Abstract

Hydrochloric acid hydrolysis in its gas form was used to produce cellulose nanoparticles from flax shives with a very high yield (> 90%). The efficiency of the transformation was examined by gravimetry, atomic force microscopy and transmission electron microscopy. A novel purpose-built anisotropic line-broadening X-ray diffraction model was used. This XRD method uses a parametric shape in order to address the issue of strongly broadened and overlapping Bragg rays that are characteristic of nano-sized crystallites. This method demonstrated the remarkable stability of the crystallite shapes during hydrolysis and its sensibility was sufficient to detect a minor co-crystallization along the hydrophilic faces. The presence of amorphous material strictosensu in the form of individual and randomly oriented chains was not necessary to describe the diffractograms accurately. Thermal FTIR with isotopic exchange was also performed using deuterium oxide to characterize the accessibility of the materials between 20 and 260 °C. Further, back-exchange experiments were performed in order to quantify the hysteretic amount of deuterium that was trapped by microstructural reorganization. These experiments showed that hydrolysis cancelled any form of deuterium trapping (water-induced co-crystallization). For the first time, thermal FTIR demonstrated that isotopic labelling of cellulose sources can produce false positives when conducted at room temperature and thermal FTIR can unambiguously distinguish between labelled cellulose groups and free deuterium oxide, which is paramount when measuring the higher accessibility of the nanocelluloses. It was also demonstrated that the high-temperature hydrogen bond reorganization and thermal degradation of the cellulose chains strongly depend on the hydrolysis and on the microstructure of the substrate.

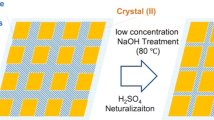

Graphic abstract

Similar content being viewed by others

References

Agarwal UP, Ralph SA, Reiner RS, Baez C (2016) Probing crystallinity of never-dried wood cellulose with Raman spectroscopy. Cellulose 23:125–144. https://doi.org/10.1007/s10570-015-0788-7

Agustin MB, Nakatsubo F, Yano H (2016) The thermal stability of nanocellulose and its acetates with different degree of polymerization. Cellulose 23:451–464. https://doi.org/10.1007/s10570-015-0813-x

Ahvenainen P, Kontro I, Svedström K (2016) Comparison of sample crystallinity determination methods by X-ray diffraction for challenging cellulose I materials. Cellulose 23:1073–1086. https://doi.org/10.1007/s10570-016-0881-6

Araki J, Wada M, Kuga S, Okano T (1998) Flow properties of microcrystalline cellulose suspension prepared by acid treatment of native cellulose. Colloids Surf Physicochem Eng Asp 142:75–82. https://doi.org/10.1016/S0927-7757(98)00404-X

Azadi A, Grason GM (2012) Defects in crystalline packings of twisted filament bundles. II. Dislocations and grain boundaries. Phys Rev E 85:031604. https://doi.org/10.1103/PhysRevE.85.031604

Battista OA, Coppick S, Howsmon JA et al (1956) Level-off degree of polymerization. Ind Eng Chem 48:333–335. https://doi.org/10.1021/ie50554a046

Beisl S, Miltner A, Friedl A (2017) Lignin from micro-to nanosize: production methods. Int J Mol Sci 18:1244

Bondeson D, Mathew A, Oksman K (2006) Optimization of the isolation of nanocrystals from microcrystalline cellulose by acid hydrolysis. Cellulose 13:171–180. https://doi.org/10.1007/s10570-006-9061-4

Bruss IR, Grason GM (2012) Non-Euclidean geometry of twisted filament bundle packing. Proc Natl Acad Sci 109:10781–10786. https://doi.org/10.1073/pnas.1205606109

Calvini P (2005) The influence of levelling-off degree of polymerisation on the kinetics of cellulose degradation. Cellulose 12:445–447

Calvini P, Gorassini A, Merlani AL (2007) On the kinetics of cellulose degradation: looking beyond the pseudo zero order rate equation. Cellulose 15:193. https://doi.org/10.1007/s10570-007-9162-8

