Abstract

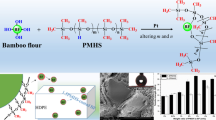

Bamboo flour/high-density polyethylene (BF/HDPE) composite was strengthened and toughened simultaneously by the surface encapsulation of BF with poly(methylhydrogen)siloxane (PMHS) and Ethylene Propylene Diene Monomer (EPDM). A elastic PMHS@EPDM shell was fabricated on BF surface by successively spraying PMHS/hexane and EPDM/hexane solutions onto BF, based on the dehydrogenation and addition reaction of PMHS with BF and EPDM. It was found that surface encapsulation of wood at high PMHS content would simultaneously increase the strength and toughness of BF@PMHS/HDPE composite. The tensile strength and impact strength were increased by 54.2% and 9.9%, respectively as PMHS content was 3.3%. Furthermore, an encapsulation of BF@PMHS with EPDM further increased the strength and toughness by 5.1% and 14.7%. Compared with the pristine BF/plastic composites (BPC), the tensile, flexural and impact strength of modified BPC increased by 62.1%, 28.0% and 26.1%. The changes in the microstructure of the interface between BF and HDPE as a function of encapsulation of PMHS and EPDM and the relationship between chemical structure, microstructure and mechanical properties were discussed in detail. This work gave a novel MAH-free method for strengthening and toughening BF/HDPE or wood flour/high-density polyethylene (WF/HDPE) composites.

Similar content being viewed by others

References

Alekseeva OV, Noskov AV, Titov VA, Nikitin D, Agafonov AV (2021) Adsorption performance of the polystyrene/montmorillonite composites: effect of plasma treatment. Chem Eng Process 167:108505

Ao YH, Tang K, Xu N, Yang HD, Zhang HX (2007) Compatibilization of PP/SEBS-MAH blends by grafting Glycidyl Methacrylate onto Polypropylene. Polym Bull 59(2):279–288

Aouat H, Hammiche D, Boukerrou A, Djidjelli H, Pillin I (2020) Effects of interface modification on composites based on olive husk flour. Mater Today: Proc 36:94–100

Ashok N, Prakash K, Selvakumar D, Balachandran M (2020) Synergistic enhancement of mechanical, viscoelastic, transport, thermal, and radiation aging characteristics through chemically bonded interface in nanosilica reinforced EPDM-CIIR blends. J Appl Polym Sci 138(12):50082

Bai T, Wang D, Yan J, Cheng W, Han G (2021) Wetting mechanism and interfacial bonding performance of bamboo fiber reinforced epoxy resin composites. Compos Sci Technol 213:108951

Bland HA, Thomas ELH, Klemencic GM, Mandal S, Morgan DJ, Papageorgiou A, Jones TG, Williams OA (2019) Superconducting diamond on silicon nitride for device applications. Sci Rep 9:2911

Cai GF, Wang JK, Nie YN, Tian XC, Zhu XD (2011) Effects of toughening agents on the behaviors of bamboo plastic composites. Polym Compos 32(12):1945–1952

Chen Y, Dang B, Jin C, Chen B, Sun Q, Nie Y (2018) Bio-inspired layered nanolignocellulose/graphene-oxide composite with high mechanical strength due to borate cross-linking. Ind Crops Prod 118:65–72

Chow WS, Ishak Z, Karger-Kocsis J, Apostolov AA, Ishiaku US (2003) Compatibilizing effect of maleated polypropylene on the mechanical properties and morphology of injection molded polyamide 6/polypropylene/organoclay nanocomposites. Polymer 44:7427–7440

Dun M, Fu H, Hao J, Shan W, Wang W (2021) Tailoring flexible interphases in bamboo fiber-reinforced linear low-density polyethylene composites. Compos Part a: Appl Sci Manuf 150:106606

Faruk O, Bledzki AK, Fink HP, Sain M (2012) Biocomposites reinforced with natural fibers: 2000–2010. Prog Polym Sci 37(11):1552–1596

