Abstract

Along with the emergence of micro and nanofibrillated celluloses and their application in papermaking, the influence of the so called fines fraction of pulps on both process and product properties has received increasing research interest in recent years. Several researchers have experimented with primary and/or secondary pulp fines to assess their effects on paper properties with not always consistent results. Our work focuses on the targeted application of the primary fines fraction of an unbleached softwood kraft pulp. The primary fines are separated from the pulp to be subsequently added to achieve blends of \(5\%, 9\%\) and \(12\%\) primary fines content. These blends were then refined in a PFI mill to evaluate the effect of the primary fines on refining as well as on paper properties of hand sheets prepared from these pulps. It is shown that the addition of primary fines enhances tensile strength in the unrefined and slightly refined state, while the maximum tensile strength of the highly refined reference pulp is not increased. A slightly increased dewatering resistance (Schopper Riegler) at comparable air permeability (Gurley) for a given tensile strength was also observed. The linear relationship between tensile index and apparent sheet density seems to be affected in the unrefined and slightly refined state where the breaking length of the fines enriched samples is higher for a given apparent density.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

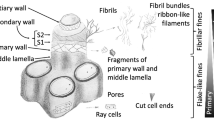

In the evaluation of fibre morphological properties of any given pulp it is standard to differentiate between the coarse and the fines fraction. The fines fraction is commonly either defined as material passing a \(76\,\upmu {\mathrm {m}}\) screen (200 mesh) in a Britt Dynamic Drainage Jar Device (according to SCAN-CM 66:05), or particles smaller than \(200\,\upmu {\mathrm {m}}\) in case of determination by automated optical analysis (according to ISO 16065-2) (Mayr et al. 2017b). Depending on their origin, pulp fines have different morphological character and are usually divided in primary and secondary fines (Odabas et al. 2016). Primary fines are produced during the pulping process and mainly consist of blocky or flake like material, which is mostly ray cells, parenchyma cells, pores and fragmental parts from the middle lamella (Odabas et al. 2016). Secondary fines are generated during refining in the stock preparation process and have a strong fibrillar character, as they mainly consist of fibrils torn from the fibre wall structure during pulp refining (Retulainen et al. 1993). Besides this highly fibrillar material, fibre fragments resembling primary fines are also produced during refining due to fibre cutting and shortening. A certain proportion of fibrillar material, however, is also present in primary fines. Hence the distinction between primary and secondary fines is to some extent more a definition of origin of the pulp fines than of morphological properties, although it will always reflect the morphology to large part as well.

In order to improve the strength properties of paper it is necessary to increase the relative bonded area and/or specific bonding strength (Dasgupta 1994; Motamedian et al. 2019). This increase can be achieved by sheet densification, which is positively influenced by addition of fine cellulosic materials such as micro or nanofibrillated celluloses or pulp fines, therefore leading to an increase in tensile properties (Bäckström et al. 2008; Taipale et al. 2010). In contrast to such micro or nanofibrillated celluloses (Sandquist 2013), which need substantial amounts of energy in production, fines may be directly accessible from process streams like filtrates, or could be separated from the pulp using suitable aggregates (Hinck and Wallendahl 1999). Due to their different morphological character, primary and secondary fines have a different effect on sheet properties. As the mainly fibrillar material of the secondary fines shows higher surface area and stronger swelling, it has a stronger effect on bonded area and therefore a stronger influence on strength properties of paper compared to the more blocky primary fines (Ferreira et al. 2000; Fischer et al. 2017; Mayr et al. 2017a, b; Motamedian et al. 2019; Odabas et al. 2016). Still, also fine cellulosic materials defined as secondary fines can differ in their fibrillar material content, respectively their fibrillar area (Mayr et al. 2017a). These differences are on the one hand caused by the pulp type being refined and on the other hand by different refining conditions in terms of specific edge load and varying refining intensities (Mayr et al. 2017b).