Camarero Espinosa S, Kuhnt T, Foster EJ, Weder C (2013) Isolation of thermally stable cellulose nanocrystals by phosphoric acid hydrolysis. Biomacromolecules 14:1223–1230. https://doi.org/10.1021/bm400219u

Ciolacu D, Ciolacu F, Popa VI (2011) Amorphous cellulose—structure and characterization. Cellul Chem Technol 45:13

De Figueiredo LP, Ferreira FF (2014) The Rietveld method as a tool to quantify the amorphous amount of microcrystalline cellulose. J Pharm Sci 103:1394–1399. https://doi.org/10.1002/jps.23909

Demšar J, Curk T, Erjavec A et al (2013) Orange: data mining toolbox in Python. J Mach Learn Res 14:2349–2353

Dong S, Bortner MJ, Roman M (2016) Analysis of the sulfuric acid hydrolysis of wood pulp for cellulose nanocrystal production: a central composite design study. Ind Crops Prod 93:76–87. https://doi.org/10.1016/j.indcrop.2016.01.048

Driemeier C, Francisco LH (2014) X-ray diffraction from faulted cellulose I constructed with mixed Iα–Iβ stacking. Cellulose 21:3161–3169. https://doi.org/10.1007/s10570-014-0390-4

Driemeier C, Mendes FM, Ling LY (2015) Hydrated fractions of cellulosics probed by infrared spectroscopy coupled with dynamics of deuterium exchange. Carbohydr Polym 127:152–159. https://doi.org/10.1016/j.carbpol.2015.03.068

Du H, Liu C, Mu X et al (2016) Preparation and characterization of thermally stable cellulose nanocrystals via a sustainable approach of FeCl3-catalyzed formic acid hydrolysis. Cellulose 23:2389–2407. https://doi.org/10.1007/s10570-016-0963-5

Duchemin B (2017a) Anisotropic size-broadening and X-ray diffraction of cellulose Iβ: a route towards crystallite shape and crystallinity determination from powder patterns. American Chemical Society, Nantes

Duchemin B (2017b) Size, shape, orientation and crystallinity of cellulose Iβ by X-ray powder diffraction using a free spreadsheet program. Cellulose. https://doi.org/10.1007/s10570-017-1318-6

Duchemin B, Newman R, Staiger M (2007) Phase transformations in microcrystalline cellulose due to partial dissolution. Cellulose 14:311–320

Duchemin BJC, Staiger MP, Newman RH (2014) High-temperature viscoelastic relaxation in all-cellulose composites. Macromol Symp 340:52–58. https://doi.org/10.1002/masy.201300123

Dufresne A (2013) Nanocellulose: from nature to high performance tailored materials. Walter de Gruyter, Berlin

Eichhorn SJ, Dufresne A, Aranguren M et al (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1. https://doi.org/10.1007/s10853-009-3874-0

Fang W, Arola S, Malho J-M et al (2016) Noncovalent dispersion and functionalization of cellulose nanocrystals with proteins and polysaccharides. Biomacromolecules 17:1458–1465. https://doi.org/10.1021/acs.biomac.6b00067

Fengel D (1993) Influence of water on the OH valency range in deconvoluted FTIR spectra of cellulose. Holzforsch Int J Biol Chem Phys Technol Wood 47:103–108

French AD, Santiago Cintrón M (2012) Cellulose polymorphy, crystallite size, and the Segal Crystallinity Index. Cellulose 20:583–588. https://doi.org/10.1007/s10570-012-9833-y

Guinier A (1963) X-ray diffraction in crystals, imperfect crystals, and amorphous bodies. W. H. Freeman and Company, San Francisco

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev 110:3479–3500. https://doi.org/10.1021/cr900339w

Hayakawa D, Nishiyama Y, Mazeau K, Ueda K (2017) Evaluation of hydrogen bond networks in cellulose Iβ and II crystals using density functional theory and Car–Parrinello molecular dynamics. Carbohydr Res 449:103–113. https://doi.org/10.1016/j.carres.2017.07.001

