1070–1075. https://doi.org/10.2112/03-0069.1

Den Hartog C (1994) Suffocation of a littoral Zostera bed by Enteromorpha radiata. Aquat Bot 47:21–28. https://doi.org/10.1016/0304-3770(94)90045-0

UNE-EN ISO 5267–1 (2001) Determinación del desgote. Parte 1: Método Schopper-Riegler

Dixon WJ (1988) BMDP statistical software manual: to accompany the 1988 software release. University of California Press, New York, Berkeley

Dönmez IE, Hafizoğlu H, Kilic A, Tümen I, Sivrikaya H (2012) Chemical composition of fourteen different coniferous species cones growing naturally in Turkey. Wood Res 57:339–344. http://hdl.handle.net/11772/5210

Draper N, Smith H (1998) Applied regression analysis. John Wiley and Sons, New York

Feria MJ, García JC, Díaz MJ, Garrote G, López F (2012) Optimization the soda-AQ process for cellulose pulp production and energy content of black liquor from L. leucocephala K360. Bioresour Technol 120:173–179. https://doi.org/10.1016/j.biortech.2012.06.034

Gabriel T, Belete A, Syrowatka FS, Neubertc RHH, Gebre-Mariam T (2020) Extraction and characterization of celluloses from varius plant byproducts. Int J Biol Macromol 158:1248–1258. https://doi.org/10.1016/j.ijbiomac.2020.04.264

García-Redondo V, Bárbara I, Díaz-Tapia P (2019) Zostera marina meadows in the northwestern Spain: distribution, characteristics and anthropogenic pressures. Biodivers Conserv 28:1743–1757. https://doi.org/10.1007/s10531-019-01753-4

Gominho J, Lourenço A, Miranda I, Pereira H (2012) Chemical and fuel properties of stumps biomass from Eucalyptus globulus plantations. Ind Crops Prod 39:12–16. https://doi.org/10.1016/j.indcrop.2012.01.026

Haddad A, Lachenal D, Marechal A, Janin G, Labiod M (2009) Delignification of aleppo pine wood (Pinus Halepensis Mill) by soda-anthraquinone process: pulp and paper characteristics. Cellul Chem Technol 43:287–294

Head of State (2007) Law 42/2007 of 13 December on Natural Heritage and Biodiversity. BOE 299, 14 December 2007 Ref: BOE-A-2007–21490. https://www.boe.es/eli/es/l/2007/12/13/42/con

Himes-Cornell A, Pendleton L, Atiyah P (2018) Valuing ecosystem services from blue forests: a systematic review of the valuation of salt marshes, sea grass beds and mangrove forests. Ecosyst Serv 30:36–48. https://doi.org/10.1016/j.ecoser.2018.01.006

Holton H (1977) Soda additive softwood pulping. A major new process. Pulp Pap Can 78:218–223. https://jglobal.jst.go.jp/en/detail?JGLOBAL_ID=201002024483489578

Hubbel CA, Ragauskas AJ (2010) Effect of acid-chlorite delignification on cellulose degree of polymerization. Bioresour Technol 101:7410–7415. https://doi.org/10.1016/j.biortech.2010.04.029

Jahan MS, Rahman MM, Ni Y (2021) Alternative initiatives for non-wood chemical pulping and integration with the biorefinery concept: a review. Biofuel Bioprod Biorefin 15:100–118. https://doi.org/10.1002/bbb.2143

Jiménez L, Pérez A, de la Torre MJ, Moral A, Serrano L (2007) Characterization of vine shoots, cotton stalks, Leucaena leucocephala and Chamaecytisus proliferus, and on their ethylenglicol pulps. Bioresour Technol 98:3487–3490. https://doi.org/10.1016/j.biortech.2006.11.009

Kaal J, Serrano O, Nierop KG, Schellekens J, Cortizas AM, Mateo MÁ (2016) Molecular composition of plant parts and sediment organic matter in a Mediterranean seagrass (Posidonia oceanica) mat. Aquat Bot 133:50–61. https://doi.org/10.1016/j.aquabot.2016.05.009

