Abstract

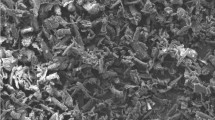

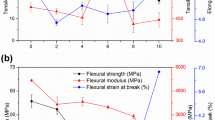

Poly(lactic acid) (PLA) is a potential green alternative for conventional petroleum-based plastics. However, the brittleness limits its application (e.g., agricultural films, garbage bags, plastic bags, food containers, food packaging). In this study, silane-compatibilized (triethoxyvinylsilane, A-151) bamboo cellulose nanowhiskers (BCNW) were introduced into a PLA matrix to toughen the composites. The A-151 successfully grafted on the surface of cellulose, and the thermal degradation stability of BCNW decreased after A-151 modification. Morphological, tensile and thermal properties of the toughened PLA bionanocomposites were investigated, and the toughen mechanism was clarified. The silane linked BCNW and PLA via Si–O–C bonds and hydrogen bonds. Elongation at break of the composites remarkably increased from 12.3 ± 1.7% (untreated) to 213.8 ± 21.6% (16 wt% A-151 treated). Both tensile strength and modulus decreased with the silane treatment. Typical toughness fracture characteristic (wire-drawing) was observed on the fractural surface. Glass transition temperature and crystallinity decreased from 45.6 °C/30.33% (untreated) to 33.6 °C/13.23% (16 wt% A-151 treated).

Similar content being viewed by others

References

JalaliA Huneault MA, Elkoun S (2016) Effect of thermal history on nucleation and crystallization of poly(lactic acid). J Mater Sci 51:7768–7779. https://doi.org/10.1007/s10853-016-0059-5

Lizundia E, Fortunati E, Dominici F et al (2016) PLLA-grafted cellulose nanocrystals: role of the CNC content and grafting on the PLA bionanocomposite film properties. Carbohydr Polym 142:105–113. https://doi.org/10.1016/j.carbpol.2016.01.041

Frone AN, Panaitescu DM, Chiulan I et al (2016) The effect of cellulose nanofibers on the crystallinity and nanostructure of poly(lactic acid) composites. J Mater Sci 51:9771–9791. https://doi.org/10.1007/s10853-016-0212-1

Xu C, Lv Q, Wu D et al (2017) Polylactide/cellulose nanocrystal composites: a comparative study on cold and melt crystallization. Cellulose 24:2163–2175. https://doi.org/10.1007/s10570-017-1233-x

Zhang Y, Wu J, Wang B et al (2017) Cellulose nanofibril-reinforced biodegradable polymer composites obtained via a Pickering emulsion approach. Cellulose 24:3313–3322. https://doi.org/10.1007/s10570-017-1324-8

Li S, Huang J (2016) Cellulose-rich nanofiber-based functional nanoarchitectures. Adv Mater 28:1143–1158. https://doi.org/10.1002/adma.201501878

Xiao W, Zaeem MA, Li GD et al (2017) Tough and strong porous bioactive glass-PLA composites for structural bone repair. J Mater Sci 52:9039–9054. https://doi.org/10.1007/s10853-017-0777-3

Lu Y, Cueva MC, Lara-Curzio E et al (2015) Improved mechanical properties of polylactide nanocomposites-reinforced with cellulose nanofibrils through interfacial engineering via amine-functionalization. Carbohydr Polym 131:208–217. https://doi.org/10.1016/j.carbpol.2015.05.047

Sung SH, Chang Y, Han J (2017) Development of polylactic acid nanocomposite films reinforced with cellulose nanocrystals derived from coffee silverskin. Carbohydr Polym 169:495–503. https://doi.org/10.1016/j.carbpol.2017.04.037

Miao C, Hamad WY (2016) In-situ polymerized cellulose nanocrystals (CNC) poly(L-lactide) (PLLA) nanomaterials and applications in nanocomposite processing. Carbohydr Polym 153:549–558. https://doi.org/10.1016/j.carbpol.2016.08.012

Xiong R, Hu K, Grant AM et al (2016) Ultrarobust transparent cellulose nanocrystal-graphene membranes with high electrical conductivity. Adv Mater 28:1501–1509. https://doi.org/10.1002/adma.201504438

Saini S, Belgacem MN, Salon M-CB et al (2016) Non leaching biomimetic antimicrobial surfaces via surface functionalisation of cellulose nanofibers with aminosilane. Cellulose 23:795–810. https://doi.org/10.1007/s10570-015-0854-1

Prahsarn C, Klinsukhon W, Padee S et al (2016) Hollow segmented-pie PLA/PBS and PLA/PP bicomponent fibers: an investigation on fiber properties and splittability. J Mater Sci 51:10910–10916. https://doi.org/10.1007/s10853-016-0302-0

Hossain KMZ, Hasan MS, Boyd D et al (2014) Effect of cellulose nanowhiskers on surface morphology, mechanical properties, and cell adhesion of melt-drawn polylactic acid fibers. Biomacromol 15:1498–1506. https://doi.org/10.1021/bm5001444

Qian S, Zhang H, Sheng K (2016) Cellulose nanowhiskers from moso bamboo residues: extraction and characterization. BioResources 12:419–433. https://doi.org/10.15376/biores.12.1.419-433

Lu T, Liu S, Jiang M et al (2014) Effects of modifications of bamboo cellulose fibers on the improved mechanical properties of cellulose reinforced poly(lactic acid) composites. Compos Part B Eng 62:191–197. https://doi.org/10.1016/j.compositesb.2014.02.030