While for secondary fines their effect on strength properties has extensively been reported by several researchers, this is not the case for primary fines, where only a few studies are available focusing on the effects of their removal or addition on paper technological properties (Bäckström et al. 2008; Chauhan et al. 2012; Ferreira et al. 1999, 2000; Mayr et al. 2017b; Motamedian et al. 2019). Due to the differences in experimental designs, these studies did not always show consistent results. Chauhan et al. (2012), for example, show that the addition of up to 10 and 20% w/w of primary fines, separated from bleached hardwood kraft pulp by means of a Bauer McNett classifier, prior to refining leads to reduced strength properties of papers produced from these pulp blends after PFI refining compared to the reference without the addition of primary fines. Ferreira et al. (1999), on the other hand, show that removal of primary fines from unbleached hardwood kraft pulp, leads to a decrease in tensile and burst index, but an increase in tear index. In this case, primary fines were removed by a Bauer McNett classifier equipped with a 200 Mesh screen. Results by Bäckström et al. (2008) in an experimental design, where primary fines were added to the pulp, again show that the addition of either primary or secondary fines to refined fibres allows an improvement of tensile index, burst index and TEA. Fines were separated with a Celleco laboratory filter equipped with a \(100\,\upmu {\mathrm {m}}\) mesh size cloth. The fine fraction was further separated by a \(20\,\upmu {\mathrm {m}}\) cloth and the passing fraction discarded to exclude colloidal fines material from the investigation. The fines content was determined acording to TAPPI Standard T261.

Our work focuses on the effect of different addition rates of primary fines of a softwood kraft pulp to the same pulp and on the effect of this addition rate on pulp and paper properties. The rates of addition are chosen in a range that corresponds to amounts of fines that may also be produced by refining in industrial stock preparation. The blends of pulp and primary fines are evaluated in the unrefined as well as in the refined refined state. Thereby the evolvement of e.g. tensile properties due to addition of fines and/or refining is accessible and allows the assessment of possible savings in refining energy through the addition of in our case primary fines.

Experimental

Materials

An industrial, never dried, unbleached softwood kraft pulp containing 85% spruce, 10% pine and 5% larch with Kappa number 27 was used in all trials. The primary fines content of the pulp was 5% determined according to SCAN-CM 66:05. A part of the primary fines fraction of this pulp was separated using a laboratory scale pressure screen implemented at the Institute for Bioproducts and Paper Technology at Graz University of Technology.

Methods

In order to separate the primary fines fraction, a laboratory scale pressure screen (Fig. 1) equipped with a \(100~\upmu {\mathrm {m}}\) hole screen (Fig. 2) was used. The reference pulp was fed to the pressure screen at a volume flow \(\dot{\mathrm {V}}_{\mathrm {F}}\) of 10 l/min at a consistency of 0.5% (w/w). The accept passing the screen with a volume flow \(\dot{\mathrm {V}}_{\mathrm {A}}\) of 4 l/min and a consistency of approximately 0.015% (w/w), was collected in vessels for sedimentation. With this process 12.5 g dry of primary fines per 1 kg dry pulp was separated. The supernatant was decanted after adequate time for sedimentation to reach a dry content of 0.5% for subsequent application. The coarse fraction was discarded.

Pulp/primary fines blends

Samples with a total fines content of 9 and 12% w/w were obtained by adding the necessary amount of previously separated primary fines to the reference pulp having a primary fines content of 5% w/w. Samples containing 30g dry matter (pulp + primary fines) were diluted to a consistency of 1,5% w/w for disintegration according to ISO 5263-1. For subsequent PFI refining the samples were thickened to a consistency of 10% w/w by filtration. To avoid loss of fines during filtration, the filtrate from thickening was added to the filter cake several times. After thickening the reference pulp and the pulp/primary fines blends were refined in a PFI mill for 1000, 4500 and 6000 revolutions (ISO 5264-2).