Khiari R, Mhenni MF, Belgacem MN, Mauret E (2010) Chemical composition and pulping of date palm rachis and Posidonia oceanica–A comparison with other wood and non-wood fibre sources. Bioresour Technol 101:775–780. https://doi.org/10.1016/j.biortech.2009.08.079

Khristova P, Gabir S, Bentcheva S, Dafalla S (1998) Soda-anthraquinone pulping of sunflower stalks. Ind Crops Prod 9:9–17. https://doi.org/10.1016/S0926-6690(98)00008-9

Kuo J, den Hartog C (2001) Seagrass taxonomy and identification key. Global Seag Res Methods 33:31–58. https://doi.org/10.1016/B978-044450891-1/50003-7

López F, Alfaro A, García MM, Díaz MJ, Calero AM, Ariza J (2004) Pulp and paper from tagasaste (Chamaecytisus proliferus LF ssp. palmensis). Chem Eng Res Des 82:1029–1036. https://doi.org/10.1205/0263876041580730

López F, Pérez A, Zamudio MA, De Alva HE, García JC (2012) Paulownia as raw material for solid biofuel and cellulose pulp. Biomass Bioenergy 45:77–86. https://doi.org/10.1016/j.biombioe.2012.05.010

López F, García MT, Mena V, Loaiza JM, Zamudio MA, García JC (2015) Can acceptable pulp be obtained from Eucalyptus globulus wood chips after hemicellulose extraction. BioResources 10:55–67

Marson A, Samec JSM, Manzardo A (2023) Consequential life cycle assessment of kraft lignin recovery with chemical recycling. Sci Total Environ 882:163660. https://doi.org/10.1016/j.scitotenv.2023.163660

Mendoza R (2021) Life Blue Natura Andalucía: protección y conservación de los ecosistemas marinos a través de la cuantificación del carbono azul. Chron Nat 8:9–12. http://hombreyterritorio.org/chronica_naturae/num8/9_12_2021.html

Montgomery DC (2004) Diseño y análisis de experimentos. Limusa, Mexico.

Moral A, Hernández MD, Tijero A, Gonzalez Z, García J, Torre MJ (2012) NIRS determination of carbohydrates from hydrothermal-treated rice straw. TAPPI J 11:27–32

Moral A, Greyer V, Aguado R, Tijero A (2023) Material revalorization of beach wrack comprising seaweed and marine phanerogams: optimization of hydrothermal treatments. Biomass Bioenergy 174:106856. https://doi.org/10.1016/j.biombioe.2023.106856

Moral A, Aguado R, Roldán R, Tijero A, Ballesteros M (2019) Soda-anthraquinone pulping and cationization of Posidonia oceanica. Bioresources 14:9228–9243. https://bioresources.cnr.ncsu.edu/resources/soda-anthraquinone-pulping-and-cationization-of-posidonia-oceanica/

More JJ, Toraldo G (1989) Algorithms for bound constrained quadratic programming problems. Numer Math 55:377–400. https://doi.org/10.1007/BF01396045

Naseeruddin S, Yadav KS, Sateesh L, Manikyam A, Desai S, Rao LV (2013) Selection of the best chemical pretreatment for lignocellulosic substrate Prosopis juliflora. Bioresour Technol 136:542–549. https://doi.org/10.1016/j.biortech.2013.03.053

Neiva D, Fernandes L, Araújoa S, Lourenço A, Gominhoa J, Simões R, Pereira H (2015) Chemical composition and kraft pulping potential of 12 eucalypt species. Ind Crops Prod 66:89–95. https://doi.org/10.1016/j.indcrop.2014.12.016

Nienhuis PH (1980) Production and growth dynamics of eelgrass (Zostera marina) in brackish Lake Grevelingen (The Netherlands). Neth J Sea Res 14:102–118. https://doi.org/10.1016/0077-7579(80)90016-2