Hofstetter K, Hinterstoisser B, Salmén L (2006) Moisture uptake in native cellulose—the roles of different hydrogen bonds: a dynamic FT-IR study using Deuterium exchange. Cellulose 13:131–145. https://doi.org/10.1007/s10570-006-9055-2

Hori R, Wada M (2005) The thermal expansion of wood cellulose crystals. Cellulose 12:479. https://doi.org/10.1007/s10570-005-5967-5

Horikawa Y, Clair B, Sugiyama J (2009) Varietal difference in cellulose microfibril dimensions observed by infrared spectroscopy. Cellulose 16:1–8. https://doi.org/10.1007/s10570-008-9252-2

Hosemann R, Hentschel MP, Baltacalleja FJ et al (1985) The alpha-star-constant, equilibrium state and bearing net planes in polymers, bio-polymers and catalysts. J Phys C Solid State Phys 18:961–971

Janoschek R, Hayd A, Weidemann EG et al (1978) Calculated and observed isotope effects with easily polarizable hydrogen and deuterium bonds. J Chem Soc Faraday Trans Mol Chem Phys 74:1238–1245. https://doi.org/10.1039/F29787401238

Klemm D, Kramer F, Moritz S et al (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50:5438–5466. https://doi.org/10.1002/anie.201001273

Kokot S, Czarnik-Matusewicz B, Ozaki Y (2002) Two-dimensional correlation spectroscopy and principal component analysis studies of temperature-dependent IR spectra of cotton-cellulose. Biopolymers 67:456–469. https://doi.org/10.1002/bip.10163

Kondo T, Sawatari C (1996) A Fourier transform infra-red spectroscopic analysis of the character of hydrogen bonds in amorphous cellulose. Polymer 37:393–399

Kontturi E, Meriluoto A, Penttilä PA et al (2016) Degradation and crystallization of cellulose in hydrogen chloride vapor for high-yield isolation of cellulose nanocrystals. Angew Chem Int Ed 55:14455–14458. https://doi.org/10.1002/anie.201606626

Lam E, Male KB, Chong JH et al (2012) Applications of functionalized and nanoparticle-modified nanocrystalline cellulose. Trends Biotechnol 30:283–290. https://doi.org/10.1016/j.tibtech.2012.02.001

Lemke C, Dong R, Michal C, Hamad W (2012) New insights into nano-crystalline cellulose structure and morphology based on solid-state NMR. Cellulose 19:1619–1629. https://doi.org/10.1007/s10570-012-9759-4

Leung ACW, Hrapovic S, Lam E et al (2011) Characteristics and properties of carboxylated cellulose nanocrystals prepared from a novel one-step procedure. Small 7:302–305. https://doi.org/10.1002/smll.201001715

Li B, Xu W, Kronlund D et al (2015) Cellulose nanocrystals prepared via formic acid hydrolysis followed by TEMPO-mediated oxidation. Carbohydr Polym 133:605–612. https://doi.org/10.1016/j.carbpol.2015.07.033

Lin N, Huang J, Dufresne A (2012) Preparation, properties and applications of polysaccharide nanocrystals in advanced functional nanomaterials: a review. Nanoscale 4:3274–3294. https://doi.org/10.1039/C2NR30260H

Lindh EL, Salmén L (2016) Surface accessibility of cellulose fibrils studied by hydrogen–deuterium exchange with water. Cellulose. https://doi.org/10.1007/s10570-016-1122-8

Lindner B, Petridis L, Langan P, Smith JC (2015) Determination of cellulose crystallinity from powder diffraction diagrams. Biopolymers 103:67–73. https://doi.org/10.1002/bip.22555

Liu Y, Wang H, Yu G et al (2014) A novel approach for the preparation of nanocrystalline cellulose by using phosphotungstic acid. Carbohydr Polym 110:415–422. https://doi.org/10.1016/j.carbpol.2014.04.040