Pulp properties

Fibre morphology was determined using a L&W fibre Tester+. This optical flow microscopy analyzer has an optical resolution of \(3.3\,\upmu {\mathrm {m}}/{pixel}\). Samples containing 0.1 g dry matter were analyzed and measurements were repeated three times. For each repetition a minimum of 100.000 particles was detected. Results are discussed based on length weighted fibre length distributions according to ISO 16065-2. The total fines content was determined using the Britt Dynamic Drainage Jar (BDDJ) according to SCAN-CM 66:05 using a 200mesh screen. The degree of beating of the samples was determined according to ISO 5267-1 (Schopper Riegler method). The separated primary fines were characterized using a light microscopy, based imaging method developed by Mayr et al. (2017a). In this method 5g of fines suspension at 0,01% consistency is prepared with deionized water. This sample is mixed with 0,06g of an emulsion working as a fixing agent for subsequent staining with methylene blue. This emulsion is prepared by mixing 5g of deionized water with 0.01g crude tall oil. The mixture is emulsified at \(80^{\circ } {\mathrm {C}}\) in an ultrasonic bath for 30 minutes. After the addition of methylene blue to the sample for enhanced contrast of the fines in imaging, microscopy sample holders were prepared with three droplets of the stained fines suspension and dried on a heating plate. Three sample holders per blend were prepared and 200 pictures were taken for each sample. Figure 3 shows an exemplary image depicting fibrils and flakes. Automated image analysis was applied based on MATLAB® to obtain values for average equivalent circle diameter of either fibrils and flakes as well as the fibril area (in %) (Mayr et al. 2017a).

In addition to the microscopy based characterisation described above we used an Alicona Infinite Focus Measurement device allowing imaging using so called shape from focus. Thereby imaging is possible at 50 fold magnification (corresponds to \(0.625\,\upmu {\mathrm {m}}/{pixel}\)) without the usual problems with depth of focus arising when you look at three dimensional particles at high resolution. Imaging was done based on the same samples described above. These imaging method (Fig. 4) gives a much more detailed qualitative impression of the fines and their morphological characteristics.

Hand sheets forming

Hand sheets of \(80~g/{\mathrm {m}}^{2}\) using the unrefined and refined reference pulp and the unrefined and refined pulp / primary fines blends were prepared according to ISO 5269-3 on a Rapid Köthen hand sheet former using white water recirculation to avoid losses of primary fines due to retention issues (Giner et al. 2015).The first four hand sheets were discarded to reach an equilibrium of fines in the recirculated white water and to achieve a 100% retention of the primary fines (Giner et al. 2015).

Hand sheets properties

Hand sheet testing was performed after conditioning the samples for at least 24 hours in the climate room at \(23^\circ {\mathrm {C}}\) and 50% relative humidity. Apparent sheet density was determined according to ISO 534, tensile properties according to ISO 1924-2 and Gurley air permeability according to TAPPI 460 om-16.

Results and discussion

Pulp properties of reference pulp and pulp/primary fines blends

Figure 5 shows the cumulative length weighted fibre length distribution of the separated primary fines with the L&W fibre \(\hbox {Tester}^{+}\), showing that 94% of the material is smaller than \(200\,\upmu {\mathrm {m}}\) with the remaining 6% of the separated material being below a maximum length of \(400\,\upmu {\mathrm {m}}\).

This cumulative fibre length distribution clearly shows that the separated material consists almost exclusively of fines and contains hardly fibres at all. Still, the evaluation of fines in such a flow cell is prone to misinterpretation of the material due to two reasons. On the one hand the fines already are—at least in one dimension—close to the minimum resolution of such a measurement device. On the other hand, especially fibrilar material is highly swollen and tends to show too low contrast to be accessible for such a device. Therefore the method based on microscopy and subsequent image analysis (Mayr et al. 2017b) is necessary, to assess the morphological properties of the fines material. This method (Fig. 6) shows, that besides the expected flake like material also a significant amount of fibrillar material is present in the separated primary fines. This is also confirmed by the the high value for fibril area (Fig. 7), showing that 60% of the projected area is fibrillar content. In comparison the fibril area of bleached softwood secondary fines is in a range of up to 75% when measured with the given method (Mayr et al. 2017b). The average equivalent circle diameter (ECD) of fibrils and flakes are of compareable size. As there is a considerable amount of fibrillar material also present in primary fines (see also Fig. 4), the positive effect of primary fines on strength properties should not be underestimated.