Olesen B, Enríquez S, Duarte CM, Sand-Jensen K (2002) Depth-acclimation of photosynthesis, morphology and demography of Posidonia oceanica and Cymodocea nodosa in the Spanish Mediterranean Sea. Mar Ecol Prog Se 236:89–97. https://doi.org/10.3354/MEPS236089

OTLE (2022) Coste del transporte de mercancías por carretera por tipo de vehículo. https://apps.fomento.gob.es/bdotle/visorBDpop.aspx?i=614 Accessed on 09 Jun 2023

Pal D, Hogland W (2022) An overview and assessment of the existing technological options for management and resource recovery from beach wrack and dredged sediments: an environmental and economic perspective. J Environ Manag 302:113971. https://doi.org/10.1016/j.jenvman.2021.113971

Pal M, Yesankar PJ, Dwivedi A, Qureshi A (2020) Biotic control of harmful algal blooms (HABs): a brief review. J Environ Manage 268:110687. https://doi.org/10.1016/j.jenvman.2020.110687

Percival E (1979) The polysaccharides of green, red and brown seaweeds: Their basic structure, biosynthesis and function. Br Phycol J 14:103–117. https://doi.org/10.1080/00071617900650121

Piñeiro-Juncal N, Díaz-Almela E, Leiva-Dueñas C, Deulofeu O, Frigola J, Soler M, Martínez-Cortizas A, Giralt S, García-Orellana J, Mateo MÁ (2021) Processes driving seagrass soils composition along the western Mediterranean: the case of the southeast Iberian Peninsula. Sci Total Environ 768:144352. https://doi.org/10.1016/j.scitotenv.2020.144352

Procurement Resource (2023) Caustic soda price trend and forecast. https://www.procurementresource.com/resource-center/caustic-soda-price-trends Accessed on 09 jun 2023

Ministry of Environment, Rural and Marine (2011) RD 139/2011 of 4 February for the development of the List of Wild Species in Regime of Special Protection and of the Spanish Catalogue of Threatened Species. BOE 46, 24 February 2011. Ref.: BOE-A-2011–3582. https://www.boe.es/eli/es/rd/2011/02/04/139/con

Saad SM, Nada AMA, Ibrahim AA, Tawfik H (1988) Soda anthraquinone pulping of bagasse. Holzforschung 42:67–69. https://doi.org/10.1515/hfsg.1988.42.1.67

Saeed HAM, Liu Y, Lucia LA, Chen H (2017) Suitable approach using agricultural residues for pulp and paper manufacturing. Nord Pulp Paper 32:674–682. https://doi.org/10.3183/npprj-2017-32-04_p674-682_saeed

Saeed HAM, Liu Y, Chen H (2018) Exploring Sudanese agricultural residues as alternative fibres for pulp and paper manufacturing. Mat Sci Eng 368:012030. https://doi.org/10.1088/1757-899X/368/1/012030

Sánchez R, Rodríguez A, Navarro E, Conesa JA, Jiménez L (2010) Use of Hesperaloe funifera for the production of paper and extraction of lignin for synthesis and fuel gases. Biomass Bioenergy 34:1471–1480. https://doi.org/10.1016/j.biombioe.2010.04.019

Seng ZAR (2001) Soda-AQ pulping of reed canary grass. Ind Crops Prod 14:31–39. https://doi.org/10.1016/S0926-6690(00)00086-8

Sharma AK, Anupam K, Swaroop V, Lal PS, Bist V (2015) Pilot scale soda-anthraquinone pulping of palm oil empty fruit bunches and elemental chlorine free bleaching of resulting pulp. J Clean Prod 106:422–429. https://doi.org/10.1016/j.jclepro.2014.03.095

TAPPI T204 cm-17 (2017) Solvent extractives of Wood and pulp. T Press

Tanner CE, Parham T (2010) Growing Zostera marina (eelgrass) from seeds in land-based culture systems for use in restoration projects. Restor Ecol 18:527–537. https://doi.org/10.1111/j.1526-100X.2010.00693.x