Lorenz M, Sattler S, Reza M et al (2017) Cellulose nanocrystals by acid vapour: towards more effortless isolation of cellulose nanocrystals. Faraday Discuss 202:315–330. https://doi.org/10.1039/C7FD00053G

Lourdin D, Peixinho J, Bréard J et al (2016) Concentration driven cocrystallisation and percolation in all-cellulose nanocomposites. Cellulose 23:529–543. https://doi.org/10.1007/s10570-015-0805-x

Mann J, Marrinan HJ (1956a) The reaction between cellulose and heavy water. Part 1. A qualitative study by infra-red spectroscopy. Trans Faraday Soc 52:481–487

Mann J, Marrinan HJ (1956b) The reaction between cellulose and heavy water. Part 2. Measurement of absolute accessibility and crystallinity. Trans Faraday Soc 52:487–492

Mann J, Marrinan HJ (1956c) The reaction between cellulose and heavy water. Part 3. A quantitative study by infra-red spectroscopy. Trans Faraday Soc 52:492–497

Marechal Y, Chanzy H (2000) The hydrogen bond network in Iβ cellulose as observed by infrared spectrometry. J Mol Struct 523:183–196

Marrinan HJ, Mann J (1956) Infrared spectra of the crystalline modifications of cellulose. J Polym Sci 21:301–311. https://doi.org/10.1002/pol.1956.120219812

Matsuoka S, Kawamoto H, Saka S (2011) Thermal glycosylation and degradation reactions occurring at the reducing ends of cellulose during low-temperature pyrolysis. Carbohydr Res 346:272–279. https://doi.org/10.1016/j.carres.2010.10.018

Matsuoka S, Kawamoto H, Saka S (2014) What is active cellulose in pyrolysis? An approach based on reactivity of cellulose reducing end. J Anal Appl Pyrolysis 106:138–146. https://doi.org/10.1016/j.jaap.2014.01.011

Michell AJ, Higgins HG (1999) The absence of free hydroxyl groups in cellulose. Cellulose 6:89–91. https://doi.org/10.1023/A:1009258732505

Müller M, Czihak C, Schober H et al (2000) All disordered regions of native cellulose show common low-frequency dynamics. Macromolecules 33:1834–1840

Nam S, Hillyer MB, Condon BD (2020) Method for identifying the triple transition (glass transition–dehydration–crystallization) of amorphous cellulose in cotton. Carbohydr Polym 228:115374. https://doi.org/10.1016/j.carbpol.2019.115374

Nevell TP, Upton WR (1976) The hydrolysis of cotton cellulose by hydrochloric acid in benzene. Carbohydr Res 49:163–174. https://doi.org/10.1016/S0008-6215(00)83134-1

Newman RH (2004) Carbon-13 NMR evidence for cocrystallization of cellulose as a mechanism for hornification of bleached kraft pulp. Cellulose 11:45–52. https://doi.org/10.1023/B:CELL.0000014768.28924.0c

Newman RH (2008) Simulation of X-ray diffractograms relevant to the purported polymorphs cellulose IVI and IVII. Cellulose 15:769–778. https://doi.org/10.1007/s10570-008-9225-5

Newman RH, Hill SJ, Harris PJ (2013) Wide-angle X-ray scattering and solid-state nuclear magnetic resonance data combined to test models for cellulose microfibrils in Mung Bean cell walls. Plant Physiol 163:1558–1567. https://doi.org/10.1104/pp.113.228262

Niinivaara E, Arshath SAA, Nieminen K et al (2018) The effect of polymorphism on the kinetics of adsorption and degradation: a case of hydrogen chloride vapor on cellulose. Adv Sustain Syst 2:1800026. https://doi.org/10.1002/adsu.201800026

Nishiyama Y, Isogai A, Okano T et al (1999) Intracrystalline deuteration of native cellulose. Macromolecules 32:2078–2081

Nishiyama Y, Kim U-J, Kim D-Y et al (2003) Periodic disorder along ramie cellulose microfibrils. Biomacromolecules 4:1013–1017. https://doi.org/10.1021/bm025772x