Garcia-Garcia D, Carbonell-Verdu A, Jordá-Vilaplana A, Balart R, Garcia-Sanoguera D (2016) Development and characterization of green composites from bio-based polyethylene and peanut shell. J Appl Polym Sci. https://doi.org/10.1002/app.43940

Guo CG, Wang QW (2007) Compatibilizing effect of maleic anhydride grafted styrene-ethylene-butylene-styrene (MAH-g-SEBS) on the polypropylene and wood fiber composites. J Reinf Plast Comp 26(17):1743–1752

Guo Y, Wang L, Wang H, Chen Y, Zhu S, Chen T, Luo P (2020) Properties of bamboo flour/high-density polyethylene composites reinforced with ultrahigh molecular weight polyethylene. J Appl Polym Sci 137(33):48971

Hsieh C-T, Pan Y-J, Lou C-W, Huang C-L, Lin ZI, Liao J-M, Lin J-H (2016) Polylactic acid/carbon fiber composites: Effects of functionalized elastomers on mechanical properties, thermal behavior, surface compatibility, and electrical characteristics. Fiber Polym 17(4):615–623

Hung KC, Chen YL, Wu JH (2012) Natural weathering properties of acetylated bamboo plastic composites. Polym Degrad Stab 97(9):1680–1685

Jiang X, Yong Z, Zhang Y (2004) Study of dynamically cured PP/MAH-g-EPDM/epoxy blends. Polym Test 23(3):259–266

Lei Z, Lv S, Sun C, Wan L, Tan H, Zhang Y (2017) Effect of MAH-g-PLA on the properties of wood fiber/polylactic acid composites. Polymers 9(11):591

Lin W, Huang Y, Li J, Liu Z, Yang W, Li R, Chen H, Zhang X (2018) Preparation of highly hydrophobic and anti-fouling wood using poly(methylhydrogen)siloxane. Cellulose 25(12):7341–7353

Lin W, Zhang X, Cai Q, Yang W, Chen H (2020) Dehydrogenation-driven assembly of transparent and durable superhydrophobic ORMOSIL coatings on cellulose-based substrates. Cellulose 27(1):7805–7821

Liu H, Wu Q, Han G, Yao F, Kojima Y, Suzuki S (2008) Compatibilizing and toughening bamboo flour-filled HDPE composites: mechanical properties and morphologies. Compos Part A- Appl S 39(12):1891–1900

Liu W, Xie T, Qiu R (2016) Bamboo fibers grafted with a soybean-oil-based monomer for its unsaturated polyester composites. Cellulose 23(4):2501–2513

Liu P, Zhong YC, Pei QX, Sorkin V, Zhang YW (2022) Simultaneously enhancing the strength and toughness of short fiber reinforced thermoplastic composites by fiber cross-linking. Compos Sci Technol 217:109076

Mei H, Zhang S, Chen H, Zhou H, Zhai X, Cheng L (2016) Interfacial modification and enhancement of toughening mechanisms in epoxy composites with CNTs grafted on carbon fibers. Compos Sci Technol 134:89–95

Ndazi BS, Karlsson S, Tesha JV, Nyahumwa CW (2007) Chemical and physical modifications of rice husks for use as composite panels. Compos Part A 38(3):925–935

Ning Z, Yingying C, Tuo W, Kun J, Jiang H-Y (2019) Preparation and physical/chemical modification of galactomannan film for food packaging. Int J Biol Macromol 137:1060–1067

Oksma K, Lindberg H (1998) Influence of thermoplastic elastomers on adhesion in polyethylene–wood flour composites. J Appl Polym SCi 68(11):1845–1855

Qian S, Sheng K, Kai L, Lopez FCA (2018) Improved properties of PLA biocomposites toughened with bamboo cellulose nanowhiskers through silane modification. J Mater Sci 53(15):10920–10932

Reddy KO, Maheswari CU, Shukla M, Song JI, Rajulu AV (2013) Tensile and structural characterization of alkali treated Borassus fruit fine fibers. Compos B Eng 44:433–438