TAPPI T203 cm-09 (2009) Alpha-, beta- and gamma-cellulose in pulp. T Press

TAPPI T207 cm-08 (2008) Water solubility of Wood and pulp. T Press

TAPPI T211 om-16 (2022) Ash in Pulp, paper and paperboard: Combustion at 525 °C. T Press

TAPPI T222 om-15 (2015) Acid-insoluble lignin in Wood and pulp. T Press

TAPPI T254 cm-01 (2010) Cupriethylenediamine disperse viscosity of pulp (falling ball method). T Press

TAPPI T257 cm-02 (2012) Sampling and preparing wood for analysis. T Press

TAPPI/ANSI T 212 om-18 (2018) One percent sodium hydroxide solubility of wood and pulp. T Press

TAPPI/ANSI T236 OM-13 (2013) Kappa number of pulp. T Press

TAPPI/ANSI T452 om-18 (2018) Brightness of pulp, paper, and paperboard (directional reflectance at 457 nm). T Press

Tomas F, Turon X, Romero J (2005) Seasonal and small-scale spatial variability of herbivory pressure on the temperate seagrass Posidonia oceanica. Mar Ecol Prog Ser 301:95–107. https://doi.org/10.3354/MEPS301095

Trégarot E, Catry T, Pottier A, El-Hacen EHM, Sidi-Cheikh MA, Cornet CC, Marechal JP, Failler P (2021) Coastal protection assessment: a tradeoff between ecological, social, and economic issues. Ecosphere 12:e03364. https://doi.org/10.1002/ecs2.3364

Vadrevu K, Lasko K (2018) Intercomparison of MODIS AQUA and VIIRS I-Band fires and emissions in an agricultural landscape: implications for air pollution research. Remote Sens 10:978. https://doi.org/10.3390/rs10070978

Vermaat JE, Hootsmans MJM, Nienhuis PH (1987) Seasonal dynamics and leaf growth of Zostera noltii Hornem., a perennial intertidal seagrass. Aquat Bot 28:287–299. https://doi.org/10.1016/0304-3770(87)90006-4

Wise LE, Murphy M, D´Adieco A (1946) Analysis of cellulose. Paper Trade J 122:35–43

Zhang L, Chen K (2017) Pyrolysis behavior of the black liquor derived from soda–anthraquinone and soda–oxygen pulping of rice straw at different reaction end points. Energy Fuels 31:514–522. https://doi.org/10.1021/acs.energyfuels.6b01735

Acknowledgments

Funding for open access publishing: Universidad Pablo de Olavide/CBUA. This publication has been co-financed by the European Regional Development Fund (FEDER) and by the Ministry of Economy, Knowledge, Business and University, of the Junta de Andalucía, within the framework of the FEDER Andalusia operational program 2014–2020. The specific objective 1.2.3 is "Promotion and generation of frontier knowledge and knowledge oriented to the challenges of society, development of emerging technologies within the framework of the reference research project UPO-1381251. FEDER co-financing rate 80%.

Funding

Funding for open access publishing: Universidad Pablo de Olavide/CBUA. This publication has been co-financed by the European Regional Development Fund (FEDER) and by the Ministry of Economy, Knowledge, Business and University, of the Junta de Andalucía, within the framework of the FEDER Andalusia operational program 2014–2020. Specific objective 1.2.3 “Promotion and generation of frontier knowledge and knowledge oriented to the challenges of society, development of emerging technologies”, within the framework of the reference research project UPO-1381251. FEDER co-financing rate 80%.

Author information

Authors and Affiliations

Contributions

All authors made substantial contributions to the conception of the work, the acquisition and interpretation of data, and writing. All authors approve the manuscript. All authors agree to be accountable for all aspects of the work in ensuring that questions related to the accuracy or integrity of any part of the work are appropriately investigated and resolved.

Corresponding author

Ethics declarations

Conflict of interest

Authors declare that they have no known competing interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Moral, A., Greyer, V., Aguado, R.J. et al. Resource recovery and reduction of tidal waste to produce cellulose through sulphur-free pulping. Cellulose 30, 9757–9773 (2023). https://doi.org/10.1007/s10570-023-05449-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05449-5