Nishiyama Y, Johnson GP, French AD (2012) Diffraction from nonperiodic models of cellulose crystals. Cellulose 19:319–336. https://doi.org/10.1007/s10570-012-9652-1

Nyström G, Arcari M, Adamcik J et al (2018) Nanocellulose fragmentation mechanisms and inversion of chirality from the single particle to the cholesteric phase. ACS Nano. https://doi.org/10.1021/acsnano.8b00512

O’Connor RT, DuPré EF, Mitcham D (1958) Applications of infrared absorption spectroscopy to investigations of cotton and modified cottons. Text Res J 28:382–392. https://doi.org/10.1177/004051755802800503

Olsson A-M, Salmén L (2004) The association of water to cellulose and hemicellulose in paper examined by FTIR spectroscopy. Carbohydr Res 339:813–818. https://doi.org/10.1016/j.carres.2004.01.005

Pääkkönen T, Spiliopoulos P, Knuts A et al (2018) From vapour to gas: optimising cellulose degradation with gaseous HCl. React Chem Eng. https://doi.org/10.1039/C7RE00215G

Panaitescu A, Grason GM, Kudrolli A (2017) Measuring geometric frustration in twisted inextensible filament bundles. Phys Rev E 95:052503. https://doi.org/10.1103/PhysRevE.95.052503

Papadopoulos J, Chen C-L, Goldstein IS (2009) The behavior of lignin during hydrolysis of Sweetgum wood with concentrated hydrochloric acid at moderate temperatures. Holzforsch Int J Biol Chem Phys Technol Wood 35:283–286. https://doi.org/10.1515/hfsg.1981.35.6.283

Pastorova I, Botto RE, Arisz PW, Boon JJ (1994) Cellulose char structure: a combined analytical Py–GC–MS, FTIR, and NMR study. Carbohydr Res 262:27–47. https://doi.org/10.1016/0008-6215(94)84003-2

Pouteau C, Cathala B, Dole P et al (2005) Structural modification of Kraft lignin after acid treatment: characterisation of the apolar extracts and influence on the antioxidant properties in polypropylene. Ind Crops Prod 21:101–108. https://doi.org/10.1016/j.indcrop.2004.01.003

Priest DJ, Shimell RJ (1963) Determination of the accessibility of cellulose films by infra-red spectroscopy. J Appl Chem 13:383–391. https://doi.org/10.1002/jctb.5010130903

Ramírez B, Bucio L (2018) Microcrystalline cellulose (MCC) analysis and quantitative phase analysis of ciprofloxacin/MCC mixtures by Rietveld XRD refinement with physically based background. Cellulose 25:2795–2815. https://doi.org/10.1007/s10570-018-1761-z

Rånby BG, Banderet A, Sillén LG (1949) Aqueous colloidal solutions of cellulose micelles. Acta Chem Scand 3:649–650. https://doi.org/10.3891/acta.chem.scand.03-0649

Reishofer D, Spirk S (2015) Deuterium and cellulose: a comprehensive review. In: Rojas OJ (ed) Cellulose chemistry and properties: fibers, nanocelluloses and advanced materials. Springer, Berlin, pp 93–114

Rousselle M-A, Nelson ML (1971) Accessibility of cotton cellulose by deuterium exchange. Text Res J 41:599–604. https://doi.org/10.1177/004051757104100708

Schwanninger M, Rodrigues JC, Pereira H, Hinterstoisser B (2004) Effects of short-time vibratory ball milling on the shape of FT-IR spectra of wood and cellulose. Vib Spectrosc 36:23–40

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Sepall O, Mason SG (1961) Hydrogen exchange between cellulose and water: II. Interconversion of accessible and inaccessible regions. Can J Chem 39:1944–1955

Strømme M, Mihranyan A, Ek R, Niklasson GA (2003) Fractal dimension of cellulose powders analyzed by multilayer BET adsorption of water and nitrogen. J Phys Chem B 107:14378–14382. https://doi.org/10.1021/jp034117w