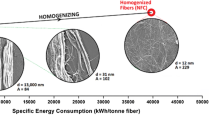

The cumulative length weighted fibre length distribution of the reference pulp and the pulp/primary fines blends in the unrefined and the refined state obtained with the L&W fibre \(\hbox {Tester}^{+}\) are depicted in Fig. 8. While the influence of primary fines addition is highly significant, a comparably low influence of refining on the fibre length distribution is visible. This shows that only a low amount of secondary fines was generated and that hardly any shortening of long fibres occurred during PFI refining, indicating that the PFI mill treatment leads mainly to fibre flexibilisation due to internal fibrillation, which has also been reported elsewhere (Gharehkhani et al. 2015; Kerekes 2005; Wang et al. 2007).

One of the pulp property related parameters that is expected to be affected due to fines addition is dewaterability. Still, in the unrefined state the effect on dewatering (based on degree of beating SR) is barely noticeable (Fig. 9). For low refining intensity of 1000 PFI revolutions an increase in dewatering resistance is noticeable especially at 12% addition rate of primary fines. This effect becomes even more pronounced at higher refining intensities of 4500 and 6000 revolutions in the PFI mill. For the 12% primary fines/pulp blend refined at 6000 PFI revolutions, the degree of dewatering resistance expressed as \({\mathrm {SR}}^{\circ }\) was more than 50% higher than the reference sample containing 5% of primary fines.

Based on the morphological evaluation of the blends it can be stated, that in case of the chosen refining aggregate barely any fines are created for all the assessed refining levels. The refining treatment almost exclusively affects the properties of the fibre material. Therefore, the technological effect of the dosed primary fines is directly accessible at different refining levels of the given pulp.

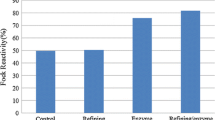

Paper properties of handsheets prepared from reference pulp and pulp/primary fines blends

A similar behavior as for the dewaterability of the reference pulp and pulp/primary fines blends is evident for air permeability (Fig. 9) with the effect of fines addition being more significant at 4000 and 6000 PFI revolutions. It seems, that the additional fines present in the pulp tend to affect air permeability and dewatering especially in already denser networks formed of more flexible fibres where they are capable of blocking the already smaller remaining pores. When it comes to mechanical properties there clearly is a positive effect on breaking length (Fig. 9) due to the addition of primary fines. This effect is reduced for higher refining intensities and therefore already densified sheets up to the point where no significant difference in breaking length is evident after 6000 revolutions in the PFI mill.

However, when it comes to applying a such treated softwood unbleached kraft pulp in paper production the main interest is to reach a certain level of tensile strength, as in industry that kind of pulp is refined to reach a certain strength level. The corresponding dewatering properties are an inevitable secondary effect that is taken into account but not adjusted to a certain target. Looking at the relationship between air permeability and tensile strength (Fig. 10) or dewatering resistance and tensile strength (Fig. 11) it becomes evident that the addition of primary fines does not have a significant effect on this relationship. Tensile strength (breaking length) tends to level out at higher dewatering resistance while air resistance still increases further. The blend containing 12% primary fines shows a slightly higher dewatering resistance (\({\mathrm {SR}}^{\circ }\)) at a given breaking length already at lower refining intensities; at an addition level of 9% such a trend is not observed. In case of air permeability (Fig. 10), no significant difference is evident whether primary fines are added or not. It is also evident that the addition of primary fines does not allow to increase tensile strength above a certain maximum level, which also can be achieved by just refining the pulp. This maximum level of tensile strength is determined by the pulp itself and seems to be a kind of intrinsic pulp property. Several other publications are also demonstrating this behavior for refined pulps and as a consequence of fines addition (Joseleau et al. 2012; Kerekes 2005; Lin et al. 2007; Odabas et al. 2016).