Raquez J-M, Murena Y, Goffin A-L et al (2012) Surface-modification of cellulose nanowhiskers and their use as nanoreinforcers into polylactide: a sustainably-integrated approach. Compos Sci Technol 72:544–549. https://doi.org/10.1016/j.compscitech.2011.11.017

Fortunati E, Luzi F, Puglia D et al (2015) Processing of PLA nanocomposites with cellulose nanocrystals extracted from Posidonia oceanica waste: innovative reuse of coastal plant. Ind Crop Prod 67:439–447. https://doi.org/10.1016/j.indcrop.2015.01.075

Rojo E, Alonso M, Saz-Orozco D et al (2015) Optimization of the silane treatment of cellulosic fibers from eucalyptus wood using response surface methodology. J Appl Polym Sci 132:42157. https://doi.org/10.1002/app.42157

Dasan YK, Bhat AH, Faiz A (2017) Polymer blend of PLA/PHBV based bionanocomposites reinforced with nanocrystalline cellulose for potential application as packaging material. Carbohydr Polym 157:1323–1332. https://doi.org/10.1016/j.carbpol.2016.11.012

Wrona M, Cran MJ, Nerin C et al (2017) Development and characterisation of HPMC films containing PLA nanoparticles loaded with green tea extract for food packaging applications. Carbohydr Polym 156:108–117. https://doi.org/10.1016/j.carbpol.2016.08.094

Li Y, Huang H, Wang Z et al (2014) Tuning radial lamellar packing and orientation into diverse ring-banded spherulites: effects of structural feature and crystallization condition. Macromolecules 47:1783–1792. https://doi.org/10.1021/ma402579d

Qian SP, Zhang HH, Yao WC et al (2018) Effects of bamboo cellulose nanowhisker content on the morphology, crystallization, mechanical, and thermal properties of PLA matrix biocomposites. Compos Part B Eng 133:203–209. https://doi.org/10.1016/j.compositesb.2017.09.040

Qian S, Mao H, Sheng K et al (2013) Effect of low-concentration alkali solution pretreatment on the properties of bamboo particles reinforced poly(lactic acid) composites. J Appl Polym Sci 130:1667–1674. https://doi.org/10.1002/app.39328

Fujisawa S, Saito T, Kimura S et al (2014) Comparison of mechanical reinforcement effects of surface-modified cellulose nanofibrils and carbon nanotubes in PLLA composites. Compos Sci Technol 90:96–101. https://doi.org/10.1016/j.compscitech.2013.10.021

Gwon J-G, Cho H-J, Chun S-J et al (2016) Physiochemical, optical and mechanical properties of poly(lactic acid) nanocomposites filled with toluene diisocyanate grafted cellulose nanocrystals. RSC Adv 6:9438–9445. https://doi.org/10.1039/c5ra26337a

Saha P, Chowdhury S, Roy D et al (2016) A brief review on the chemical modifications of lignocellulosic fibers for durable engineering composites. Polym Bull 73:587–620. https://doi.org/10.1007/s00289-015-1489-y

Qu P, Zhou Y, Zhang X et al (2012) Surface modification of cellulose nanofibrils for poly(lactic acid) composite application. J Appl Polym Sci 125:3084–3091. https://doi.org/10.1002/app.36360

Qian S, Sheng K (2017) PLA toughened by bamboo cellulose nanowhiskers: role of silane compatibilization on the PLA bionanocomposite properties. Compos Sci Technol 148:59–69. https://doi.org/10.1016/j.compscitech.2017.05.020

Graupner N, Labonte D, Muessig J (2017) Rhubarb petioles inspire biodegradable cellulose fibre-reinforced PLA composites with increased impact strength. Compos Part A Appl Sci Manuf 98:218–226. https://doi.org/10.1016/j.compositesa.2017.03.021

Geng S, Haque MM-U, Oksman K (2016) Crosslinked poly(vinyl acetate)(PVAc) reinforced with cellulose nanocrystals (CNC): structure and mechanical properties. Compos Sci Technol 126:35–42. https://doi.org/10.1016/j.compscitech.2016.02.013

Safdari F, Carreau PJ, Heuzey MC et al (2017) Effects of poly(ethylene glycol) on the morphology and properties of biocomposites based on polylactide and cellulose nanofibers. Cellulose 24:2877–2893. https://doi.org/10.1007/s10570-017-1327-5

Qian S, Mao H, Zarei E et al (2015) Preparation and characterization of maleic anhydride compatibilized poly(lactic acid)/bamboo particles biocomposites. J Polym Environ 23:341–347. https://doi.org/10.1007/s10924-015-0715-x

Myoung SH, Im SS, Kim SH (2016) Non-isothermal crystallization behavior of PLA/acetylated cellulose nanocrystal/silica nanocomposites. Polym Int 65:115–124. https://doi.org/10.1002/pi.5038

Acknowledgements

This work was financially supported by the Natural Science Foundation of Zhejiang Province (No. LY16E030003), the Research Funds of NBU (No. ZX2016000752), the Foundation of Ningbo University (No. XYL17025) and the K.C. Wong Magna Fund in Ningbo University.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Rights and permissions

About this article

Cite this article

Qian, S., Sheng, K., Yu, K. et al. Improved properties of PLA biocomposites toughened with bamboo cellulose nanowhiskers through silane modification. J Mater Sci 53, 10920–10932 (2018). https://doi.org/10.1007/s10853-018-2377-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2377-2