Suchy M, Virtanen J, Kontturi E, Vuorinen T (2010) Impact of drying on wood ultrastructure observed by deuterium exchange and photoacoustic FT-IR spectroscopy. Biomacromolecules 11:515–520. https://doi.org/10.1021/bm901268j

Thybring EE, Thygesen LG, Burgert I (2017) Hydroxyl accessibility in wood cell walls as affected by drying and re-wetting procedures. Cellulose 24:2375–2384

Thygesen A, Oddershede J, Lilholt H et al (2005) On the determination of crystallinity and cellulose content in plant fibres. Cellulose 12:563–576. https://doi.org/10.1007/s10570-005-9001-8

Usov I, Nyström G, Adamcik J et al (2015) Understanding nanocellulose chirality and structure–properties relationship at the single fibril level. Nat Commun 6:7564. https://doi.org/10.1038/ncomms8564

Viëtor RJ, Mazeau K, Lakin M, Pérez S (2000) A priori crystal structure prediction of native celluloses. Biopolymers 54:342–354

Wada M (2002) Lateral thermal expansion of cellulose Iβ and IIII polymorphs. J Polym Sci Part B Polym Phys 40:1095–1102. https://doi.org/10.1002/polb.10166

Wada M, Heux L, Sugiyama J (2004) Polymorphism of cellulose I family: reinvestigation of cellulose IVI. Biomacromolecules 5:1385–1391

Wada M, Hori R, Kim U-J, Sasaki S (2010) X-ray diffraction study on the thermal expansion behavior of cellulose Iβ and its high-temperature phase. Polym Degrad Stab 95:1330–1334. https://doi.org/10.1016/j.polymdegradstab.2010.01.034

Wadehra IL, Manley RSJ (1965) Irreversible exchange of hydrogen in the drying of cellulose at high temperature. J Appl Polym Sci 9:3499–3502. https://doi.org/10.1002/app.1965.070091026

Watanabe A, Morita S, Kokot S et al (2006a) Drying process of microcrystalline cellulose studied by attenuated total reflection IR spectroscopy with two-dimensional correlation spectroscopy and principal component analysis. J Mol Struct 799:102–110. https://doi.org/10.1016/j.molstruc.2006.03.018

Watanabe A, Morita S, Ozaki Y (2006b) Study on temperature-dependent changes in hydrogen bonds in cellulose Iβ by infrared spectroscopy with perturbation–correlation moving-window two-dimensional correlation spectroscopy. Biomacromolecules 7:3164–3170. https://doi.org/10.1021/bm0603591

Watanabe A, Morita S, Ozaki Y (2006c) Temperature-dependent structural changes in hydrogen bonds in microcrystalline cellulose studied by infrared and near-infrared spectroscopy with perturbation–correlation moving-window two-dimensional correlation analysis. Appl Spectrosc 60:611–618

Yu H, Qin Z, Liang B et al (2013) Facile extraction of thermally stable cellulose nanocrystals with a high yield of 93% through hydrochloric acid hydrolysis under hydrothermal conditions. J Mater Chem A 1:3938–3944

Acknowledgments

The authors thank the National Technical and Research Association (ANRT) and the Public Investment Bank (BPIfrance) for their financial support, Nicolas Hucher (Normandie Université, URCOM EA 3221 FR CNRS 3038, 76600 Le Havre, France) for his help with the zetasizer and FTIR measurements (bleaching process), Bernard Cathala (BIA INRA Nantes, France) for his input on this work and Maëlle Coquemont (Normandie Université, CMABio3, Caen, France) for her expertise in microtoming. We also thank Yoshiharu Nishiyama (CERMAV, Grenoble) for the useful discussions on thermal degradation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Leboucher, J., Bazin, P., Goux, D. et al. High-yield cellulose hydrolysis by HCl vapor: co-crystallization, deuterium accessibility and high-temperature thermal stability. Cellulose 27, 3085–3105 (2020). https://doi.org/10.1007/s10570-020-03002-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03002-2