Both air permeability and dewatering resistance are affected by sheet densification due to flexibilisation of the fibres during refining on the one hand and by blocking of the pores by presence of additional fines on the other hand. Apparent sheet density is directly related to tensile strenght (breaking length) as it is shown in Fig. 12 . This clearly linear relationship between sheet density and tensile strength is to be expected as higher apparent densitie leads to an increase in relative bonded area and thus tensile properties. The significant effect of fines on sheet densification and its consequence for mechanical properties has already been reported in the past (Retulainen et al. 2002).

In principle, it should be irrelevant how this densification is achieved, be it by fibre flexibilization, fibre shortening and/or generation of fines. However, a slight increase of breaking length for a given apparent density is generated by the addition of primary fines. An explanation for this observation could be that the increased amount of primary fines in case of less refined and thus less flexible pulp fibres generates additional bonded area due to an aggregation of the fines in the interstices between two crossing fibres during dewatering. The improvement of fibre fibre bonding due to fines acting as a kind of bridging material has already been described in the literature (Bäckström et al. 2008). At higher refining intensities leading to a higher degree of flexibilization, this effect is less pronounced and no significant difference between the reference and the two blends with additionally added primary fines is evident for denser sheets above 700 [\(kg/{\mathrm {m}}^{3}\)]. An explanation for this behaviour may be that at such high densities with the breaking length approaching 10 kilometers and more the strength of single fibres starts to affect the strength of the sheet and bonded area is not as dominant as it is at lower densities.

Overall, an increase in the amount of primary fines shows the potential to reach a desired level of tensile strength in slightly refined pulps at reduced refining energy demand, giving less dense (i.e. more bulky sheets) at a similar or slightly increased level of dewatering resistance.

Conclusion and outlook

For unbleached softwood kraft pulp the addition of primary fines originating from the same pulp leads to an increase in tensile strength in the unrefined state as well as at low refining intensities. The maximum achievable level of tensile strength on the other hand is not increased by the addition of primary fines, but stays at the level of the reference. However, in terms of refining energy the addition of primary fines shows the potential to reach a certain level of tensile strength at lower refining energy consumption at similar or only slightly increased dewatering resistance. At the same time the apparent density is slightly lower at a given tensile strength in the unrefined state and at low refining intensities. At higher refining intensities the addition of primary fines does not contribute to the level of tensile strength, as the fibre network is already highly densified due to fibre flexibilization in PFI refining. Here, additionally added primary fines mainly tend to block pores and thereby increase dewatering resistance and reduce air permeability. In this laboratory study, primary fines showed a positive contribution to fibre fibre bonding at lower refining intensities. A direct comparison to the effect of secondary fines generated during refining is not possible based on this study, as only a very low amount of secondary fines was produced during the PFI refining. This will have to be observed, when it comes to the applicability of our results under industrial conditions, which is planned as a next step in our evaluations. An industrial refiner will produce a higher amount of additional secondary fines and might also show some fibre shortening during refining. It will therefore be interesting to see, to which extent the results of these trials in an industrial setting differ from the findings reported in this lab study.

References

Bäckström M, Kolar MC, Htun M (2008) Characterisation of fines from unbleached kraft pulps and their impact on sheet properties. Holzforschung 62(5):546–552. https://doi.org/10.1515/HF.2008.081

Chauhan VS, Kumar N, Kumar M, Thapar SK, Chakrabarti SK (2012) Use of primary fiber fines as organic fillers in papermaking. Taiwan J Forest Sci 27(2):201–214

Dasgupta S (1994) Mechanism of paper tensile-strength development due to pulp beating. Tappi J 77(6):158–166

Ferreira PJ, Matos S, Figueiredo MM (1999) Size characterization of fibres and fines in hardwood kraft pulps. Part Part Syst Char 16(1):20–24

Ferreira PJ, Martins A, Figueiredo M (2000) Primary and secondary fines from Eucalyptus globulus kraft pulps. characterization and influence. Paperi Puu-Pap Tim 82(6):403–408