Ritchie RO (2011) The conflicts between strength and toughness. Nat Mater 10(11):817–822

Seo YR, Bae SU, Gwon J, Wu Q, Kim BJ (2020) Effects of Methylenediphenyl 4,4’-diisocyanate and maleic anhydride as coupling agents on the properties of polylactic acid/polybutylene succinate/wood flour biocomposites by reactive extrusion. Materials 13(7):1660

Sombatsompop N, Yotinwattanakumtorn C, Thongpin C (2005) Influence of type and concentration of maleic anhydride grafted polypropylene and impact modifiers on mechanical properties of PP/wood sawdust composites. J Appl Polym Sci 97(2):475–484

Stefani D, Júnior MAD, Francisquetti EL, Reis FDSD, Borsoi C, Hansen B, Catto AL (2021) Influence of coupling agent on post-consumption polypropylene composites reinforced with malt bagasse fibers. J Compos Mater 55(29):4333–4346

Sun J, Li H, Han L, Song Q (2019) Enhancing both strength and toughness of carbon/carbon composites by heat-treated interface modification. J Mater Sci Technol 35(3):157–167

Wang H, Sheng KC, Lan T, Adl M, Qian XQ, Zhu SM (2010) Role of surface treatment on water absorption of poly(vinyl chloride) composites reinforced by Phyllostachys pubescens particles. Compos Sci Technol 70(5):847–853

Wu J, Yu D, Chan CM, Kim J, Mai YW (2000) Effect of fiber pretreatment condition on the interfacial strength and mechanical properties of wood fiber/PP composites. J Appl Polym Sci 76(7):1000–1010

Xiao F, Gao J, Huang X, Hu Q, Li R, Zhang X (2021) Effect of poly(methylhydrogen)siloxane modification on adjusting mechanical properties of bamboo flour-reinforced HDPE composites. Cellulose 28(9):5463–5475

Ma X, Ji T, Ma X, Zhao X, Wang W, Guo H, Shen s, Fan C, Yang M, Hou X. (2021) Effects of difunctional reactive polyhedral oligomeric silsesquioxane on the properties of EPDM. J Appl Polym Sci 139(2):51486

Yang B, Liang C-W, Lu F-X, Chen P, Chen Q-T, Chen J, Hu L, Xia R, Miao J-B, Qian J-S, Min K, Cao M (2019) Effect of Bamboo flour (BF) content on the dynamic rheological characteristics of bf-filled high-density polyethylene (HDPE). J Macromol Sci B 58(2):341–354

Yu S, Oh KH, Hong SH (2019) Enhancement of the mechanical properties of basalt fiber-reinforced polyamide 6,6 composites by improving interfacial bonding strength through plasma-polymerization. Compos Sci Technol 182:107756.1-107756.12

Zhang W, Yao X, Khanal S, Xu S (2018) A novel surface treatment for bamboo flour and its effect on the dimensional stability and mechanical properties of high density polyethylene/bamboo flour composites. Constr Build Mater 186:1220–1227

Zhang X, Xiao F, Feng Q, Zheng J, Chen C, Chen H, Yang W (2020) Preparation of SiO2 nanoparticles with adjustable size for fabrication of SiO2/PMHS ORMOSIL superhydrophobic surface on cellulose-based substrates. Prog Org Coat 138:105384

Funding

The authors gratefully acknowledge the support from the Leading Project of Fujian Province of China (2019H0008), and Innovation Fund project of Fujian Agriculture and Forestry University (KFA19113A).

Author information

Authors and Affiliations

Contributions

TW wrote the main manuscript text and prepared figures; XZ revised the main manuscript text and gave experimental guidance; KO revised the main manuscript text; SO and FX did experiments. And all authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest regarding the publication on this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wen, T., Zhang, X., Ou, S. et al. Core–shell encapsulation of PMHS@EPDM onto BF surface for strengthening and toughening of BF/HDPE composites. Cellulose 30, 5749–5759 (2023). https://doi.org/10.1007/s10570-023-05255-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05255-z