Fischer W, Mayr M, Spirk S, Reishofer D, Jagiello L, Schmiedt R, Colson J, Zankel A, Bauer W (2017) Pulp fines-characterization, sheet formation, and comparison to microfibrillated cellulose. Polymers 9(12):366. https://doi.org/10.3390/polym9080366

Gharehkhani S, Sadeghinezhad E, Kazi SN, Yarmand H, Badarudin A, Safaei MR, Zubir MNM (2015) Basic effects of pulp refining on fiber properties—a review. Carbohyd Polym 115:785–803. https://doi.org/10.1016/j.carbpol.2014.08.047

Giner Tovar R, Fischer WJ, Eckhart R, Bauer W (2015) White water recirculation method as a means to evaluate the influence of fines on the properties of handsheets. Bioresources 10(4):7242–7251 10.15376/biores.10.4.7242-7251

Hinck JF, Wallendahl U (1999) Improving sulfite pulp quality and mill operations through the removal of fines. Orlando, Florida, pp 601–608

Joseleau JP, Chevalier-Billosta V, Ruel K (2012) Interaction between microfibrillar cellulose fines and fibers: Influence on pulp qualities and paper sheet properties. Cellulose 19(3):769–777. https://doi.org/10.1007/s10570-012-9693-5

Kerekes R (2005) Characterizing refining action in PFI mills. Tappi J 4(3):9–14

Lin T, Yin X, Retulainen E, Nazhad MM (2007) Effect of chemical pulp fines on filler retention and paper properties. Appita J 60(6):469

Mayr M, Eckhart R, Bauer W (2017a) Improved microscopy method for morphological characterisation of pulp fines. Nord Pulp Pap Res J 32(02):244–252. https://doi.org/10.3183/NPPRJ-2017-32-02-p244-252

Mayr M, Eckhart R, Thaller A, Bauer W (2017b) Characterization of fines quality and their independent effect on sheet properties. In: Transactions of the 16th Fundamental Research Symposium Held in Oxford pp 299–322

Motamedian HR, Halilovic AE, Kulachenko A (2019) Mechanisms of strength and stiffness improvement of paper after PFI refining with a focus on the effect of fines. Cellulose 26(6):4099–4124. https://doi.org/10.1007/s10570-019-02349-5

Odabas N, Henniges U, Potthast A, Rosenau T (2016) Cellulosic fines: properties and effects. Prog in Mater Sci 83:574–594. https://doi.org/10.1016/j.pmatsci.2016.07.006

Retulainen E, Moss P, Nieminen K (1993) Effect of fines on the properties of fibre networks. In: Products of papermaking 10th Fundamental Research Symposium pp 727–769

Retulainen E, Luukko K, Fagerholm K, Pere J, Laine J, Paulapuro H (2002) Papermaking quality of fines from different pulps—the effect of size, shape and chemical composition. Appita J 55(6):457–467

Sandquist D (2013) New horizons for microfibrillated cellulose. Appita J 66(2):156–162

Taipale T, Österberg M, Nykänen A, Ruokolainen J, Laine J (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17(5):1005–1020. https://doi.org/10.1007/s10570-010-9431-9

Wang X, Maloney TC, Paulapuro H (2007) Fibre fibrillation and its impact on sheet properties. Paperi Ja pPuu 89(3):148–153

Acknowledgments

We are grateful for the support by our industry partners in the frame of the FLIPPR2 project, Mondi, Sappi, Zellstoff Pöls AG, a member of Heinzel pulp, and Papierholz Austria. The K-Project FLIPPR2 is funded as part of COMET-Competence Centers for Excellent Technologies promoted by BMVIT, BMWFW, Styria and Carin-thia. The COMET program is managed by FFG.

Funding

Open access funding provided by Graz University of Technology.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mandlez, D., Zangl-Jagiello, L., Eckhart, R. et al. Softwood kraft pulp fines: application and impact on specific refining energy and strength properties. Cellulose 27, 10359–10367 (2020). https://doi.org/10.1007/s10570-020-03467-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03467-1